A sewer sololift is an electromechanical equipment that pumps human waste products from low-lying plumbing fixtures to the level of the main outlet line. The use of a sewer pump allows the installation of sanitary equipment in the basement floors of a building where, for some reason, there is no sanitary pipeline.

Sololift for washing machine.

What is a sololift and why is it needed?

Based on their content, wastewater is divided into gray and black household waste. The first comes from the shower, washbasin, kitchen sink and contains liquids contaminated with grease and detergents. The latter flows from the toilet and can include personal hygiene items, feces and various by-products.

In a standard sewer system, wastewater flows by gravity into the sanitary main and is discharged to the place of treatment or disposal. For normal operation of the system, it is necessary that all sources are located above the inlet pipe of the outlet manifold. Otherwise, connecting household appliances without the use of additional equipment will be impossible.

This problem can be solved by installing a sanitary pump with a grinder - a sololift - into the system (see video). The forced sewerage method allows hydraulic equipment to be placed in any part of the building.

Applicable:

- for the installation of additional bathrooms in the basement or basement;

- to organize the protection of internal sewerage from the backflow of liquid from the main collector;

- to improve showers and toilets in hotels and office buildings.

Manufacturers and models

Not many companies produce individual sewerage installations. However, the price range is quite wide. Traditionally, European manufacturers are distinguished by good quality, but high prices. No one will be surprised if we say that Chinese sewage pumps cost less, but their quality is worse. In general, the choice, as usual, is expensive and high quality, or cheaper and...

Forced sewerage installations Grundfos (Grundfos) - Sololift (Sololift)

The well-known manufacturer of plumbing fixtures Grundfos produces Sololift pumps for forced sewerage. At the moment, a modified Sololift2 line has been launched. There are no moving parts in contact with drains. The exception is the chopper, but its drive is also “dry”. This makes repairs less of a hassle. There are several Sololift models for different cases:

- WC1 - with a chopper, one main and one additional input. Suitable for connecting toilet and washbasin.

- WC3 is a pump with a grinder for connecting a toilet and three additional inlets.

- CWC3 - the same as WC3, only for connecting wall-hung toilets. Main characteristics of Sololift sewage pumps

- C3 is a high-capacity fecal pump that can pump out wastewater with temperatures up to +90°C, pump wastewater from a bathtub, from a washing machine and/or dishwasher.

- D2 - pump for hot wastewater (with temperatures up to +90 °C) without solid impurities. It can be connected to a shower, washbasin, washing machines and dishwashers.

Sololift sewer pumps are not the cheapest equipment, but they work reliably and meet the stated characteristics. The company also supports warranty repairs.

Pumps for toilets, bathrooms, kitchens and technical rooms SFA

This company specializes in the production of sanitary pumps. There are several lines to solve different problems and connect various devices:

- Saniaccess is a household pump grinder for a toilet with the ability to connect a washbasin and shower (modifications with numbers 2 and 3, respectively). Has low productivity.

- Sanibest is a high-performance toilet and sewer pump. Suitable for private homes with high intensity of use and for public spaces.

- SANIBROYEUR is a silent toilet pump, has a grinder, and can transport wastewater 4 m up or 100 m to the side. Dimensions SFA SANIBEST Pro

- Sanipack is a compact sewer pump to which you can connect a wall-hung toilet and a shower/sink/bidet. Can be built into a partition due to its small size.

- Saniplus Silence is a powerful pump that can remove water from several plumbing fixtures. It features low noise operation and high productivity. Can handle bathroom drainage.

- Sanipro XR Silence is the quietest model for pumping sewage from a full bathroom (without a bathtub).

- SaniTop - installation of forced sewerage for connecting a toilet and sink. This newer model is quieter compared to Saniaccess and has a more powerful pump.

SFA products work reliably and cost slightly less than Grundfus. You can choose a model for any combination of plumbing fixtures. Overall, the SFA sewage pump is a good option. Equipment installation is standard - place it in any convenient place. There is only one limitation - it is better for the outlet pipeline to start from a vertical section, if there is one on your route. If this is not possible, the length of the horizontal section should be no more than 30 cm.

The height of the vertical section is calculated taking into account that the horizontal section must have a slope towards the inlet of at least 1% (1 cm per 1 meter of pipe).

CompactLift fecal pumps from Aquatik

Toilet pumps Compact Lift are produced by the Chinese company Aquatic. This is a more budget-friendly option for individual sewer installations. They have a low noise level.

At the moment there are only three modifications:

- Compact LIFT 250. Installation for pumping out gray waste (without feces and toilet paper). A low power of 250 W and a flow rate of 119 liters/min allows you to connect a shower and sink. Sewage pump Aquatik Compact LIFT

- Aquatik Compact LIFT 400. Compact sewage pump with the ability to connect a toilet with direct outlet and three additional plumbing fixtures. Power - 400 W, productivity 149 liters/min.

- Aquatik Compact LIFT 400 A. For connecting wall-hung toilets. The technical specifications are similar. series

Aquatik provides a warranty on its pumps for bathrooms and toilets for 1 year from the date of sale. Failure to operate (presence of fibrous inclusions in drains) may result in refusal of warranty repair.

Willo sewage pumps

The German company Willo is known for producing reliable devices. Toilet pumps are no exception. Good quality plastic, thick tank walls, reliable pump. The following models are available:

- HiDrainlift 3-24 - for servicing clean drains without feces and toilet paper (shower, washbasin, urinal). Power 300 W, flow rate 58 liters/min.

- HiDrainlift 3-25 is a pump for connecting a toilet with direct outlet and three additional pipes for connecting a shower, washbasin, etc. Power 400 W, maximum productivity 100 liters/min.

- HiSewlift 3-15 - for connecting one floor-standing toilet. Plus has one additional input for connecting a washbasin/shower/urinal/bidet. Power 450 W, maximum flow 75 liters/min. Dimensions of one Willo bath pump model

- HiSewlift 3-35 - one input for pumping out toilet drains and three inputs for connecting devices with gray waste - washbasin/bidet/urinal/shower. Power consumption 450 W, capacity 75 liters/min.

- HiSewlift 3-I35. More compact installation with parameters similar to HiSewlift 3-35.

- DrainLift KH 32. For connecting a wall-hung toilet, equipped with three additional pipes for connecting plumbing equipment with clean drains. Power consumption 450 W, can pump out no more than 75 liters/min.

- DrainLift XS-F - similar to DrainLift KH 32, but smaller in size, for installation in a wall niche.

- DrainLift TMP 32. For connecting gray drains - without faeces and toilet paper. There are two outlets to which you can connect washing machines or dishwashers. Characteristics of three models of Willo sewage pumps

- DrainLift TMP 40. For pumping domestic wastewater (without faeces). It can be connected to the kitchen - it is possible to supply drains from the sink and dishwasher. It differs from all models in the standard configuration - it has a float switch that will turn off the dishwasher pump if there are signs of overfilling of the tank.

The Willo range of sewer pumping units allows you to solve any problem when it comes to equipping bathrooms and toilet rooms in private homes. For commercial or more intensive use, Willo has other solutions.

Pressure sewage pumps STP (Jemix)

These custom sewer installations are manufactured in China. The price category is average. Reviews, as usual, are different - some are completely satisfied, others categorically dislike it.

So, here are the sewerage pumps Jemix offers:

- STP-100 Lux. For connecting a toilet with two additional inputs (washbasin, urinal, shower). Power 600 W, productivity 200 liters/min, vertical lift height - 9 m, horizontal lift - 90 m, maximum temperature +90 °C.

- STP-400 Lux. Toilet pump with similar connection options. Only the wastewater temperature is not higher than +40 °C, power 400 W, productivity 100 liters/min, wastewater lifting height - up to 8 meters, horizontal transportation - up to 80 m. Approximate prices for sewage pumps STP (Jemix)

- STP-800. You can also connect one floor-standing toilet + two additional inputs. But the power is 800 W, the pressure is 150 liters/min, the lift is 9 m, horizontally - 90 m. Only warm waste water can be transported - up to +40 ° C.

- STP-200. With one input for connecting a toilet and two additional ones. Less power - 400 W, can pump out 100 liters/min, maximum height - 8 m, horizontal transportation - 80 m, temperature of the transported medium is not higher than +40 ° C.

- STP-250. For drainage of gray waste (without solids). It has two entrances (shower, washbasin, bidet). Power 250 W, drainage lifting height up to 5 m, horizontal transportation no further than 50 m, can pump out no more than 80 liters/min.

- STP-500 Lux. This pump is for toilet use only. No additional outputs

It differs from those described above in its increased power - some models raise drains by 9 meters. Most of the sewerage pressure pumps described above can lift wastewater up to 4-5 meters. So this is where the Jamicks win. In this parameter they have only one competitor - Sololift Grundfos with its lifting height of 8 meters. But its price category is completely different (as is its quality, for that matter).

Design and principle of operation

Sololift contributes to an effective solution to the problem of removing domestic waste without carrying out expensive major repairs in the building in use. Small-sized installations do not spoil the appearance of the premises. They can be built into any floor and wall structures.

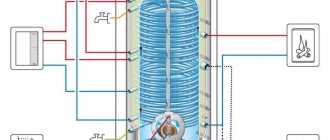

The structure of the mechanism consists of the following set of parts:

- small-sized housing made of high-strength plastic;

- an electric motor with cutting blades mounted on its shaft;

- check valve;

- liquid level sensor.

The complete set has 3 inputs. One is for the toilet. The other two are for the shower stall and for the kitchen sink. The liquid is drained through a separate pipe located in the lid of the device.

Sololift device.

When contaminated wastewater enters the sololift chamber and reaches the recommended level, the level sensor is activated, which starts the electric motor with the cutting device. The wastewater treated in this way begins to flow through the check valve through the sewer pipe into the collector.

When the container is empty, the sensor automatically turns off the power to the pump. The valve blocks the passage of the exhaust pipeline, preventing the backflow of liquid into the device tank.

Classification and types

There is no single classification of forced sewer installations, but they can be divided according to several parameters:

- Presence of a chopper. It is needed if the sewer pump is connected to the toilet.

- Performance. This is the volume of wastewater that can be pumped per unit time. There are installations with low productivity and even very solid ones. The choice depends on the number and type of connected devices.

- The temperature of the pumped out medium is from 40 °C to 90 °C. Everything is clear here - drains from a dishwasher, washing machine, and bathtubs require sewer pumping stations capable of pumping wastewater at high temperatures.

- Duration of work. There are installations that can only be turned on for a short time (they are installed on one or two devices), and there are more “long-lasting” ones (can be used to drain the wastewater of an entire house). This is usually indicated in the specifications as the duration of operation. The percentage may be 50%. This means that the installation works for 30 seconds and rests for 30 seconds. The operation/cooling interval can be specified in seconds or minutes.

A sewer pump can be installed in the kitchen to remove waste from the sink and/or dishwasher.

When choosing a pump for forced sewerage, it is worth remembering that they are not designed to connect a bathtub. Bathrooms contain too much water, pumping out which will cause the pump to overheat and block. As a result, it will take a long time to drain the water from the bathroom. There are only a few models of forced sewerage that will cope with this task - SFA Saniplus Silence and Sololift C3. These sewer pumps do a great job of discharging large amounts of warm water.

Other companies propose to make an intermediate pit for forced pumping of drainage from the bathroom into which to drain the water. From it, pump it into the sewer using any suitable device. Taking into account the fact that the pit must be below the drainage level, this method is not always acceptable. And, despite the high cost of SFA Saniplus Silence and Sololift C3, it is often more profitable to install it than to carry out a huge amount of excavation work.

To prevent the tank from overfilling there is an additional alarm device. In some companies it simply beeps when the container is full, in others it also turns off the device connected through it (washing machine or dishwasher).

Choosing a sololift for sewerage

The name sololift unites a whole group of pumping units that have the same purpose, but different performance characteristics:

- WC - model for the toilet, equipped with cutting tools and a powerful electric drive;

- C - small-sized station, can be built into floor and wall structures;

- D - installation for washbasin, shower;

- numbers 1, 2, 3 indicate the number of pipes for connecting additional plumbing.

For example, Grundfos Sololift D - an installation for gray drains (shower, washbasin) with one inlet pipe; Sololift D-3 is a station with the ability to connect three sanitary fixtures. Mechanisms produced by different manufacturers differ in their configuration and functionality. Therefore, when choosing a station model, you need to read the operating instructions and get advice from specialists.

To make a technologically correct choice of a sanitary installation, a number of conditions must be met:

- Draw up a preliminary diagram of the arrangement of devices.

- Determine the number of plumbing fixtures to be connected, taking into account the characteristics of the drains.

- Compare the obtained values with the technical capabilities of the device.

- Take into account the installation conditions of the sololift and check them with the installation passport.

Criterias of choice:

- distance of vertical and horizontal supply of wastewater;

- device performance;

- electric motor power;

- temperature of the pumped liquid;

- weight and dimensions of the station;

- body material;

- price.

Application area

Sewerage distribution diagram

Pumps are used to pump out wastewater in buildings where, for technical reasons, it is impossible to install a sewerage system operating on the principle of gravity flow. The manufacturer offers several models for pumping black and gray wastewater. The following nodes can be connected to the system:

- baths, showers;

- shells;

- bidet;

- toilets of various designs;

- washing machines and dishwashers.

Due to their small size, Sololift stations can be combined with floor and wall devices, so they do not spoil the design of the bathroom or toilet.

Installation and connection

To connect a sololift, it is best to use polymer or metal-plastic profiles with a diameter of 23-32 mm.

Installation instructions:

- It is prohibited to install the station below floor level, in a pit.

- Supply pipelines must be placed relative to a horizontal surface with a slope of 1-3%.

- The vertical section of the outlet line should begin immediately behind the device body (recommended length - 6 m).

- For “WC” models, the distance between the unit and the floor-standing toilet should be minimal (130-150 mm).

- The length of the pressure pipeline is subject to the height of the liquid rise, taking into account local friction losses.

- The unit is secured to the floor using steel bolts included in the delivery kit.

- When installing, you should take into account the recommended distances between the housing and equipment installed nearby - for ease of repair and maintenance of the device.

- If several pumps are installed, the connection should be made in groups separated from each other by the type of equipment being serviced (shower, toilet, dishwasher, etc.).

- The insertion into the central manifold should be made at an angle that does not impede the passage of the main fluid flow.

- Combining discharge pipelines from different pumping installations is not permitted.

Sololift installation diagram.

The connection of the station to the electrical network must be carried out by professional installers in compliance with safety regulations. The pumping unit must be equipped with a grounding device and a residual current circuit breaker (RCD).

The principle of operation of the Sololift sewage pumping unit

There is nothing complicated in the operation of the station, all household waste accumulates in a container, after it is filled to the required level, the pumping equipment is turned on, the operation of which is controlled by a special relay. After this, the water flows into the sewer main.

Distance from the device to the mass release point:

- 7 m - vertical;

- 100 m - horizontally.

All parameters are indicated by the manufacturer in the product passport. To facilitate the removal of masses, the station is equipped with a grinder that can even handle personal hygiene products.

It is important! A sewer pump with a grinder will cope with single hits of household rags or personal hygiene products; systematic jamming of objects can damage the pumping equipment.

Rules of operation and maintenance

The sololift is part of the house's sewer system, therefore, it, like all plumbing in the building, is subject to standard operating rules:

- It is prohibited to throw rags, personal hygiene items, etc. into toilets.

- Do not pour flammable solutions or acids into sinks or washbasins.

- Discharge of solid food waste into the sewer system is not permitted.

- Avoid uncontrolled water consumption and leaks (risk of overheating of the station engine).

- If the line is clogged, exclude the possibility of operating the pump until the breakdown is repaired.

- When cleaning polyethylene pipes, do not use steel wire.

- Protect the main line and sololift casing from mechanical loads and exposure to high temperatures.

Maintenance of the station itself comes down to periodic inspection and cleaning of the walls of the polymer chamber from fat and lime deposits.

To perform routine maintenance you need:

- turn off the power supply;

- remove the top cover;

- pour in a special cleaning solution (detergent);

- let stand for 5 minutes;

- put the cover back in place;

- Drain the water from the toilet tank and wait until the pump turns on.

To wash other appliances, simply place detergent in the liquid drain hole, wait a little and turn on the water.

If the operating station is located in a building with temporary residence, then to preserve the device for the winter period you will need:

- Turn on the water and wait until the sololift operates twice.

- Then turn off the liquid supply valve.

- Remove the cover of the device.

- Using a rag, dry the inside of the container.

- Close the tank.

Design features

The operating principle of Sololift sewerage installations is quite simple. The model is used as the main receiver for wastewater; secondary outlets are connected using auxiliary pipes with a diameter of 5 cm, which are located in the lower sector. Input lines for drains can be implemented using equipment for a standard sewer network, and the outlet elements used to drain liquid must be reliably sealed, since pumping is performed under pressure. That is why during installation it is important to purchase branded components, including a check valve and other elements of plumbing fittings.

The housing contains the pump itself with a separator element and knives that grind large waste. The principle of operation is the operation of an automatic unit, which turns on when the tank is filled and activates the pump; the device is connected to a standard electrical outlet. Energy consumption even for younger models is small, so installing pumping equipment allows you to install an efficient sewer network in a private house or apartment.

Brief overview of popular sololift models

Sololift WC 1.

Small-sized compact Sololift units are used in apartments and country houses where wastewater cannot be drained into the sewer by gravity due to the natural slope. The design of the device guarantees quick installation and minimal operating requirements.

Main representatives of the model range:

- pump WC-1;

- Sololift WC-3;

- CWC installation.

Sololift wс 1

The station is designed to drain wastewater from the toilet and washbasin. The pump is delivered assembled and is immediately ready for installation and long-term operation.

The mechanism is equipped with a professional cutting tool and an automatic air vent valve. A powerful electric motor equipped with thermal protection provides high torque and easy starting of the device.

An impermeable reservoir made of polymer material can withstand liquid pressure of up to 2.5 m of water column. The lid is equipped with a carbon filter and a valve that protects the system from overflow. Some stations can be equipped with an audible alarm that is triggered in the event of “dry running” or depressurization of the tank. Sololift WC-1 is installed directly behind the toilet, in an open manner.

Slolift wс 3

WC-3 differs from the previous model in the number of connected plumbing fixtures. It is designed to simultaneously drain wastewater from the toilet, washbasin and bidet.

Specifications:

- weight - 7.3 kg;

- productivity - 150 l/min;

- pressure force - 8.5 m;

- temperature of the pumped liquid - +5...+50°С;

- power consumption - 620 W.

The inlet openings on the unit body are designed for installation of pipelines with a diameter of 22-40 mm. The delivery set includes eccentric pipes that allow the connection point to be shifted by 10 mm.

Station СWS 3

Sololift CWC-3 differs from its predecessors in size. Its thickness (160 mm versus 175 mm) allows for hidden installation of the device. The station is designed for pumping liquids from wall-mounted toilets, showers, bidets and washbasins. The standard container volume is 6-9 liters.

The installation is equipped with a dry electric drive and self-regulating pipes with a diameter of 32-40 mm. On the housing cover there is a hole with a plug for manually unlocking the cutting shaft (there is no need to open the housing).

The bottom is smooth with rounded walls. This shape of the tank minimizes the likelihood of stagnation zones and sediment formation. The pressure sensor is located outside the tank and does not interfere with the passage of wastewater when the pump is running.

Station CWC-3.

Technical characteristics and markings of the device

Today, a number of Sololift models are represented by a line of products of various modifications. All products are produced in white plastic cases with a certain differentiation according to purpose and configuration. Pumping units of this kind are intended for residential premises, offices, and industrial buildings.

Devices of this type are equipped with shredders, but can only process toilet paper; waste must be prevented from entering drains.

If this is not possible, you need to select other similar equipment. Some models are capable of processing more complex contaminants in the form of sanitary pads. This feature is reflected in the device passport.

Watch the video

Sololift Grundfos C3 repair and maintenance. How to disassemble and clean.

The Sololift product line includes the following types of pumping equipment:

- C-3, where the index “C” indicates the size of the product, equal to 125 millimeters;

- D-3, the marking indicates the applicability of the device only for sinks and shower stalls; using it with a toilet leads to sewer blockages;

- WC – designation indicating the presence of a cutting device for grinding inclusions in the kit, allowing it to be used with a toilet;

- WC-1 – the pump is equipped with one inlet;

- WC-3 – the device has 3 inputs.

Such systems can be installed with toilets, bidets, and washing machines.

Equipment of this class can operate with substances with temperatures up to + 45 degrees. If it is necessary to process streams with hot water, you need to use a device model C-3.

Devices of this class provide a power of up to 10 meters with a productivity of about 4.3 cubic meters per hour of operation.

The design features and complete set of devices of this class give them the following capabilities:

- there is an overheating protection function;

- the use of a carbon filter is provided to eliminate sewer odor;

- The cable length of 1.2 meters allows you to choose where to place the pump.

Units of this type operate on a 220 volt network. The use of hydrodynamic thermal relays is provided to prevent the container from overflowing. Non-return valves are installed on the pressure pipes, protecting the device from overflow and liquid leakage to the outside.

Metal parts can work in aggressive environments because they are made of anti-corrosion steel.

Advantages and disadvantages of use

Advantages of sololift:

- a powerful electric drive with a cutting device that can handle toilet paper and personal hygiene items;

- smooth, impenetrable body;

- small station sizes;

- the device operates automatically;

- the presence of a carbon filter on the housing lid eliminates the appearance of unpleasant odors in the room;

- ease of maintenance and repair.

One of the disadvantages is the high sensitivity of the electric pump to sudden voltage changes. Not all models have the ability to pump large volumes of water (bathroom, etc.).

Pros and cons of the design

The equipment has the following advantages:

- efficient operation even when connected to a small diameter pipeline;

- small dimensions, the ability to install the device in confined spaces;

- convenient operation;

- a number of improved models have a vortex design, due to which blockages do not form in the system;

- no need to use expensive tools for installation;

- compatibility with various types of interior.

One of the disadvantages is the overpriced device. Another problem is complex repairs that are difficult to do on your own. Most owners turn to professional repairmen to fix breakdowns, which requires additional costs. On the other hand, with proper operation and initially correct installation, the system rarely needs maintenance.