There are several reasons for the popularity of insulated Swedish stoves in private housing construction. Reliable Scandinavian technology reduces the impact of frost heaving forces from the ground, perfectly accumulates heat, and the installation of USF in comparison with other types of foundations is one of the fastest.

In addition, a slab foundation with a ready-made concrete base does not require screeding, is immediately prepared for final finishing and is 20–30% cheaper than other types of foundation, if you take into account the heated floor and built-in communications.

We will tell you about the main points that you need to pay attention to when arranging the USP: from preparing the foundation and laying communications to reinforcement and concreting.

Features of foundation construction.

- Basic information about the Swedish foundation slab

- Necessary work for organizing a Swedish slab foundation

- Making a reinforced concrete Swedish slab

- About the Swedish slab foundation technology

The construction industry, like other industries, is constantly improving its work. New technologies and new materials are being created. The construction of any building or structure begins with the foundation. It can be strip, pile, columnar or tiled. These are standard types of base, and they have existed for quite a long time, but recently a type of base has appeared, such as a Swedish plate. Most people build buildings on their own and make a Swedish slab foundation with their own hands.

Laying a Swedish slab.

Swedish stove diagram.

Basically, in the past, owners preferred a strip base, but it requires a large amount of cement and various devices and suitable conditions. Today, Swedish foundation slabs are very popular.

Thermal insulation methods

Concrete block foundation: sand cushion, blocks.

In addition to the option that involves constructing a foundation pit using liquid concrete mortar, there is another way to insulate a home. It is due to the fact that instead of mortar, individual concrete blocks are placed in the pit. They are ready-made material for the foundation, which is already reinforced and pressed into rectangular slabs. They can be columnar (have a regular rectangle in cross-section) and ribbon. They are concrete blocks in the form of trapezoids. The wide base of such slabs allows them to withstand enormous loads on the foundation and soil.

Basic information about the Swedish foundation slab.

Today, such a foundation is considered the most economical, as it is made from energy-saving slabs. For residents of our country, the technology is new, but has long been tested in Europe.

The climate of European countries is similar to our Russian one, and builders have long paid attention to this type of foundation. In recent years, almost all houses are built according to designs by European builders and often with their own hands. The cost of such a foundation is not small, but there are many advantages from installing it.

Properties of Swedish foundation slabs:

Drawing of a Swedish stove.

Drawing diagram of a Swedish stove using Russian materials.

- it doesn’t take much time to lay such a foundation with your own hands;

- The technology for manufacturing such a base is very easy, and the work does not require additional complex equipment, does not require much physical effort, and does not require additional building materials. Another important advantage is that the price also includes pipes and all necessary communications;

- When the slabs are poured and hardened, it is possible to obtain a finished floor that is not only smooth, but also warm. Then you can connect the heating and lay any floor coverings;

- the foundation is made using the latest hydro- and thermal insulation materials with already built-in heated floor systems, which means the house will always be warm and less money will be spent on heating.

What are the disadvantages of USP?

For all its advantages, this design also has disadvantages: [1] It is problematic to install USP in areas with a slope. In principle, this is possible, but the site will need to be leveled by adding sand, and this is a very expensive undertaking. [2] It is impossible or unreasonably expensive to create a basement or cellar in a house located on the USP. [3] Communications are laid inside the slab, and therefore their repair in the event of an emergency is either impossible or difficult.

Dmitry Andriadi, head of the BAUHAUS company: “If water is poured into the underfloor heating system integrated into the USHP, and in winter it freezes during a power outage, the pipes will break and it will be impossible to repair them. You will have to dismantle the floor covering, install a new heated floor on top of the existing one, perform a screed, and lay a new floor covering. Therefore, it is better to initially fill the heating system with antifreeze. But if the heated floor is damaged, for example, when drilling with a hammer drill, then local repairs are quite possible. As for the pipes of water supply and sewerage systems, accidents that could completely disable them are unlikely.”

We recommend reading: Protective layer of concrete for reinforcement: standard thickness, restoration methods

Let us note a few more features of USP. One- or two-story houses are most often supported on such a foundation. But if there is a well-thought-out design calculation, it is possible to construct a USP under heavy buildings (more than two floors) or under houses with an uneven load (when part is one-story and the other is two-story). USP assumes a low base. The height of the foundation is usually 300-400 mm. This is convenient, because at the entrance to the house you can make a staircase just a couple of steps high. The most comfortable, almost barrier-free environment. This solution is especially relevant when elderly people or people with disabilities live in the house. If you absolutely need a high base, you should prefer another Scandinavian know-how - an insulated Finnish foundation (UFF). This is a shallow strip foundation with insulated floors along the ground. The solution to the problem of a low base within the USP is to increase the thickness of the sand cushion and/or the thermal insulation layer under the slab. But these are additional costs.

Necessary work for organizing the foundation is a Swedish slab.

Before you start making this base, you need to carefully think through everything and prepare everything.

All work is carried out comprehensively, there should be no mistakes.

If the planned building is small in size, then everything can be calculated independently and done with your own hands. The main thing is to take into account that all communications correspond to the project.

Basic parameters of the Swedish slab foundation:

Scheme of pouring the foundation slab.

Scheme of pouring the foundation slab.

- the thickness of the overall slab is made by casting reinforced concrete and should be from 120 to 180 mm;

- along the entire perimeter it is necessary to make stiffening ribs of at least 300×300 mm, they will be the foundation for the load-bearing walls;

- Under all future walls, internal stiffeners are made at intervals of 1.5 to 4 mm. Reinforcing strips must be at least 200×200 mm in size;

- The depth of the foundation can be any, it all depends on the wishes of the owner, so you need to think about the base in advance. To do this, it is necessary to make the foundation deeper, which means that the first floor will be lowered.

Laying communications

In the sand cushion, in accordance with the developed scheme, communication pipes are laid with the embeds brought to the surface. During the work process, it is necessary to ensure reliable fixation of pipes in space using reinforcement and clamps in order to exclude the possibility of their displacement during the process of pouring concrete and other operations for laying USP.

A crushed stone fill with a layer height of 100 mm is formed under the future foundation. It is advisable to use crushed stone of the middle fraction, with an element size in the range of 20-40mm.

About the foundation technology of the Swedish slab.

Scheme of a concrete slab with a reinforced screed.

Scheme of a concrete slab with a reinforced screed.

- First, dig a shallow pit, the size of which is slightly larger than the area of the building. Often its depth can be about 2 m, this is quite suitable for a ground floor. It is necessary to make additional recesses for the internal and main walls. This is necessary to create stiffeners;

- then pour an even layer of sand. Sometimes geotextiles are laid on it. With its help, water passes well, but sand is retained perfectly. Typically, the sand layer should be from 10 to 15 cm. Everything must be thoroughly compacted;

- A drainage system and utility lines are laid on top of the sand. This includes water supply, electricity supply, and sewerage. Everything should be removed with reserve and should also be well protected from clogging;

- Next, an even gravel layer is laid. Everything needs to be compacted carefully again to get a dense and even surface. When compacting, you need to use water, that is, first pour water over the layer, and then compact everything again;

- the next layer is foam. It is laid in two layers, and in the middle there is waterproofing. In this case, you need to use a polymer film. You can simply lay a layer of polystyrene foam on the ground. Typically, the thickness of the thermal insulation is about 20 cm, but in place of the stiffeners it can be about 10 cm;

- Pipes are laid on a layer of foam plastic. This is necessary for installing water floors. The pipes need to be inflated with air so that they do not become wrinkled when the concrete is poured;

- Then I lay out reinforcement and mesh on the pipes. This will make the foundation more reliable;

- When the preparatory layers are ready, you can pour concrete and then level everything.

The technology for laying a Swedish slab foundation is not complicated, and you can do everything yourself. You just need to prepare all the building materials and study the execution technology.

What is a Swedish stove and how to lay it.

Before starting to build a house, you need to choose a reliable foundation. It is important that the solution is rational and optimal and allows you to make a foundation for a house at minimal cost. One of the popular options for private housing construction is the “insulated Swedish stove” (abbreviated as USP). The technology for constructing this foundation allows you to simultaneously perform several actions that are required when building a foundation with your own hands.

At the end of this article there is a video with instructions on how to build a Swedish slab foundation with your own hands.

What is a Swedish stove?

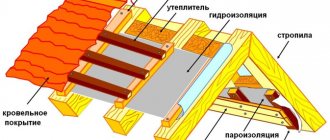

The technology for manufacturing USPs has been used relatively recently. The process of use in Europe has begun. The structure is an insulated monolithic slab in which the main communications and a water floor system are laid. The manufacturing technology of such a foundation allows you not to worry about the occurrence of frost heaving forces, which are so feared by any type of foundation. Foundation structure:

Swedish slab foundation.

Installation of an insulated Swedish stove.

The construction of an insulated monolithic slab (USP) does not have any significant differences in manufacturing from a conventional one. This type of foundation has the following advantages:

- Possibility of installation of heated floor slabs and other communications in the structure. This greatly simplifies the process of building a house. There is no need to arrange a technical underground, where water supply and sewerage pipes are usually laid. Due to this, not only the costs of work are reduced, but also their duration.

- USP allows you to reduce the cost of operating a house. In addition to installing a heating system, the technology provides for the installation of insulation, which prevents a decrease in the temperature in the premises. The foundation allows you to retain heat inside the house and not let it sink into the ground.

- The walls are protected from dampness due to the absence of conditions for condensation. Due to this, they are not afraid of mold, mildew and rot. The Swedish slab foundation allows you to increase the durability of the entire house.

- This support part is suitable for almost all types of buildings with different geological site conditions. Due to the fact that the foundation is not buried in the ground, the influence of the groundwater level on it is excluded. The monolithic slab has a high load-bearing capacity, so the technology is suitable both for the construction of light frame and wooden buildings with your own hands, and for massive brick houses.

- Preventing frost heaving. This phenomenon makes the foundation especially vulnerable because it leads to uneven shrinkage of the foundation. Heaving occurs when simultaneously exposed to two factors: moisture and negative temperatures. Having gotten rid of at least one of them, you don’t have to worry about the safety of the structures. A monolithic insulated Swedish slab (USP) is a foundation that prevents the soil from cooling in winter directly under the building site. This is due to the fact that there is a water heating system in the floor, which, although separated from the ground by a layer of insulation, still gives off some of the heat to it.

- The evenness of the slab surface allows the flooring of the first floor to be laid without additional measures. This allows you to simplify finishing work, reduce the cost and time of building a house.

- The construction of the foundation does not require heavy equipment. An insulated slab, like other monolithic options, allows you to carry out work without the use of cranes. In addition, the non-buried option does not involve serious development of the soil: it is enough to just remove the fertile layer of soil, the depth of which is 20-30 cm (the work can be done with your own hands) and tamp it.

- The structure always has the same temperature. USHP does not have freeze-thaw cycles, which lead to a limited service life of house elements.

USHP: expensive or not?

The disadvantages of this foundation include its high cost. Indeed, USP from specialized companies costs an average of 9,000 rubles. up to 11,000 rub. per m2. That is, the cost of a foundation with an area of 100 m2 is approximately a million rubles. This is a lot of money! But let's look at an alternative option, which at first glance seems budget-friendly. We choose a different type of foundation for a stone house, for example, a strip foundation. We add to it the cost of drainage, insulated blind area, all engineering systems, ground floor slabs, heated floors and leveling screed, as well as the costs caused by the stage-by-stage implementation of work (involving specialized specialists for each operation, multiple purchases and deliveries). As a result, the total costs will be significantly higher than the costs of USP. If you have to pay 1 million rubles for USP, then the “tape” with all the “extras” made by a specialized company will cost 1.3 - 1.5 million rubles. You can view projects of aerated concrete houses and request a full estimate for them in the YTONG free projects catalog

Selection of thermal insulation material.

Before starting work, it is important to choose high-quality insulation so that problems with the foundation do not affect you. To ensure normal temperature and humidity conditions and retain heat in the volume of the house, USHP will require an effective heat insulator with low thermal conductivity.

The building materials market offers a wide variety of insulation materials, but usually only one type is suitable for foundation work - extruded polystyrene foam (Penoplex). The other two materials from the top three in popularity cannot be used for the following reasons:

Swedish plate foundation construction technology.

Scheme of an insulated Swedish stove.

- mineral wool is not resistant to moisture, its use for the underground part of the house is unacceptable, since when wet it shrinks and ceases to perform its functions;

- polystyrene foam is an inexpensive material that does not have high strength, and the foundation is constantly subjected to increased loads and transfers them to the foundation soil.

Insulation of Swedish foundation slab with polystyrene foam.

Insulation of the foundation and blind area with polystyrene foam.

The advantages of extruded polystyrene foam include:

- durability;

- resistance to rot, mold and mildew;

- resistant to moisture, characterized by low water absorption;

- some manufacturers produce types that are classified as low-flammable materials (fire resistance during foundation construction is of little relevance, since the insulation is protected on one side by a layer of concrete, and on the other by soil);

- safety for humans, the material does not emit harmful substances and does not lead to diseases;

- increased strength (compared to foam plastic) allows it to withstand loads from people, furniture and equipment.

It is important not to allow the thermal insulator to come into contact with chemical compounds or solvents. It decomposes when exposed to this.

Construction technology.

To make a reliable USHP foundation with your own hands, you must carefully follow the technology and order of laying materials. The most important component of the structure is concrete. You can order it from the factory or prepare it yourself (the first option is preferable). For the installation of USHP, it is recommended to use concrete of classes B20-B25, the exact value depends on the load. To avoid problems, it is important to learn how to properly pour concrete before starting the process. It is worth remembering the most important thing: pouring a monolithic reinforced concrete slab is carried out in one step, otherwise the structure will not work as a single whole. More details about this can be found in the video instructions at the end of the article.

Laying a Swedish slab.

The process of laying a Swedish slab.

Construction is carried out in the following order:

- Removal of the fertile soil layer (on average 20-30 cm).

- Laying a sand-gravel cushion, which includes sand of medium or coarse fraction (the use of fine sand is not permissible). The thickness is selected depending on the characteristics of the foundation soil. It is important to perform compaction correctly using a compaction platform or weights.

- Laying "Penoplex".

- Installation of a drainage system made of pipes with holes laid in a layer of crushed stone. The distance from the drainage to the foundation is taken to be no more than 1 meter.

- Installation of formwork is carried out using slab and side elements.

- The structure must be reinforced with meshes, the diameter of the rods is at least 12 mm in increments of 100 or 200 mm, depending on the load (the greater the mass of the house, the smaller the spacing of the rods). The exact diameter and pitch are selected by calculation based on load-bearing capacity. When installing reinforcement, it is necessary to raise it to provide a protective layer of concrete (70 mm). Special plastic clamps are used for lifting.

- After the fittings, underfloor heating pipes are laid, which are connected to the distribution unit.

- Concrete is poured, after which you will need to wait 2-3 weeks before further work begins.

This video clearly presents instructions for constructing a USP, describes the pros and cons, and gives feedback from the builders.

The structure will gain full brand strength after 4 weeks.

In the first weeks, concrete needs constant moisture (every 2-3 hours), which will prevent shrinkage cracks from appearing.

On-site preparation

The entire layer of plant-soil or silty soil is completely removed, after which a sand cushion is formed from sand of medium fractions. The use of crushed stone for these purposes cannot provide any practical advantages, except for increasing the cost of work.

In the process of forming the pillow, it is necessary to maintain a thickness of at least 400 mm, and also to ensure the presence of a horizontally level finished surface. As a result, on slopes the thickness of the cushion in different parts may not be the same.

A drainage system is created along the perimeter of the future foundation slab, and the base itself is covered with geotextile before filling with sand. To ensure the necessary reliability, it is necessary to provide a 150mm overlap at the joints of the rolled material. The backfill itself is carried out layer by layer with compaction every 150mm (pouring, vibrating plates).

How does a Swedish slab foundation work and what are its advantages?

The Swedish slab foundation is a shallow monolithic slab that occupies the entire base area of the house and is insulated around the perimeter. A heated floor system, which is considered the most effective in the field of heating private construction, is directly connected to it.

The foundation is Swedish plate technology.

Schematic cross-sectional representation of the Swedish slab foundation.

It is effective on all soils, with any occurrence of groundwater, and can be installed with your own hands.

Area of possible application of UVF

When considering the technical characteristics of the foundation of a Finnish slab of insulated construction, we can talk about its acceptable use in all climatic zones of Russia, for any type of soil during the construction of buildings with a weight load of up to 3 tons per 1 linear meter of strip foundation.

This characteristic will correspond to the majority of frame-type buildings being erected with a height of up to 2 floors.

When increasing the support cushion of a strip foundation, it is allowed to increase the weight of building structures to 4-5 tons, but in this case, a mandatory verification calculation is required using the method of strip foundations.

Advantages and disadvantages of the Swedish stove.

As reviews show, a foundation of this type has its positive and negative sides. Among the advantages of the design are the following:

- speed of slab installation. On average, it takes up to two weeks to produce;

- the surface of the structure turns out to be perfectly flat, so it can serve as the floor of the first floor, which does not require additional leveling;

- the level of heat loss in the house is reduced due to the presence of insulation along the entire perimeter of the slab;

- the insulation located in the thickness of the structure “cuts” cold bridges, which also improves the protection of the room from the cold;

- communications can be laid in the foundation, which improves the aesthetic appearance of the building;

- heating the soil under the slab eliminates problems caused by the possibility of soil heaving in winter;

- To work with the foundation, you do not need any other equipment other than a concrete mixer.

The foundation is Swedish slab.

The construction of the foundation is Swedish slab.

The USP foundation also demonstrates disadvantages, including:

- the impossibility of constructing a structure on excessively heaving soils;

- the inability to save on building a house, since the ushp slab is quite expensive;

- the technology is not designed for multi-story buildings made of heavy materials: brick and stone.

Despite the higher cost of a Swedish stove compared to a conventional monolithic structure, a device of this type allows you to save on home heating. A comparative calculation shows that the technology pays for itself within ten years of operating the house.

Field of application of UVF

Studying the technical characteristics of an insulated foundation made of Finnish slabs, we can confidently say that such a structure can be used in areas with different climatic conditions, is suitable for any soil composition, and can withstand loads of up to three tons per linear meter of strip foundation.

Each of the given characteristics corresponds to the majority of frame-type structures under construction, the height of which reaches two floors.

By increasing the supporting base of the foundation strip, it is possible to add the mass of the building structure at the rate of four to five tons. But in this case, it is necessary to perform a mandatory verification calculation using the strip foundation method.

Foundation manufacturing technology.

The Swedish stove is installed according to the following steps:

- First, a shallow pit is developed. Calculation of its width should include the size of the house along the perimeter plus a little allowance on each side. Recesses are also made for load-bearing walls.

- The pit is covered with an even layer of sand. In some cases, geotextiles are appropriate. It allows water to pass through but retains the sand layer. Its thickness should be 10-15 cm.

- The layer of sand is carefully compacted. Drainage and water supply, sewer and electrical communications are laid on top of it. It is necessary to allow a small margin for their length.

- A layer of gravel is laid to cover the pipes. It must be compacted so that the monolithic reinforced concrete slab is perfectly level. To do this, the layer of material is moistened with water.

- Two layers of polystyrene foam are laid, between which waterproofing is laid. You can use a polymer curling iron. The insulation layer should be 20 cm.

- The pipes of the heated floor system are laid on top of the foam. In order for them to retain their volume when poured with concrete, they should be inflated with air.

- Reinforcing mesh is laid out.

- The multilayer structure is immediately poured with concrete and immediately leveled.

Following the technology of multi-layer cake, a Swedish stove with your own hands is quite feasible and does not require the involvement of specialists.

The foundation is Swedish plate technology.

Construction of a Swedish slab foundation (video).

Rules for foundation reinforcement.

To ensure that the slab retains its rigidity and shape throughout its entire service life, reinforcement is used. Before starting work, it is necessary to calculate the rods and prepare them for operation, as well as the wire for connecting the intersections of the rods.

It can have a cross-section with a diameter of 4 to 8 mm. It is necessary to cut pieces of it into 20 cm pieces. The amount of reinforcement is calculated based on the rule that the distance between its rods is from 20 to 40 cm.

The material should not be rusty or have the slightest deformation in its structure . To bind the Swedish slab, it is necessary to use two layers of reinforcement. The first is located at a height of 5 cm from the bottom of the pit, and the second is located just below the level of the formwork.

To tie the rods together, you should use a special hook or a tying gun. If you plan to build heavy walls of a house, you can also use welding. It is important to securely fix the corners of the ligament. To construct a Swedish stove, it is better to use ribbed rods with a cross section.

They are tied with wire, in a figure eight knot. To prevent the insulated Swedish plate from deforming, you must try to ensure that the bond is as strong as possible. It is important to remember that the rods should not come into contact with the ground, as this can cause corrosion.

How to make a calculation?

If you plan to build a “buffet wall” for a small building, then you can calculate the parameters yourself, adhering to the following parameters:

Swedish stove diagram.

The foundation layers are Swedish slab.

- the thickness of the overall slab is made by reinforced concrete casting and should remain within the range of 120-180 mm;

- along the perimeter of the base it is necessary to equip stiffening ribs no less than 30x30 cm. They will become the basis for load-bearing walls;

- internal stiffening ribs are erected under the walls of the house along the entire perimeter in increments of 1.5 to 4 m;

- the size of the reinforcing strips must be no less than 200×200 mm;

- The foundation can have different depths. If a basement room is planned, the pit can reach 2 m;

- the slab is reinforced with a steel rod with a diameter of 10-14 mm and a cell of 20×20 m; Two-layer reinforcement is produced, with a distance between layers of more than 100 mm. It is necessary to ensure that the reinforcement mesh is completely absorbed by the concrete.

Insulation of the foundation.

Foundation technology involves integrating a heated floor system into it. To make an insulated Swedish stove possible, you must follow the following rules for installing heating pipes:

- the pipe arrangement must be dense, and along the outer walls a higher density is required than in the middle of the slab;

- in order to balance the flow of pipes and ensure optimal heat transfer, the distance between them must be at least 10 cm;

- to ensure uniform distribution of heat flows, the distance between the pipes should be no more than 25 cm; temperature changes on the floor should not exceed 4 degrees, then they will not be felt by the foot;

- heating pipes must be laid in the foundation at least 15 cm from the external walls;

- It is recommended to calculate the length of pipes so that it is not more than 100 m, because excessive length leads to hydraulic losses.

Recommendation: Not a bad review article, from it you will learn about the foundation technology of the Swedish slab. In reality, the technology is simple and accessible. But you don’t need to pretend to be a smart guy or a smart girl, it’s better to turn to specialists. They will make competent and correct calculations. As a result, you will not lose your money.

Warm floor

The diameter of the pipes used to install heated floors is 16-20mm. In this case, a smaller diameter is used in cases where the total length of the created loop does not exceed 70 meters. If its length is longer, then a transition to wider pipes is required.

In places where load-bearing wall structures will be located in the future, pipes are placed in special sleeves with a length of about 400-500mm.

At the same time, preparations are being made for the installation of collectors in accordance with the existing house-building plan. To do this, reinforcement with a diameter of 12 mm (2-4 rods) is driven into the right place, released on the surface at a distance of 1.5 meters. A board is attached to the reinforcement for subsequent installation work. The joints with supply pipelines require additional installation of protective corrugation.

After forming the heated floor contour, it is necessary to fill it with water and conduct a full test. If no defects are found and the heated floor is operating normally, it is pressure tested.