Despite the fact that an induction boiler costs 2-3 times more than its heating element counterpart, an increasing number of users prefer this type of heater. Thanks to its simple and trouble-free design, the unit is durable and maintenance-free. Due to the high power, the connection of the installation must be coordinated with the Distribution Zone.

The induction boiler has a safe design.

The history of the appearance of heating equipment

The prerequisite for the creation of heat generators of this type was the discovery of electromagnetic induction made by Michael Faraday on August 29, 1831. Before him, this phenomenon was observed by Francois Jean Dominique Arago, but could not explain and reveal it.

Induction is the occurrence of an electromotive force in a closed conductor when the magnetic flux passing through it changes.

This can be achieved in 2 ways:

- Varying field parameters. To do this, change the strength or direction of the current flowing in the electromagnet coil.

- The movement of the conductor relative to the field or vice versa. To do this, for example, a permanent magnet is rotated.

Later, this phenomenon was studied in detail by Jean Bernard Foucault. He called volumetric currents arising in a material under the influence of an alternating magnetic field eddy currents. This is due to the circular trajectory of the charges. They are also called Foucault currents, named after the researcher.

According to the Joule-Lenz law, electricity induced by a magnetic field causes an increase in the temperature of the conductor. E. Colby took advantage of this in his experiments on non-contact heating of steel. In 1900, in the Swedish city of Jaising, she built the first induction melting furnace with a power of 78 kW. The project manager was engineer F. Kjellin.

In 1900, the first induction melting furnace was built.

Subsequently, the technology was developed and began to be used to solve a wide range of problems, in particular:

- ultra-pure smelting, soldering and welding of metals;

- bending and heat treatment of machine parts;

- creating jewelry;

- disinfection of medical instruments;

- heating miniature workpieces that are at risk of damage when in contact with gas-flame and arc equipment;

- surface hardening, including products of complex shapes;

- activation, training and degassing of cathodes in the production of vacuum electronic devices.

Due to the large size of the first installations, this method was not initially used in everyday life.

Later they began to produce:

- kitchen stoves;

- water heaters;

- heat generators.

General information about induction heating boiler

The production of such units began in the 90s. last century. Many models are cylindrical in shape, so they fit well even in small spaces.

Purpose of the inverter

The most expensive models are equipped with an electrical converter that processes the mains current as follows:

- straightens;

- again makes it variable with a frequency of up to 80 kHz instead of the standard 50 Hz.

Inverters are equipped with an electrical converter.

At the first stage, a simple diode bridge is used. On the second there is a circuit of fast-acting key transistors and a microprocessor that controls them.

Increasing the frequency of the current leads to a similar change in the magnetic field it generates. As a result, the so-called skin effect. It consists in the fact that due to the interaction of constantly changing primary and secondary fields, free charge carriers are displaced into the surface layers of the product. As a result, the current density increases, and hence the heating intensity, since, according to the Joule-Lenz law, these quantities are interrelated:

ω = j*E.

The temperature deep within the material increases due to thermal conductivity. As the frequency of the inductor's magnetic field increases, the layer thickness decreases. As a result, the current density increases.

Specifications and functionality

The device passport indicates the following parameters:

- power;

- voltage – 220 or 380 V (1- or 3-phase);

- dimensions and weight;

- installation method - wall or floor;

- highest coolant temperature;

- maximum pressure in the tank.

The induction boiler has a high efficiency of up to 99%.

Often referred to as efficiency. But this is a marketing ploy - any electric boiler, regardless of its operating principle, operates with 99% efficiency.

The weight of a 15 kW unit is 15 kg (Comfort brand unit), 5 kW – 11 kg (ELC Indukcion).

Functionality:

- Smooth launch. This eliminates sudden voltage fluctuations in the home network.

- Power adjustment within a wide range. For example, a heater with a nominal capacity of 6 kW has 3 stages of 2 kW each.

- Maintaining the coolant temperature within user-specified limits. The device automatically selects the desired mode and turns off if necessary.

- Programming. The user sets the heater operating schedule for each day of the week. For example, on weekdays from 8-00 to 17-00. When no one is home, the coolant temperature is set to a minimum.

- Room thermostat. Using a remote sensor, the device monitors the air temperature in the room and selects the optimal operating mode.

- Weather-compensated control. Some models also monitor the outside temperature and adjust performance ahead of time when it changes. This avoids wastage of energy.

- Remote control. The GSM module allows you to turn on the device and change its settings from your smartphone.

- Display of operating parameters on the screen. There are models with a touch screen.

The double-circuit unit additionally provides hot water supply in flow mode.

Many models are equipped with an expansion tank and pump.

Device

The device consists of the following components:

- Housings with thermal and electrical insulation.

- Boiler tank with core.

- A coil of wire wrapped around it, filled with a compound.

- Automation block.

- Terminal box for cable connection.

Installation of an induction boiler.

Principle of operation

The operation of the boiler is based on the induction effect. Part of the work done by electric current is spent on creating a magnetic field around the conductor. If it is assembled into a coil, this share increases many times over. Thus, the boiler winding acts as an electromagnet-inductor that generates an alternating field.

It induces Foucault currents in the heat exchanger and core, thereby causing them to heat up.

Main types

Different types of boilers differ in the design of the heat exchanger:

- Casing. The device consists of 2 parts located inside and outside the coil.

- Volumetric or inductive-conductive. The boiler tank is located inside the winding and contains a ferrite core.

- Tubular. The first induction heaters belonged to this type. The heat exchanger is a set of pipes that go around the winding.

The units are also divided into models with and without an inverter.

Coolant circulation

The boiler is simple in design; various types of circulation can be used - with natural movement of the coolant, a circulation pump.

Circulation pump

Some heater models have circulation pumps installed. They help disperse coolant through the heating system. The circulation pump used in the heating system reduces the load on boiler equipment, and the energy consumption of the equipment is reduced several times.

The versatility of boiler heating elements

You can use different types of coolant:

- Tap water, but the device is more vulnerable to scale formation. Plain, untreated water carries debris that causes breakdowns.

- Distilled water. Scale formation is excluded, the liquid does not contain heavy metal salts and does not contribute to the formation of deposits. No debris from entering. Coolant promotes longer operation.

- Antifreeze. Suitable for cottages, private houses. It is used in premises where the owners do not live permanently. In the absence of owners, in order to prevent freezing, the systems are filled with antifreeze.

Distilled water, antifreeze

Main advantages of use

Compared to heating elements, non-contact heating boilers have the following advantages:

- Resistant to voltage surges. They can even withstand lightning strikes and zero ground breaks.

- Reliability and durability. These qualities are due to a simple design: the working part of the boiler consists of a pipe and a wire wound around it.

- Heat exchanger tightness. Its integrity is not compromised, so leaks are excluded.

- No scale. According to the manufacturers, it is not formed due to microvibrations of the heat exchanger walls.

- Large heating surface area. It is multiple times higher than that of the heating element. This ensures rapid heating of the coolant.

The induction boiler is resistant to voltage surges.

Compared to gas, solid fuel and diesel analogues, induction is superior because:

- Does not produce exhaust and does not require a chimney.

- It works silently.

- Able to regulate power over a wide range and at high speed.

- Due to the absence of fire, it is not a fire hazard.

- It is equipped only with electronic automation, which means it has all modern functions - programming, weather control, etc.

Owner reviews

- Over a year of use, of course, it is difficult to give an objective assessment of the operation of the VIN-5 boiler, but still some trends can be noted. First of all, there were no complaints about the operation of the system. I haven’t yet felt the terrible influence of the “colossal” magnetic field either... What’s most pleasing is that you can forget about the existence of a heating boiler in the house, and you also had to pay a little less for the light, a good thing. Alexander, Leningrad region

. - Having carefully studied the design of induction boilers, I came to the conclusion that there really was nothing to break. According to the parameters, “SAV-5” turned out to be the most suitable option, and it was bought for 36 thousand. I can’t say that the energy savings are really significant, but compared to an old boiler, you have to pay less. Otherwise, there are no complaints about 2 seasons. Nikolay, Taganrog.

- Two years ago I installed Geyser-20 and am very pleased that I installed it. Over the course of two seasons, the cost was somehow forgotten, but the warmth and comfort remained. Besides this, no anodes, rinsing, remove-hang, etc. for you. An analysis of receipts for the period of use of the boiler showed that electricity costs, although not much, were less. So I recommend it to everyone! Andrey, Novosibirsk.

- I really liked the idea of sitting in a warm place and not doing anything for it, just paying for the light, and even then less than for a classic boiler, I decided to try it. I installed a 50 kW Edison induction unit in the house, now I sit warm, do nothing and am very pleased. The main thing is that you don’t need to call any specialists, because the city is as much as 75 km away. And if all jokes aside, I haven’t had any complaints in 3.5 years, that’s a very good thing. Dima, Moscow region.

The selection was made in such a way as to further characterize the products of the brands discussed above based on real reviews from owners.

If the cost of an induction device is beyond the family budget, but you have practical skills in plumbing and welding and basic knowledge in electrical engineering, you can make a heater yourself.

Criteria for choosing a good boiler: what to look for

When purchasing a unit, consider the following:

- Power. For a standard house, 1 kW is required for every 10 square meters. m area.

- Voltage. The 380 V model is suitable only for those who have 3 phases connected to their house.

- Maximum pressure in the boiler tank. It must withstand the load from the pump and the weight of the water column.

Models with several power levels are preferable - when starting, they do not cause a sharp drop in voltage in the network.

When purchasing a unit, consider the power and voltage.

Due to the high cost of electricity, it is recommended to choose a boiler with functions that allow you to use energy economically:

- with weather-compensating automatic;

- programmable.

Review of popular manufacturers and models

More and more companies are mastering the production of induction boilers. Some brands have become especially popular.

VIN

The brand belongs to the “Alternative Energy” thermal equipment plant. The company produces induction-conduction heaters with volumetric heat exchangers. All boilers are equipped with inverters. The cost is 37-40 thousand rubles.

VIN – heater with a volumetric heat exchanger.

SAV

Equipment of this brand is produced by NPK INERA.

Peculiarities:

- shell heat exchanger;

- lack of inverter.

The devices operate at a standard network frequency of 50 Hz. Because of this, they are larger than inverter ones, but cost less - 27-32 thousand rubles.

"Geyser"

The brand belongs to the Kostroma Boiler Equipment Plant. The company produces a series of heaters with a rated power of 5, 10, 15, 20, 25, 50, 100, 250 kW. The first requires a voltage of 220 V, the others - 380 V.

Geyser units are of the inductive-conductive type.

All units are of the inductive-conductive type.

"Edison"

The model range of this brand includes heaters with a rated power of 4.7, 13, 22, 50, 100, 250, 500 kW.

The most productive installation is capable of heating an object with an area of 5000 square meters. m. Its weight is 1.5 tons.

The minimum price for Edison products is 35 thousand rubles.

The models are not equipped with inverters, so the youngest representative of the line weighs 40 kg with a power of 4.7 kW.

"Miratron"

The company offers several induction heaters with capacities ranging from 6 to 30 kW. The company uses only high-quality materials in the manufacture of units. All of them have a connector for connecting a weather sensor, and a programming function is provided.

"Miratron" is an induction heater made of high-quality materials.

A 6 kW model costs 45 thousand rubles, a 15 kW model costs 65 thousand rubles.

DIY methods

Thanks to a simple device, you can make a small induction heater yourself.

The easiest way is to install an electromagnet next to the cast iron battery. Home craftsmen also assemble more efficient designs.

From a welding inverter and plastic pipes

This is the most common option.

Proceed in the following order:

- Take a piece of thick-walled plastic pipe DN50 0.5 m long. Most often, a product made of polypropylene is used.

- Using a special heater, weld the coupling on one side, after inserting a circle of metal mesh into it. The part must completely cover the end of the pipe.

- Pour scraps of stainless wire 7 mm thick and up to 5 cm long into the water heater. They will serve as a core.

- Cover the second end of the pipe with a metal mesh and weld the coupling.

- Wind 90 turns of enameled copper wire around the body. This is an inductor coil.

- Connect a 15 A welding inverter with a smooth current control function to the wire.

The device can be made from a welding inverter.

It is permissible to replace couplings with fittings with metal threads.

The heater is ready, you can connect it to the pipeline.

Principle of operation

To understand how an induction unit functions, you need to familiarize yourself with the following important points:

- water enters the boiler unit through the inlet pipe;

- the inverter turns on and high-frequency current is supplied;

- vortex flows begin to first heat the core, and then the entire heating element as a whole;

- the resulting heat is transferred directly to the coolant;

- The heated coolant is transferred to the heating system through the outlet pipe using hydrostatic pressure.

Expert advice: water, antifreeze, oil and other petroleum-based liquids can act as a coolant in an induction boiler.

Self-installation instructions

When installing the device between it and building structures, maintain the following minimum distances (cm):

- walls – 30;

- floor and ceiling – 80.

The device is leveled in a strictly vertical position.

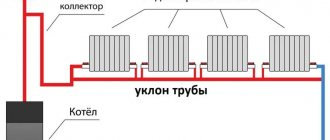

Connecting the boiler to the heating system

Induction heaters are intended only for closed circuits with forced circulation of coolant.

There are 2 reasons for this:

- high hydraulic resistance;

- high heating rate - the medium boils before it has time to escape into the system under the influence of convection.

Induction boiler connection diagram.

Therefore, the circuit must be equipped with:

- Circulation pump with mesh filter. It is connected to the boiler on the “return” side.

- Diaphragm expansion tank. Placed right there.

- Safety group consisting of a pressure gauge, air vent and safety valve. It is installed on the “supply” side no further than 0.5 m from the boiler without any fittings in this area.

The “return” is connected to the heater from below. “Feed” – to the upper pipe.

Electrical connection

The device is supplied with its own cable from the distribution board. The cross-section of the conductors is selected according to the amount of current consumed. The line is protected by a circuit breaker and an RCD. The boiler body is grounded.

Results

So, the efficiency of induction boilers is approximately 99%, they operate silently, using any liquid heat carrier, they do not require maintenance, and it is also safe and practical. Although such a boiler is quite expensive, such costs are recouped. And if you create it yourself, it will be even more profitable.

https://youtube.com/watch?v=F6yIXht5gks

Of course, the choice is yours, but it’s better to contact specialists who will tell you whether such heating is suitable for you.

But, in general, induction boilers are an excellent alternative to traditional heating systems. Date: September 25, 2021

Operating rules and maintenance

Do not do the following:

- Fill the system with a coolant that is not listed as permitted by the manufacturer.

- Turn on the device in dry running mode or with the pump stopped.

- Carry out repair or maintenance work without turning off the power to the unit.

- Keep metal objects near the heater.

The device cannot be turned on in dry code mode.

Check periodically:

- performance of the RCD;

- ground loop resistance.

Induction heaters do not require maintenance. In rare cases, the heat exchanger may become covered with scale, then it is washed with a solution of citric acid or a special product. To eliminate such phenomena, fill the system with demineralized water.

Loosening contacts

Terminal contacts in heating element models, most of them, can be in temperature difference mode. Heating at maximum load, and cooling when switched off.

And this imposes obligations for their revision and tightening.

And in induction, there are supposedly no electrical contacts. In fact, they are always and everywhere, including induction ones.

But as for the former, in recent years specimens with high-quality screw clamps have begun to be produced.

Or there may be screw connections with a locking washer, which do not require maintenance, or spring clamps, which also go without control and revision for years.

In fact, these are just made-up benefits.

Approximate cost of induction heating for a private house

In rated power mode, the boiler operates only a small part of the time - when the outside temperature drops to extremely low values. In a building built in accordance with energy saving standards, the average performance of the heat generator for the entire cold season is 1/3 of the maximum.

Let the area of the house be 150 square meters. m. Then:

- rated power of the device at the rate of 1 kW per 10 sq. m – 15 kW;

- the average for the heating season is 5 kW.

If the duration of the cold period is 7 months (213 days), the total energy consumption is equal to:

Р=5*24*213=25560 kW*h.

The cost of 1 kWh in rural settlements, for example, the Samara region, as of the first half of 2021 is 3.02 rubles.

The costs for an induction boiler will be high.

Heating costs will be:

Z=25,560*3.02=77,190 rub. for 7 months or 11,027 rubles. for 1.

Of all types of heating, electric is the most expensive.

To reduce costs, proceed as follows:

- Switching to a 2-part tariff. For villages and hamlets of the Samara region. the price of 1 kWh at night in 2021 is 1.66 rubles.

- A heat accumulator is installed in the heating system. This is a large container encased in mineral wool.

The boiler operates only at night, heating the liquid in the storage tank to +95°C. During the day, the heating circuit, as needed, selects hot water from the tank through a mixing unit.

The costs in this case will be:

Z=25,560*1.66=42,430 rub. for 7 months or 6061 rub. for 1.

In this scheme, the boiler works at night simultaneously on the heating system and on the battery. Therefore, we need a model with 2 times the power - 30 kW.

Examples of homemade designs

You can make a homemade induction heating boiler in a slightly different way. In the modified design, the heater will be a steel pipe through which the coolant flows (as in factory-made models). A vertically installed sleeve made of a plastic pipe of sufficiently large diameter should be firmly fixed to the floor (glued or embedded in a screed).

Homemade induction heater

The pipe from the heating circuit is inserted into the sleeve through a side hole in the lower part, then a vertical section, which, at the exit from the sleeve, is connected to the entrance to the heating circuit. We wind the inductor wire around the sleeve. This version of a homemade boiler has less hydraulic resistance than the one described above.

Boilers are made with toroidal winding, which are the most efficient. To create such a model, you need to make a ring from a pipe (two semicircular sections can be connected by welding), which will play the role of a heater core. The wire is wound around a plastic housing. It is advisable to cover the latter with thermal insulation.

Negative sides of boilers

The disadvantages of induction heaters are:

- High price. The device costs 2-3 times more than its heating element counterpart.

- Large weight and dimensions. Household models generally weigh from 40 to 80 kg.

- High cost of energy resources. In Russia, the average cost of an electric kWh is 3.5 rubles, while that obtained from burning main gas is only 0.5 rubles.

- Difficulty connecting. According to the standards, only 5-7 kW is allocated for an apartment and a house; if there is an electric stove, it is 88-11. To increase the limit, you need to obtain permission from the Distribution Zone and replace the supply cable. There have been cases when, in order to connect a 15 kW boiler, people had to pay for the replacement of a transformer at a substation.