Thanks to technology, achieving the task is not difficult.

For example, polymer wells, which have become an alternative to conventional reinforced concrete products.

Let's find out if they are as good as they say.

What it is

Polymer sand rings and wells are made from composite materials: plastic and sand. When ready assembled, the product is highly durable. They are made in separate parts, which is why they are also known as prefabricated ones.

The polymer sand well consists of:

- rings;

- bottom;

- hatch;

- cone-shaped lid.

Rigidity is achieved by incorporating sand into the matrix of the polymer material. Thanks to this, such a product copes with the negative and aggressive effects of the environment. They have proven themselves positively in heaving soil conditions. The connection process is carried out using tongue-and-groove technology.

Summary

Compared to alternative technical solutions intended for the construction and reconstruction of wells, septic tanks and other hydraulic structures, the products look decent, practical and economically profitable. This is achieved thanks to the following advantages:

- the sizes of plastic rings, inserts and additional elements ensure high-quality and unhindered restoration of wells built on the basis of standard reinforced concrete rings;

- for the restoration of old wooden log houses (Finnish wells), the manufacturer’s assortment includes plastic inserts and rings of reduced diameter;

- All products are made from safe and durable materials that meet the requirements of sanitary and environmental standards (linear polyethylene and HDPE 100).

Simplicity and high quality of assembly are ensured by the design features of plastic rings, wells and inserts: threads cut in production conditions, as well as the presence of special socket connections guarantee the strength, tightness and durability of quickly assembled connections.

Kinds

Polymer sand wells come in different types. They differ mainly in the shaft material used:

- Smooth, one- or two-walled.

- Corrugated, one-, two-wall.

- Combined.

They differ in access: serviced and not. In the latter option, control is exercised only from above. In most cases, all elements are manufactured separately, making it possible to combine them.

The prefabricated manifold has the following technical characteristics:

| Dimensions | There are some standards for diameter, for example, “Ecosys” has an external diameter of 950 mm and an internal diameter of 900 mm. Structure height up to 1500 mm. There are other sizes available for sale. Based on the dimensions of the finished product, the price of the septic tank also differs |

| Ring diameter | Without a bottom, the internal one can have 600, 680, 800 and 900 mm. The outer diameter with and without a bottom is as follows: 650, 730, 850 and 950 mm |

| Cap diameter | Its size is selected individually from 550 to 900 mm. |

| Wall thickness | The cap and ring are 25mm. This is enough for the structure to cope with the load from the outside. As the diameter increases, the wall thickness increases proportionally |

| Ring height | Ranges from 500 to 1500 mm (one). The higher the parameters of the product, the more weight it has |

| Compound | Of the total mass of the product, 75% is sand filler. The remaining 15% is dye and polymer as a binder. Due to this, the product is waterproof. This combination copes well with temperatures down to -70 °C. Can survive up to 500 freeze/thaw cycles |

How to check the size of rings for a well according to GOST

Choosing a well ring manufacturer is usually a headache. There are usually several manufacturers of different sizes. Who to give preference to? You can collect reviews from your neighbors and choose a couple of manufacturers. Then it’s worth driving around and seeing with your own eyes, because “normal quality” is different for everyone. What to look for and how to inspect well rings? This is how the same GOST defines verification.

Measurements are taken along two perpendicular diameters. This means that one of the points is selected. The second one will be located opposite it, and the other two will be located perpendicular (a straight line drawn at an angle of 90° - as in the figure).

How to check the size of a concrete ring for a well

- At four points, located in pairs opposite each other, the wall thickness is measured. Moreover, it is advisable to check this parameter from below and from above. If the rings are locking, check the parameters of the tenon/groove - they must match. And it is also necessary to control both from above and from below.

- Also at four points, check the height of the ring.

Plates and rings are checked using the same method. Four points are selected - two on perpendicular lines and measurements are taken at them. The measured values must match. Permissible deviations are no more than 1.5%.

Which ones are better and how to determine quality

There are two technologies for the production of concrete rings: vibration casting and vibration pressing. In the first case, concrete is poured into collapsible molds, compacted with a submersible vibrator and left until it sets. This usually happens after 6-8 hours. Then the molds are removed and the rings are left to “ripen” so that they gain enough strength for sale - 50%.

They can be installed in 28 days, so it’s better not to buy “fresh” rings. Another point: in the last days of ripening, cracks may appear. So it is best to purchase well rings that have been “aged” in a warehouse. As you can see, the technology is simple; apart from the forms, there is no equipment. This allows us to open small workshops that make these products. In this case, the quality depends entirely on who mixes and pours the molds.

You need to choose based on the quality of the walls and edges, the absence of defects and deviations in size

To produce well rings using vibrocompression, special equipment is required. Not only the forms, but also the brick making machine itself. It creates a certain pressure and vibration frequency at each stage of the process. The result is more uniform concrete, smooth and even edges, and a perfectly formed edge or lock. But the price is also higher - more expensive equipment.

Which manufacturer to choose

In the Russian Federation, about 250 manufacturers are engaged in the production of reinforced concrete rings, covering the entire territory of the country. Therefore, traveling outside your region in search of cheap prices is not economically profitable. The savings will be consumed by transportation. However, the products of some factories are in special demand. We can highlight:

- "VTG Stroy" in Mytishchi, Moscow region, shipping its products throughout the country. Their KS 10.9, KS 15.9 and KS 20.9 rebated and flat models complete with a lid and hatch are in particular demand. The average cost is 2.1 thousand rubles.

- OJSC "Plant of Industrial Construction Parts", operating for more than 45 years in Tyumen. It has its own accredited construction laboratory, which allows not only to monitor quality, but also to develop new technologies.

- in Novokuznetsk is a supplier of high-quality reinforced concrete products throughout the Kemerovo region. In addition to producing standard designs, the company is also willing to accept orders for individual projects.

- in Krasnodar is distinguished by a wide range and high production capacity. Prices for reinforced concrete products start from 1.4 thousand rubles.

These manufacturers strictly monitor production technology and guarantee the quality of their products.

Advantages and disadvantages

Polymer-sand prefabricated rings have positive and negative sides:

Pros:

- They are light in weight, which simplifies the transportation process. There is no need to rent lifting equipment. Additional load on the soil is also eliminated.

- Compact sizes. Prefabricated septic tank technology allows installation of the structure even in the basement.

- The ability to assemble it yourself without the involvement of specialists.

- High tightness.

- Operational life more than 15 years.

- The material used is resistant to aggressive chemical environments.

- Range of colors and sizes.

- Resistant to soil influence.

- Ease of processing.

- They do not allow moisture to pass through.

Cons: There are no disadvantages as such. The problem may come down to the wrong choice of components and cover, which cannot cope with the resulting load. Therefore, having made the right choice and performed high-quality installation, polymer sand products will last for decades.

What is it suitable for?

Thanks to their excellent technical characteristics, sand-polymer prefabricated rings have found a wide range of uses:

- For the construction of a caisson.

- Construction of tanks for technical water.

- Sewage collection facilities.

- When installing a drainage system.

- Lookout.

Let's look at the features of some of them.

Observation

An ideal solution if underground communications are being laid. It is especially effective if there are connection points along the route or a long sewer pipe is laid. An inspection well made of polymer products will allow you to service the water supply or clean the sewerage system.

Rotary

If the highway has a 45-degree turn or branches, then a collector is also constructed from this material. Additionally, he serves as a lookout.

Variable

If along the route it is necessary to combine pipes of different heights into one sewerage or water supply system. It can also be used when it is necessary to bypass underground structures. If the natural landscape has a large slope, then a drop well will reduce the speed of wastewater. The difference can be arranged to a height of 300 to 600 mm.

Comprehensive restoration of drinking wells

Drinking wells fail for various reasons. Most often, the walls of a structure lose their former tightness, after which surface runoff begins to flow into it like a river. Sometimes the opposite happens: the well dries up hopelessly and water appears in it only under very rare circumstances.

If there is an old abandoned well on your site, it can be turned into a sealed tank with a capacity of 1.2 m³, designed to store drinking, rain or melt water. This will again be helped by plastic inserts of the “ROTOLINE” series with a height of 2000 mm, additional elements for them, as well as special adapters that provide a hermetically sealed insertion of pipes with a diameter of 25 to 160 mm.

Installing them in an abandoned well is not so difficult, but why not give an empty source of water a full second life...

Compare reinforced concrete and polymer sand

| Characteristic | Polymer sand | Reinforced concrete |

| Transportation and installation | It has less weight, so transportation is greatly simplified. It is possible to transport with your own car. It is quite possible to do the installation yourself. The weight of the ring can be about 60 kg, so unloading can be handled alone | Weight on average up to 500 kg (one). For delivery it is necessary to hire transport. For installation, the use of lifting equipment is mandatory. Given the nature of the local area, this is not always possible. |

| Easy docking | The tongue-and-groove technology speeds up the assembly process. After connection, an impenetrable seam is formed that does not require additional sealing. It is enough to treat each seam with silicone | It is difficult to achieve a perfect fit and tight fit. After installation, the seam is sealed |

| Resistance to frost and moisture | Polymer sand copes with this perfectly, without damage | Reinforced concrete has large pores through which moisture will flow. Water that penetrates into concrete freezes and because of this gradually destroys it. |

| Resistance to aggressive environments | Polymer sand is neutral to various chemical environments. Ideally proven when used both in a cesspool and with drinking water | Reinforced concrete rings must be subjected to additional processing |

| Easy to process | To make a hole, it is enough to use a household power tool. The resulting cut is not afraid of moisture and contact with aggressive environments | It is difficult to make technological holes for laying a pipeline |

Installation and connection

The process does not involve complex technological steps.

It is quite possible to do the work yourself, without involving specialists. CM. below in the video. Thus, the installation of set rings for a well made of polymer sand is carried out in the following sequence:

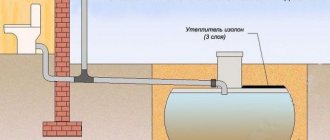

- At the first stage, a pit is dug to install the structure and lay water supply or other communications. The depth of the trench is below the soil freezing level.

- A sand cushion 200 mm thick is made. The poured sand is carefully compacted, and a layer of concrete up to 300 mm is poured on top.

- After the concrete has hardened, the bottom of the well is installed.

- Before installing the ring, all joints are treated with a special sealant and mastic.

- As you progress, holes are drilled for the outlet/input of water supply or sewerage pipes.

- Each pipe outlet at the cut hole is sealed with a rubber seal and sealant.

- Water supply is connected.

- Finally, a top ring with a hole for a lid or hatch is installed.

- After completion of the work, the empty space is filled with soil and compacted around the entire perimeter.

Do-it-yourself sewerage installation in a private house from concrete rings

The construction of a system of concrete rings, like any other sewer system, is carried out in stages.

The order of work is as follows:

- selection of a construction scheme;

- calculation of the capacity of the well taking into account the number of residents;

- choosing a suitable location for installing a septic tank;

- formation of a pit of the required size in accordance with calculations;

- installation of concrete rings;

Installation diagram of a septic tank made of concrete rings

- supply of pipe system;

- sealing seams between parts and joints;

- falling asleep of the structure.

Calculation and selection of a sewerage scheme made of concrete rings

A sewerage system based on concrete rings may include a septic tank with one, two or three chambers.

If a small number of people live in a house, it is better to choose a single-chamber structure for construction work, including a drainage well and a sump. Two-chamber systems are used when the house has a large amount of plumbing equipment, for example, a bathtub, sinks, toilet, washing machine, dishwasher, etc. In this case, the sewage system will consist of two containers and a drainage well.

Septic tank made of four concrete rings

The scheme may also include placement points for concrete trays for storm drainage, which are installed around the perimeter of the building’s blind area and in other problem areas where liquid can accumulate after heavy rainfall. This system will protect the topography of the site and the foundation part of the building from erosion by water.

The optimal design should take into account all the calculations necessary for comfortable use, in particular, the capacity of the well. This indicator depends on the daily water consumption of the residents of the house. The average amount of fluid consumption per person per day is about 150-200 liters. To calculate the optimal volume of a septic tank, this figure must be multiplied by the number of people living in the house on a permanent basis. To the result you need to add 20%, which will cover unplanned overruns and storm sewer drains.

Please note! According to building codes, a septic tank with an optimal volume must accommodate wastewater consumed within three days.

Installation diagram of septic tanks made of two concrete rings

To find out the number of rings required for the manufacture of a septic tank, you need to divide the total volume of the septic tank by the volume of the concrete product.

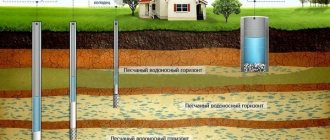

Preparing a site for the construction of a sewer system for a private house made of concrete rings

After the sewerage diagram has been drawn up and calculated, a location for installing the well is selected.

It is worth considering certain requirements:

- the minimum permissible distance between the house and the septic tank is 10 m;

- the level of groundwater movement should lie below the mark where the bottom of the well will be located;

- The minimum permissible distance between the source of drinking water and the septic tank is 50 m.

Preparing the site for sewerage construction

The construction area must be cleared of debris and stones. Next, a pit is dug, the size of which can accommodate a drainage well and a septic tank chamber with a margin of 30 cm on each side. In those places where storage chambers will be installed, concrete should be poured. Thus, the penetration of waste liquid into the soil and its contamination is prevented. Then it is necessary to form a drainage layer in the form of a sand cushion. Recommended thickness – 30-50 cm.

As an alternative to concreting, concrete rings equipped with a solid bottom can be used. These products will protect the surrounding soil from runoff pollution. Under the drainage well you need to form a cushion consisting of gravel, crushed stone and sand. Its minimum thickness is 50 cm.

Supply of pipes to the sewerage system

What is the service life

If we compare composite material with reinforced concrete products, the latter has a limitation of 50 years. If reinforced concrete does not completely collapse during this period, it will lose its operational properties. Also, every year you will have to check the tightness of all joints and the entire structure as a whole.

As for polymer rings, they will not lose their positive properties throughout their entire service life. According to forecasts, such structures will last for centuries. However, this will be possible provided that installation technology and proper maintenance are followed.

Sewer stairs KL-1

We produce ladders for sewer wells of any size at the customer's request.

| Type of stairs | Length (m) | Price |

| KL-1-2.0 | 2,0 | 2430 |

| KL-1-2.5 | 2,5 | 2955 |

| KL-1-3.0 | 3,0 | 3480 |

| KL-1-3.5 | 3,5 | 4000 |

| KL-1-4.0 | 4,0 | 4530 |

| KL-1-4.5 | 4,5 | 5000 |

| KL-1-5.0 | 5,0 | 5570 |

| KL-1-5.5 | 5,5 | 6110 |

| KL-1-6.0 | 6,0 | 6650 |

The price list shows average prices including VAT and delivery.

When building modern drinking wells, special reinforced concrete rings are used. To prevent the work from being delayed, they are immediately brought to the site and unloaded near the place chosen for digging the well. The exact quantity that will be required to construct the mine becomes known only after the aquifer has been found.

Price

The price tag for polymer products will differ depending on the features and technology of creation, as well as the manufacturer itself. The final cost is affected by diameter, height, wall thickness, etc. Plus, each element of a prefabricated well will have an individual cost. Approximate prices are shown in the table below:

| View | Characteristics | Price thousand rubles |

| Ready well “Yenisei” Height 2 meters | Thickness 50 mm and outer diameter 110 cm | 14,5 |

| Ready well “Yenisei” Height 3 meters | Thickness 50 mm and diameter 110 cm | 21.3 |

| Polymer ring | Height 20 cm and diameter 100 cm | 1700 |

| Ring with cap | Diameter 80, height 30, neck diameter 75 cm | 29 |

Important! There may be a different manufacturer in your area, and therefore the price will be different. Therefore, it is better to compare several manufacturers before purchasing.

Main characteristics of concrete rings

The use of prefabricated reinforced concrete structures in construction can significantly reduce the time required to complete work, while increasing productivity. It is the rings that are considered the product most often used in construction processes.

Application area

The scope of use of such products can be very different:

- Construction of drinking wells;

- Arrangement of inspection wells necessary to monitor the condition of communication systems;

- Construction of septic tanks;

- Arrangement of storm drainage, etc.

Septic tank diagram

Advantages and disadvantages

The advantages of structures of this kind include:

- High level of strength;

- Durability;

- Frost resistance;

- Easy installation;

- Ease of operation;

- Small price.

But there is one significant drawback, which lies in the heavy weight. So, for example, the answer to the question of how much a concrete ring with a diameter of 1 meter weighs is 600 kg. This means that transporting such a product to the construction site is impossible without special equipment.

Sizes of structures

Overall dimensions and weight of concrete rings are two parameters directly related to each other. Both the weight and the overall dimensions of such products may vary, depending on the type of product being created and the purpose of its use.

Today there are rings of the following sizes:

- KTs-10. The height of such a product is 0.9 m, the outer diameter is 1.16 m, and the weight of a concrete ring with 1 meter of inner diameter is 0.6 tons;

- KTs-15. Such a ring is called medium and has the following parameters: height - 0.9 m, internal diameter - 1.5 m, external diameter - 1.6 m, product weight - 1 ton;

- KTs-20. The ring is 0.9 m tall, weighs 1.5 tons, and has external and internal diameters of 2 m and 2.2 m, respectively.

Standard sizes

Note! The product marking consists of the letters KC or KS and an indication of the size of the internal diameter of the product in decimeters.

Modern manufacturers offer rings with a diameter from 0.72 to 2 meters and a standard height of 90 cm.

In addition to such standardized products, there are also non-standard ones, which are called additional ones.

Such products may differ from standard ones in the following parameters:

- The shape of the structure itself;

- Wall thickness, which varies from 65 mm to 115 mm;

- The presence of locks on the surface, which simplify the process of assembling the structure;

- Height;

- Diameter.

So, for example, you can purchase large-diameter concrete rings (more than 2 m) or even square products.

Square designs

Advice. The advantages of using square-shaped reinforced concrete structures include the possibility of installing them on a concrete slab. This eliminates the need to construct a concrete screed at the bottom of the well, and besides, it is easier to dig a square hole than a round one.

Types of rings

Based on the type of construction, this kind of construction is divided into two main types:

- Direct. The connection of such rings is made using metal staples and cement mortar;

- With a lock - such products are equipped with an annular protrusion at the top and a recess at the bottom. Installing similar elements on top of each other allows you to create strong connections, which eliminates the possibility of displacement.

Castle ring