Cement-bonded particle boards are widely used in the design of private houses and apartments. They are especially in demand if you urgently need to level the surface and reduce the time for repairs. The material is environmentally friendly, has an affordable price, and the floor made of fiberboard over wooden joists is reliable. The main thing is to study the installation rules, have time and patience.

Using DSP

Advantages of expanded polystyrene concrete

In the production of polystyrene concrete, various additional components can be used, but it is the combination of concrete and polystyrene granules that gives the material valuable qualities for construction - strength, resistance to rotting, fire safety. Advantages of expanded polystyrene concrete:

- good heat and sound insulation properties;

- belongs to the group of low-flammable materials G1;

- plasticity sufficient for the manufacture of window and door lintels;

- high structural strength;

- light weight and ease of handling;

- frost resistance;

- wide scope of application.

An important advantage is the ability to independently prepare polystyrene concrete, for example, for insulating floors and roofs.

Methods of using cement mortar and foam chips

Polystyrene concrete is used for construction purposes in the construction of enclosing structures, load-bearing walls, partitions, and as insulation for floors, walls, and roofs. Building blocks are made from it.

The wide possibilities for using expanded polystyrene concrete are due to its price and the construction potential of the material. It is easy to transport, polystyrene blocks are easy to lay. Thermal insulation from a solution of cement and foam granules does not require the additional use of sheets of foam plastic, penoplex or mineral wool.

Instructions for preparing concrete with foam chips

To make polystyrene concrete with your own hands, you will need polystyrene granules, sand, plasticizer, cement and an air-entraining additive. To mix the solution, use a concrete mixer. Doing this manually is difficult.

Preparatory work

- The floor surface must be cleaned of dust and checked for differences in height (level), chips, protrusions, and depressions. Eliminate all irregularities: chop off the protrusions, fill the depressions and cracks with cement mixture.

- To prevent the finished screed from cracking, the perimeter of the room must be covered with damper tape.

- Then install beacons - linear ones are better, they make it easier to level the laid mortar.

Now you can proceed to preparing the mixture for the screed.

Preparing the mixture

To make the process easier, you can buy ready-made foam chips. Its advantages are the integrity of the granules and uniform size. In our online store it is sold in convenient packaging - 0.3 m3 per bag.

In order to save money, some craftsmen shred the foam scraps that remained after construction. This option is acceptable, but the strength of the finished solution will be worse. Firstly, crushed crumbs come in different sizes; secondly, the broken integrity of the granule increases the ability of the material to absorb moisture.

Saponified wood resin is well suited as an air-entraining additive; it entrains 20% more air into the cement mixture than its analogues. This means that this mixture greatly increases the heat-shielding properties of expanded polystyrene concrete.

There is no need to skimp on cement. Polystyrene foam granules slightly reduce the strength of the solution, so to obtain a reliable screed it is better to choose the M500 brand.

Proportions and mixing

To prepare polystyrene concrete for screed, you need to follow the following proportions:

- 4-5 buckets of granules (fraction 3-5 mm);

- 2 buckets of sand;

- 1 bucket of cement;

- 0.5-1 bucket of water;

- air-entraining additive (SDO - 32-33 ml);

- plasticizer - in the quantity specified by the manufacturer.

Step 1. Polystyrene and plasticizer. In order for the foam granules to adhere well to the cement and not float to the top, they must be poured into the concrete mixer first. Then add about a third of the plasticizer diluted in water and wait until all the granules are wet.

Step 2. Cement and plasticizer. You need to pour all the cement into the rotating drum of the concrete mixer, and then pour out almost all the remaining water with the plasticizer diluted in it.

Installation of PVC windows- Covering the drain hole with your own hands

- How to lay flexible tiles on the roof?

Step 3. Saponified wood resin. Dilute the SDO in the remaining water, add to the drum and mix for another 3 minutes.

If you observed the proportions of expanded polystyrene concrete when mixing, then you have a high-quality solution ready for pouring.

Pouring the mixture

Filling the floor with polystyrene concrete with your own hands requires the following steps:

- Moisten the prepared surface with water to improve adhesion. If the surface is moisture-repellent, then for better adhesion you can install a metal mesh.

- Pour the solution onto the base above the level of the beacons and immediately level it with the rule. The minimum thickness of polystyrene concrete screed is 50 mm. If you want to increase sound insulation in an apartment, then make a layer of 80-90 mm.

- After a day, you need to pull out the beacons from the floor and fill the resulting cavities with polystyrene concrete. This is necessary so that when the floor subsides, the beacons do not stick out and spoil the flooring.

- Cover the polystyrene concrete screed with polyethylene and leave to dry for 3 days.

- Remove the film and leave the floor uncovered until completely dry.

The floor is ready for further covering with parquet, laminate, tiles.

Kneading process

Due to the characteristics of polystyrene granules, the procedure must follow the sequence of laying the components. So, they begin work by adding cement and water in a ratio of 1:2 to obtain a liquid solution. Then a plasticizer is added (fumed wood resin such as SDO or detergent). Approximately 20 ml is poured into each bucket of water. Sometimes the finished mixture is immediately poured into the primary solution. This approach allows you to mix it evenly.

Next steps:

- Pour in polystyrene granules (measure the volume in advance).

- Stir until their surface is evenly wetted.

- Pour in the remaining cement, pour in the remaining water.

- Mix the solution until completely ready.

If the recipe requires the addition of sand, a means of accelerating setting, they are added simultaneously with the second batch of cement. The higher the grade of polystyrene concrete, the longer the mixing process will take (due to the hardness and thickness of the mixture). When mixing “manually” with a mixer, it is important to achieve uniformity of the mass throughout the entire volume of the container.

When using a mobile station, it is enough to follow the boot sequence. After the cycle is completed, the polystyrene concrete will be ready to be pumped to the screed site. Immediately after the tank is empty, it is ready to load the next batch of material. If you buy a ready-made mixture, it’s easy to put the production on stream (as long as there are enough workers).

Other methods

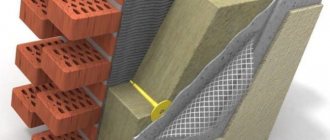

There are alternative ways to arrange a screed with insulation - using sheet heat insulation. Such a screed is called a floating screed due to the impossibility of making the structure rigid between the main surface and the floor covering.

Screed using foam sheets

The screed pie includes several layers that are laid on a pre-leveled base. The bottom one is a waterproofing material necessary to prevent moisture from collecting at the base. Then the foam is laid. Above the heat-insulating layer is a reinforcing frame, and on top is a cement mortar.

Floor screed with polystyrene foam insulation

Expanded polystyrene is a type of foam, but more dense and consisting of closed cells. They provide absolute moisture resistance. The improved characteristics of expanded polystyrene influenced the cost of the material, but not how to make a screed with it. The work process looks similar to that described above.

Most people can make a screed from polystyrene concrete. Lightweight but durable eco-friendly material increases sound insulation, retains heat in the house and lasts for many years.

How to properly lay a vapor barrier on the ceiling?- Is it possible to glue wallpaper on whitewashed walls?

- Imitation of a brick wall made of gypsum plaster

Features of manufacturing DSP

The production of such plates is carried out in a certain sequence:

- A solution consisting of water, to which salts have been added, and components such as aluminum and liquid glass is poured into a container intended for mixing.

- Chips are poured there for mineralization.

- Then add water and cement and mix thoroughly.

- The finished composition is sent under a press, after which the material takes the form of cast slabs with a smooth surface. You can see how they look in the photo.

Materials for light floor screed

If it is necessary to pour a thick layer or low load-bearing capacity of the floor, a light floor screed made of concrete with low-density fillers is used. These include: expanded clay, perlite, vermiculite and polystyrene; dry screed is included in a separate category. In addition to reducing the load per 1 m² of the supporting structure, sound insulation is increased and heat loss is reduced.

Types of screeds

There are 2 types of polystyrene concrete screeds, incl. thermal insulation and structural. In the first case, a solution is prepared that has a lower density but a higher thermal conductivity coefficient. This composition allows you to create a screed that will retain heat well. However, this variety can withstand less load and is characterized by low resistance to mechanical damage.

The second option involves preparing a dense solution, the weight of which will be 600 kg per 1 m³. This screed is more durable and abrasion resistant, but it will retain heat worse.

Fillers for lightweight concrete

Despite the fact that lightweight cement screed can dramatically reduce the structural loads on the load-bearing elements of the building, labor costs increase. Unlike heavy fillers of ready-mixed concrete - crushed stone, gravel, foam materials do not sink in water, they float after laying the mixture, giving the surface an uneven, rough appearance.

It is necessary to additionally level the screeds with self-leveling floor, putty or sanding. For the convenience of individual developers, manufacturers produce ready-made mixtures with the specified fillers for lightweight screeds.

Dry screeds do not have these problems, since technically they consist of expanded clay sand and a gypsum fiber sheet laid on it in two layers.

Expanded clay

By analogy with expanded clay blocks, a lightweight concrete screed with this filler dramatically reduces the weight of load-bearing structures. However, in comparison with other materials discussed in this manual, expanded clay has a fairly high density of 850 – 1600 kg/m³, depending on the granule fraction.

According to GOST 25820, lightweight concrete is divided according to its performance properties:

- thermal insulation - thermal conductivity after drying is 0.14 units, density D500, strength 0.3 MPa maximum, which is not enough for floor screed;

- thermal structural - with a similar density of the product, the strength increases to 1 MPa, which makes it possible to make light screeds from them;

- structural – density from D2000, compressive strength from 12.5 MPa, suitable for any load-bearing structures.

Making screeds from expanded clay concrete.

- How to strengthen floor beams in a wooden house?

Sand and stone foundation

Strengthening floor slabs with metal beams

Since structural expanded clay concrete weighs almost the same as ready-mixed concrete, the developer does not receive any benefits for reducing floor loads. Therefore, structural and thermal insulation modifications are used. By deliberately reducing the strength, the loads per m² of the floor slab can be lightened.

Important! The filler inevitably floats to the top when laying the screed, so the surface has to be leveled additionally.

Proportions of expanded clay concrete for screed.

Thus, it is necessary to reduce the expanded clay fraction to a maximum of 5 mm and use sand or small granules.

Polystyrene

After expanded clay concrete, lightweight concrete screed filled with polystyrene foam granules is the most popular among developers. Polystyrene concrete is regulated by GOST R 51263 in terms of density from D150 to D600. Materials D150 – D225 are exclusively thermal insulating. For screeds, it is allowed to use only polystyrene concrete D250 - D600 of strength classes B0.5 - B2.5, respectively, with a tensile/flexural strength of 0.36 - 0.76 MPa.

The density of the mixture in this case is 150 – 600 kg/m³, the material belongs to the structural category, and can withstand the loads from the traffic of residents and the weight of furniture. The main nuances of a concrete screed with this lightweight filler are:

- It is prohibited to rest partitions, heavy equipment and heating appliances on the screed;

- even after high-quality mixing of concrete, polystyrene granules float to the top, the surface turns out uneven, additional leveling is necessary;

- the structure is reinforced with mesh or fiber made of steel, polymer fiber (usually polypropylene).

In the form of individual granules in concrete, polystyrene reduces structural properties. Therefore, you should use a fraction of 2 - 3 mm maximum, and make a screed with a thickness of 4 cm.

Perlite

Another way to lighten the weight of concrete is to use heat-treated volcanic glass – perlite – as a filler. The structural material expanded inside high-temperature furnaces is called perlite concrete and has a density of 300 – 600 kg/m³.

During firing, moisture is completely removed from perlite, and the screed is highly waterproof. When cement stone is formed, lime is released inside the concrete, which reacts with perlite. At the same time, the structure of the structural material is improved and it is strengthened.

For screeds, pearlite sand M200 - M300 is used, which makes it possible to obtain concrete of class B2.5 - B10.

Vermiculite

The next filler option for lightweight concrete is rock mica expanded during firing - vermiculite. This product is abrasion resistant, chemically neutral, but easily absorbs up to 4.5 times its weight in moisture. Therefore, vermiculite concrete screeds are used only in dry rooms. The density of the mixture is 300 – 800 kg/m³, the construction material is lightweight.

The building materials manufacturer Kvalitet experimentally identified the proportions of vermiculite concrete components for light screeds:

Important! The filler material has virtually no effect on the rate of hydration. Therefore, leveling the screed and installing the floor covering is carried out after 21 – 28 days.

Dry screed

Conditionally light screeds include a dry screed made of two-layer gypsum fiber board with fine-grained expanded clay sand underneath. The system is patented by the largest manufacturer of gypsum fiber boards, but can be made from gypsum fiber blocks from other companies without reducing characteristics.

The minimum thickness for a leveling layer of expanded clay chips is 4 cm, which allows for a qualitative redistribution of operational loads over the entire surface of the floor. The thickness of the gypsum plasterboard is 2 cm, so the total thickness of the structure is 6 cm minimum; it is not recommended for screeds thicker than 10 cm. The weight per 1 m² of flooring is 36 - 60 kg, depending on the thickness of the structure.

Comparative characteristics

In comparison with wood (the lightest structural material), which has indicators of 500 kg/m³, 0.15 W/m*C (density, thermal conductivity, respectively), lightweight concrete suitable for screeds has the following characteristics:

| Type of concrete | Density (kg/m 3 ) | Load on floors depending on layer thickness (kg/m2) | |||

| 40 mm | 60 mm | 80 mm | 100 mm | ||

| expanded clay concrete | 850 | 34 | 51 | 68 | 85 |

| vermiculite concrete | 500 | 20 | 30 | 40 | 50 |

| polystyrene concrete | 450 | 18 | 27 | 36 | 45 |

| perlite concrete | 400 | 16 | 24 | 32 | 40 |

| commodity | 1900 – 2500 | 88 | 132 | 176 | 220 |

| dry screed classic GVL + expanded clay | 1250 + 400 | – | 36 | 55 | 60 |

The domestic standard GOST 25192 provides a classification of concrete by density:

- especially light – less than 500 kg/m³;

- light – 501 – 1800 kg/m³;

- lightweight – 1801 – 2200 kg/m³;

- heavy – 2201 – 2500 kg/m³;

- especially heavy – more than 2501 kg/m³.

For example, expanded clay concrete with a density of 850 has a thermal conductivity of 0.38 units, absorbs 2–3 times less moisture than lumber, and is classified as lightweight concrete. When choosing a filler, you should consider the following nuances:

- filler fraction is the main factor affecting density;

- at the same time, the strength automatically changes;

- There are structural, heat-insulating and combined concretes that have a rational combination of these properties

Therefore, by using a large fraction of expanded clay, perlite or polystyrene, you can reduce the density and weight of the screed. However, such material will cease to be structural and will turn into insulation. In other words, the screed will reduce heat loss, but will gradually deteriorate, since the coarse filler that facilitates its construction affects the strength of the structure.

According to the above requirements, it is necessary to select the concrete filler fraction for the screed of the following sizes:

- expanded clay - 5 mm, you can use dry backfill for dry screed, packaged in bags;

- perlite – 0.1 – 0.6 mm;

- vermiculite – 0.6 – 2 mm;

- polystyrene – 2 – 3 mm.

Thus, the weight of the structural screed material can be reduced by using various low-density concrete fillers. As a bonus, the developer receives a reduction in operating costs due to lower heat loss in the floors of the building.

Advice! If you need floor repair specialists, there is a very convenient service for selecting specialists from PROFI.RU. Just fill out the order details, the experts will respond and you can choose who to collaborate with. Each specialist in the system has a rating, reviews and examples of work, which will help with the choice. Looks like a mini tender. Placing an application is FREE and does not oblige you to anything. Works in almost all cities of Russia. Without your desire, no one will see your phone number and will not be able to call you until you yourself reveal your number to a specific specialist.

If you are a master, follow this link, register in the system and be able to accept orders.

Polystyrene concrete - for the construction of lightweight and insulated floors

Contents: Polystyrene concrete screed. Description of the building material, scope of application, types of floors, composition of polystyrene concrete, comparison, example of implementation in a private house, cost of polystyrene concrete, request for a price for work with the material.

Unlike rigid insulation materials such as polystyrene foam, polystyrene and heat/sound insulation from mineral slabs, polystyrene concrete levels out differences without repeating the unevenness of the concrete base, and taking into account the load-bearing capacity of polystyrene concrete it is possible to reduce the height of the top layer of cement sand screed to 30-40mm. What cannot be achieved when using mineral slabs and expanded polystyrene slabs, foam plastic since they are large-format and unstable bases.

WE PRODUCE LIGHTWEIGHT FLOORS AND INSULATION FROM POLYSTYRENE CONCRETE A

Polystyrene concrete made from expanded polystyrene granules is a lightweight floor screed filled with polystyrene granules. For the installation of lightweight and warm screeds, we offer a variant of the device using polytherm as a filler in the cement mortar.

GOST for polystyrene concrete (screed), based on the state standard GOST R 51263-99, according to technical conditions, provides a light mortar composition of granular filler based on a cement-sand binder composition. The low density of foamed polystyrene granules allows for a light weight solution that can be changed according to the requirements of a particular application.

Floor screed – lightweight. Expresspol offers you the technology for preparing a lightweight floor screed from a polystyrene concrete mixture, which is suitable for insulating floors made of sand concrete, roofs, attics (application layer of at least 40-50 mm) excellent characteristics for sound insulation of interfloor ceilings (layer 50-60 mm) with subsequent laying of semi-dry screed. Also, the installation of lightweight floors with POLYTERM granule filler to reduce the load on floor slabs in dilapidated buildings, on problematic foundations, including wooden floors with large deviations in level/plane with a pouring thickness of 80 mm.

EXPANDED POLYSTYRENE GRANULES – LIGHT AND WARM BASE FOR SCREED

Easy to use, the solution is prepared at the construction site, the density of the solution is adjusted in proportion to the amount of added cement and sand in accordance with the requirements of the design documentation.

Polystyrene concrete screed, lightweight floor structures.

Options for installing screeds with polystyrene filler using semi-dry technology using mechanization for the production of PSB polystyrene concrete, supply to the work site and smoothing the surface (grinding).

Laying engineering communications, heated floors, power supply wires, low current.

Examples (section) of floor construction in section with light granule filler, proportions.

1. Cement-sand screed (semi-dry) thickness of at least 40 mm with polystyrene granules in the ratio 1:4:4 (cement-granules-sand) 2. Thermal insulation. Cement - polystyrene granules in a ratio of 1:3, thickness from 40mm 3. Polyethylene film 80 microns 3. Concrete base, monolithic ceiling.

1. Semi-dry screed with fiber, high strength with a rubbed surface, thickness of at least 40mm. 2. Polystyrene concrete from 40 mm (1:3 cement-polytherm) 3. Polyethylene film 80 microns 4. Concrete base (concrete slabs, monolithic ceiling)

1. Lightweight floor screed , it is possible to change the proportion (cement-sand-granules) depending on the thickness of the layer, finish coating and area of application. 2. Concrete base, monolithic floors. 3. Technical polyethylene film 100 microns

Polytherma granules - a light and warm filler for lightweight floors

The use of polystyrene granules POLYTERM as a filler for floor screed does not require any additional chemical additives. The chemical composition is applied to the granules during the production of POLYTERMA, reacting with water when stirred, providing adhesion to the cement mortar with improved properties, forming a homogeneous mass.

Polystyrene concrete - a type of lightweight concrete - is a composite material that includes Portland cement, mineral filler (sand), porous filler - polystyrene foam granules, and water. Polystyrene concrete is a low-combustible material and has a flammability group of G1. The materials used are from the mixture.

1. Cement M-500 2. POLYTERM polystyrene granules 3. Coarse sand 4. Entraining additive, foam converter 5. Water 6. Plasticizer (to increase the properties of the solution and its installation)

Alternative to expanded clay, expanded polystyrene, polystyrene foam

Laying engineering communications in almost all types of floors including heated floors, power supply wires, low current. Solving problems with polystyrene concrete allows you to create a lightweight floor structure, replace polystyrene foam, EPS in the event that the base has large differences and it is not possible to lay thermal insulation without prior preparation. And in cases where a large number of communications are laid along the floor.

Polystyrene concrete screed, insulation and light mortar

expanded polystyrene – light and warm screed technology

An example of polystyrene concrete installation in a country wooden house, wood frame using Finnish technology. Country house developer HONKA company

The floor in the bathhouse is made of blocks on a strip foundation

A strip foundation means that in interior spaces the floor, as a rule, will lie entirely on the ground and there is no gap between the ground and the floor layer. Here, a more complex technology is used to insulate the floor, since the installation of a layer of insulation is preceded by the installation of a number of other layers.

In the diagram, the foam is designated as EPS (Extruded Polystyrene Foam). These are different materials that differ in the degree of thermal protection and in price. It is better to take EPPS, but if the budget is limited, then ordinary polystyrene foam, such as PS-25, will do.

So, in order, the sequence of work. The first step is to remove all debris and remnants of vegetation from the soil, and then cover it with a layer of geotextile. This material is not on the diagram, since its use is optional. It is used to protect the subsequent layer of sand from being absorbed by the soil, which will certainly happen in a few years.

Then a layer of sand 10-15 cm thick is poured onto the prepared soil. The sand is spilled with water and compacted - this is important. After the sand has dried, a layer of reinforced concrete screed 10 cm thick is laid on it. The reinforcement is made of metal mesh with a cell size of 20x20 cm and a rod thickness of 10 mm. Dense waterproofing is placed on the concrete with an overlap on the walls.

We lay sheets of foam plastic with a density of at least 40 kg/m³ and a thickness of 10 cm on the waterproofing. If EPS was chosen as the heat-insulating material, then it can be laid in a layer 5 cm thick. Another layer of waterproofing film is laid on the insulation, and another layer is poured on top of it one concrete screed with reinforcement.

Porcelain tiles are installed on the screed with a slope towards the drain hole, if we are talking about a steam room or a washing room. In the rest room, you can put OSB boards on the floor or make a finished floor from wooden boards.

You should always remember that when insulating the floors in a bathhouse, you need to reliably protect the foundation from moisture coming from the interior. Regardless of whether the base is made of wooden beams or concrete, it must be insulated from water by a dense, continuous layer of water barrier film overlapping the walls. This overlap is connected with a special waterproofing tape to the vapor barrier film of the walls and forms a continuous layer with it without cracks or cuts.

Source

Floor screed using foam plastic

Polystyrene foam under screed is used quite rarely as insulation. Usually, when leveling floors, other types of insulation are used. But it is worth noting that for the first floors of apartment buildings, foam plastic is the best option for screeding. There are two ways to insulate floors with this material: use granules or whole sheets. In the first case, foam granules are added directly to the solution. One can argue about the effectiveness of this method, but given that the technology is gradually gaining popularity, there is still a result. We are more interested in the second method, which we will tell you about.

Why foam?

The answer to this question is clear: the material has a number of undeniable advantages. For example:

- The structure of the foam is porous, which provides the material with low thermal conductivity. Accordingly, heat will not leave the room, and cold air will not get inside.

- Due to its structure, foam is not affected by moisture. Therefore, in some cases, you can save on laying a layer of waterproofing.

- Polystyrene foam belongs to the category of fireproof materials. It burns, of course, but without the constant presence of an open source of fire it quickly goes out.

- In addition, the material is lightweight, easy to use and is not subject to rotting or destruction over time.

The method of performing foam screed has its own characteristics and nuances. It is worth noting that the technology is quite simple, so absolutely anyone can cope with the work.

Tools required for installing cement bonded particle boards

Attention! Before laying, all sheets must be carefully prepared and measured so that they fit the parameters of the room being repaired. The sheets must be laid out, carefully adjusted and marked so that they are not mixed up during finishing installation.

According to user reviews, the slabs are very convenient when installing floors, especially when you need to reduce work time. Many people praise its versatility and elasticity (the two outer layers are made from minimally sized chips, and the inner layer is made from longer and larger ones). Consumers also appreciate the perfectly flat surface that these slabs can provide. They easily replace the usual concrete screed.

DSP is perfect for bathroom floors

Technology

The work process begins with the preparation of the rough coating. To do this, the concrete base of the floor is leveled using cement mortar. After this, the base is cleared of construction debris and dust. Then you need to fill the initial screed. This is necessary for the final leveling of the floor base. The recommended thickness of such a screed varies from 3 to 5 centimeters. We recommend using the minimum thickness. Do not forget that waterproofing, insulation and the main screed will be installed. To this you can add the thickness of the finishing coating. Floors that are too thick will reduce the height of the rooms in the apartment.

After the preliminary screed has set, you can begin laying the waterproofing layer. Usually special waterproof films are used under foam plastic. They are laid overlapping, all seams are taped with special tape. Remember that the waterproofing layer should extend approximately 10 centimeters onto the walls of the room.

It is not recommended to use mastic or bitumen under foam plastic as waterproofing. A conflict of materials will arise and, as a result, the foam will begin to melt. If you still decide to use bitumen, then a plastic film should be laid between the layers of waterproofing and insulation.

Sheets of foam plastic are laid on the moisture-proof layer. Remember that the higher the apartment is, the thinner the foam can be used under the screed.

The sheets are coated with glue and laid on waterproofing. This is done in such a way that the seams of adjacent sheets are not on the same straight line. After all the sheets have been laid, there should be a small gap between the wall and the insulation. This is a precautionary measure in case the building shrinks. Gaps are sealed using damper tape. The gaps between the foam sheets are covered with adhesive.

To adhere the insulation to the finishing layer of the screed, it is necessary to perform reinforcement. To do this, pour a thin layer of cement-sand mortar. Recommended thickness is 1-1.5 centimeters. A metal reinforcing mesh is installed in the poured solution.

It is worth noting that screed on polystyrene foam can be done without reinforcement. This material has a denser structure, so it is quite capable of providing reliable adhesion.

Then the main screed is poured. For this, a concrete mixture is usually used. The thickness of the coating must be at least 5 centimeters. To fill the screed evenly and without much difficulty, it is recommended to use special beacons. The role of beacons is played by a metal profile, which is laid on a reinforced layer and leveled. The screed is poured between the beacons and leveled with a special strip or rule. Final smoothing is done using a spatula.

When leveling the screed with a spatula, do not forget to periodically pierce the surface with a thin metal rod. This is necessary to remove air from the solution structure. This nuance will have a positive effect on the strength of the floor.

The screed must dry for at least 28 days. This is exactly how long it takes for concrete to gain maximum strength. If work is carried out in the summer, it is recommended to periodically spray the concrete with water. After this, you can begin finishing the floor.

Properties of DSP

Cement particle board for flooring combines all the advantages of building materials such as OSB, chipboard, plasterboard and fiberboard, and in some respects it surpasses them:

- Thanks to its multilayer structure, DSP has high strength, similar to OSB. This figure is higher than that of GVL.

- Since the slab has a smooth and even surface, it does not require additional processing before installing the final finish. With this quality, cement products have much in common with chipboard, OSB and plasterboard (about

How to make warm and light screeds from familiar materials

The use of cement-sand screeds to level the floor can lead to increased pressure on the interfloor slabs. In order to avoid overload, it is worth using a lightweight material - monolithic polystyrene foam. It is made using cement and polystyrene. A mixture of these components makes it possible to obtain a floor screed made from polystyrene concrete that is sufficiently warm, lightweight, and resistant to cracks and shrinkage. Such properties are provided due to the characteristics of foamed polystyrene granules. Moreover, both the density and weight of the resulting warm screeds can be changed depending on the conditions of use by changing the proportions of the materials included in their composition.

And in order to make the base faster, use the ready-made Knauf UBO mixture. This is a dry construction mixture based on special cement and polystyrene foam granules as a filler. The permissible layer thickness is from 3 – 30 cm.

Expanded polystyrene coatings are currently considered one of the most popular. And the main reasons for this are the following advantages of a warm screed made of monolithic polystyrene foam concrete:

- increased service life compared to most other polymer materials;

- good thermal parameters, allowing you to obtain a comfortable microclimate in the room even without the use of additional insulation;

- environmental safety achieved through the use of only food-grade polystyrene embedded in cement in the production of the material.

In addition, among the advantages of the polystyrene foam base is the ease of its manufacture. Filling a light floor screed can be done directly on site and in almost any conditions. Moreover, the dimensions of the mixing installation do not exceed 0.8 m in width, and the weight is 100 kg.

The disadvantages of the resulting floor covering include only two characteristics of the material - its relatively high price. If you buy a ready-made mixture, a bag of UBO weighing 25 kg (a fairly large bag) will cost about 450 rubles. With a consumption of dry mixture per 1 sq.m with a layer thickness of 30 mm - 17.6 kg.

In any case, when using light fills, you will have to make an additional reinforcing cement floor screed.

Laying tiles on a wooden surface

Scheme for installing tiles on wooden floors.

Installation of a tiled covering on a wooden base is possible only if it maintains its integrity and does not rot. The weight of ceramic tiles, additionally increased due to the adhesive composition, can lead to deformation of the wooden floor, its cracking and destruction. Plank floors that, upon examination, appear unsuitable to withstand heavy loads, are best dismantled. It is more advisable to get rid of a rotten subfloor, which will no longer be helped by any surface preparation. If the wooden boards are of reliable strength, it is enough to make sure that they are well attached to the joists and that there are no too wide gaps between them.

Loose floorboards are secured with self-tapping screws or dowel nails, and the gaps between the boards are puttied, having previously been reinforced with thin wood chips. Preparing a floor made of chipboard or plywood is carried out in the same way. The use of a waterproofing underlay when laying tiles on a wooden surface is mandatory. Wood has the ability to absorb moisture well and change size with temperature changes, and insulating the subfloor will prevent the tile covering from becoming unstable.

https://kuhnyamoya.ru/youtu.be/ukXcbORkvWA