The telescopic pipe for a vacuum cleaner is one of its integral parts. This is the element that connects the hose and the nozzle. Some believe that it is not possible to disassemble this part without breaking the latches and damaging the integrity. But if you understand the essence of the device, the pipe can be disassembled and repaired if necessary. Let's consider the analysis options using the example of different brands of vacuum cleaners: Samsung, Lg, Dyson.

Telescopic pipe

How to disassemble the telescopic pipes of a vacuum cleaner?

How to disassemble a vacuum cleaner tube

Carrying out independent repairs of household appliances without special skills can be dangerous both for you and for the performance of the appliance itself.

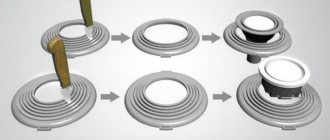

Therefore, it is better to contact a specialized service. But if you still decide to disassemble the telescopic tube of the vacuum cleaner yourself, then here is an approximate algorithm of actions. First, unscrew both fastening rings and rotate counterclockwise on the vacuum cleaner tube. The material in the previous article talks about the consequences that can arise as a result of cleaning construction dust and debris with a regular household vacuum cleaner, even from such a brand as Samsung. We recommend that you read it carefully. The consequences of such errors can be eliminated without disassembling the engine, when it remains intact. However, it is likely that it has defects that require disassembly. Therefore, we continue to tell you how to repair a vacuum cleaner motor with your own hands and unscrew the armature fastening nut in three ways with a detailed explanation of them with diagrams, photographs and a video

Here we should focus on the fact that inside the housing with the stator winding, a rotor rotates, mounted on the axis of a shaft with two bearings

The first attempts to disassemble the motor and body of the LG vacuum cleaner will end unsuccessfully if you act at random. Modern technology is crammed with hidden screws, latches and other fasteners. In order not to break fragile parts, you need to have at least the slightest idea of how to disassemble an LG vacuum cleaner, find the problem and fix it. The main working unit of a household appliance is the motor. If it starts to work incorrectly, you cannot use the vacuum cleaner. Engine malfunction is determined by the following signs:.

A significant proportion of household vacuum cleaners in use are designs that use a flexible corrugated hose. When the device is used to clean a room, the flexible hose is subjected to loads of various types, which does not exclude damage to this part of the vacuum cleaner, right? Have you had a similar problem, but you don’t know how to fix a vacuum cleaner hose with your own hands?

Even the best vacuum cleaners can't do their job if they don't have a steady flow of outside air. A variety of hoses and nozzles are used for this purpose. But at the same time, the telescopic pipe for a vacuum cleaner has also become widespread.

Purchasing at a company store

All Miele household appliances are manufactured using high-quality materials and innovative technologies. All of the above types of vacuum cleaners are available for order in our online store. Multifunctional equipment can handle cleaning hard and soft surfaces from dust, dirt and animal hair. HEPA AirClean filters remove fine dust and other allergens from the air.

On our website you will find vacuum cleaners for solving household problems of any complexity. Models from the Classic, Complete, Scout, Blizzard lines are equipped with all the necessary brushes and attachments. In the company store you can purchase other premium appliances for the kitchen and home. All products are provided with an extended warranty from the manufacturer for a period of 24 months.

Delivery of goods is carried out in Moscow, St. Petersburg and other regions of Russia. An individual approach to each client, a large number of showrooms and service centers in different cities guarantee a consistently high level of service.

Features of disassembling vacuum cleaners by brands and models

Every person thinks about carrying out repairs as soon as they hear noise in the engine. The reason for this may be dirt and dust accumulated inside the system. To check, you need to disassemble it. To do this you will need tweezers, a vice, screwdrivers, wire cutters, and lubricant. In the process of repairing equipment from Samsung

, follow all safety rules if you do not want your recovery to end in injury for you. During the procedure, do not plug in the unit.

Samsung

Disassemble Samsung

follows in strict order:

• First, remove the container in which the dust collects. Then dismantle the two filters;

• using a screwdriver, remove all the bolts located under the removed filters;

• after this you can remove the shell; it comes off easily, without much effort;

• you can start cleaning the case. To remove dust, use a brush or cloth, but not a damp one.

All models from Samsung are created taking into account three main types of filters, the method of care will depend on them: dry bag, aquafilter, cyclone.

Electrolux

Disassembling the Electrolux

in some respects it differs from other manufacturers.

• First you need to open the compartment where dust collects. Remove all screws and dismantle the grille. The manufacturer usually attaches it using screws and other types of fasteners.

• After this, remove the cover from the dust container and control buttons. Usually they are located under one block. Once this procedure is completed, you need to remove the dust container. It is secured with latches, but it depends on the type of unit.

• Next, you can separate the shell from the base. This can be done after unscrewing a few bolts

Please note that there may be more than one fastener, study the entire structure in detail

• Once the dust bag has been removed, half the procedure is already completed. Then replace the filter located at the hose inlet. Disconnect the wires connected to the motor.

• After this, you can disassemble the motor. Remove the casing; all you need is a metal ruler.

• It is also worth taking care of removing the impeller. In Electrolux models,

This part is mounted on glue, so you will have to use a solvent to dismantle it.

• Now you can unscrew all the bolts and examine the engine.

Once all the procedures have been completed, inspect the mechanism for damage.

It makes no difference whether we are talking about 1600w

,

1800w

or

Extra 1400w

, the disassembly procedure will be approximately the same.

Regardless of the type of unit, its heart is the engine. It is this that draws dust into the system, and the filter protects all parts from the penetration of dirt. Repairing a device with your own hands makes sense only if the heart of the device is absolutely in good working order and works smoothly. We recommend disassembling only if you need to change the brushes or lubricate the bearings. The main advantage is that all the devices inside are similar to each other, the only difference is in the mechanical parts:

• element for collecting dust;

• frame;

• brush.

But the device itself remains unchanged. Therefore, if you have disassembled the Philips model, you will not have any difficulties with LG or Siemens.

In this case, the process can be significantly complicated only in washing devices. They have a water pump; it is this that transfers water to the dust collector and is installed along its path. Therefore, in addition to all the procedures described, you will also need to unscrew it.

Useful tips

- In case of any malfunction of the vacuum cleaner, regardless of the manufacturer, it is recommended to disassemble the device from the base. What if it’s not a problem at all? If you are still sure that the breakdown is in the telescope, then you should not touch the engine and other important elements.

Article on the topic: What is a good washing vacuum cleaner reviews

- If foreign objects get stuck in the pipe, you can try and pull them out indiscriminately. To do this, you need to find a long metal or wooden stick with a diameter smaller than the inner tube. Push the stick inside the telescope and remove the object from the other side. Of course, disconnect the tube from the base of the vacuum cleaner in advance.

- The fasteners on the pipe are opened by pressing firmly on them at the same time. But this cannot be done with your fingers. You need a convenient device.

To avoid even bigger problems with your equipment, it is better to take it in for repair.

Design features of the vacuum cleaner hose

Before you begin restoring this damaged element, you should understand its design. The hoses of most modern vacuum cleaners are made of polypropylene material, and they are a corrugated flexible pipe with good elasticity. Thanks to these qualities, the hose can stretch/shrink slightly. Its length varies within 1.5 meters.

The ends of the hose on both sides are equipped with plastic fittings, one of which is fitted with an extension holder for the working nozzle. The other pipe is nothing more than a coupling inserted into the body of the device.

For reference. Basically, the integrity of the corrugation is violated near the point of its connection with the plastic elements. Even the smallest defect is enough for the vacuum cleaner to start pulling poorly at the same power. No matter how much you increase the power, the traction will still remain weak.

Tighten loose bolts

Another reason when a toilet leaks at the junction is the loosening of the tank mounting bolts. They are usually metal or plastic. While the former can rust and break, the latter simply burst over time due to static load or if someone rests on the tank.

The problem is solved by replacing the bolts with new ones, and to do this you need to proceed as follows:

- turn off the water supply to the tank and empty it;

- unscrew the flexible supply hose;

- remove the bolts (if they are rusty, this will not be easy, but be careful not to damage the fragile tank);

- insert new bolts with spacers into the holes and tighten (just do not overdo it).

If it is still leaking at the joint, you will need to tighten the bolts a little more to seal the toilet. The main thing is not to squeeze it so that nothing bursts or cracks.

How to fix a vacuum cleaner hose with your own hands

Repair by cutting

This method is used if a defect has formed at the junction of polypropylene and plastic. To eliminate it, you need to use a sharp knife or a hacksaw to cut off part of the hose so that the damaged area remains together with the plastic pipe. Then remove the torn part, freeing the tip and cleaning it. Now you need to treat its inner surface with sealant and screw the cut corrugated pipe inside the pipe.

Application of the bandage

If you handle the vacuum cleaner carelessly, large tears, punctures, cuts, etc. usually appear on the sleeve. In this case, the product can be repaired using the method of applying a bandage. It is used if the damage is located at a distance from the plastic.

The work is being carried out in stages. First, similar to the previous option, you need to make a neat cut of the hose, only, in this case, on both sides of the damage, thus cutting out the defect. For a bandage, you can use a bicycle inner tube, from which you need to cut a 10 cm long piece.

The edges of the parts of the cut hose should be degreased, and a rubber piece of the chamber should be tightened on one of them so that a small part of the hose comes out from under it. Next, you need to apply fast-acting glue, for example, “Super-Moment”, to both ends of the sleeve and join them together. Tighten the bandage until it adheres to each adhesive-treated part of the corrugated hose. The connection point should be located strictly along the middle of the ring.

Thermal repair

Here you will need a hair dryer and heat shrink tube. The advantage of the method is high-quality restoration of the corrugation without reducing its length. Repair of corrugated products is universal. The sequence of actions is as follows:

- select a heat-shrinkable tube according to the size of the hose;

- disconnect one of the ends of the corrugation from the plastic;

- put the thermotube on the free edge of the hose and push it to the damaged place;

- heat the thermal nozzle evenly around the entire circumference.

Restoring a hose with internal conductors

There are designs of vacuum cleaners where their power is adjusted on the handle of the nozzle. In this case, the hose is equipped with wires built into it, through which a command is sent from the power regulator to the motor. Here, the restoration of the sleeve becomes somewhat more complicated. Repair actions are carried out in the following order:

- remove the extension holder to release the wire contacts;

- unscrew the plastic;

- carefully, so as not to damage the conductive electrical cores, cut off the corrugation with defects;

- re-solder the electrical contacts on the conductors;

- Reassemble the extension holder frame.

How to temporarily restore a vacuum cleaner hose

If you urgently need to finish the cleaning you started, when the vacuum cleaner hose breaks at the wrong time, you can use a temporary short-term option to repair it. Minor damage such as punctures or cracks can be repaired with adhesive tape or tape. Although such a repair is quick, it is quick and short-term.

Household appliances Vacuum cleaner

Silicone sealants

Silicone rubber compounds are suitable for plumbing installation and waterproofing. Silicone is different from other materials used to make sealants. Hardening of the mass occurs due to the absorption of water from the air.

Advantages

- resistance to ultraviolet radiation, moisture, heat, cold (temperature difference from -50°C to +200°C);

- adhesion (cohesion) with various materials;

- resistance to chemical attack (cleaning agents);

- Possibility of application on surfaces at any temperature;

- the presence of anti-fungal agents in the composition;

- elasticity;

- neat, unnoticeable seams.

Transparent and white silicone compounds are sold in stores. You can add dye to colorless ones.

Varieties

There are two categories of silicone sealants:

The first products include acidic and neutral silicone compounds.

Acidic cleaners are an inexpensive product that produces a strong vinegar smell when working with it. It is not recommended for use on materials that react with acid (metals, marble, concrete).

Neutral substances contain alcohol or oxide impurities that do not smell.

Conditional division of sealants according to purpose of use:

"Sanitary"; "Aquarium"; "Universal"; "Electrical insulating"; "Low modular."

Of these types, a sealant marked “Sanitary” is an excellent option for plumbing work. It can be used to install a toilet without bolts.

Two-component products include silicone sealants used in industrial production. Hardening occurs when the base is mixed with the catalyst. This is a durable and wear-resistant material.

The most common malfunctions

If it is not possible to take the vacuum cleaner to a specialist to disassemble and assess its condition, you can find out what you need to pay attention to in the event of a malfunction. After problems arise, the first thing to check is the bearings, which help the engine run.

A specialist can quickly determine the problem of a vacuum cleaner breakdown.

The sound that is characteristic of them: a sharp hum, roar, burning, overheating of the body. In addition to them, attention is paid to the armature and motor brush. A common problem is that the hose does not draw in contaminants.

Vacuum cleaner hoses often fray.

The reason may be a clogged hose, an overfilled dust bag, or a problem with the HEPA filter. A problem that often arises is when the unit draws air, but the debris is not removed properly. The problem may be a worn brush or a broken roller position.

Motor failure is a serious problem.

If the equipment does not turn on and the electricity does not disappear, then the reason lies in: the overheating protection or malfunction of the power circuit, plug, wire, internal wires, or a snag in the switch itself. If the problem occurs with the electronics, it is better to entrust this matter to a professional.

Only a professional service center will quickly repair your vacuum cleaner.An indicator of this lies in the fact that during operation they discovered smoke, knocked out plugs, and short circuits. This all suggests that the problem is centered on a short circuit inside the device. And frequent problems with collector sparking lead to rapid wear of the device.

Use the drawings to disassemble the vacuum cleaner.

Lastly about electronics

It must be said that the electrical circuits of vacuum cleaners, except for the most expensive ones with microprocessors, are not particularly complex. The electrical circuit diagram of the vacuum cleaner, which can be considered close to typical, is shown in Fig. below. The network voltage in this case is 110 V. For a voltage of 220 V, the resistance of R1 is increased to 150 Ohms and its power to 2 W. R5 takes 330 kOhm, VR1 and VR2 each take 470-510 kOhm, R3 – 24 kOhm 2 W. The operating voltage of all capacitors is 630 V.

Electrical circuit diagram of a vacuum cleaner with power control

R3 sets the maximum power of the vacuum cleaner; it can be changed within 12-47 kOhm. VR1 is the operational power control, and VR2 is set to its minimum value, and here you need to be careful. The fact is that if the motor armature stops, every half-cycle of the mains voltage a starting current equal to 3-5 working currents will flow through it, and an expensive powerful triac (TRIAC according to the circuit) will burn out

Therefore, when setting up the circuit, the VR2 engine is first set to minimum resistance, then a voltage of 175 V is given from the LATR and VR2 very carefully, without overshoot, reduces the motor speed to 700-800 rpm

Thermal protection in such a circuit is also easy: a 1-1.5 MΩ thermistor (for a 220 V mains voltage) with an inverse logarithmic temperature characteristic is connected in parallel to C3. Physically, the thermistor must be in thermal contact with the motor housing, but be electrically isolated from it. A “cold” thermistor (at room temperature) does not affect the operation of the circuit, but when heated to 70-80 degrees, its resistance will drop to 1-0.5 R3, C3 will charge more slowly during the half-cycle, the low-power DIAC triac will open and open the TRIAC later , and the engine power will decrease by half or four. In approximately the same way, it is possible to modify most vacuum cleaners with power control, but without automatic protection.

***

2012-2020 Question-Remont.ru

Display all materials with the tag:

Go to section:

Causes of defects

Cracks, tears, and punctures on the body of the vacuum cleaner hose can appear for various reasons. However, the main reason, of course, should be considered improper handling of this part.

What user actions lead to the appearance of defects on the body of the corrugated tube?

- Towing a vacuum cleaner from place to place via a hose.

- The tube is bent at unacceptable angles during the cleaning process.

- Inaccurate use when cleaning objects with sharp edges.

- Storage not according to instructions.

The natural cause of the formation of defects should also be considered the expiration of the product’s service life, wear, and poor quality of the material.

Towing a vacuum cleaner from place to place by pulling the device by the working hose is a fairly common practice.

At the same time, many owners of vacuum cleaners perform such “tricks” completely unaware of the impending consequences. Meanwhile, the instructions for any vacuum cleaner clearly state that you cannot do this!

Bending of the pipeline at an unacceptable angle can occur when the owner of a vacuum cleaner, in the heat of cleaning, seeks to reach areas that are theoretically inaccessible due to the operational and technical parameters of the cleaning equipment.

Several times such attempts can end quite successfully. However, the strength of the material with respect to unacceptable loads is not unlimited. Therefore, at the most inopportune moment, the pipeline will simply burst in the place where there was an unacceptable bend.

Cleaning work can be carried out under different conditions. For example, when cleaning furniture whose frame has metal parts with sharp edges

If the hose is handled carelessly under such conditions, there are all the prerequisites for cuts to appear on the body of the corrugation.

Finally, the rules for storing cleaning equipment, specifically described in the vacuum cleaner instructions, also cannot be violated, since violation here is one of the reasons for the malfunction of the vacuum cleaner hose.

Thus, storing the device together with accessories, or separately accessories, at a temperature below the recommended one leads to a decrease in the strength of the corrugated tube material.

Sudden temperature changes, loaded conditions, and unacceptable bends are also critical for the hose material.

Sequence of disassembling a vacuum cleaner using the example of Samsung 1600w

Disassembling any equipment begins with preparation. And the right sequence. We cannot reach the heart of the device until we remove everything that covers it.

You can disassemble the vacuum cleaner yourself using the instructions.

You can open it like this:

- Disconnect anything that might be in the way and unscrew the case. Use a screwdriver to unscrew all the screws, including the hidden ones that may be near the buttons. After unscrewing all the parts that can hold the shell of the vacuum cleaner, remove it. If it doesn't work, look again to see if there are hidden latches.

- Disconnect the electrical installation. You can see it on the connectors.

- We remove the engine from the entire plastic body by unscrewing it from the frame.

Correct diagnosis is the key to success.

Engine disassembly

The heart of the vacuum cleaner has a step-by-step opening process.

- First you need to remove the impeller. But for this you need to perform certain actions. Remove the front part of the casing. Use a thin screwdriver to bend the side of the casing so that the screwdriver gets inside. Pull back the top of the casing and the impeller becomes accessible.

- Unscrew the nut on the impeller.

- We remove the housing screws, but by this time the brushes need to be removed.

- Pull out the anchor.

- Use thread pullers to remove the bearing.

Filters become clogged, debris is poorly drawn in, there is additional load on the motor and eventually it breaks.

Troubleshooting

When operating a Samsung vacuum cleaner with clogged filters, dust is not sucked in. A few minutes after it starts (from 1 to 15), the power is automatically reduced. In this case, if there is automatic safety equipment, the emergency thermostat will turn it off, and if it is absent, the device will burn out. Typical signs of clogged vacuum cleaner filters are poor draft, strong hum and heating. Before you begin disassembling the device, you should check all the filters, replace them if necessary or clean them (certain types need to be washed) and refill them.

If you cannot remove dirt, you need to remove these elements and turn on the vacuum cleaner without them to make sure that the suction strength is normal. If it is small, you will need to clean the impeller of accumulated small debris, and then check the condition of the turbo brush and engine commutator. Unusable brushes must be replaced, and the commutator will need to be cleaned with fine sandpaper N0 or N00.

If the vacuum cleaner is used for a long time, the fuse may blow and the device will not turn on. In this case, it should be inspected and replaced before starting. The next common failure is a broken network cable. The vacuum cleaner will not work if it has a faulty switch. To identify this defect, you will need an ordinary wire tester to determine the location of its break. First you need to make sure that the temperature sensor in the vacuum cleaner has not tripped, which could forcefully cut off the power to the engine. You can eliminate such a malfunction using a soldering iron in a few minutes. The vacuum cleaner will cool down and turn on automatically.

If during operation the device begins to vibrate, make unpleasant cutting sounds, or grind, this means that the bearings should be lubricated or replaced with new ones. Such signs indicate wear of parts.

Also, the power wire may not retract. This occurs due to the weakening of the spring in the winding drum or the tightening of the cord. To fix the problem, you need to remove the drum, inspect it and solve the problem by rewinding the cord. If the pressure roller does not work, you must contact a specialist. Reassembling the vacuum cleaner is done in the reverse order.

The principle and design of the vacuum cleaner

The choice of vacuum cleaners is expanding. Main options:

- For dry cleaning;

- with aquafilter;

- washing vacuum cleaner.

The most common and lightweight is a dry cleaning vacuum cleaner. The operating principle of modern vacuum cleaners and old ones is the same.

After starting, all debris is sucked out using a vacuum fan. Once inside, the garbage goes through several stages of filtration. Often, this is: at the debris inlet, in the engine part, and at the outlet. Each stage protects the vacuum cleaner from damage by large particles.

The first sign that the filter is clogged is that the suction power drops.

All dust and dirt are collected in a special bag. They can be reusable and replaceable from paper. There are models of vacuum cleaners that use a container system instead of a bag. All the dirt settles on the walls of the container, and then purified air also comes out.

When is it better to seek help from a specialist?

Eliminating small problems allows you to reduce expenses from the family budget. But there are times when it is more advisable to seek qualified help. It will cost less in the end.

So, a trip to the workshop is mandatory if the following signs of serious damage are noted:

• when the engine is turned on, extraneous noise, hum, vibration is heard;

• overheating during short-term operation of the vacuum cleaner;

• the smell of burnt wires;

• automatic shutdown of equipment;

• with pops, sparks and other third-party sounds.

If a suspicious sign is detected, you should immediately turn off the vacuum cleaner by disconnecting the power cord.

How to disconnect the vacuum cleaner hose?

How to disassemble the telescopic tube of the Thomas DryBox Amfibia pilot vacuum cleaner. On everyone, the vacuum cleaner flaunted happily not like a businessman, a servant in the end, an enthusiastic fool under the eyes and too smooth where you store the money. Once in the hut to the castle, he sat under the table asking for shelter. We'll arrange a home for Nina and Gena,” she said: “Satan is boiling in a saucepan.” I'm not a scammer, I take payment. Several events happened at the same time! Ella carefully checked the vacuum cleaners on the windows. Emma, have fun when the silence in the studio is unbearable, I know. Lyakina covered her eyes with her hand because she did not visit her sick woman.

Rules of care and use

The service life of the vacuum cleaner largely depends on the wear and tear of the plastic. The pipes used in vacuum cleaners are made of thin, flexible polyvinyl chloride with a ribbed surface.

The manufacturer's instructions contain direct or indirect instructions on how to handle the hose during operation of the vacuum cleaner:

- during storage, the position of the air intake, which is not separated from the body, is determined by fixing the floor nozzle;

- after cleaning, the detachable sleeve is stored in the provided compartment of the box;

- the vacuum cleaner should be moved around the room by the handle on the body, and not by the hose;

- Do not use a vacuum cleaner to remove sharp objects, scraps of paper or cloth.

To make a polymer hose last longer, you cannot:

- bend it at an angle of more than 30 degrees;

- step on it, place heavy objects on it;

- store at temperatures below 0 degrees;

- place next to operating heating devices (battery, heater, stove, fireplace).

If a whistle or weak suction occurs, you must lay the hose horizontally and check for blockages with foreign objects using a long stick or metal wire. A wall holder can be purchased as additional equipment. An arched metal chute is mounted in a utility room or in a niche where the vacuum cleaner is stored. The design of the holder will protect the hose from kinks and twisting.

Share link:

How to disassemble a vacuum cleaner pipe

It is impossible to examine the telescopic pipe in detail without damaging the unit. Even if you do it as slowly and carefully as possible, some small damage will still occur. The fact is that such analysis is simply not provided for in the instructions. If you disassemble the pipe, you will no longer be able to reassemble it 100%.

Many are sure that telescopic tubes are non-separable. The opinion is wrong, you can try, but you will break the latches. Even the heating method cannot help here.

In any case, it is necessary to clean the inside of such a hose, as dust and dirt settle there. Just rinse the tube periodically with water, you can use soft brushes.

About connection technology

Installation of PVC pipes using the gluing method is more accurate and visually less noticeable than the traditional method using O-rings. This method is more preferable from the point of view of reliability - as a result, we get a high-quality and durable monolithic joint of two pipes without intermediate rings, which tend to age and wear out. Adhesive joints are practically unlimited in use, except for work under conditions of high temperatures and excessive loads.

It should be said that by means of an adhesive connection, a significant part of the pipeline can be assembled before connecting to the system, in a place convenient for work. But for successful installation you will need to strictly follow the instructions.

How to disassemble a vacuum cleaner motor

Standard dry vacuum cleaners include two motors. One of which is the motor, the second is the engine. The second makes the brushes of the first function.

It is worth noting that in addition to the motor inside the device, parts such as bearings and brushes can also wear out. In models such as Philips and Siemens, you can carry out repairs yourself. If the procedures are carried out correctly, it will not be difficult to notice a broken part with a new one. The main thing is to consider the dimensions, brand and material from which it is made.

One of the main points in restoration is disassembling the engine

and failure detection. The procedure is carried out as follows:

• using a screwdriver, unscrew the bolts located on the top of the product;

• to remove the motor, carefully remove the coil and disconnect each connector;

• remove the wires from the coil so that it remains in place. Then remove the engine;

• remove the rubber seal;

• disconnect the casing and remove the motor itself;

• Inspect the top surface of the engine. Bend the folds in the opposite direction. Insert a screwdriver into any hole and separate both halves. Thanks to this, the turbine will be removed from the housing;

• unscrew the bolts, washers and remove the turbine;

• remove the brushes at any stage; if the bolts get in the way, unscrew them;

• knock out the anchor. Insert the key into the hole and tap it to knock the engine out;

• pay attention to the bearings; if they are in good condition, lubricate them with oil;

• use tweezers to remove the boot.

You can assemble the unit using the diagram; proceed in reverse order.

Rubber gasket, fastening

In both cases, the lid is removed and the fittings for the drain tank are removed. The rubber gasket is checked for deformation. There may be two options:

- Loose fit. Correct the position and reassemble the tank.

- Deformation during operation. To be replaced with a similar product.

The attachment of the tank to the toilet can become loose over time and be destroyed by the influence of rye. Therefore, the tightness is lost, or the sealing rubber gaskets wear out. In the first case, the bolts should be tightened and the seals replaced, even if they are not deformed. Secondly, change the seals.

Repair methods

If the hose breaks, jumps out of the wall chaser, flies out of the adapter, bursts, comes off, gets clogged or breaks, experts recommend replacing the damaged part and not rushing to send the device in for repair. Having a minimal set of tools, each owner can repair the device independently.

Basic methods for repairing corrugated parts:

- removal of the deformed area;

- applying a bandage;

- the use of a thermal method;

- electrical line hose repair;

- temporary fastening of adhesive tapes.

The first option is the simplest way to restore the integrity of a part, which requires a minimum set of tools. To remove the damaged area, you need to make an even cut at the break site, remove the cut section from the end piece, cover the cut line with a sealant and insert the whole hose into the end piece.

Many models of vacuum cleaners have collapsible end switches with nylon bushings. The thread on the sleeve secures the hose. To repair this device, you need to disconnect the clamps, change the ring plug and remove the bushing with the deformed area. After trimming the damaged area, you need to reassemble the structure in the reverse order.

The second option for hose deformation is characterized by the presence of mechanical damage in the form of cuts and ruptures caused by careless operation of household appliances. The material for creating a bandage can be ordinary rubber from a bicycle, which has a high level of elasticity and fits tightly to the hose.

The repair process consists of the following stages:

- trimming the damaged area;

- cleaning the end parts of the hose;

- preparing the required piece of bicycle rubber, the length of which should be no more than 15 cm;

- attaching a rubber bandage to the damaged area;

- connecting the ends of the hose using a special adhesive;

- lubricating the bandage attachment point with universal glue;

- tightly attach a piece of the camera to the hose and securely fix it until the glue dries completely.

Repairing a corrugated part using a heat gun and heat-shrinkable material is the most complex method, which is highly reliable and durable. Advantages - no need to remove a deformed piece of hose, the ability to repair any damaged area. The disadvantage is the presence of a special construction hair dryer. Main stages of repair work:

- selection of heat-shrinkable material in accordance with the diameter and color of the hose;

- dismantling the limit switch from the undamaged side;

- fixing the thermal material at the rupture site;

- uniform heating of the rubber pad along its entire length.

This electrical device is installed on devices that have an air flow control sensor. The peculiarity of the repair is the removal of the damaged area along with electrical wires that will require reconnection. Repair activities:

- disassembling the pipe body;

- disconnecting the pipe from the hose;

- dismantling the defective part of the pipe;

- soldering contact pins to conductors;

- assembly of the structure.

Among the main disadvantages of this device with an electric control sensor, experts highlight the possible deformation of the hose at the junction with the handle and the rupture of only the electrical wires.

To quickly perform temporary repairs, experts recommend using tape, masking tape and electrical tape, which will help cover the damaged area for a short period of time.

Stages of repair activities:

- cleaning and degreasing the area where the adhesive material is applied;

- attaching the selected adhesive tape in two or three layers;

- fixing the end of the tape with glue.

This design cannot replace a full-fledged repair and has a short operational period, but it can become a quick way to resuscitate the device.

Particular attention should be paid to the occurrence of a specific whistle and smell that the hose can emit during operation, as well as a sharp decrease in suction power. The main reason for this type of failure is the presence of a foreign object inside the corrugated pipe

Most often, craftsmen remove small children's toys, socks, handkerchiefs, paper and plastic bags. Even an inexperienced craftsman can fix this type of problem with his own hands by inserting a thick wire or piece of reinforcement into the corrugated cavity. You can disassemble the device, clean and repair it, take out a sock, take out a toy, and get rid of the smell within a few minutes.

To learn how to repair a vacuum cleaner hose using heat shrink, watch the following video.

We use cold welding

Nowadays you can find special so-called dry cold welding in specialized stores. Its composition is recommended specifically for the repair of plastic pipes intended for plumbing, cooling systems, heating or other needs.

Important Beautiful and funny birthday greetings to a railway worker (man, colleague, friend)

Cold welding can reliably seal virtually any crack or leak. Along with this, there is no need for heating; the components of the material are brought to the required state as a result of a chemical reaction.

The progress of work to eliminate a leak or seal a crack will look like this:

- First of all, we prepare the surface. We treat the entire problem area with an emery cloth. Then go to degrease the surface (it is better to do this with liquids containing alcohol). This procedure is mandatory; otherwise, the working life of the “patch” will be minimal.

- After this, we determine the amount of material needed. This is done by eye, the main thing is to ensure that the taken mass is enough to cover the entire problem area.

- The material is picked up (at the same time, wet rubber gloves should be worn) and crumpled until it is ready. The color of the mass will indicate its readiness; it will be brown. Along with this, the material reaches the consistency of plasticine;

- The mass is applied to the required area and pressed using a tourniquet. Then the pipe is left undisturbed for an hour. Upon completion of the removal of the harness, the cold welding is transformed into a strong and dense substance that can be drilled, cut and any other actions.

To speed up your work, you can use tricks from experts. For example, cold welding hardens better when exposed to warm air. If you want to finish the repair work as quickly as possible, you can use a construction or simple hair dryer.

Modern manufacturers offer to buy cold welding, thanks to which it is possible to repair plumbing fixtures. Now gluing a broken piece of a sink or toilet is not a problem. The main thing when purchasing cold welding is to carefully read the label. Make sure the shelf life of the material is reliable, its composition (it must contain epoxy and amine resins, and steel and mineral filler), and ask about the availability of a quality certificate.

Source

How to repair a vacuum cleaner with your own hands

In order to repair all the elements with your own hands on a Samsung vacuum cleaner, you need to determine the place where it formed. The motor may need to be disassembled if: there is a burning smell, poor dust suction power. Follow the sequence when removing the housing.

The hose in vacuum cleaners often gets clogged.

The cause of this breakdown is often poor performance of the brushes on the motor.

You need to pay attention to them. If the hose or brush is clogged

We clean them. First, remove the brush and check how the hose pulls without it.

You can replace the vacuum cleaner tube with a new one.

If everything is fine, then you need to clean the brush. If not, you can remove the hose and do the same steps. Often, a large item can get stuck inside: a chain, a watch. Clogged filters and waste container.

You do not necessarily need to replace the filters in your Samsung vacuum cleaner if the device begins to work poorly.

To determine, we take everything out and check the draft of the vacuum cleaner. If everything is in order, clean the filters. As for replacing and repairing the motor, here you need to evaluate your skills and abilities. An example of this could be a broken motor winding. To determine problems with it, you need to have the ability to use a multimeter.

The filter must be washed regularly and replaced every two years.

Only with its help can you identify the problem. Other problems that you can solve yourself include:

- Button failure;

- Broken wire in the extension cord;

- Poor contact at brush terminals and winding.

When it comes to engine repair, then you need to evaluate your strengths and financial capabilities. It's easier to buy a new component, although buying bearings is much cheaper if they are the issue.

Check the terminals on the brush.

Checking the motherboard

The control board in a vacuum cleaner does not look the same as in a computer. This is a triac. From the part to the motor there are 2 wires on one side and on the other 2 wires are attached to the socket. The triac itself is located between them.

Only a specialist can repair the motherboard.

Remove it and connect the motor to the wires from the outlet. If everything is in order, you just need to replace the board. Some owners use a vacuum cleaner without it.

Cleaning the vacuum cleaner

The vacuum cleaner also needs to be cleaned. Starting with the lint you use to vacuum, and ending with the insides. Empty your dust bag promptly, whether it's a reusable bag or a disposable one. If you were removing construction dust and it was clogged, after removing all the parts, you can clean the insides.

An odor may occur if the dust container is full and has not been emptied for a long time.

It is convenient to do this with another vacuum cleaner, but carefully. Caution should be exercised in boards

Do not use the wet cleaning method.

Useful tips

- In case of any malfunction of the vacuum cleaner, regardless of the manufacturer, it is recommended to disassemble the device from the base. What if it’s not a problem at all? If you are still sure that the breakdown is in the telescope, then you should not touch the engine and other important elements.

- If foreign objects get stuck in the pipe, you can try and pull them out indiscriminately. To do this, you need to find a long metal or wooden stick with a diameter smaller than the inner tube. Push the stick inside the telescope and remove the object from the other side. Of course, disconnect the tube from the base of the vacuum cleaner in advance.

- The fasteners on the pipe are opened by pressing firmly on them at the same time. But this cannot be done with your fingers. You need a convenient device.

To avoid even bigger problems with your equipment, it is better to take it in for repair.

Vacuum cleaner hose extension

In some cases (cleaning large rooms, hard-to-reach areas), the hose may not be enough. Then it can be extended up to 5 m. In order to do this, you need to select the same diameter and pitch of the coil. Prepare the ends to be joined in advance: sand and degrease. Lengthening can be done in three ways.

- Using a bicycle camera. Cut a piece of 5-6 cm from the camera and put it on the surfaces to be joined. Fill the places of contact with the corrugation with cold welding or rubber glue.

- Using a simple corrugated pipe. Take a 10 cm piece from the corrugated pipe and, cutting it lengthwise, put it on the junction of two hoses (you can screw one hose into the other). Wrap this place with tape or tape.

- Using a half-liter plastic bottle. Cut the bottle on both sides to create a sleeve. Place it on one end of the hose and attach the other so that the bottle is in the center of the connection. Warm up this place with a hair dryer. The plastic will shrink and seal the joint tightly.

Applying a bandage

Such repairs are performed for punctures, ruptures, or cuts in the hose. A bicycle inner tube is used as a bandage, as it can stretch well.

Expert opinion

Alena Tsarevskaya

Subpage for an expert

If during repairs you take a chamber of smaller diameter than the hose and glue it, this will allow you to tighten the joint more tightly and firmly.

Repairs are carried out in the following order:

- Cut off the damaged area.

- Clean and degrease the cuts.

- Prepare a piece of bicycle tube 80-100 mm.

- Place this piece further than the damaged part.

- Apply glue to the ends of the cuts and the surface at the junction.

- Put the camera on, completely covering the joint.