During the repair process, for one reason or another, it may be necessary to expand the doorway. It is quite possible to do this, but it is important to follow some rules. The process itself is very labor-intensive, so it should only be performed if there is really a need for it and alternative methods cannot be used.

If the doorway is significantly widened, reinforcement installation is required

Prices: Diamond cutting (diamond blade)

| Thickness of structures (cm.) | Brick | Concrete | Monolith | Asphalt |

| Up to 12 | 400 | 700 | 900 | 300 |

| 13-15 | 600 | 900 | 1300 | 450 |

| 16-19 | 800 | 1200 | 1600 | 580 |

| 20-22 | 1200 | 1600 | 2000 | 800 |

| 23-25 | 1600 | 2000 | 2300 | – |

| 26-30 | 2000 | 2300 | 2800 | – |

| 31-35 | 2300 | 2800 | 3300 | – |

| 36-40 | 2800 | 3300 | 3800 | – |

| 41-50 | 3300 | 3800 | 4300 | – |

| 51-60 | 3800 | 4300 | 4800 | – |

| 61-70 | 4300 | 4800 | 5300 | – |

| 71-80 | 4800 | 5300 | 5800 | – |

When determining the distance of the future door opening, rely on the type of your house. If the walls are made of brick or reinforced concrete, then the cut standard is from 70 to 2000 mm in width and 2.1 m in height. If the room or office is located on the lower floors, then it is worthwhile to make the necessary strengthening of the doorway.

Before expanding the opening, you will need to remove everything unnecessary, including furniture, and also protect the ceiling and walls from dust and dirt with film.

Ways to change the size of the opening

There are not so many ways, but they will all ultimately lead you to the desired result:

- Moving to a new apartment is always associated with the fact that repair work and redevelopment are required, since people’s preferences and tastes are different, and so are their possibilities. If you are faced with the fact that the opening in the apartment is too wide, which is simply not needed, then it should be adjusted to the parameters that you need. If you encounter a large opening that is not needed, then use tongue-and-groove slabs. They are lightweight, making installation easier. In addition to this material, you will also need to buy a mortar that will be applied to the ends of the slabs. A perfect match is achieved due to the fact that the slabs have special tongues and grooves. After about 5 minutes, you can begin to increase the walls to the size you require. In addition, a new space made from such a slab will have a high level of rigidity, and the perpendicular walls will avoid additional load.

- If you only need to slightly correct the door space, then it will be enough to use wooden beams. This option is the most common for this type of work, since it does not take much time, does not require spending a lot of effort and money, and even a beginner can do such work. First, you will need to decide what the dimensions should be by which the opening will be reduced and cut the bars according to measurements. The support beam should be fixed at the top and bottom, and then connected to the leveling beam, which is located vertically. For excellent results, use a building level.

- If you wish, you can significantly reduce the door opening, and then use foam concrete blocks. Their main characteristics are lightness and manufacturability. Before performing the installation, you should first remove the floor covering, if any, and then fasten the ceiling as best as possible with the first layer of blocks. When performing such work, the solution should be laid out before installing the blocks. Vertical seams can be made staggered, so lay the new row not from a solid one, but from half a foam block, which will be cut in half. To ensure that the wall section is as strong as possible, during installation you should use the screws that will be required to bind the overall masonry together. Once everything is finished, you can install the new door.

- Also, to reduce the doorway, bricks are used, which are laid on a special mortar. It’s better to do it yourself, since there is no need to buy a large amount of material, and throwing money away is stupid. The main disadvantage of brick is its weight, so it is extremely rarely used, except when it is necessary to reduce the opening of an interior door not in width, but in height.

- One of the most popular options for such work is plasterboard, which has a huge number of advantages and compares favorably with other materials used for reduction. If you have gypsum board, you can make an opening of any size and shape, with rectangular, arched and simply complex shapes. If the wall overhang is minimal, then reinforcement is not required. If the area to be reduced is significant, then the use of a metal profile will be required, but there is a limitation, and it should not be neglected - gypsum board never reduces the opening for the door, but only the space between the interior of the house or apartment.

Now you can find out how to decide on the size and type of block.

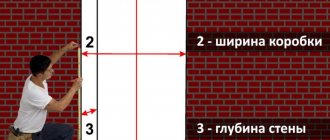

How to correctly measure a doorway?

We talked in detail about how to correctly measure a doorway yourself in the article How to measure the entrance doorway?

- Measure the width, height and depth of the doorway

- Measure each indicator at three points outside and inside the apartment

- Fix the smallest size

When taking measurements, be sure to take into account the curvature of the walls. The door must be level, otherwise the opening will need to be modified.

If the distortions are minor, the size of the door is selected taking into account the distortion so that the structure is level. To do this, you will need the help of a specially trained surveyor who is familiar with the nuances of different openings. Depending on the material and thickness of the walls, the characteristics of the opening, the specialist will select the necessary option for finalizing the opening and help calculate the correct size of the entrance door.

In what cases is a doorway reduced?

In a large room, specialists usually design a large and bulky interior door. But over time, it sags under the weight, and begins to open and close poorly. Also, a large door when open takes up a lot of space.

The doorway is also reduced for:

safety - when the opening is combined with the wall, the door opens only 80 degrees, and you can hit the handle while passing by;

correct design - when the opening is combined with the wall of the room, cut-off door frames are most often visible;

installing a purchased door - the size of the opening does not always allow you to install the model you like;

freeing up space near the walls during redevelopment;

A narrow opening and a compact door will save space for furniture

correction of errors in construction work;

Builders' work is not always flawless

changing the configuration of the opening - in cases where it is necessary to create an arch.

What is it for?

Expanding a doorway involves increasing its main dimensions by certain values. Such operations are not performed very often, since all dimensions are adjusted to the standard dimensions of the door leaves. But sometimes you need to widen the hole. There are several main reasons that lead to such actions:

- Redevelopment of the premises. This process involves changing the basic positions or dimensions of the main structural elements of the house. This is done quite rarely, since in most cases it requires coordination with various government organizations.

- Door installation. Many owners of apartments or private houses decorate their premises with beautiful wide door panels. This additionally provides several advantages, since, if necessary, it allows you to carry large items through the doors.

Preparation for work

Arch design

Having decided on which wall the doorway will be expanded, you need to find out about it:

- Is there hidden wiring inside the wall?

- Presence of fittings or pipes.

- Is there a chimney and where is it located?

To obtain this information, you must use a metal detector. If any obstacles are found in the wall, they can be removed:

- Move the electrical wiring to another location.

- Retreat at least 300 millimeters from the chimney.

- By dismantling pipes and moving them to another place - but this will require the help of a specialist.

Expansion of openings in load-bearing walls

Our company actively uses diamond cutting technology. This completely prevents the formation of dust. Also, by widening the opening in a panel house, you can get an even seam that will not have cracks or chips. Our services are especially often used in apartment buildings, since the absence of vibrations is an important parameter.

We would argue that widening a brick opening requires the utmost care. If you approach the matter without the proper approach, you can simply destroy the masonry. To prevent such problems, when carrying out work to expand openings, professionals strengthen the structure.

To strengthen the structure, a channel is usually used, and all the voids that form in it are subsequently filled with cement mortar.

Only after the solution has hardened does diamond cutting of the openings begin (here https://almaztehrez.ru/almaznaya-rezka-otverstij/ for more details).

Dismantling walls that are made of concrete also requires additional reinforcement. For strengthening, a U-shaped channel is usually used. Before starting work with a load-bearing wall, the master must see the appropriate permit

, since otherwise his activities would be illegal.

Why do you need to reduce the opening?

Changing dimensions may be required in a number of cases:

- during redevelopment, if during the renovation it was decided to install narrower doors;

- to increase the free area of the walls, if you need to place additional pieces of furniture, and the doorway is wide enough; More often, such a need arises in the living room or hall; for comparison, the entrance to the bathtub and toilet is initially characterized by a small width;

- correction of errors that were made during the construction of the facility;

- it is necessary to reduce the doorway in order to change its configuration, for example, if you need to make an arch from a rectangular structure.

Valid parameters

In a private house, solving the problem of rebuilding individual parts of the building is much easier. However, we must not forget about the established norms and restrictions. In an apartment, any such actions should be agreed upon in advance with the BTI. Violation of the standards when trying to expand the opening can lead to the wall not being able to withstand the load and the building becoming dangerous for people to stay in it.

To prevent this, it is important to know what restrictions exist for expanding the opening of an entrance or interior door. For most designs, the standard dimensions are 70-80 cm. Most often, a change in these values is due to the purchase of a door block of the wrong size.

The maximum permissible openings are 200 cm wide and 210 cm high. It is advisable not to build them in load-bearing structures. An exception may be the entrance door opening, but in this case it should be further strengthened.

Scheme of strengthening an opening in a load-bearing wall with a lintel made of channels

In general, it is not recommended to widen the passage by more than 100 cm, otherwise it is necessary to install additional supports on the sides and, possibly, in the center of the opening.

Height increase

In addition to expanding the doorway in the load-bearing wall, it may also be necessary to increase its height. In this case, you cannot do without moving the horizontal jumper. Without it, the entire load will fall on the fragile door structure, which can lead to the collapse of the wall.

How to safely increase the height of a doorway? To do this, you must first install supports in the passage. Then, using a grinder, vertical cuts are made to knock off the excess concrete. The old jumper is removed. Its edges can be left in the wall or replaced with a brick backing. The new crossbar is installed higher and covered with mortar. Further work can be done only after it has dried.

To safely increase the height of the opening, you need to install a jumper

It is not recommended to carry out such manipulations in a load-bearing wall. If such a need is unavoidable, follow the rules for performing dismantling work and in no case deviate from the established norms; violation of them is fraught with a fine and, in addition, is life-threatening.

Required Tools

Tools you will need:

- Roulette. With its help, you can measure all the parameters of the doorway with the necessary accuracy.

- If the opening is empty, it is necessary to have a building level to measure the verticality of the walls and determine the parallelism of the border of the top of the opening to the floor of the room.

- A simple ruler is needed to measure the length of small openings and the width of joints.

- You also need to prepare a notepad and pen for writing down data. Instead of a pen, you can use a pencil. It is not only the measurement results that need to be recorded. It is better to draw a diagram with dimensions, indicate completeness, as well as special conditions.

Options for reducing the opening

Narrowing the space allocated for the doorway may be required in different cases. Sometimes the reason for this is a minor redevelopment of the room. Also, in most cases, there is no point in leaving a wide opening, while taking up potentially useful space. If you decide to change the dimensions of the passage, you can do this in several ways:

- Smooth cut. In this case, no fundamental changes are expected. You just need to reduce the opening by the specified size. The perimeter remains smooth and rectangular in shape. In other words, the wall area is simply added.

- Arch. Since sometimes you have to reduce the doorway not only in width, but also in height, erecting an arch is a very good option, especially if you plan to leave the space empty. In this case, you can slightly narrow it at the top and create an oval arch.

- Complex design. Partial filling of the opening or its shaped design is expected. It is best to work in this case with drywall. You can put up a vertical partition instead of a wall and make shelves in the free space. This is relevant in the case of zoning a room such as a studio.

By reducing the size of the doorway, you can change its shape

The materials mainly used for work are:

Tools for work

To increase the doorway in modern construction, various tools and devices can be used. There are several ways to dismantle excess wall:

- Rough method. In this case, tools such as a sledgehammer, hammer drill, jackhammer and the like are used. In this case, it is necessary to first outline the contours and use tools to knock off the excess. Of course, the process is very labor-intensive, and there is another threat here - the formation of microcracks due to high impact loads. This may require additional finishing work and generally impairs the strength of the wall structure.

- Dry cutting . For this purpose, such a familiar tool as a grinder is used. With its help, you can easily cut out the desired shape of the contours. It also copes with reinforcement. The downside is that you have to cut on both sides, and it’s not always possible to match the cuts exactly. In addition, dry cutting leads to the formation of a large amount of dust and quickly wears out the diamond blade.

- Wet cutting. For this purpose, you can use a spray bottle and irrigate the work surface while working with an angle grinder, but a more rational method would be to use a special construction cutter. It is equipped with a large diamond blade and a water container. With its help, you can cut an opening of the required size in one step and at the same time with minimal contamination. True, the cost of such equipment is considerable.

Basic methods of dismantling part of a wall in an opening

When carrying out such work, be sure to use personal protective equipment: goggles and a respirator, they will protect you from dust and small fragments.

Effect of wall thickness

Wall thickness is the main indicator that helps determine the cutting method. If the depth of the slot is no more than 10 cm, you can use a grinder. If the concrete thickness is 8-10 cm, you need to work with a high-power machine. If the wall is 15-16 cm, you need to use a circular saw (discs with a diameter of 350-400 mm). You can use a grinder, but you will have to work in several stages and there is a risk of the tool overheating.

For concrete with a thickness of 30 cm or more, you need to use a special wall cutting tool, it can be of manual or machine type. Concrete up to 60 cm thick is cut with a tool such as a chain saw or ring cutter. Concrete over 60 cm thick is cut using machines using a 100 cm disc, or rope cutting devices.

How to determine the required door leaf size?

Now that you know the dimensions of your opening, you can move on to choosing the parameters of the door leaf. To do this, subtract 10-15 mm

, and then find the appropriate value in the table.

Standard sizes of Torex door leaves

Doors to the apartment | |

Delta | |

| height, mm: | 2030; 2050; 2070; 2100 |

| width, mm: | 860; 880; 950; 1000 |

Super Omega | |

| height, mm: | 1970; 2000; 2030; 2050; 2100, 2150*, 2200* |

| width, mm: | 860; 880; 950; 1000, 1030 |

Ultimatum | |

| height, mm: | 1970, 2000, 2030, 2050, 2070, 2100, 2150*, 2200*, 2300* |

| width, mm: | 860, 880, 900, 950, 1000 |

Professor | |

| height, mm: | 2000*; 2030; 2050; 2070; 2100; 2150*; 2200* |

| width, mm: | 880; 900; 950; 1000 |

Cyber | |

| height, mm: | 2050, 2100 |

| width, mm: | 860, 950 |

Doors to a private house | |

Snegir | |

| height, mm: | 2000; 2050; 2100; |

| width, mm: | 880; 950; 1000 |

Domani | |

| height, mm: | 2000; 2050; 2100 |

| width, mm: | 880; 950; 1000; 1100 |

*size increases due to extensions

If the specified dimensions do not suit you, you have a non-standard doorway. But don’t be afraid, you can always order the front door according to your dimensions or adjust the opening to the standard.

Covering the passage with plasterboard sheets

To reduce a doorway with plasterboard, the craftsman will need a tape measure, a metal profile, a hacksaw, a cutter, glue, a screwdriver, primer and plaster. The thickness of the profile wall must be at least 0.55 mm, and the width of the parts must be 100 mm.

The marking should continue: from all previously drawn lines on the floor, they retreat inward by the thickness of the plasterboard. A U-shaped profile is screwed to the base with self-tapping screws. The back side of the profile is glued with soundproofing tape. The same is done on the upper slope. After this, install one of the racks (without fastening), try on and cut out two strips of drywall.

The slopes, walls and cut pieces of plasterboard are primed and dried. Then the strips and the bare part of the wall are covered with a layer of mounting adhesive (for example, Knauf Perlfix) or gypsum plaster. The drywall is pressed tightly against the surface of the wall and against the stud, and excess glue is usually squeezed out along the entire height. The inner corner between the strip and the slope is carefully sealed with plaster. After checking the plane using the rule, fix the rack and U-shaped profiles. The sheet and the stand are fastened with self-tapping screws.

Do the same with the second plasterboard strip. To make installation more convenient, it is first glued, then the edge of the guide is bent and the stand is inserted, after which the edge is bent again. If the wall is thicker than 10 cm, jumpers are placed every 5 cm between the racks. After this, the side of the slope is covered with plasterboard. At the end the walls are plastered and puttied. This method of closing the opening allows you to safely install interior doors if the extension width does not exceed 200 mm.

It is not at all difficult to reduce the height of the doorway: as reviews indicate, plasterboard is the optimal material for this. From the ceiling to the marked level of the slope, 2 (two) vertical profiles are attached on each side. Then they install 2 guides to the ceiling and between the side slopes. Vertical gypsum board strips are mounted on both sides, connecting them to the profiles, and a horizontal sheet is inserted into the lower guides parallel to the threshold. Screws are used for fastening.

Panel house

Most often there is a need to expand the doorway in a panel house. In high-rise buildings, this issue is quite problematic, since in addition to a large amount of construction waste, there is also a negative reaction from neighbors to such noisy repair work. That is why it is necessary to reduce the time of dismantling the structure as much as possible. The best option, affordable, is a grinder.

First you need to completely remove the old door frame from the opening. The supporting wooden beams are also dismantled. Next, you need to make the appropriate measurements and outline the contours of the desired passage dimensions.

If an opening is being expanded in a load-bearing wall, especially one adjacent to the front door, an important aspect is the temporary strengthening of the structure. It is best to initially cut out only the top part and move the jumper. Despite the increase in width, it should go deeper into the wall by at least 15-20 cm on each side.

When expanding an opening in a panel house, an important aspect is temporary strengthening of the structure

Cutting is carried out along the intended contour, first on one side of the room, and then on the other. The most problematic areas are the exit of the reinforcement. After the metal bars are cut, you can take a sledgehammer and remove excess concrete. If the opening area is large, you need to work in squares. To do this, the wall is divided into sections and additional lines are cut. Dismantling is done from top to bottom so that the upper tiers do not fall on you during the work process.

Is changing the dimensions and location of the passage considered redevelopment?

To expand or narrow a doorway in a panel house, you will have to change the length of the adjacent wall. In the technical passport for the apartment, the door is shown schematically. Dimensions are usually not indicated, but the BTI has all the data. When expanding or narrowing the passage in the wall, the layout of the room, originally provided for in the project, is violated. Over time, if you want to sell the apartment, great difficulties will arise with the preparation of documentation.

By law, changing the size or location of the opening for a door block is considered redevelopment. It is advisable to legitimize the corresponding actions. To obtain permission to expand or narrow an interior doorway in a panel house, you need to contact the BTI.

How to increase?

So, now you know exactly how to increase the size of a doorway. But what to do if you need to reduce them? This situation may arise if you cut off the excess when expanding the space. Or you simply needed an extension to install a smaller door.

The specific method required to implement such work depends entirely on the material from which the wall is made. When building up a brick opening, bricks, cement mortar, a spatula and other auxiliary tools are used. Take accurate measurements and start laying. Please note that to increase the height of the opening, it is important to make a lintel from a wooden block and reinforcement.

If you neglect this rule, the structure may simply collapse.

When you need to reduce the opening for an interior door, you will need regular drywall. After taking all measurements, apply a special adhesive composition to the side and top of the opening. Then glue the pre-cut drywall pieces. This method is the most optimal when remodeling an apartment. It won't require a lot of time or money. To build up an opening in a wooden house, you should use timber.

And to change the size of the opening in a concrete wall, it is optimal to use cement mortar.

Extension order

Interior enlarged passage

Increasing the door passage in walls made of any material involves performing sequential actions:

- Marking the required dimensions of the structure.

Marking

- Dismantling the desired area.

Dismantling works

- Strengthening the opening to ensure its strength and prevent collapse or deformation.

Strengthening the opening

Impact tools, sawing tools, or hole-drilling equipment can be used to dismantle the structure.

Depending on the material from which the wall is built, these may be:

- Hammer.

- Jackhammer.

- Special circular saw with diamond wheel.

- Bulgarian.

- Electric drill with diamond drill.

- Hand tools: chisel, hammer, sledgehammer.

Advice: More attention should be paid to working with high-strength concrete walls. It requires very precise work that avoids vibration and damage to surrounding structures.

For work you will need the following materials:

- Wooden beam.

- A corner with dimensions of at least 35x35x4 mm.

- Components for making concrete mortar.

- Boards.

- Hardware.

To better imagine the process of increasing the door opening, you should watch the video in this article.

Expanding the passage in a brick wall

Opening in a brick wall

The work is performed in the following sequence:

- Mark along the contour.

Sequence of work in a brick wall

- If necessary, the jumper is moved.

- The upper masonry is reinforced with a metal channel.

- Using a grinder, a part of the wall is cut out according to the marks.

Cutting a brick wall

- To clear the perimeter, use a chisel with hammer blows, a drill or a hammer drill.

- It is better to remove excess elements from the wall by hand, after first removing the mortar from the seams (see How to make a doorway in a brick wall - several simple methods and one complex one).

- A welded structure is installed around the perimeter.

Reinforcing the opening

Advice: After completing the work, you should check the integrity of the brick wall. If splits or cracks are found in the seams, they need to be plastered.

Step-by-step action plan

First option

Let's consider the most common option - expanding the doorway in a brick wall. Before starting work, a reinforcing metal bridge must be installed above the opening.

We knock off a layer of plaster from the surface in the places where the expansion is designed and above the opening so that the lintel and the masonry above it are visible - 30 cm is enough.

We mark the future opening with chalk, stylus, or other material that leaves a noticeable mark. The width of the opening cannot exceed 2 meters because the redistribution of loads can become dangerous, or, if this occurs, then they install an additional support - a column.

If the lintel (purlin) turns out to be shorter than the width of the opening, it should be supported with racks while the work is being carried out to avoid accidental collapse.

It will absorb part of the load from the overlying structures, and you can work calmly. Its edges must extend beyond the boundaries of the future opening at a distance of at least 250 mm on each side.

Let us now consider the most popular option, when the frame is made of two paired channels No. 14-20, which are tightened together with through pins with washers and nuts.

Before installing a new lintel over the opening in the wall, seats are made - niches on both sides, immediately above the existing lintel.

The depth of the niche for installing the channel should be approximately equal to the size of the channel shelf, so that it does not protrude beyond the plane of the masonry and is subsequently hidden under a layer of plaster.

For reasons of strength, the number of studs should be at least three - with a diameter of 16 mm or more, the distance between the studs should not be more than 400 mm.

When tightening the channels for a uniform fit to the surface of the niche, an M-100 solution is placed under the walls of the channel, which fills the unevenness on the inner surface of the niche.

Holes with a diameter slightly larger than the diameter of the studs are drilled in the walls of the channels. The holes on both channels must be coaxial. The channel is installed in a niche and through holes are marked in the wall, which are then drilled. After this, the jumpers are installed.

Now you can begin dismantling the masonry to widen the doorway along the markings to the foundation or floor slab.

The expansion of an opening in a brick wall is associated with obtaining smooth vertical edges of the opening being broken, which is achieved by sawing out fragments of masonry with a grinder saw with a diamond blade.

Oh, and this is a thankless task - dust is everywhere, wetting with water will not help either. You have to work in a respirator. The cutting is done, it is convenient to disassemble the masonry using a hammer drill.

If the length of the lintel is less than the width of the opening and it seems to “hang” over it, then it must be dismantled.

The next step is to install the side posts that frame the opening and rest their upper end against a metal beam—the lintel. They are made from a corner of 75-100mm. The connection with the beam is fixed by welding in the corners at the junction of the stiffeners.

The racks must be rigidly fixed in the opening, for which they are connected to each other along the thickness of the wall with strip steel, to which pointed pins made of reinforcement with a diameter of 12 mm are welded into the wall.

At the bottom of the opening, a spacer is made from a 45-50mm corner or reinforcement with a diameter of 20-25mm, which is then hidden in the thickness of the floor. All metal elements are welded together, forming a strong metal frame - the so-called “clip”.

It is also possible to expand the doorway in a brick wall with reinforcement of the lintel from two corners No. 100-150. The corners are connected to each other by tightening strips and strips. Then everything is done in the same way as described above.

We strengthen the widened opening with a corner

3 secret ways to narrow a doorway

One of the problems that owners have to face when moving into a new apartment is doorways that are too wide or, on the contrary, too narrow. In this situation, there is only one way out - to narrow or increase such passages. To do this, you need to carefully study how to reduce the doorway, and stock up on the necessary tools to perform such an operation.

By the way, a correctly executed reduction in the doorway can significantly change the appearance of the apartment. That is why such work must be approached responsibly: without haste and fuss.

Narrowing a doorway can be done in several ways:

- brickwork or foam blocks,

- plasterboard construction,

- using a wooden beam.

No one will deny that moving a doorway, reducing this passage or expanding it is painstaking work. The success of such an operation largely depends on how correctly the measurements and markings are carried out.

When marking, experts recommend using the rule of the appropriate size: using a construction pencil or marker, make marks on both sides of the doorway.

These marks must be located strictly in one vertical plane (floor and top frame).

Installation of wooden beams

The width of the wooden beam used to narrow the door passage must correspond to the thickness of the walls framing the opening. If the beam is wider than the wall, all excess should be removed using a plane, and then the board should be sanded: thanks to this, the cladding will be smooth and beautiful, without burrs and other defects.

Then you should carefully measure the opening again and transfer these measurements to the prepared board. Afterwards, the timber is adjusted to size and fixed in the doorway using special nails or self-tapping screws (the heads of the fastening elements must be level with the surface of the wood). For greater reliability, the timber should be fastened in several places.

Next, using a special putty, the seams between the wall and the wooden structure are sealed. Afterwards, the timber is coated with a primer designed for treating wooden surfaces. Then the structure must be covered with chipboard panels or plasterboard.

This method of narrowing the doorway has its advantages and disadvantages. The main advantage is that filling the opening does not require much effort from the home craftsman: the wooden lintel is installed very simply.

And besides, as you know, wood is an environmentally friendly and warm material. The disadvantage is that during operation the wooden lintel can become deformed, thereby losing its aesthetic appeal.

Brickwork

Foam blocks or bricks are usually used to narrow openings in panel houses and buildings with thick walls. Cement mortar is used for masonry. It is prepared from sand (3/4 part), cement (1/4 part) and water (just enough water is taken so that the mixture turns into a thick mass).

Laying bricks and foam blocks should be carried out exclusively on a flat surface, so you need to measure the floor with a building level and, if necessary, level it. And in order for the lintel and the wall to be securely fastened to each other, reinforcement is used: this strengthens the doorway, thanks to which a heavy structure can be installed here in the future.

To lay brick you will need a spatula, a trowel, a building level and a rubber hammer. The cement mortar is placed on the stone using a trowel, and then the brick is lightly tapped with a hammer (thanks to this, the cement mixture is evenly distributed and the brick lies tightly).

To prevent seams from laying bricks from appearing, the brick filling of the opening and the frame is plastered and treated with putty. The same procedure will allow you to align the wall with the new “extension”, that is, hide the visual border. After the finishing layer has dried, begin installing the door frame.

It is worth paying attention to the following point: if someday a home craftsman decides to widen such a passage, the only way out in this situation will be to cut the doorway.

Plasterboard construction

The easiest and most economical way to narrow a doorway is to erect a plasterboard structure. On the side of the doorway where the wall is planned to be built up, the remnants of the plastered surface are removed. Then the prepared wall is treated with a primer.

Before you begin to build a plasterboard structure, you should measure the doorway and make markings. To do this, take an aluminum rule and place it along the opening, after which, using a construction pencil or marker, draw a line - the future continuation of the wall.

The same operation is performed on the second side of the passage, after which a line perpendicular to these two lines is drawn at the appropriate distance (this is the edge of the future guide).

Next, using the markings made, they calculate the exact dimensions of the plasterboard elements that will be needed to level the wall and build it up. These dimensions are then laid out on the plasterboard sheet and guides.

Next, the floor and the upper frame are connected to the guides. A thick layer of special glue is applied to the wall (the pigtail is also covered with this adhesive) and a pre-prepared plasterboard element is glued.

Then carefully bend the guides and insert the supporting profiles into the places provided for them. The plasterboard sheet is attached to the guides using self-tapping screws. Filling the resulting cracks is carried out using putty or a special solution (the same finishing mixture allows you to even out all the roughness and eliminate flaws).

All that remains is to prime the surface and cover it with finishing panels of your choice or cover it with wallpaper. By the way, sheathing a structure is not so difficult: the main thing here is to take into account the features of the material used and strictly follow the recommendations from professionals.

Knowing how to lay out a doorway, enlarge it or narrow it, you can create real miracles: a little imagination, and your room will change beyond recognition.

Rate this article: ( 4 votes, average score: 4.00 out of 5)

Standards and approvals

Regardless of the purpose of the building, it has an opening for a door to enter the building and for communication with neighboring rooms.

There are several reasons why you need to increase the size:

- Many people want to visually expand the space, make it light and spacious, without changing the dimensions of the living space, as in the photo.

- The opening cannot accommodate the purchased modern fashionable door design.

- Making doors to order.

Advice: Before enlarging the opening in a panel house, you should keep in mind that this is painstaking and not entirely simple work with existing risks, in compliance with standards and tolerance norms.

There are no particular problems in enlarging the door opening in any wall.

But in a load-bearing wall they are quite large:

- In the absence of a building plan, it is impossible to determine the purpose of the wall, whether it will be load-bearing, which will require additional reinforcement of the structure, or whether it is enough to just reinforce the ceiling with beams.

- It is necessary to have agreement with the BTI. This will confirm the fact that the load on the wall with an increase in the width of the door will not exceed the impact norm.

- You must obtain the appropriate permit to carry out work.

When remodeling an apartment, it is necessary to take into account the parameters of the standards specified in SNiP.

The following dimensions are provided for door blocks:

- The width of the structure is from 55 to 80, which depends on the purpose of the opening.

- Doors for plumbing units, transitions to the kitchen - 55 centimeters.

- For living rooms, bedrooms and entrances - at least 80 centimeters.

- Height can vary from 190 to 210 centimeters.

- Thickness - 75 millimeters.

- Manufacturers offer ready-made blocks with frame widths ranging from 15 to 70 mm.

Advice: When determining the dimensions, you should adhere to the requirements of SNiP and familiarize yourself with the existing restrictions on its expansion.

How much you can expand is suggested by the instructions, which combine the following rules:

- The maximum permissible dimensions of the partition for a load-bearing wall can be: width - 2 meters, height - 2.1 meters.

- When increasing in size, the spans between adjacent rooms must be additionally strengthened at the ends with supports.

- Extended passages in the main walls to their maximum size or more are recommended to be reinforced with supports in the center.

Important documents when expanding the passage between rooms in an apartment are:

- Plan of work stages.

- Architectural plan.

- Floor plan of the building.

- Extract from the house register, if available.

- Certificates from the BTI regarding permission to carry out redevelopment.

Prices for specialist services

The cost of the service for widening openings in concrete walls consists of a number of factors. It depends on the complexity of the work and its scale. The location matters, as well as the qualifications of the builders.

Approximate prices for different cities of the Russian Federation:

In Moscow and the Moscow region, the cost of work starts from 800 rubles per meter. Additionally, you will have to pay for strengthening the openings.- In St. Petersburg, prices vary widely. The minimum bet is 420 rubles.

- In Kazan, craftsmen offer to do this work for 500 rubles.

- In Yekaterinburg, prices are lower, they start from 350 rubles per meter.

When choosing a specialist, you need to read the reviews that clients have left about him.

Design Features

The technology for expanding walls is quite complex and cannot always be done manually. Very often, auxiliary tools are used for this. Depending on the destruction technology, such operations can be divided into several types:

- Manual. Changing the dimensions of an opening in a partition or load-bearing wall is carried out using human physical effort. For this, several types of chisels, crowbar, hammers, etc. are used. One of the advantages of this method is that it is performed practically without dust, but at the same time it takes a relatively long time.

- Mechanical. This approach involves the use of power tools, which greatly simplifies the destruction of materials. Such operations are performed using rotary hammers, impact drills and grinders of varying power and size. With their help, you can quickly increase the width in both brick and concrete walls.

The technology for expanding the doorway also depends on the wall material:

Door and window openings

In the partition

Marking the opening in the wall

- In principle, from a technical point of view, there is not much difference in such actions as expanding or creating a new seat, since moving a doorway in a brick wall means, first of all, inserting and securing a lintel at the top . This function is the most important for both partitions and load-bearing walls, and dismantling is much easier. But, first of all, you need to outline the location of the opening or its expansion.

Channel as a crossbar (lintel)

- As a rule, in such openings on partitions, a thick beam is installed as a crossbar, and if you need to expand it, then all the same, just like when creating a new opening, you need a new lintel . Therefore, first of all, mark the place for such a beam and cut it out with a grinder (building bricks cut well with a diamond-coated disk). Then insert the crossbar there and fix it tightly so that its ends have absolutely no play.

- The ends of the lintel must extend beyond the edges of the opening by at least 10 cm in each direction . You can use a wooden beam or a metal profile as a beam, and the rigidity of the fixation of the ends of the crossbar will be responsible for the reliability of the fastening. Fill possible gaps with stones, broken bricks and throw in cement-sand mortar to create a monolith - this instruction is the same for partitions and load-bearing walls.

A brick wall is cut with a grinder

- To make the opening neat, the vertical lines also need to be cut with a grinder, as shown in the photo above . Of course, a disc with a diameter of 250 mm is best suited for this, but not every home has such a powerful angle grinder - the most common is an angle grinder with a 180 mm disc, but you can also use this one.

- Standard or double sand-lime brick M 150 has a bed width of 120 mm, therefore, if the partition is made of half a stone, then even a large disk will not cut through it . But if the masonry is made with a solid single brick in a quarter stone, then a 230 or 250 mm disc will go right through it, and a 180 mm disc will go through a little more than half. For dismantling, this option is not a problem - the brick will still break and the contour will be relatively smooth.

- When the crossbar is inserted and firmly fixed, you can begin dismantling the masonry and you need to start with one brick, clearing the seams around it as much as possible . Then you simply break this brick with your own hands using a hammer and chisel or hammer drill. You can also, to facilitate dismantling, drill 5-10 holes through the brick (this is easy to do with a hammer drill) and after that the stone will split much better.

Advice. When cutting bricks with a diamond-coated disc, a lot of dust arises, which settles for a long time afterward. To reduce its amount, generously wet the cutting area with water, and place the grinder on vertical lines so that it throws dust onto the floor and not into the ceiling.

In a load-bearing wall

Core cutter for concrete 100 mm

- If you don’t know what kind of masonry is on the load-bearing wall and the opening needs to be made initially (not widened), then go through the wall with a crown cutter for concrete and the diameter, while trying to take the crown as large as possible so that your hand can fit through it, or you can even illuminate it with a flashlight . This way you can find out the number of bricks that you have to go through, because the masonry can be well, two and a half bricks, then insulation, and then another half brick. You understand that the visible front of work is much easier than the incomprehensible, that is, invisible.

Homemade reinforcing frame in a load-bearing wall

- The beginning of dismantling is the same as on the partition - you draw out the opening, cut out a place for the crossbar and firmly fix it . Then you select an opening on one side of the wall and make metal supports for the crossbar, as can be seen in the photo above. At the same time, do not forget that the price of negligence or neglect of safety rules in this case is human health or even life - an unsupported ceiling may fall.

- The brickwork of the doorway is dismantled on both sides of the wall so that the supports are on both sides and the structure does not weaken . After the opening is ready, the metal supports are connected to each other with metal strips for rigidity.

Advice. In order for the opening to coincide on both sides of the load-bearing wall, you need to drill through it at the cut points (in the corners and several holes along the lines). The hammer drill must be strictly perpendicular to the wall.

- Well, if you are interested in how to properly brick a doorway, then on both sides, after 2-5 rows, drill pieces of reinforcement into the end of the wall to create a bandage . After such an operation, the masonry will be complete and after plastering or puttying no one will know that there was an opening there before. (see also External and internal decorative brick plaster)