The replacement of ordinary wooden windows with plastic ones was carried out almost everywhere. Indeed, new window units do an excellent job of retaining heat inside the apartment and protecting from street noise, but, as in the case of the “previous generation,” problems occur with double-glazed windows, the solution of which sometimes requires partial or complete replacement of this element.

Thus, there is often a need to replace broken glass in a double-glazed window. To solve the problem, it is not necessary to completely change the glass unit in a plastic window - just remove the damaged element and install new glass. You can do this yourself or hire specialists from a company that installs window systems.

If the owners decide to hire a company, it should be borne in mind that in most cases replacing glass alone will cost approximately the same price as installing a new double-glazed window , and therefore glass should be replaced with the help of professional installers only in the following cases:

- if stained glass is to be replaced;

- if you need to change the glass in a multi-chamber (triple or more) package;

- when the inner glass is damaged, and the outer glass is a particularly durable and expensive triplex.

When is window system repair necessary?

The work can be carried out by specialized companies or in-house - all you need to do is follow the technological process so that the block in the frame lasts a long time.

Repair of the package without replacing the window structure is necessary in the following cases:

- Mechanical damage - despite the fact that a reliable sheet is inserted during the manufacture of the modular system, cracks may appear from a strong impact.

- Insulation of the apartment - single glass is being replaced with a double-glazed unit.

- Improving sound insulation will protect the room from extraneous sounds; install double or triple windows or change the size of the chambers.

Regardless of the reason why you need to change the glass unit in a plastic window, the services of engineers are cheaper than purchasing and ordering a different design. You can do the work yourself; detailed video instructions will help you with this.

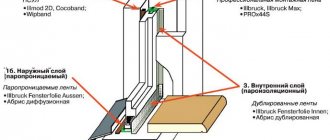

Types of linings and their purpose

There are several types of linings, different in purpose and location. The most commonly used are straightening plates paired with seam liners and spacer pads.

- Universal Rebate Insert Rebate Insert (Rebate Leveler) - Used to straighten the beveled profile rebate before installing the support pad. An additional function of the liner is to create holes to remove moisture and ensure air circulation between the frame and the glass unit.

Each system of PVC profiles uses its own rebate inserts, which are maximally compatible with these profiles. There are also more universal seam inserts that can be used with different profiles.

- Straightening plates Support pads (straightening plates; support-propping liner) - plastic plates installed on the rebated liner to distribute the load from the glass unit and create the necessary gap. The lining can be made with a transverse collar interacting with the edge of the seam liner. In this case, depending on the location in the sash, the task of both supporting and spacer lining is performed.

The thickness of the straightening plates varies from one to 6 mm, and each thickness has its own color: 1 mm - white, 2 mm - blue, 3 mm - red, 4 mm - yellow, 5 mm - green, 6 mm - black. By selecting the thickness of the support pads, the gaps between the glass unit and the profile are adjusted.

The length of the plates is from 8 to 10 cm, the width is equal to the thickness of the glass unit + 2 mm. The use of pads with a width less than the thickness of the glass unit is prohibited!

- A spacer

(propping liner) is a hybrid of a seam liner and a straightening plate with a lower load-bearing capacity. It is used exclusively to create the necessary gap (spacing) between the double-glazed window and the profile in places that do not experience special loads. It is rarely used, as it is successfully replaced by straightening plates, but in some cases, for example, when wedging anti-burglary glazing, only spacer pads are used. - Underlay bridge Underlay bridge

— a support lining used in double-glazed windows with a straight seam, that is, when a seam liner is not required. It is a straightening plate with channels for ventilation of the fold on the bottom side. In this case, depending on the location in the sash, the task of a supporting or spacer lining is performed.

- Auxiliary lining

- used exclusively during wedging of a double-glazed window. Upon completion of the work, the auxiliary lining is removed. If the support pad is not removed, there is a risk of glass damage.

Dismantling the structure or local replacement

The service life of Euro windows is 20-25 years. The owners are interested in whether it is possible to replace the glass unit in the structure without purchasing another “stained glass window”. If the profiles are washed and remain clean, the frames close and open, there is no need to install the window unit. You can simply install modern Euro windows.

Advantages of local replacement of glass in plastic windows:

- low price – 50% of the cost of a new design;

- no need to dismantle the old window system;

- no construction waste;

- there is no need to finish the slopes after work.

Disadvantages - whether it is possible to replace the double-glazed window with an updated filling depends on the condition of the frame and fittings; it is permissible to carry out local work if the euro-window is installed efficiently and there are no drafts.

How much does a double-glazed window replacement service cost on average in the market?

The cost of services for replacing or repairing double-glazed windows is quite high, but we must take into account the fact that it is not profitable for craftsmen to go out for “penny” repairs. On average, companies that install PVC windows charge from 2,500 to 4,500 rubles per sq.m.

This cost most often includes delivery. If you need to replace glass in a double-glazed unit, you need to be prepared for an amount of 1,500 to 2,500 rubles per sq.m. excluding the cost of material and delivery of glass to the customer.

How to restore a module

To install glass on a plastic window, it is not necessary to contact a specialized company. You can install double-glazed windows yourself.

To do this, you just need to follow a number of rules:

- select a tool;

- take product dimensions;

- order another stained glass window;

- dismantle the damaged product;

- install double glazed windows;

- make adjustments.

If there is a small defect associated with the lack of tightness of the module, there is no need to refuse repairs, otherwise you will have to replace the double-glazed window with a new design along with a metal-plastic profile, and this will cost more.

Basic insertion rules

To install the product without errors, you must follow the established rules :

- Select installation time. The warm season is the optimal time for this process. It is best to plan it in the summer - from May to September.

If a move or an unexpected breakdown still forces you to postpone the work to another time, then it is allowed to install double-glazed windows at an ambient temperature of no lower than -5°C and no more than 28°C.- Take measurements carefully. The tightness and efficiency of the new package depends on the quality of measurements.

- Attach the glazing beads strictly to the place from which they were removed.

If the size of the product is large, then it is necessary to work only with a partner to avoid possible damage. For those who are dealing with product installation for the first time, working together will be much more useful.

Devices for restoring a modular system

To replace a double-glazed window in a plastic window, you will need tools yourself. With their help, the frame with the canvas is removed and another one is installed.

You can repair a plastic window with your own hands if you have:

- knife;

- roulette;

- pin screwdriver;

- caliper;

- glass suction cups;

- rubber hammer;

- tape;

- material, wider in size than the product;

- cotton gloves.

Some devices can be replaced with others that perform similar functions. Depends on skill and availability of tools.

When measuring, one bead should remain in place and hold the module. An exception is determining the thickness of the metal profile.

Design and Basics

Due to the multi-faceted challenges, different requirements and large number of options, wedging technology must be planned.

The purpose of proper wedging is to divert the resulting load onto the pads and further onto the structure.

It should be taken into account that the glass edge and the insulating glass edge connection system must never be overloaded. This is the only way to avoid glass breaking and other damage.

Wedging serves a variety of purposes and should be evaluated primarily for the embedded condition. Different positions of the pads in the structure serve different functions, although these may change over time as the sash is used.

Operating principle

Diagonally, the weight of the structure is transferred first to the pads and then to the frame. Similarly, as on the panel door shown, the pressure diagonal serves to keep the leaf in its position and thus ensure its perfect functioning. The placement of the pads on the pivot window creates this diagonal of pressure. (see Figure 1c)

Functions

Pads perform multifaceted tasks that must be assessed primarily in the installed state. Their functions are different and they can be changed momentarily depending on the type of opening. Below you will find a description of these functions:

Important! Wedging is not intended to transfer other types of load, such as wind load, to the structure.

Tasks

Summarizing the above, we can highlight the following tasks that linings must perform in order to avoid damage to the glass edge or edge joint and to ensure the long-term serviceability of the window, door and façade:

Important! The frame structure must be installed sufficiently stable so that it can easily bear the weight of the glass. If the glass must carry or stabilize additional loads from the frame structure, the glass manufacturer should be consulted.

Taking measurements, purchasing a new product

On the spacer frame there is a marking with the thickness, width, height of the metal profile, and information about the component parts. If there is no information, you will have to take measurements yourself by measuring the removed module.

To take measurements without dismantling the frame, you need to take measurements between the metal profile of the sashes: from one outer edge of the bead to the other on both sides. Subtract 2 cm from the received data for adjustment.

Important parameters during repairs are the ratio of the gap and glass thickness between adjacent frames. If there is no information on the product, you will have to measure it yourself. To do this you need:

- use a tape measure to measure the thickness of the metal profile;

- measure the thickness of the external and internal fastening;

- Subtract the dimensions of the glazing bead from the thickness of the metal profile to obtain the thickness of the package.

Taking into account the number of chambers, calculate the distance between the glasses (in Euro-windows, the canvas is usually installed - 4 mm).

Checking the sash geometry

The easiest way to check the geometry of the sash is to measure its diagonals and compare them with each other, since the diagonals of a regular rectangle are always equal.

At the same time, for sashes it is allowed to increase the diagonal from the bottom hinge to 2 mm in relation to the other diagonal. If it is smaller, then the sash is probably not wedged, and there is a risk of its further sagging. It is wrong to measure the geometry of the sash relative to the frame, because the frame itself can also be skewed.

4-02-2021

Report an error (Ctrl+Enter)

Removing a damaged product

Removing broken glass is quite simple if you have the tools. To remove a plastic window with your own hands, you will need:

- Spread a clean cloth on the floor surface.

- Cover the damaged filling with tape to prevent splinters from scattering.

- Remove the glazing beads. You will need a knife, spatula, rubber hammer. It's better to start with the side fastenings.

All instructions on how to change a double-glazed window in a plastic metal profile say that it is better to first dismantle the outer beads. But in the transom it will not be possible to remove them without damage. First, the longer ones are removed - from below and from above.

Whether it's easy to change packages depends on skill. To dismantle the fasteners, you must:

- insert a screwdriver or chisel between the bead and the metal profile;

- holding the spatula horizontally, hit 2-3 times with a rubber hammer (a gap of 1-2 mm should appear);

- pull the nail to the side and towards you.

When removing the fasteners with a marker or pencil, apply grooves to the fold in order to correctly install the bag, especially if there is a different thickness. In this case, the components are changed and cut off.

Next, to remove a double-glazed window in a plastic window with your own hands, you need to:

- The latch on top should be removed last - it protects against falling. An assistant will be needed for insurance.

- The package is removed from the sash. If the sealant has stuck to the metal-plastic, use a spatula to press the canvas away from the block.

- Place the removed window panel on a cloth, carefully break it (or glue it with tape, take it outside).

- Throw away the broken triplex.

Some modular systems have nuances that should be taken into account before you change the glass unit in a plastic window yourself.

Instructions for replacing glass at home

To replace broken glass in a PVC or aluminum window frame package yourself, you will need to follow these steps:

- Remove the defective glass unit from the window frame. To do this, you must first remove the glazing beads by prying them up with a sharp and durable tool: a knife, a chisel, a screwdriver. Dismantling begins from the side surfaces, then the lower and upper beads are removed. At this moment, it is advisable to involve another person who can insure the technician against an accidental fall of a double-glazed window.

- Lay the material out on a flat surface and place the glass unit on it with the damaged glass facing up.

- Cut the sealant around the perimeter of the broken glass and detach it from the overall package. For a double glass, a cut is made in the middle; for bags with a large number of chambers, one glass is carefully separated without affecting the lower layers.

- Clean off any remaining sealant and wipe the surface of the entire glass using a special product.

- Cut the new material exactly to size - it is advisable to entrust this process to professionals.

- Apply a thin layer of sealant around the perimeter of the base and install the glass on it.

- The joint should also be filled with sealant to completely eliminate the occurrence of voids.

- Insert the finished double-glazed window into the base, performing fastening in the reverse order.

Installation of a new modular system

Whether it is possible to replace only part of the structure depends on its performance. If the fittings and components are in good condition, partial repairs are possible.

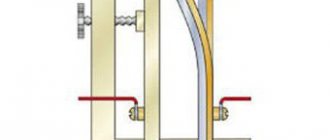

How to correctly insert a double-glazed window into a plastic window:

- Check the fastening of the sealing material from the outside.

- Install gaskets for the blind bag 2 from below into the fold (along the perimeter) of the sash, 4 pieces for the movable sash. Diagonally, one on each side, 10 cm from the corner.

The number of strips from manufacturers may vary. When removing the window package, you need to remember where the gaskets were.

Then, independent replacement of a double-glazed window in a plastic window is performed in the following order:

- The module is installed on gaskets. First check its position, otherwise the geometry will be broken and it will be impossible to correct it.

- The seal is installed from the inside.

- The beads are installed back: first from above, from below, then from the side. They are mounted into the grooves using a rubber hammer from the edge to the middle (until clicks are heard).

After replacing a damaged double-glazed window with a new product, you need to adjust the sashes. Use a furniture wrench to tighten the screws on the hinges.

Placement of pads

Linings must be located strictly in certain places. In fixed windows, the linings are arranged as follows - two supporting ones at the bottom of the glass unit, and spacers on the sides. In tear-off doors, linings are placed according to the principle of a panel door - the diagonal pressure serves to keep the door in its position.

It is recommended to install no more than two support pads on any side of the glass unit.

In this case, you need to maintain the correct distance from the corner of the sash to the lining. Usually they are placed at a distance equal to the length of the lining - 10 cm. In some cases, it is permissible to reduce the distance to the corner to 2 cm, but it must be remembered that reducing the distance to the corner increases the stress on the edge of the glass since too much of the glass unit remains unsupported. And if you move too far from the corner, the entire considerable weight of the glass unit will fall on the middle of the profile and cause its deformation.

For very wide windows, it may be necessary to increase the distance to the corner in order to position the pads in areas where the frame structure can be supported to support the load. A distance of up to 250 mm is allowed.

The arrangement of support and spacer pads is described in detail in GOST 30674-99 “Window blocks made of polyvinyl chloride profiles”.

When wedging doors made of PVC profiles, the principle of placing the linings remains the same. The only difference is that when using reinforced locks, it is recommended to install additional pads in the locking areas.

There is debate about the need to wedge sections whose filler is sandwich panels, even among experienced installers, since it is believed that it does not have sufficient rigidity. Nevertheless, even a thin-walled panel, clamped on all sides, is capable of maintaining its geometry under significant loads, just as a fiberboard sheet with a thickness of only 4 mm fixed to the back of a cabinet successfully preserves its geometry.

How to restore stained glass glazing

“Stained glass” has features that do not allow you to change a damaged package yourself. When repairing, you must consider:

- It is cheaper to remove and install a new Euro-window than to purchase another modular system. But engineers must do the work.

- The pieces of glass are placed in “cells” that are taken out not inwards, but outwards; this requires scaffolding and an aerial platform.

It is impossible to make a pattern according to the color scheme. You will need to bring a whole stained glass window to the master, where measurements are taken with special devices, with the help of which the glazing is restored.

Glazing beads

So, first of all, we remove the glazing beads (long ones first, then short ones). To do this, use a sharp chisel and a hammer to knock out the glazing bead from the groove of the window profile.

how to remove bead

For convenience, insert any plastic or wooden plate into the resulting gap

and draw from one corner of the window to the other. We remove the glazing beads and check the location of the seam inserts (usually black) on which the straightening plates are located (the color may vary).

You can replace a single-chamber unit with a 2- or 3-chamber package

When repairing a damaged Euro-window, you can replace the single-glazed unit with a two-chamber or three-chamber one.

Replacing single glazing with double glazing is possible if:

- The dimensions of the rebate allow installation of 2-chamber glazing. Here are several options:

- package of 3 canvases identical in width;

- the new design is larger, but a narrow bead can be used.

- The fittings and profile will withstand heavier glazing (the weight will increase by 30%). If you need to strengthen the reinforcing plates inside the metal profile, it is easier to change the module completely. The hinges can be replaced individually.

It is not recommended to change single glass in a plastic window without consulting a specialist.

Three-chamber glazing is installed instead of a 2-chamber structure in the same way. One difference is that the modular system with three chambers is 25% heavier than the double block; strengthening the frame is most often not required.

About the important thing: don’t miss out

In general, replacing a double-glazed window is not as scary as you initially think. The procedure will take a couple of hours (excluding drying of the sealant). The main thing is to wait for the glass unit to be manufactured. Here are some useful tips that will definitely come in handy when replacing:

- make replacements during daylight hours - if the panel breaks, the fragments will be in your field of vision;

It is better to replace glass in a plastic window during the day, then all inaccuracies will be visible immediately

- when replacing at the breaking stage, be sure to lay something under the structure, preferably fabric. Let it be an old sheet that you don’t mind throwing away later. Further use of the product for its intended purpose is undesirable.

- It is better to break glass when replacing it with a rubber hammer - it produces much less fragments. It is also convenient and quick for them to put glazing bead parts in place.

- Call an assistant to replace it if the glass itself is very large and it is extremely difficult to hold it alone.

- Try to touch the glass as little as possible with your bare hands - only touch the edge protected with tape and use special suction cups to hold the system.

- Before replacing, carefully inspect the “fresh” glass to see if it has any cracks, bulges, or holes. If there is even the slightest suspicion of imperfection, refuse the installation so as not to have to redo it again in a month.

- Your own safety should come first - do not work with the frame suspended, be sure to protect your face and body from small fragments.

- If one of the cameras on a two-chamber or three-chamber glass breaks, you will have to replace the entire glass, otherwise the structure will quickly break again.

Cost of seals for metal-plastic structures

Manufacturers offer different options to add functionality to Euro-windows.

The most common methods:

- Replacing a single triplex with glass with two chambers will improve the thermal insulation characteristics.

- Anti-resonance glazing improves noise insulation in the room.

- Energy-saving “stained glass” windows allow you to retain heat.

- Triplex – reliably protects against noise and cold.

This material is used for glazing private households, apartments, country cottages, gazebos and open verandas.

Straightening plates

If in a “blind” window the rebated liners are usually placed at the bottom and on the sides, then in the sash they are installed at two corners. In the bottom corner on the hinge side

and in the upper opposite.

The glass unit is leveled using plastic straightening plates

straightening plate

different colors. Moreover, a certain color corresponds to a certain thickness (white - 1mm, blue - 2mm, red - 3mm, and so on). The width of the plates is chosen equal to the thickness of the glass unit (most often 24, 32 or 40 mm).