In recent years, living in a wooden house has become a fashionable trend. And there are reasons for this. For example, living in it is quite comfortable and at the same time wood is an environmentally friendly building material. If earlier life in a wooden house was associated with many inconveniences, now it is comfort and the use of innovative technologies. The heating system occupies a special place in the house. Some people refuse the idea of hiring qualified specialists who charge quite a lot of money for their heating services. For this reason, they decide to make heating for a wooden house with their own hands. We will look at the basic principles of installing a heating system, as well as possible options for how and from what it can be made.

Features of heating and its types

Heating installation

One important factor should be taken into account, which directly affects the choice of heating type. The tree, after a short time, loses its natural moisture and, accordingly, dries out. This will entail some consequences, namely settlement of the house. For this reason, the type of heating should be chosen individually in each case. It is first necessary to carry out careful calculations, as well as draw up a project that can facilitate installation work. One mistake in incorrect calculations can lead to the most unexpected and unpleasant consequences, for example, burst pipes or complete defrosting of the system. If the electrical heating calculations are carried out incorrectly, then the matter may end in a short circuit. And if you chose an air system, then it will be impossible to fix anything. The choice of heating type will be directly influenced by the available energy source. Today the following can act as an energy carrier:

- Liquid fuel.

- Electricity.

- Solid fuel.

- Gas.

Based on this, you can select the “heart” of the entire heating system of a wooden house - the boiler.

Material selection

Well-fired solid clay bricks are used to construct the furnace. It is possible to use ordinary building solid bricks made of clay, provided that the firebox is lined with refractory bricks. The masonry mortar is made from oily clay with the addition of fine sand.

The part of the chimney located above the roof level must be made of sand-lime brick with cement mortar. The temperature of the flue gases in this area of the chimney is already low, and exposure to heat and atmospheric moisture (as well as exposure to wind and precipitation) will quickly destroy the clay brick.

For the manufacture of doors, grates, and valves, finished cast iron products are used, produced at enterprises specializing in the production of such products.

Choosing a boiler is an important planning milestone!

If your closest source of energy is gas, then depending on the size of your home, you should purchase a wall-mounted or floor-mounted boiler. These boilers are equipped with a built-in pump, as well as special protection. If you do not have a chimney, you should choose a boiler in which the combustion chamber is closed. And to remove air from the boiler, you can use a coaxial pipe. This method will allow you to save money on chimney installation. Moreover, the wall-mounted gas boiler is automatic. If the system volume exceeds 100 liters, then it is recommended to install a second expansion tank. In case of heating, it will also compensate for pressure. This will prevent the pressure in the boiler from rising as the temperature rises proportionally.

Installation of a wall-mounted double-circuit gas boiler

If gas is not available to you, then you can use electricity. In this case, you should purchase an electric boiler with automation. It already has a built-in expansion tank and pump. To prevent the negative impact of power surges on the boiler, it is recommended to additionally install a voltage stabilizer. It is quite possible to design a practical heating system using an electric boiler.

Electric boiler

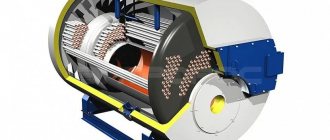

There is another option for heating a house - solid fuel boilers. For such boilers it is necessary to create special operating system conditions. In some cases, the operating temperature of the coolant at the outlet can be up to 100° C, so you should carefully select the pipes. For example, you can use plastic pipes. But in this case a special decoupling is required.

Long-burning solid fuel boiler

When you have decided on the type of boiler, you should select radiators and pipes for a particular heating system of a wooden house. Based on the fact that the quality of metal pipes has deteriorated significantly in recent years, you can choose metal-plastic or polypropylene. As for radiators, their choice directly depends on what kind of heat transfer you would like to receive. You should also pay attention to the interior. Some types of radiators would fit perfectly into the overall idea of the whole house. In wooden houses, the radiators will most likely be connected using the bottom connection, since hiding the pipes in the wall with the top connection will be problematic. So, the pipes will pass under the floor and exit only near the radiator. It is important to correctly calculate the number of sections in a particular room. As a rule, the calculation is based on the following indicator: 1 section per 1.5 sq. m. Once you have calculated the number of required sections, as well as the radiators themselves, all you have to do is design the heating system.

Electricity: simple, convenient, but unprofitable?

Electric heating is perhaps the simplest, most convenient and fastest way to heat a wooden house. It is environmentally friendly and its operation is easily automated. Options for implementing electric heating using various equipment are possible: electric boiler plus batteries, convectors, IR heaters, film heating, warm baseboard. The initial investment in any of the above equipment is much less than in a gas or liquid fuel heating system.

But there are many “buts”. First, there must be good new wiring designed to withstand high loads. Otherwise, by turning on the electric heating, you risk, at a minimum, being left without light for some time, and at maximum, putting out a fire. Secondly, the effectiveness of such systems, whatever one may say, leaves much to be desired. And thirdly, the cost of electricity in relation to the heat received from it is very high. So this option for heating a wooden house can be reasonable only in two cases: when visiting the home occasionally (on weekends, on vacation, during vacation) and to “back up” the main system.

Electric convectors are affordable, compact, environmentally friendly and hygienic devices for heating a wooden house

Installation work

Gas heating

In most cases, the most affordable heating is gas. As mentioned above, the first step is to design the layout of the entire heating system. Thanks to it, you can find out exactly how much building materials you will need. The success of all your work will depend on the correctly chosen scheme. The use of water as a coolant is based on its circulation throughout the system. Before warm water enters the pipes, it is heated in the boiler. The heat is then distributed throughout the heating system. Water can move through the system in two ways: forced and natural. This is what will determine which heating scheme you choose. The circuit can be designed as either a two-pipe or a single-pipe. If you choose a forced system, then you can make a two-pipe circuit. Each of these schemes has its own differences and features. Let's consider how to install a two-pipe and one-pipe heating system in a wooden house.

Types of thermal media

To transfer heat from the generator to the heated room, water is most often used, which has been heated to a certain temperature and circulates through a pipeline.

Today this is the most affordable and simple solution. By correctly calculating the number of radiators and the power of the boiler, you can organize a high-performance system that does not require any special care.

In addition to water heating, in a private wooden house the following is used:

- air;

- oven;

- electric.

A combination option is also often used. A well-designed scheme makes it possible, without spending a lot of money, to build a system that will completely warm up the house in a matter of hours.

If water is used as a heat transfer agent, it must first be filtered. This will significantly increase the service life of heating equipment

Single pipe system

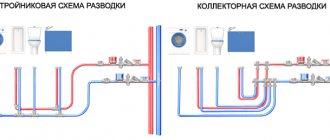

Single-pipe connection diagram

Now we will analyze the option of installing a single-pipe heating system in a two-story wooden house. However, it is immediately worth noting the fact that its use has not only advantages, but also disadvantages. So, as for the disadvantages, the lower radiators tend to heat up less. This will result in different air temperatures on each floor. Such a system will significantly save building materials. And in order to make the temperature in each heated room the same, you just need to add sections to the radiator. The pump can increase circulation if it is mounted at the cold water inlet.

If a natural heating system is being installed, then it is important to install the boiler at the lowest point in relation to the radiators. Otherwise there will be no circulation. It is absolutely necessary to install the expansion tank. This will increase the efficiency of the entire system.

The main problems with furnaces with a water circuit.

The main problem with furnaces with a water circuit is the other side of the coin of its main advantage. Water, being a good coolant, heats up quickly and transfers heat well. And metal conducts heat well...

This is why furnaces with a water circuit cool down quite quickly. It is a well-known fact that for effective heat transfer and heating of a house, a certain surface temperature is needed. So, a stove with a water circuit gives this temperature during heating and for a short time after. Then the following happens.

The stove, having a water circuit inside, cools down quite quickly, with some exceptions (some models). And the pipes themselves, due to the above characteristics, give off heat quite quickly and also cool down.

A familiar story - a stove with a water circuit is fired twice a day, if not more. But for me, twice a day is already too much to fire up the stove. So it’s better to install two stoves in the house, there will be less hassle, and the effect (efficiency) from firewood will be greater. I'm not kidding…

But quickly cooling down and firing the stove “like at work” twice a day is not so bad...

Such intensive use of the furnace—frequent firing—leads to accelerated destruction of the furnace masonry. Old hydronic furnaces look old not because of their age, but rather because of their essence. They are constantly oiled, because they are constantly drowned, the masonry collapses and cracks. I have a friend who heats her stove in cold weather without stopping... She has a stove with a water circuit.

The third problem arises when the register is installed not in the firebox, but, for example, in the hood. When lighting such a stove, when the coolant has cooled down, a large volume of condensate occurs. According to our calculations, during the first heating of such a furnace, up to 2 liters of condensate leaks into the furnace! If you do not make special devices for collecting condensate, this stove will always get wet...

And this is fraught with constant problems with lighting the stove, huge amounts of soot on the register and rapid clogging of the stove.

Two-pipe system

Two-pipe scheme

Using this heating system, you can easily achieve the same heating for each installed radiator. But unlike a single-pipe system, in this case large financial costs will be required. Each battery must be equipped with shut-off valves that will control the temperature in each individual battery. This heating scheme in a wooden house is used in most cases when gas heating is available. In such a house, you can immediately attach the batteries to the wall or to a pre-installed block. A two-pipe system is installed with a solid fuel boiler.

Self-installation

To make your own stove heating, you need to think through everything down to the smallest detail in advance so that you don’t have to solve unforeseen problems later. It is necessary to calculate the thermal power of the future furnace and the amount of material required.

Where to place

If you plan to install a brick stove in a house under construction, you need to determine its location on the plan so that it can heat as large an area as possible. The ideal location would be approximately in the center of the house at the junction of several partitions. In this case, the chimney will be able to heat the premises of the second floor or attic.

For more efficient heating of the rooms on the upper floor, holes are provided in the ceiling for the circulation of heated air. There must be at least two such holes in the ceiling within one room - one near the stove, the other on the opposite side.

Electric heating

If in your case schemes using gas boilers are not available, then you can use electricity as a coolant. There are a large number of options for creating heating. For example, you can make a heated floor, which is purchased with ready-made mats and installed during the floor installation process.

Electric heated floor

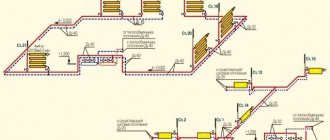

You can also use an electric water boiler. Metal-plastic pipes Ø16 or Ø20 cm are laid from it. They are mounted on a heat-insulating layer. As for the scheme itself, here you can choose a combined or spiral one.

Water heated floor

From the collector pipe, a contour should be drawn from the wall at a distance of ten centimeters. The next contour should be located at a distance of forty centimeters from the first. This gap is necessary in order to mount the return line. Thus, the pitch between the supply and return pipes will be twenty centimeters.

The pipes are secured to a special mesh using fasteners. Once the entire system is ready and all pipes have been laid, it should be checked. This can be done in two ways. For example, you can pour water under pressure. If a leak is detected, then it should be repaired immediately. Another option is simpler; for this, air is pumped into the system. At the location of the leak, the air will make noise as it exits, and you will notice a leak.

It is necessary to produce high-quality thermal insulation of the floor.

Important Tips

Choosing a heating mechanism for your wooden house is a responsible matter, and this is already clear from the previous section. It is necessary to take into account many details, not forgetting about various theoretical and practical aspects. But besides purely technical issues, you should pay attention to simpler and more vital tips. Like, for example, these:

- Before making your final choice, it is better to consider not just one or two, but all heating options. In addition to those described here, there are even exotic methods of heating rooms - quartz heating, etc. And what if this is the right one?

- User reviews are a really valuable thing. Hearing real stories from people about which heating was right for them in their specific circumstances allows you to see your situation in a brighter light and make decisions with more confidence.

- Heating is very important, and its importance cannot be overestimated, but even the best system can show low efficiency if the walls and roof are poorly insulated. So first you should take this seriously and remove all the shortcomings.

You cannot independently carry out not only installation of equipment, but also other work related to its operation - replacement of parts, etc. This is not a question of safety alone - a specialist will install the system so that the efficiency is maximum.

The issue of an alternative heating source also deserves attention. This is not often talked about, but many have probably heard how their neighbors or friends’ gas boiler suddenly stopped working in the middle of winter.

Gas systems are not repaired as quickly as we would like, and the situation turns out to be very unpleasant and even dangerous. You have to either go live in some other place (if there is one), or buy heaters - and the wiring may not be able to withstand such a quantity of them, plus the energy costs are huge.

But if an electric boiler was initially installed in the house as an alternative heating option, then the problem is solved on the same day. The equipment itself is inexpensive, so it can be installed without much burden on the budget with any other heating system that is planned to be used as the main one.

The good old method of stove heating

Stove heating

Stove heating is one of the old means of heating indoor air. This type of heating today can be made on the basis of solid fuel, as well as using electricity. The latter is an innovative solution. In this case, heat comes from heat generators with forced and natural draft. Many people associate stove heating with wood. One of the modern developments of this kind involves a project for a fireplace and a brick stove, for example, “Buleryan”. However, in addition to firewood, you can use other heat sources, such as coal.

When installing stove heating, it is important to take into account all the instructions of SNIP. In this case, it is recommended to use it for heating a one-story and two-story house, not counting the basement. The surface of the furnace should not be allowed to heat up to temperatures above 1200° C.

When building such a heating system, you will most likely need the help of a qualified specialist, since not everyone knows how to properly lay out the firebox.

A more complex water heating system using wood

It is a pyrolysis boiler. which consists of two sections. In the lower section, firewood is burned, and in its upper part, the gas generated during combustion circulates. Due to the fact that in this design, gases do not immediately enter the chimney, its efficiency is higher, and such a boiler consumes less firewood.

It is tied with thick-walled pipes through which water circulates, heated by the boiler.

It is necessary to take into account that for the normal functioning of such a boiler, it is necessary to use only dry firewood. If the farm has a pyrolysis boiler, then there should also be a supply of well-dried firewood.

There are systems that use hot air rather than water for heating. It passes along the circuit and is supplied to the living quarters. Cooled air, according to the physical law of convection, falls down, enters special air intakes and again enters the boiler.

Subtleties of radiator selection

Radiators are one of the most important components of the system. After all, they distribute heat throughout the living space. Therefore, their choice should be taken with full responsibility, and not buy the first product you come across.

Batteries are divided into categories depending on their design and the material from which they are made. Since a wide assortment can drive an unprepared buyer into a dead end, before going to the store it is necessary to understand the advantages and disadvantages of each type.

Tubular radiators made of steel

Tubular batteries, as a rule, are classified as products in the highest price segment. They fully comply with all quality standards and have a number of advantages over their analogues.

First of all, such structures can easily withstand sudden changes in pressure, and in the event of a heat cut, the battery will not become air-filled.

Also, tubular radiators have a smooth surface both outside and inside. Thanks to this, they have an attractive appearance, due to which they will harmoniously fit into any interior.

Tubular steel radiators are an expensive proposition. But at the same time, they last for about a quarter of a century, which completely pays for the costs.

Cast iron

Cast iron radiators were first used more than a century ago. But even today they have not lost their relevance and are actively installed in heating systems.

The reason for this is its ease of maintenance and simply enormous service life - cast iron will faithfully last for about 50 years. At the same time, it retains heat well. The products take a long time to heat up, but after turning off the heating they will heat the room for a long time.

Taking into account all their advantages, cast iron appliances have only one insignificant disadvantage - they are heavy. Thus, the weight of one section can reach 6 kg, and the weight of the entire battery can be 36 kg.

Even in comparison with bimetallic and aluminum products, cast iron structures are a good and universal solution with many advantages

Panel steel radiators

Steel is an excellent heat conductor. Therefore, batteries made from it are considered the most effective and are recommended for installation by all specialists. In addition, they are a monolithic structure, which greatly simplifies installation.

Provided that steel radiators are used in a house or country house with an autonomous heating system, they have no disadvantages. If all recommendations are followed, the service life can reach 30 years.

Batteries of this type are often supplemented with heat exchangers. But this in no way affects the appearance of the structure.

Aluminum structures

Such products appeared in Italy more than 35 years ago. Since their invention, aluminum heating radiators immediately became popular and won the recognition of professionals.

When choosing a heating radiator, first of all you should familiarize yourself with the material of the sections. The heat transfer of the battery, its service life and weight depend on it

And this is not at all surprising, because these structures are distinguished by their lightness, high heat transfer, and attractive design. But they are poorly resistant to corrosion and are susceptible to airing.

Aluminum batteries can be cast or extruded. The first type is a monolithic structure, and the second is a blank formed by a press, from which finished products are subsequently cut.

Cast structures are considered more reliable and durable. In other respects, their analogues are in no way inferior to them.

Aluminum batteries are relatively lightweight. This makes them easy to transport and connect, something you can do yourself

Bimetallic structures

These types of batteries are made from an alloy of aluminum and steel. These metals have completely different characteristics, and as a result of their combination, a material with excellent performance is obtained.

More precisely, these radiators show high thermal conductivity and can easily withstand water hammer. If assembled with high quality, bimetallic products last about 50 years. But they are quite expensive.

Even despite the high price, it is better to spend money once and buy a bimetallic radiator from a reliable supplier. Thanks to its long service life, it will fully justify the investment.

Built-in floor convectors

This heating device is a tube made of copper and aluminum through which the coolant moves. The main advantage of floor convectors is the ability to build them directly into the floor.

In this case, the structure does not take up precious residential square meters, but at the same time warms the building well. The only thing that comes out is the decorative grille or panel.

If installation is carried out incorrectly, drafts may form inside the room. In addition, you need to carefully monitor the cleanliness of the heating element - air flows carry dust well.

It is better to choose a floor convector made of copper, steel or aluminum. In this case, the structure will last a long time, and the house will warm up almost instantly

Cast iron stove

Cast iron stoves, although small in size, are capable of heating a fairly large room with a volume of up to 80-90 cubic meters. meters. This option will be ideal for a country house, since the device has a hob function. Thanks to their elegant design, today they are also happily installed in expensive mansions, as they are an interior decoration.

Cast iron heating stove

The best option of all cast iron models is a long-burning stove. It is capable of transferring heat into the room for a long time, despite the fact that firewood is placed in it once during the entire heating period. This effect is achieved due to the internal design of the furnace, which allows the active flame to be reduced to slow smoldering.

A long-burning boiler-stove can also have a water circuit.