Removable or permanent formwork for monolithic construction of foundations is used almost everywhere. Such equipment for monolithic construction is used when it is necessary to create concrete or reinforced concrete structures, lintels, floor slabs, pool bowls and other things. It is necessary to build formwork equipment in order to give future brick and concrete structures the desired shape and texture.

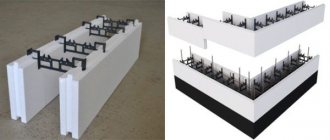

Technoblock formwork

Previously, formwork construction technology was exclusively removable. That is, after the monolithic concrete hardened, it was dismantled, leaving bare concrete. Nowadays, permanent formwork for foundations is becoming increasingly popular. In particular, do-it-yourself permanent formwork from the company Tehnoblok, a well-known manufacturer of building materials.

Features and purpose

Anyone who has ever been to the construction of a monolithic building, swimming pool or other turnkey residential structure has probably seen the formwork equipment with their own eyes. This is a prefabricated structure, mainly made of wood and steel (corrugated sheet), which is installed in a certain position, and then it is fixed with spacers and jumpers.

The technology for formwork equipment is such that it is clearly leveled horizontally and vertically, mounted in the right places, and then prepared for further use. After its final assembly, all that remains is to install the reinforced mesh of reinforcement, lintels inside the structure and fill everything with concrete.

However, it is worth understanding that not every person can cope with such a task , and quite a lot of time is spent on building the formwork.

Interesting studies in the field of monolithic construction have proven that technology spends approximately half of the time on equipping load-bearing concrete structures or floors of a building, a swimming pool bowl, as well as the foundation for a brick house is spent on assembling formwork or other similar preparatory work.

Moreover, this figure can only increase if a person without serious experience works with structures. In this case, it may take much longer to assemble and equip all the elements.

The technology of conventional formwork is removable, which means that at the end it will still need to be disassembled. This technology is at least quite effective, but in practicality it is not as effective as permanent formwork for the foundation.

Permanent formwork technology

Do-it-yourself permanent formwork for monolithic turnkey construction is convenient for almost everyone. Its equipment is simpler, since all the elements made of wood concrete are pre-fitted to each other and you do not need to seriously worry about any block of brick moving out or seriously tilting (of course, this is provided that the permanent formwork for the foundation is assembled correctly).

An example of conventional permanent foam formwork

After pouring, the chip-cement concrete permanent formwork is not removed ; it is left in place as the body of the walls, pool bowl or other structures. This allows not only to reduce the time spent on construction, but also to improve the process of constructing buildings.

After all, permanent formwork can be made from Arbolite, expanded polystyrene or other similar materials, for example, there is also the Durisol technology.

Such designs of houses made from permanent formwork allow you to combine several useful aspects. For example, formwork made of polystyrene foam or Arbolite allows you not only to quickly create a turnkey concrete wall for a house or swimming pool, but also to insulate it at the same time.

Types of permanent turnkey formwork, as well as modern permanent formwork blocks that are on the market, are quite simple cast or prefabricated structures made of foam plastic, wood concrete in the form of bricks, also when Durisol technology is used or from glass magnesite, etc.

The Technoblock company has gone much further. These guys have improved the technology of permanent formwork, making it much more efficient and convenient than wood and corrugated sheets. All this with a minimal increase in the cost of materials.

Permanent formwork made of glass fiber reinforced concrete, Durisol, as well as permanent formwork made of polystyrene concrete or wood concrete, are mobile prefabricated panels . But don’t be scared, assembling these panels is very easy, because all the elements are adjusted to each other, the fasteners are measured, and even the holes in the formwork are already pre-drilled.

All that is required of you is to assemble the structure from Durisol brick on a turnkey basis, like a large construction set. The process is entertaining, and also, very importantly, extremely useful. After all, using this technology you can not only collect specific elements, you can also combine them at your discretion.

For example, if you need to build an external load-bearing wall of a house or a swimming pool bowl, then you just need to slightly change the design of Durisol permanent formwork in order to simplify all your work processes as much as possible.

Thus, for the installation of external walls or a basement floor made of permanent formwork, Technoblock facing permanent formwork is used.

Its peculiarity lies in the use of an external facing sheet, which consists of cast molded concrete and foam insulation.

Facing formwork Technoblock

The inner sheet can also be combined. As a rule, it is assembled from cheaper concrete corrugated sheets, and then additionally insulated with a layer of foam plastic.

Moreover, profiled foam sheets can not be installed at all, or they can be installed, but their thickness can be adjusted depending on the specific conditions of the situation.

As you can see, this assembly process makes the use of Technoblock formwork extremely effective, as evidenced by numerous laudatory reviews.

Just imagine how much time you would have to spend on the same processes using conventional formwork.

At first you would have to struggle to assemble it, especially above the attic or for the pool. Then you need to pour concrete into the lintels and wait for it to harden.

After this, you need to place the insulating foam corrugated sheet on the mastic with dowels (using Technoblock materials, you will not encounter such a problem, because facing slabs made of concrete and foam plastic are firmly held on screw clamps and do not need additional fixation).

And then you still need to tackle the cladding of the building, especially the attic. As you can see, the duration of work processes increases several times.

Advantages and disadvantages

So, permanent formwork Velox, permanent formwork made of csp, as well as Technoblock or Durisol, have their pros and cons of use.

Main advantages:

- Mobility.

- Efficiency.

- Practicality.

- The ability to significantly speed up the construction process.

- The ability to combine elements at will and discretion.

- Reliable, well-thought-out design of jumper fastenings.

- High quality of materials used.

Main disadvantages:

- Slightly increased cost (but it’s worth considering that you would have to pay a lot more for separate insulation and cladding).

- The average speed of construction of load-bearing structures is slowing down, although only slightly.

- You have to combine blocks with each other or use standard designs for assembly from Technoblocks, Arbolite or Durisol.

- There is no possibility to rent it.

Basic physical and mechanical characteristics of the material

Plates made from basalt fibers are characterized by strength and elasticity. They are designed for operation at low and high temperatures, which expands the possibilities of using the material. Insulation is recommended for private and civil construction.

Main technical characteristics of the blocks:

- thermal conductivity – 0.035-0.039 W/(m*K);

- compressibility – from 5 to 10%;

- vapor permeability – 0.3;

- water absorption – up to 1.5% by volume;

- content of organic substances – 2.5%;

- flammability group - NG.

Product parameters:

- length – 1000, 1200 mm;

- width – 400, 500, 600, 1000 mm;

- thickness – 30-200 mm.

The dimensions of the slabs are standard; they are the same for all types of insulation produced.

Design, types and their differences

The developers of permanent formwork Technoblock, Durisol, and Arbolita were able to come up with and implement a rather interesting concept for a prefabricated structure. Velox permanent formwork, like the others, consists of two sheets that form the edges of the supporting structure.

Inner sheet is usually cheaper and simpler. It is made of ordinary concrete, but of a cast system. That is, the profiled sheet is immediately ready for applying putty or a finishing layer of plaster . And this is a big plus, because you will be able to save on thoroughly leveling the walls, especially above the attic.

The outer profiled sheet, especially if we mean a facing model, consists of foam plastic slabs, which are then covered with a concrete slab made of “cast marble”. The peculiarity of the outer slab is its texture and the ability to select a specific texture of the profiled sheet.

Since the Arbolite formwork is already insulated, all you have to do is apply a layer of thin putty to the concrete, prime it, and then paint it.

Agree, if you compare the financial and time costs with conventional facade work, the advantage will clearly not be in their favor.

Moreover, this entire system is assembled in an elementary way. All slabs have pre-drilled holes for fasteners. If your model does not have holes drilled, then you will have to do it yourself.

Main types of formwork Technoblock

The fasteners themselves are also available. These are special screw L-shaped hooks.

Plastic spacers are attached to the hooks. The spacers are made using such technology that even their dimensions can be changed, and quite simply. With the help of plastic spacers you can change the final thickness of the future structure.

Using the same formwork you can create both a wall with a thickness of 50 mm and a load-bearing structure with a thickness of 250 mm.

Having understood the design of permanent formwork Technoblock, let’s turn to its popular varieties. Here are a few of them:

- Technoblock standard.

- Technoblock combi.

- Technoblock without insulation.

- The technoblock is removable.

Standard models are permanent structures insulated on both sides, which are used most often. They are used when it is necessary to create walls of plinths, foundations, powerful external load-bearing structures, etc.

The technoblock combi has insulation on only one side. Variations of finishes can be combined. For example, leave the finishing and insulation only on the outside, and install a regular enclosing concrete slab from the inside.

Models without insulation differ from standard ones only in its absence. They are often used for pouring columns, pool bowls, internal load-bearing walls or partitions.

Construction of walls from facing permanent formwork Technoblock

Well, removable systems consist of two durable plywood sheets. The corrugated sheets are mounted and fixed using a similar technology; only after the concrete has hardened, the plywood is removed . The spacers and screws are left inside the concrete structure, since they are consumable elements.

The convenience of Technoblock removable formwork lies in its practicality and readiness for work. You can assemble such a structure in a matter of minutes, while with homemade models you will have to seriously tinker. However, we note that such a system cannot be rented.

Reviews about Technoblock formwork

Now we recommend that you pay attention to reviews about permanent formwork of the Technoblock type. Reviews from customers always help to better understand the situation. After all, nothing gives such a clear picture as reviews from a person who has already used this product.

Valentin, 29 years old, Kharkov:

At work we were building a house using Technoblock formwork. We used standard models with external insulation. I can say that I have never seen anything more convenient in my life.

My colleagues and I calculated that by using this system we saved money on rent and about a week of time. And this is according to the most conservative estimates. If you are willing to pay more for such material, then take it without hesitation.

Anton, 42 years old, Penza:

I used Technoblock formwork to fill the outer walls of a large cottage. After work I had only pleasant impressions. However, I will note in advance that the internal slabs will have to be trimmed, and this is not so easy. Otherwise, the material and technology are thought out to the smallest detail. It is very convenient to work.

Kirill, 39 years old, Kamenka:

I was very pleased with this formwork. I have never seen anything more convenient in my life. Not only can you adjust the thickness of the walls and select insulation, but you can also change the facing panels the way you want.

Technoblock wins by a huge margin over all other models of factory formwork.

Formwork assembly process from the Technoblock company (video)

Description of Technoblock insulation

Technoblock - basalt mineral wool insulation

The raw material for the production of stone slabs of the Technoblock series are basalt rocks. During the production process they are transformed into thin, durable fibers. Numerous air layers in the structure of the material provide excellent heat and sound insulation characteristics. Stone wool is produced in the form of slabs. This format simplifies the installation of insulation.

One of the disadvantages of mineral wool products is the loss of insulating properties when wet. The Technonikol company solved this problem by treating products with water-repellent compounds. Technoblock slabs have medium hardness, they are elastic, and quickly restore their shape after compression. Thermal insulation material is designed for external wall insulation. It provides a comfortable temperature in the room and meets fire safety requirements.

Flaws

The scope of use of the Technoblock is limited by its two biggest disadvantages. The first is that the material is designed to perform construction work at medium speed. This makes it difficult to use in situations where the timing of the cladding is paramount. If it is necessary to solve such a problem, it is better to use other materials, the installation of which does not require individual modification of each element.

The second disadvantage arises from the shape of the blocks. There is a need to optimize the project for the size of basalt wool sheets. If this is not done, the strength of the structure will be significantly reduced. The cladding will lose its wear resistance, and over the years there will be a risk of its destruction. To avoid this, it is recommended to comply with the standard specified by the Technoblock manufacturer. Unfortunately, this is not always possible.

Application area

Technoblock basalt wool is used in the construction of buildings as a thermal insulation and acoustic barrier.

Slabs that retain their shape and are resistant to moisture and frost are used in layered masonry. They are the middle layer between the outer and inner walls, made of brick or concrete blocks. During the installation process, an air gap is left to prevent the formation of condensation on the insulation. One of the areas of application of Technoblock is hanging facade systems. The technology consists of constructing a cladding with a gap for ventilation. Mineral wool fits tightly into the prepared frame, preventing the appearance of gaps. To fix it to the wall, disc-shaped dowels are used. Holes are drilled for fasteners using a hammer drill. The flat plastic head of the dowel should be flush with the surface of the slab. The layer thickness depends on the thermal design calculation. When laying two layers, the effectiveness of thermal insulation increases.

Ventilated facades can be installed for houses made of any building material. One of the important requirements for their installation is to ensure fire safety. In the event of a fire, the fire quickly spreads throughout the structure. The use of Technoblock Standard insulation eliminates the occurrence of such a situation. Basalt material does not burn and can withstand temperatures up to 600°.

Insulation can be installed when insulating building floors and attics. They are intended for non-load-bearing surfaces. The technoblock reduces heat loss and serves as effective sound insulation.

pros

The technoblock is highly wear-resistant and immune to weather changes and other natural factors. Taking this into account, the material can be installed in the facade system. Technoblock is most often used as one of the layers of exterior finishing.

In addition, basalt wool is not afraid of rodents. Other biological factors, including mold and mildew, will not harm it. The technoblock does not create conditions suitable for their development. As a result, the finishing will retain its original appearance and performance qualities, and will also reduce the risk of rotting and premature wear of other materials used in cladding facades or ceilings.

Basalt wool is easy to process. This does not require special tools; the material is cut using a knife. The blocks can be given any shape; there is no standard: the main thing is that the elements fit together.

Construction news

Viessmann: simplifying heating and hot water circuits

At the beginning of February 2021, as part of the business program of the international exhibition Aqua-Therm, a symposium “Efficient heating systems in combination with renewable energy sources” was held, organized by the German Association of Heating Equipment Manufacturers.

KNAUF is developing the direction of modular construction

The KNAUF Group, one of the world's largest manufacturers of construction and finishing materials, continues to implement a project to create systems for modular housing construction. The technology is based on the use of ready-made elements - modules, which can significantly speed up the process of building construction.

Redverg brings open type inverter generators to market

Circular saw from Makita

Makita launches the CA5000XJ circular saw for cutting grooves in aluminum composite panels (also often called Alucobond).

"INTERSKOL": the birth of a new cluster

A year ago, the Russian company opened a new plant in the Special Economic Zone “Alabuga” (Republic of Tatarstan).

Shower System Rain

System Rain is not just a shower, but a real tropical shower in your home!

Source

What buyers say

This section has collected several reviews from those who have already used the material in their home or had it insulated to order. Perhaps you will find their opinions useful.

Density 45 kg per cubic meter differs from 35 Rockwool LIGHT BUTTS. The cost of both is in a similar range Alexey

I enjoyed working with the material. I used it in frames, both hundred and fifty. Keep in mind that it compresses a little worse than the Optima; it has a density of 35. And one more thing: if the space between the racks is less than 580 millimeters, you may have to trim it. Yuri

A standard Technoblock should have a density of 40–50 kg per cube, and most often 40–42, the minimum is used. I personally have not seen quality certificates with greater density. Well, at least I’m talking about the Yurginsky plant, I don’t know about the others. Plus, keep in mind that they add slag, unlike Rockwool, so in the end the slabs look darker and the melt pellets inside are visible. And this is not only an external joke, but also improves thermal conductivity. So, at similar prices, I would still take Rockwool. Sergey

So, we have highlighted the main characteristics, reviews and descriptions of TechnoNIKOL Technoblock Standard and its “brothers”. Now you have all the information you need to make a decision about the type of insulation.