Two types of heating

One of the differences between an open heating system and a closed one is the presence of a leaky expansion tank.

It is into this that excess water enters during expansion. The liquid from this reservoir constantly evaporates and needs to be periodically replenished. The design of an open-type heating system is not complicated. It includes elements such as:

- large diameter pipes;

- boiler for solid, liquid or gaseous fuel;

- radiators;

- expansion tank.

The boiler is located at the lowest point of the system and heats the water. The heated liquid expands, then enters the pipeline under pressure and then moves to the radiators, where it is partially cooled. Rising to the highest point, where the expansion tank is located, the coolant begins to move downwards towards the heater. Natural circulation occurs rather slowly. Sometimes the open type of heating is upgraded with an electric pump.

Today, the closed type of heating is more popular. This system is completely sealed. In addition to the main elements, it uses one or more electric pumps.

The expansion tank must be installed in a place convenient for maintenance

This system is characterized by a special membrane expansion tank. It is a high-strength steel container, divided in half from the inside by a rubber partition. One part is filled with inert gas, and excess water enters the other. As the liquid expands, it fills the tank. It presses on the membrane and compresses the gas. When the pressure decreases, the coolant is pushed back into the pipe.

More details about open and closed expansion tank:

Which heating system is better - open or closed - depends on the room in which it will be used. Each type has its own pros and cons. When choosing the appropriate type, you need to take into account the location and installation conditions, desires and possibilities, as well as many other nuances. For example, if there is no electrification in the house, only an open type is possible, and when using an electric boiler, a closed type is possible.

Filters

Mud filters are essential elements of modern heating systems. When installing mud filters, it is important to take into account the rules for their installation, since it is during installation that mistakes are often made. It is also important to remember to clean them from time to time. Sometimes it is enough to install one dirt filter into a closed heating system. It is installed on the section of the main line through which all the coolant passes. Such a place could be, for example, the area in front of the main circulation pump.

Basic rules for installing mud filters:

- It is preferable to install the filter on horizontal sections of the pipeline.

- When installing the filter, it is important to ensure that the direction of movement of the coolant coincides with the marks marked on the body of the device.

- The tap branch, equipped with a screen, nut (or drain cock), should be located at the bottom.

- The dirt filter must be installed in a place that is easily accessible for maintenance.

- Shut-off valves (half-turn valves) should be installed at the inlet to the filter, as well as at the outlet.

Autonomous heating systems

The water that fills the boiler, pipes and radiators expands when heated. The pressure inside rises sharply. If you do not provide for the possibility of removing the additional volume of water, the system will rupture. Compensation for changes in water volumes when temperature changes occurs in expansion vessels. As the temperature rises, excess water moves into the expansion vessel. As the temperature decreases, the system is replenished with water from the expansion vessel.

- The open system is constantly connected to the atmosphere through an open expansion vessel. The vessel is made in the form of a rectangular or round tank. The form doesn't matter. It is important that it has sufficient capacity to accommodate the additional volume of water resulting from the thermal expansion of the circulating water. The expansion vessel is located in the highest part of the heating system. The vessel is connected to the heating system by a pipe called a riser. The riser is attached at the bottom of the tank - to the bottom or side wall. A drain pipe is connected to the top of the expansion tank. It is discharged into the sewer or outside the building. A drain pipe is needed in case the tank overflows. It also ensures a constant connection between the tank and the heating system and the atmosphere. If the system is filled with water manually using buckets, the tank is additionally equipped with a lid or hatch. If the tank capacity is selected correctly, the water level in the tank is checked before turning on the heating. The water pressure in an “open system” is equal to atmospheric pressure, and does not change when the temperature of the water that circulates in the system changes. No overpressure safety device is required.

- A closed system is isolated from the atmosphere. The expansion vessel is sealed. The shape of the vessel is chosen so that it can withstand the greatest pressure with minimal wall thickness. Inside the vessel there is a rubber membrane that divides it into two parts. One part is filled with air, the other part is connected to the heating system. The expansion vessel can be installed at any point in the system. As the water temperature increases, the excess enters the expansion vessel. The air or gas in the other half of the membrane is compressed. As the temperature decreases, the pressure in the system decreases, water from the expansion vessel under the action of compressed air is forced out of the expansion vessel into the system. In a closed system, the pressure is higher than in an open system and constantly changes depending on the temperature of the circulating water. In addition, the closed system must be equipped with a safety valve in case of a dangerous increase in pressure and a device for releasing air.

Open heating system

District heating

Water for central heating is heated in a central boiler room or thermal power plant. This is where the expansion of water with temperature changes is compensated. Next, hot water is pumped into the heating network by a circulation pump. Houses are connected to the heating network by two pipelines - direct and return. Having entered the house through a direct pipeline, the water is divided in two directions - for heating and for hot water supply.

- Open system . The water goes directly to the hot water taps and is discharged down the drain after use. An “open system” is simpler than a closed one, but in central boiler houses and thermal power plants it is necessary to perform additional water treatment - purification and air removal. For residents, this water is more expensive than tap water, and its quality is lower.

- Closed system. The water passes through the boiler, giving off heat to heat the tap water, connects with the heating return water and returns to the heating network. The heated tap water flows into the hot water taps. A closed system, due to the use of heat exchangers, is more complex than an open one, but tap water is not subject to additional processing, but is only heated.

Closed heating system

The terms “open system” or “closed system” do not apply to the entire central heating system of a city or town, but to each house individually. In one central heating system it is possible to connect houses with both an “open system” and a “closed system”. Gradually, open systems should be supplemented with heat exchangers and turn into closed systems.

Repair and construction Comment

Why are they called closed or closed?

The pump creates a slight increased pressure in front of the fluid and a vacuum behind the impeller. If the system has an open expansion tank and atmospheric pressure, then it is possible that the liquid will simply pour out of it or other hydraulic troubles will occur... For normal operation, there must be a slight increased pressure in the system, the norm is 1.5 - 2.0 atm for an unheated state .

To maintain increased pressure, the system is closed and a closed-type membrane expansion tank is used, one half of which is initially pumped with air to a pressure of 1.3 - 1.4 atm. Now, during thermal expansion, the liquid does not escape “into the pan”, but its excess part compresses the air in the tank and the pressure in the system increases slightly. The heating system turns out to be closed (closed).

Prices: summary table

| Manufacturer and model | Maximum CO power, kW | Response pressure, bar | Thread diameter, inch | price, rub. |

| TIM JH-1024-1.5 | 50 | 1,5 | 1″ BP | 990-1 200 |

| VALTEC VT.460.0 | 44 | 3 | 1″ BP | 1 650-1 800 |

| Watts KSG 30 | 50 | 3 | 1″ BP | 2 600-3 400 |

| Caleffi 302631 | 50 | 3 | 1″ BP | 4 500-4 750 |

Open heating system.

The easiest type of network to install and with acceptable efficiency. In addition, it has a fairly low price.

This system can operate both on the principle of forced circulation of coolant (with a pump) and as a gravity circuit.

In the second case, the movement of the liquid will be determined by a number of physical laws and the angle of inclination of the pipes.

We recommend: Cooling towers of open and closed types: their design, operating modes, photos

The operation of an open network consists of two stages that constantly follow each other:

- Supply of hot coolant from the boiler to all appliances.

- "Return." All excess liquid is sent to the expansion tank and cooled back into the boiler.

Scheme of an open heating system

In an open heating system, you can use both a single-pipe and a two-pipe heating scheme. In the first case, both processes occur in one pipeline, and in the second, supply and return are carried out in pipes separated from each other.

The simplest single-pipe open-type system includes the following parts:

- Boiler for heating the coolant.

- Heating devices (batteries)

- Open type expansion tank

- Pipeline

In a two-pipe open network the pipeline footage has been increased due to the creation of separate supply and return circuits.

But at the same time, liquid of approximately the same temperature is supplied to each battery, and thus the main disadvantage of the single-pipe circuit is eliminated.

It is also worth choosing how circulation will occur throughout the entire system, either it will be natural circulation or a forced circuit with a circulation pump.

Circulation pump in the heating system

Considering the gravitational and forced open heating supply schemes, it is worth noting:

- With a gravity flow circuit, the circulation of the coolant occurs due to its expansion when heated. In addition, there must be an element such as an accelerating riser (its height must be more than 3.5 m). In the second type, a circulation pump is installed to increase the efficiency of the system. Under its influence, the fluid speed increases by 0.4-0.6 m/s and more uniform heating of the heating devices occurs. However, it is worth remembering that the operation of the pump is due to the presence of electricity.

- The use of a gravity system should be used in rooms up to 60 square meters. m. The recommended pipeline length is no more than 30 m. And the presence of an accelerating riser is required. The operating conditions of the compulsory scheme are not so strict. In addition, you can create a combined network in which, when the pump is turned off, gravity circulation will occur.

When installing an open heating system, you need to consider the following:

- For good coolant circulation, the boiler should be installed at the lowest point of the network (usually the basement), and the expansion tank as high as possible (usually the attic). However, you should not forget that in cold weather the attic must be insulated.

- The liquid level in the open expansion tank will constantly decrease as a result of its evaporation into the environment. As a result, air jams may appear, reducing the performance of the network. That is why it is necessary to constantly monitor its level.

- Since the system is open to evaporation of the coolant into the environment, for safety it is worth using only water (for example: antifreeze evaporation is toxic).

- Laying the pipeline should be done with a small number of turns and with a minimum of connecting elements.

- In winter, when the system is turned off, the water should be drained from it. To prevent damage.

Recommendations for use

The expansion tank is installed as high as possible, in the attic, which is not heated. The tank is open, constant access of oxygen is provided. Constant monitoring of the tank level helps prevent air pockets in the pipeline. It is necessary to ensure that the water heats up slowly as the water circulates slowly. If you bring the temperature to the maximum (boiling point), there is a risk of rapid wear of the entire heating system. If you do not use heating in winter, you must drain the coolant to preserve the pipes, radiators and boiler.

Installation recommendations

Installation of an open heating system must be carried out strictly according to the instructions, otherwise there will be a risk of leaks and freezing of water in winter. We present the following recommendations:

- It is necessary to install the boiler as low as possible in relation to pipes and heating appliances;

- It is necessary to insulate the expansion tank when installing in the attic. This prevents the water from freezing;

- Due attention is paid to the slope when installing the pipeline;

- It is recommended to avoid numerous bends, elbows and bends;

- It is important to use the least amount of connecting elements;

- A pipe with the largest diameter is installed at the outlet of the boiler.

It is important to choose the correct pipe section:

- If the area of the house is 50-100 sq. m - you need to use pipes with a diameter of 40 mm. The larger the total area of the heated room, the larger the diameter.

- The pipes that go to the radiators have a similar diameter to the riser. The pipes that lead to the radiators may have a smaller cross-section.

- The recommended slope of horizontal pipes is 0.005-0.01%. It is carried out from the boiler towards the radiators.

Advantages/disadvantages of an open system

The main advantages of an open system are:

- Uniform heating. Heat is supplied to all heated rooms, creating a comfortable and cozy atmosphere.

- Quiet operation. Achieved due to the absence of a circulation pump.

- Long-term operation. The pump may fail; it does not exist in an open system.

- Independence from electricity. Will not be disturbed by network fluctuations or complete power outages.

Open systems have become less popular. One of the reasons is the following disadvantages:

- High prices for equipment. An open system uses large diameter pipes.

- Difficult installation. It is necessary to calculate the slope of horizontal pipe sections.

- There is a risk of water freezing in an open expansion tank.

- Danger of corrosion of pipes and radiators. An open expansion tank allows oxygen to enter the system.

- Changing the coolant level. Constant monitoring of the expansion tank is required.

- Inability to use antifreeze.

- Long time to heat up.

Dependent heat supply systems

Dependent heat supply systems are systems in which the coolant through a pipeline enters directly into the consumer’s heating system. There are no intermediate heat exchangers, heating points or hydraulic insulation. There is no doubt that such a connection scheme is understandable and structurally simple. It is easy to maintain and does not require any additional equipment, for example, circulation pumps, automatic regulation and control devices, heat exchangers, etc. Most often, this system attracts with its, at first glance, cost-effectiveness.

However, it has a significant drawback, namely, the inability to regulate heat supply at the beginning and end of the heating season, when excess heat appears. This not only affects the comfort of the consumer, but also leads to heat loss, which reduces its initially apparent efficiency.

When energy saving issues become relevant, methods for transitioning a dependent heat supply system to an independent one are developed and actively implemented, this allows heat savings of about 10-40% per year.

Independent heating systems

Independent heat supply systems are systems in which the heating equipment of consumers is hydraulically isolated from the heat producer, and additional heat exchangers of central heating points are used to supply heat to consumers.

An independent heat supply system has a number of undeniable advantages. This:

- the ability to regulate the amount of heat delivered to the consumer by regulating the secondary coolant;

- its higher reliability;

- energy-saving effect, with such a system heat savings are 10-40%;

- it becomes possible to improve the operational and technical qualities of the coolant, which significantly increases the protection of boiler installations from contamination.

Thanks to these advantages, independent heat supply systems have become actively used in large cities, where heating networks are quite extensive and there is a large variation in heat loads.

Currently, technologies for reconstructing dependent systems into independent ones have been developed and are being successfully implemented. Despite significant investment, this ultimately has its effect. Naturally, an independent open system is more expensive, but it significantly improves the quality of water compared to a dependent one.

Closed heating system: differences from an open one.

Diagram of a closed heating system

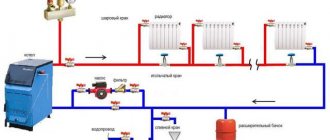

This network includes the following elements:

- Boiler for heating coolant

- Air vent valve

Air vent operating diagram - Thermostatic valve

- Heating devices (radiators, heated floors, etc.)

- Pipes

- The expansion tank is a closed type, that is, sealed from the environment

Expansion tank of a closed heating system - Balancing valve

- Ball valve

- Pressure gauge

- Connecting elements

The main difference between a closed and open heat supply system is that with a closed type, the coolant is completely isolated from the environment.

Circulation pump in a closed heating system

This system has a built-in pump to facilitate fluid circulation. Such a scheme eliminates a large number of disadvantages that are present in open heating.

Recommendations for use

The membrane-type tank is sealed, which prevents evaporation of the coolant. This means that antifreeze can be used. Its use makes it possible to leave your home for a long time in winter: the risk of freezing and damage to the system is reduced to almost zero.

Installation recommendations

To ensure proper functioning of a closed heating system, we recommend adhering to the following tips:

- The expansion tank is installed directly indoors. At the same time, the costs of pipeline elements are reduced and the coolant does not freeze.

- Using pipes of smaller diameter does not mean that you need to install pipes with a minimum cross-section. This method of saving money can have a destructive effect on the entire heating system. There is a risk of increasing pressure in the pipeline, and the pump may not be able to cope with this.

- Particular attention must be paid to the correct installation of the pump. The rotor is located horizontally relative to its own axis. This contributes to silent operation and less friction with the coolant.

- The circulation pump and expansion tank are installed in front of the boiler entrance.

Advantages/disadvantages of a closed system

The main advantages of a closed system are:

- Easy to install the system.

- Lower cost of heating structure. This is achieved due to the possibility of using pipes with a smaller diameter.

- There is no need to control the coolant level. The tightness of the expansion tank does not allow the coolant to evaporate.

- Ability to regulate temperature. This occurs when the amount of coolant supplied increases/decreases.

- Possibility of floor heating. A special additional element is connected to the heating system.

A closed heating system has one significant drawback. The system depends on the electrical supply. Constant power consumption must be ensured. You will have to purchase backup power supplies in case of an emergency. The best option is liquid fuel power plants.

Rating of popular models

Among the manufacturing companies involved in the development of safety valves, the following popular companies can be distinguished: Watts and Valtec. The manufacturer Watts is famous for its fairly extensive range of devices for the heating system, among which the safety unit occupies an important place.

The KSG series has various threaded body devices, differing in their sizes (from standard to compact) and material of manufacture:

- cast iron;

- steel;

- brass.

Additionally, some models come complete with heat-insulating casings. Units from the KSG line are typically equipped with a relief valve designed for a critical pressure of 3 bar. Installation into the heating main is carried out using a 1-inch diameter connector with internal thread.

The KSG model range from Watts, designed for operation in a boiler room with heat generators with a capacity of 50-200 kW

Valtec is not inferior in quality to its products to the previous brand. The company presents a line of devices for boilers and expansion tanks - the VT 460 and VT 495 series, respectively.

The VT 460 model range is designed to operate with domestic heating units with a power of up to 44 kW, at a maximum pressure of 3 bar. However, the prices for ready-made devices are far from cheap, so the solution of self-assembly of such a unit can be called advisable.

Valtec develops protective blocks designed for all types of heat generators. A characteristic feature of the VT 460 series is the packaging of safety group modules in a compact brass housing

Expansion tank for closed heating system

The expansion tank is designed to compensate for changes in coolant volume depending on temperature. In closed heating systems, this is a sealed container divided into two parts by an elastic membrane. At the top there is air or inert gas (in expensive models). While the coolant temperature is low, the tank remains empty, the membrane is straightened (picture on the right).

Operating principle of a membrane expansion tank

When heated, the coolant increases in volume, its excess rises into the tank, pushing back the membrane and compressing the gas pumped into the upper part (in the picture on the left). This is displayed on the pressure gauge as an increase in pressure and can serve as a signal to reduce the combustion intensity. Some models have a safety valve that releases excess air/gas when a threshold pressure is reached.

As the coolant cools, the pressure in the upper part of the tank squeezes the coolant out of the container into the system, and the pressure gauge readings return to normal. That's the whole principle of operation of a membrane-type expansion tank. By the way, there are two types of membranes - disc-shaped and pear-shaped. The shape of the membrane does not affect the operating principle in any way.

Types of membranes for expansion tanks in closed systems

Volume calculation

According to generally accepted standards, the volume of the expansion tank should be 10% of the total coolant volume. This means that you must calculate how much water will fit in the pipes and radiators of your system (it is in the technical data for radiators, and the volume of the pipes can be calculated). 1/10 of this figure will be the volume of the required expansion tank. But this figure is only valid if the coolant is water. If non-freezing liquid is used, the tank size is increased by 50% of the calculated volume.

Here is an example of calculating the volume of a membrane tank for a closed heating system:

- the volume of the heating system is 28 liters;

- expansion tank size for a system filled with water 2.8 liters;

- the size of the membrane tank for a system with non-freezing liquid is 2.8 + 0.5 * 2.8 = 4.2 liters.

When purchasing, select the nearest larger volume. Don't take less - it's better to have a small supply.

What to look for when purchasing

There are red and blue cans in stores. Red tanks are suitable for heating. The blue ones are structurally the same, only they are designed for cold water and cannot tolerate high temperatures.

What else should you pay attention to? There are two types of tanks - with a replaceable membrane (they are also called flanged) and with a non-replaceable one. The second option is cheaper, and significantly, but if the membrane is damaged, you will have to buy the whole thing. For flanged models, only the membrane is purchased.

Place for installing a membrane type expansion tank

Usually they place an expansion tank on the return pipeline in front of the circulation pump (if you look in the direction of flow of the coolant). A tee is installed in the pipeline, a small section of pipe is connected to one part of it, and an expander is connected to it through fittings. It is better to place it at some distance from the pump so that pressure differences are not created. An important point is that the piping section of the membrane tank must be straight.

Installation diagram of an expansion tank for membrane-type heating

A ball valve is installed after the tee. It is necessary to be able to remove the tank without draining the coolant. It is more convenient to connect the container itself using an American nut. This again makes installation/disassembly easier.

Please note that some boilers have an expansion tank. If its volume is sufficient, installing a second one is not required.

The empty device does not weigh much, but when filled with water it has a significant mass. Therefore, it is necessary to provide a method of mounting on the wall or additional supports.

Circulation pump

The circulation pump ensures the operation of the closed heating system. Its power depends on many factors: the material and diameter of the pipes, the number and type of radiators, the presence of shut-off and thermostatic valves, the length of the pipes, the operating mode of the equipment, etc. In order not to go into the intricacies of calculating power, the circulation pump can be selected according to the table. Select the nearest larger value for the heated area or the planned thermal power of the system, and find the required characteristics in the corresponding line in the first columns.

You can select the parameters of the circulation pump from the table

In the second column we find the power (how much coolant it can pump in an hour), in the third - the pressure (system resistance) that it is able to overcome.

When choosing a circulation pump in a store, it is advisable not to save money. The entire system depends on its performance. Therefore, it is better not to save money and choose a trusted manufacturer. If you decide to buy unknown equipment, you need to somehow check it for noise levels. This indicator is especially critical if the heating unit is installed in a residential area.

Strapping scheme

As mentioned earlier, circulation pumps are installed mainly on the return pipeline. Previously, this requirement was mandatory, today it is only a wish. The materials used in production can withstand heating up to 90°C, but it’s still better not to take risks.

In systems that can also operate with natural circulation, during installation it is necessary to provide for the ability to remove or replace the pump without the need to drain the coolant, as well as for the possibility of operation without a pump. To do this, a bypass is installed - a workaround through which coolant can flow if necessary. The installation diagram of the circulation pump in this case is shown in the photo below.

Installation of a circulation pump with bypass

In closed systems with forced circulation, a bypass is not needed - without a pump it is inoperative. But two ball valves on both sides and a filter at the inlet are needed. Ball valves make it possible, if necessary, to remove the device for maintenance, repair or replacement. The dirt filter prevents clogging. Sometimes, as an additional element of reliability, a check valve is also installed between the filter and the ball valve, which will prevent the coolant from moving in the opposite direction.

Connection diagram (piping) of a circulation pump to a closed-type heating system

How to tie solid fuel boilers

The connection diagram for a wood-burning heat generator is designed to solve 3 problems (in addition to supplying the batteries with coolant):

- Preventing overheating and boiling of the TT boiler.

- Protection against cold “return” and excessive release of condensate inside the firebox.

- Work with maximum efficiency, that is, in full combustion mode and high heat transfer.

The presented wiring diagram for a solid fuel boiler with a three-way mixing valve allows you to protect yourself from condensation in the firebox and bring the heat generator to maximum efficiency mode. How it works:

- While the system and heater are not warmed up, the pump drives water through the small boiler circuit, since the three-way valve is closed on the radiator side.

- When the coolant heats up to 55-60 degrees, the valve set to the specified temperature begins to mix in water from the cold “return”. The heating system of a country house is gradually warming up.

- When the maximum temperature is reached, the valve completely closes the bypass, all water from the TT boiler goes into the system.

- A pump installed on the return line pumps water through the jacket of the unit, preventing the latter from overheating and boiling. If you put the pump on supply, the chamber with the impeller can fill with steam, pumping will stop and the boiler is guaranteed to boil.

The principle of heating using a three-way valve is used for piping any solid fuel heat generators - pyrolysis, pellet, direct and long-term combustion. The exception is gravity distribution, where the water moves too slowly and does not provoke condensation. The valve will create high hydraulic resistance, preventing gravity flow.

If the manufacturer has equipped the solid fuel unit with a water circuit, the coil can be used for emergency cooling in case of overheating. Please note: the fuse on the safety group is triggered by pressure, not temperature, and therefore is not always able to protect the boiler.

A proven solution is to connect the DHW coil to the water supply through a special thermal relief valve, as shown in the diagram. The element will be triggered by a temperature sensor and at the right moment will pass a large volume of cold water through the heat exchanger.

Using the Buffer Capacity

The best way to increase the efficiency of a TT boiler is to connect it to heating through a buffer tank. At the inlet of the heat accumulator we assemble a proven circuit with a three-way mixer, at the outlet we install a second valve that maintains the required temperature in the batteries. Circulation in the heating network is ensured by a second pump.

A balancing valve on the return line is needed to adjust the performance of the pumps

What we gain thanks to the thermal accumulator:

- the boiler burns at maximum and reaches the declared efficiency, fuel is used efficiently;

- the likelihood of overheating is sharply reduced since the unit dumps excess heat into a buffer tank;

- the heat accumulator plays the role of a hydraulic arrow; several heating branches can be connected to the tank, for example, radiators of the 1st and 2nd floors, floor heating circuits;

- a fully heated tank maintains the operation of the system for a long time when the wood in the boiler firebox has burned out.

TT boiler and storage water heater

In order to load an “indirect” boiler using a wood heat generator, you need to embed the latter into the boiler circuit, as shown in the picture. Let us explain the functions of individual elements of the circuit:

- check valves prevent the coolant from flowing in the other direction along the circuits;

- the second pump (it is enough to take a low-power model 25/40) provides circulation through the spiral heat exchanger of the water heater;

- the thermostat turns off this pump when the boiler reaches the set temperature;

- An additional air vent prevents the supply line from becoming aired, which will be above the standard safety group.

In a similar way, you can connect the boiler to any boiler that is not equipped with an electronic control unit.

Date: September 25, 2021

Types of communications by type of circulation

Types of water circulation in a heating system

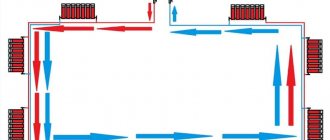

In open and closed lines, the coolant can move in two ways.

Natural circulation

The system is organized without a pump and operates on the difference in liquid density during heating and cooling. The coolant is heated in the boiler, becomes less dense and light, and as a result is directed upward. In a cold state, water moves through the outlet riser - a pipe with a large diameter. Along the wiring and to the heating devices, the coolant moves from top to bottom, cooling as heat is released.

When cold, the density of water increases and it is directed to the heating tank. The pipeline is installed at an angle. The system is characterized by energy independence - it can be used in a private home or in a country house. Among the disadvantages of natural circulation:

- complexity of installation due to large diameter pipes;

- unaesthetic appearance;

- the need to periodically top up the coolant;

- small area of heated rooms.

The system uses a leaky open container.

Forced circulation

A circulation pump is used for communications, activating the movement of water. The system is characterized by simplicity of arrangement, advanced capabilities and small pipe diameter. The user regulates the temperature himself or sets it automatically. The disadvantage of forced circulation is energy dependence.

Pressure water

| Pipe diameter | Wall thickness | Price for 1 p.m. VAT included |

| TU 6-49-53883187-01-05 SDR 17 | ||

| 16 t | 2 | 13,75 |

| 20 t | 2 | 16,82 |

| 25 s | 2 | 21,46 |

| 32 s | 2,3 | 31,61 |

| 40 s | 2,4 | 41,76 |

| 50 s | 3 | 65,25 |

| 63 s | 3,8 | 103,96 |

| 110 s | 6,6 | 291,82 |

| 160 s | 9,5 | 608,82 |

| 225 s | 13,4 | 1206,46 |

| 315 s | 18,7 | 2349,49 |

| 400 s | 24 | 4114,22 |

Pressure water

Installation rules

Open expansion tank

The rules for connecting equipment and creating a system depend on its type.

Requirements for installation of an open system

When setting up you should:

- Select the lowest point for the heat source and the highest point for the tank.

- Use pipes with a large diameter for the movement of coolant.

- A narrow pipeline is necessary to normalize pressure.

- Install a high riser that will distribute the water evenly.

- Avoid a large number of turns, forks and connections.

- Install the system in a limited space - up to 159 square meters.

- In private households it is better to install a good circulation system.

The open system is suitable for a small country house or cottage.

Installation procedure for a closed system

Closed expansion tank

If a closed-type heating system with a pump and expansion tank is installed, you must:

- Place the boiler in the basement and the expansion tank in the attic.

- Ensure high-quality thermal insulation of rooms with a container and riser.

- Do not use a large number of shaped elements.

- Avoid overheating the water.

- Drain the coolant if the system does not start in winter.

- Form a pipe slope of 2-3 mm per 1 m of contour.

The principles for calculating the cross-section and slope of a closed heating pipeline are prescribed in SNiP 2.04.01-85.

For electrical cable

| Pipe diameter | Wall thickness | Price for 1 p.m. VAT included |

| TU 6-49-53883187-01-05 SDR 17.6 | ||

| 16 s | 2 | 9,43 |

| 20 s | 2 | 12,10 |

| 25 s | 2 | 15,48 |

| 32 s | 2 | 20,26 |

| 40 s | 2,3 | 27,71 |

| 50 s | 2,9 | 42,99 |

| 63 s | 3,6 | 63,88 |

| 110 s | 6,3 | 149,75 |

| 160 s | 9,1 | 315,88 |

| 225 s | 12,8 | 619,44 |

| 315 s | 17,9 | 1890,00 |

| 400 s | 22,7 | 3138,75 |

For electrical cable

Independent organization of the heating system

Boiler room arrangement

A good and high-quality heating option can be made with your own hands, if you take into account the costs of design, equipment purchases and the complexity of the organization. The best option for a private home would be a closed type of communications with a circulation pump and tanks. Its creation is carried out like this:

- Communication calculations. Ordered from a design company or produced using an online calculator.

- Coordination of the project, obtaining permits and technical conditions.

- Purchase of equipment. You will need a heating boiler, a pump, pipes, an expansion tank, radiators (circuits if you plan to have a heated floor), air vents, shut-off devices, and automatic controllers.

- Boiler installation and boiler room equipment. High-quality ventilation is organized in the room and a chimney is installed. The walls, floor and ceiling surfaces are sheathed with fire-resistant materials.

- Installation of a circulation pump, distribution manifold and measuring instruments.

- Pipeline connections to battery locations.

- Installation of radiators.

- Pressure testing of the system. The first launch is carried out in the presence of specialists.

The collector circuit is difficult to install and is expensive, but by adjusting the circuits, the living conditions in the room will be comfortable.

There are several differences between open and closed heat supply communications. It is worth choosing a heating system depending on the conditions and installation location. It is easy to organize an open highway yourself. Specialists must create a closed system.

Myth 1: classification according to the type of expansion tank

Closed systems are heating systems that use a closed (membrane) expansion tank.

Open systems are systems with an open expansion tank.

An expansion tank is needed in order to absorb excess coolant during its expansion, since as the temperature rises, the liquid increases in volume.

Without devices that absorb excess coolant, the pressure in the system increases, which sometimes leads to dire consequences, for example, a pipeline rupture and shut-off and control valves may fail.

An open expansion tank (Fig. 1) is not sealed - it is connected to air. It is mainly used in gravity heating systems of private houses. In such systems, liquid circulates without a pump, due to temperature differences.

Fig.1. Open expansion tank in a gravity heating system

A closed (membrane) expansion tank (Fig. 2) is a hermetically sealed metal container divided into 2 chambers by an elastic membrane. Hence the name “membrane”.

Rice. 2. Closed (membrane) expansion tank in the heating system

Equipment selection rules

For each model of the protective block, the accompanying documentation specifies the parameters for which it is designed.

The main criteria influencing the choice of device:

- thermal characteristics of the boiler for which the unit is designed, kW;

- maximum coolant temperature, °C;

- nominal pressure;

- compatibility with coolant - water, steam or antifreeze;

- diameter of the connecting thread - if there is a mismatch, it will be enough to purchase adapters of the required diameter.

Correct selection of the power of the safety unit ensures reliable protection of the boiler from any malfunctions in the operation of the heating circuit.

Myth 2: according to the type of connection of the building to heating networks

Closed systems (meant in this context) are building heating systems that are connected to external heating networks through a heat exchanger. That is, the consumer’s heating system is not connected in any way to external networks, hence the name “Closed”.

In fact, this type of connection is correctly called Independent (Fig. 3).

Fig.3. Scheme of independent connection of the heating system to heating networks

With this connection, the coolant from the source (CHP) circulates through the heat exchanger, giving off heat.

When designing the entire heating system of an object, for example, a residential apartment building, it becomes clear what type of heat exchangers is suitable: shell-and-tube, shell-plate, or it is necessary to buy a plate heat exchanger.

The heat exchanger is installed in the building’s individual heating unit (IHP).

Currently, this type of connection is replacing the outdated one - Dependent .

Open systems are heating systems connected directly to heating networks or through an elevator. In this case, the coolant comes from external heating networks to the end consumer, having previously passed through an elevator to lower the temperature.

The supply temperature in heating networks is 110-150 °C; such a hot coolant cannot be used in heating systems, as burns from radiators and pipelines will be possible.

The elevator, in addition to lowering the temperature of the coolant, performs one more function - it creates the pressure that is necessary for the movement of the coolant in the intra-house system (Fig. 4).

Fig.4 Diagram of dependent connection of the heating system

It would be correct to call such a connection – Dependent .