Have you thought about installing water heating in your home? It is not surprising, because a single-pipe heating system for a private house can be traditional and completely energy-independent or, on the contrary, very modern and fully automatic.

But you still have doubts about the reliability of this option - you don’t know which scheme to choose and what pitfalls await you? We will help clarify these issues - the article discusses schemes for arranging a single-pipe system, the pros and cons that await the owner of a house with such a heating system.

The article is provided with detailed diagrams and visual photographs depicting individual elements used in heating assembly. In addition, a video has been selected with an analysis of the nuances of installing a single-pipe system with heated floors.

The difference between one-pipe and two-pipe systems

Water heating systems are divided into two main types - single-pipe and double-pipe. The difference between these schemes lies in the method of connecting the heat-transfer batteries to the main line.

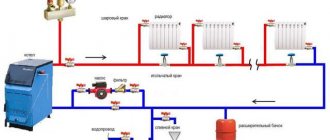

A single-pipe heating main is a closed annular circuit. The pipeline is laid from the heating unit, the radiators are connected to it in series, and lead back to the boiler.

Heating with one line is simply installed and does not have a large number of components, so it allows you to significantly save on installation.

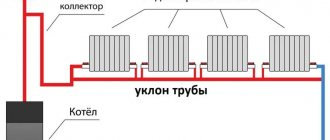

Single-pipe heating circuits with natural coolant movement are installed only with overhead wiring. A characteristic feature is that the diagrams have supply risers, but no return risers

The movement of the coolant of two-pipe heating is carried out along two lines. The first serves to deliver hot coolant from the heating device to the heat-transfer circuits, the second serves to drain cooled water to the boiler.

The heating batteries are connected in parallel - the heated liquid enters each of them directly from the supply circuit, and therefore has almost the same temperature.

In the radiator, the coolant releases energy and, when cooled, goes into the outlet circuit - the “return”. This scheme requires double the number of fittings, pipes and fittings, but allows you to arrange complex branched structures and reduce heating costs due to individual adjustment of radiators.

The two-pipe system effectively heats large areas and multi-story buildings. In low-rise (1-2 floors) buildings with an area of less than 150 m², it is more advisable to install single-pipe heating from both an aesthetic and economic point of view.

The two-pipe radiator connection scheme is not widely used in individual heating systems for private houses, since it is more difficult to install and maintain. In addition, double the number of pipes looks unaesthetic

Types of wiring

There are two ways to install a single-circuit system indoors:

- horizontal;

- vertical.

Thus, horizontal wiring involves the use of a minimum number of pipes. The components are connected in series. This may cause air pockets. In addition, there is no possibility to regulate the heat flow.

Vertical wiring involves laying a central line through the attic, from which pipes extend to each radiator. This method allows water to be delivered to the batteries at the same temperature. The main feature is a common riser for radiators, regardless of the number of floors of the building.

Options for single-pipe heating devices

Elements of any heating system:

- heat source – boiler (solid fuel, electric, gas boiler;)

- heat-releasing devices - radiators, underfloor heating circuits;

- a device that ensures circulation of the coolant - a special accelerating section of the main line, a water pump;

- a device that compensates for excess coolant pressure in the line - an open or closed expansion tank;

- pipes, fittings and related plumbing fittings.

Depending on the type of devices used, the heat supply scheme will also depend.

Image gallery

Photo from

Solid fuel heating unit

Electric boiler in an autonomous circuit

Gas floor boiler

Wall-mounted boiler for cottages and apartments

Systems with natural and forced circulation

The circulation of the coolant in the heating system can be carried out naturally - under the influence of physical phenomena, or forced - through a circulation pump.

In the first case, the heating movement through the system is spontaneous and is called natural, in the second - forced or artificial.

Based on design features, single-pipe heating schemes are divided into two types. The first is an outdated but simple flow circuit, the second is an improved circuit with bypasses

To ensure the movement of fluid in the gravitational system, an accelerating section is required. This is a vertical pipe extending from the boiler through which the heated coolant rises.

At the top point, the pipeline is smoothly turned down, so the water rushes along the pipeline with acceleration.

For a heating scheme with overhead wiring, as well as for two-story houses, the supply pipe serves as such a section, since it rises to a sufficient level.

To heat a one-story building with lower horizontal wiring, an accelerating manifold is installed, the height of which should not be less than 1.5 m from the level of the first radiator.

The acceleration section is a device that ensures the circulation of coolant in a gravity heating system. The bore diameter of the pipes of this section of the main must be larger than its main part.

For example, if the main pipe diameter is 25-32 mm, a pipe with a diameter of 40 mm is chosen for the accelerating manifold.

The upper point of the accelerating manifold is located in a convenient place near the boiler. Lower the manifold pipe in such a way as to ensure a sufficient height difference between the lower outlet of the accelerating manifold and the lowest point of the main to maintain a constant pipeline slope

The main advantages of the gravity system are complete energy independence (in combination with a solid fuel boiler), simplicity and the absence of complex instruments.

There are quite a lot of disadvantages:

- To minimize hydraulic resistance, pipe diameters must be large enough.

- Each built-in device and device creates obstacles to the movement of liquid, therefore the system has a minimum number of shut-off valves. This creates difficulties during repairs, as it requires a complete shutdown of the system and draining of the coolant from the main line.

- For reliable operation, the gravity system must be carefully calculated and balanced, selecting the optimal pipe diameters and the number of radiator sections. The outermost radiators in the system should be larger than those into which the coolant flows after leaving the boiler.

Installing a circulation pump in the system neutralizes almost all of its shortcomings. The device gives the coolant an additional impulse, allowing it to overcome the hydraulic resistance of pipeline elements.

Forced single-pipe heating schemes are most often implemented in private homes.

Thanks to the modernization of the flow system by installing bypasses, coolant at operating temperature is supplied to all devices almost simultaneously

The pump can be installed anywhere in the pipeline. But it is worth considering that hot water reduces its service life by affecting rubber parts (gaskets and seals).

Therefore, it is more advisable to install the unit on the return pipeline, where the cooled coolant circulates. Before it, it is mandatory to include a coarse filter to protect against possible contaminants.

It is advisable to connect all devices and devices of heating systems through shut-off valves and bypasses.

Such installation will allow repair and maintenance of individual elements without the need to stop the entire system and completely drain the water.

The bypass can be unregulated or adjustable. In the first case, it is a simple pipe connecting the supply and discharge pipelines. In the second - equipped with a three-way shut-off valve

Advantages of a heating system with forced circulation:

- You can implement more complex and branched circuits, increase the length of the circuits;

- There is no need for increased pipe diameters - the pump creates pressure in the line sufficient for movement and uniform distribution of liquid;

- Circulation is carried out at a given speed and does not depend on the degree of heating of the coolant and the presence of an accelerating section;

- There is no need to observe inclination angles when laying the pipeline, because... the movement of the coolant is stimulated by the pump.

In addition, you can install control devices on each radiator and maintain optimal heating mode, reducing energy consumption and heating costs.

There are only three disadvantages of single-pipe forced heating:

- dependence on electricity supply;

- noise - some hum that a running pump produces;

- cost - the cost of the device is higher compared to the gravitational circuit.

Neutralizing them is quite simple. Energy dependence is solved by installing an autonomous electric generator or by switching the system to a natural circulation mode.

To make the operation of the pump almost inaudible, it is enough to install it in a non-residential area - a bathroom, toilet, boiler room.

At the highest points of the line, especially with forced heating with a closed expansion tank, it is necessary to provide for the possibility of bleeding the air released from the water. For radiators these are automatic air vents or Mayevsky valves, for pipelines - an air separator

Open or closed heating system?

To prevent excessive increases in hydraulic pressure in the system and its surges, an expansion tank is installed. It accepts excess water during expansion, and then returns it to the main line when it cools, restoring the balance of the system.

There are two fundamentally different designs, which determine the appearance of the entire system.

An open type expansion tank is a partially or completely open container that is connected to the main line at its highest point, directly after the boiler.

To prevent liquid from overflowing over the edges at a certain level, a drain is provided through which excess water will be drained into the sewer or onto the street.

In one-story houses, the compensating tank is often placed in the attic - in this case it must be insulated.

In order not to constantly monitor the coolant level, water supply is connected to the expansion tank and a simple float valve is installed

A heating system with such a compensating device is called open. It is used when installing energy-independent or combined heat supply.

It involves direct contact of the hot coolant with air, resulting in its natural evaporation and saturation with oxygen.

Based on this, the open heat supply scheme is characterized by the following disadvantages:

- When installing the pipeline of gravity systems, it is necessary to observe slopes - in this case, the air released in the system will be vented into the tank and the atmosphere.

- It is necessary to regularly monitor and replenish the volume of water in the container in a timely manner, preventing its excessive evaporation.

- Antifreeze cannot be used as a coolant, as toxic substances are released when it evaporates.

The oxygen contained in the circulating fluid causes corrosion damage in the steel parts of heating devices, reducing their service life.

However, it also has its advantages:

- There is no need to constantly monitor pressure in the line;

- Even with small leaks, the system will properly heat the house as long as there is a sufficient amount of liquid in the line;

- You can even replenish the coolant in the system with a bucket - just pour the expansion tank into the water to the required level.

The closed-type expansion tank is a durable, sealed housing, the internal volume of which is divided into two parts by a membrane. One cavity is filled with air, the second is connected to the main line.

When heated, the coolant, increasing in volume, pushes the membrane towards the air chamber, which plays the role of a damper. As the water cools, the hydraulic pressure decreases and the compressed air balances the system, squeezing excess water back into the pipeline.

All closed tanks are equipped with an air valve. In emergency mode, when the pressure in the air chamber exceeds the permissible limit, it releases the gas and protects the device from destruction

A system with a membrane-type expansion tank is called closed. This is a closed hydraulic line completely devoid of air access.

A compensating tank can be built in anywhere in the system, but most often it is installed on the return pipeline near the boiler to increase ease of maintenance.

A closed heating system is characterized by the presence of slight excess pressure. Therefore, a security group becomes a mandatory element of the backbone.

The unit consists of an air vent, a pressure gauge and a safety valve for discharging the coolant in emergency mode. Mounted with shut-off valves on the supply pipeline to allow shutdown in case of repair.

If there is a rise in the pipeline, then it is located at its highest point.

Image gallery

Photo from

Security Group Components

Functional purpose of the device

Component location

Location specifics

Efficient single-pipe system design

When designing heating, many factors are taken into account - the availability of a stable power supply and a separate room for equipment (boiler room, boiler room), the number of floors and layout, the aesthetics of the future structure, etc.

In each individual case, the location of the equipment and methods of connecting it will be different.

For a very small room - a country house - the most effective will be a simple gravity flow scheme for sequentially connecting batteries directly into the main pipeline.

When installing two or three radiators, it is not necessary to install a large number of shut-off valves - in this case it is easier to drain water from the system if necessary.

In buildings with a larger area, the heat supply system is a complex, sometimes branched, structure. In this case, the best option is forced heating according to the “Leningradka” scheme with a diagonal connection of heat-transfer batteries and adjustable bypasses.

This scheme guarantees maximum heating of the radiator area and the ability to adjust and configure the operating mode. To disconnect any of the system elements, you do not need to drain the water from the entire line

We analyze the single-circuit heating scheme in a private house

When designing a detached property for living, one of the points is its heating. The same question arises when purchasing a ready-made structure. A single-circuit or multi-circuit heating system is installed in a private house. Others choose multi-circuit. It all depends on the size of the house, the type of system and the needs of the owner. The first option is most often used, since it is easy to install and requires fewer components. A boiler is used for heating, and water is used as a coolant.

Methods for connecting a radiator to the main line

The heat transfer of radiators depends on the method of their connection to the main line.

There are three main types of connection:

- Diagonal;

- Lateral;

- Lower.

Let's look at the features of each of these methods in more detail.

Diagonal or cross connection

Diagonal, or cross, connection is the most effective. Maximum heating of the battery area is achieved, and there is practically no heat loss.

According to this scheme, the supply pipeline is connected to the upper radiator pipe, and the outlet pipe is connected to the lower pipe located on the opposite side of the device. For devices with a large number of sections, only the diagonal connection type is used.

Lateral or one-sided connection

Lateral, or one-sided, connection allows for uniform heating of all sections of the device.

For connection, the supply and discharge pipelines are connected on one side. Most often, this connection is used for heating installations with overhead wiring.

Heating heat transfer when radiators are connected sideways, with supply from top to bottom, is 97%. With the reverse movement of the coolant - from bottom to top - this figure is 78%

Bottom connection of radiator with pipeline

Bottom connection is not the most efficient heating scheme. However, it happens quite often, especially when the main pipeline is hidden under the floor.

The inlet and outlet pipes are connected to the lower pipes located on different sides of the radiator.

The heat transfer rate with bottom connection of radiators is 88%

General provisions

Excessive reinforcing items affect the quality of the heating system and cause its elements to wear out faster. Loose pipes and connections (without clamps or clamps) last much longer. This must be taken into account when connecting batteries to the system.

It is also necessary to take into account that the entire heating system must be made of the same material: polypropylene, metal (of the same brand).

Connecting a single-pipe heating system is suitable for small cottages and apartments.

This closed system (see diagram) will heat a room in which no more than 10 radiators can be placed. The remaining heating devices will not make sense (even a large surface area), since as the distance increases, cooled water will simply reach them through the pipes.

Single-pipe systems are simple both in design and installation. They are more cost-effective and low-cost.

Connecting a heating radiator to a two-pipe system Connecting aluminum radiators Connecting an electric boiler to a heating system Scheme and steps for connecting a gas heating boiler to a heating system

Advantages and disadvantages of a single-pipe system

Single-pipe heating has gained wide popularity in the field of private construction.

The main reasons are the relatively low cost of the structure and the ability to install it on your own, without the involvement of specialists.

But a single-pipe heating system has other advantages:

- Hydraulic stability - the heat transfer of other elements of the system does not change when individual circuits are disconnected, radiators are replaced or sections are expanded;

- The construction of the main line requires a minimum number of pipes;

- It is characterized by low inertia and warm-up time due to the smaller amount of coolant in the line than in a two-pipe system;

- It looks aesthetically pleasing and does not spoil the interior of the room, especially if the main pipe is hidden;

- Installation of the latest generation shut-off valves - for example, automatic and manual thermostats - allows you to precisely adjust the operating mode of the entire structure, as well as its individual elements;

- Simple and reliable design;

- Easy installation, maintenance and operation.

When connecting control and monitoring devices to the heating system, it can be switched to a fully automatic operating mode.

Integration with the Smart Home system is possible - in this case, you can set programs for optimal heating modes depending on the time of day, season and other decisive factors.

A single-pipe heating line can be completely hidden with finishing. Such a device not only does not spoil the appearance of the room, but also becomes its detail - an interior item.

The main disadvantage of single-pipe heat supply is the imbalance of heating of heat-transfer batteries along the length of the main line.

The coolant cools as it moves along the circuit. Because of this, radiators installed far from the boiler heat up less than those located close to them. Therefore, it is recommended to install slowly cooling cast iron appliances.

Installing a circulation pump allows the coolant to warm up the heating circuits more evenly, however, if the pipeline is of sufficient length, significant cooling is observed.

The negative effects of this phenomenon can be reduced in two ways:

- In radiators remote from the boiler, the number of sections is increased. This increases their heat-conducting area and the amount of heat given off, allowing rooms to be heated more evenly.

- They draw up a project with a rational arrangement of heat-emitting devices in the rooms - the most powerful ones are installed in children's rooms, bedrooms and “cold” (northern, corner) rooms. As the coolant cools down, the living room and kitchen proceed, ending with non-residential and utility rooms.

Such measures minimize the disadvantages of a single-pipe system, especially for one- and two-story buildings with an area of up to 150 m². For such houses, single-pipe heating is the most profitable.

Features of operation

Boiler room in the house

In a single-circuit system of a private house, they try to use pipes of different diameters. This avoids disturbances in coolant circulation. If for some reason pipes of the same diameter are used, please note that the hydrodynamic pressure in the batteries will be higher than on the return line. This will definitely affect the deterioration of heating performance as a whole.

What can be done in this case? There is only one way out - install two taps, one of which is on the bypass, and the second is on the inlet pipe from the water supply.

The temperature of radiators can be controlled and regulated by installing a control valve on each device. It is better for this type of shut-off valve to be a three-way valve. It usually replaces two simple taps at once.

Conclusions and useful video on the topic

Not only radiators, but also underfloor heating circuits are connected to the single-pipe heating main. The video shows how to carry out such installation.

Single-pipe heating is a simple and reliable system. However, for effective heating it is necessary to carefully select its individual elements. To do this, it is advisable to seek advice from a specialist, who will help you perform an assessment calculation.

Do you disagree with the diagrams presented in our article? Or do you have practical experience in installing single-pipe heating in a private home? Your experience will be useful to our readers. Feel free to share your knowledge in the comments below.

Thermal calculation

Indoor comfort depends not only on the layout, but also on the amount of thermal energy that the batteries release to the air in the rooms. Therefore, in order not to freeze in winter, you need to make the correct thermal calculations. By the way, this is also indicated by the instructions enshrined in the current SNiP.

Thanks to the correct calculation, you can choose:

- boiler of the required power - a weak one will not be able to heat the house, a powerful one will burn expensive energy resources in vain;

- radiators of the required area - this will help to significantly reduce the cost of their purchase.

Calculations can be made independently (using a special computer program) or contact a specialized engineering company. The second option is more expensive, but this way you will be sure that the data provided to you is correct.

Before installing heating, you need to perform a thermal engineering calculation of the structure

In addition, the engineers of this organization will also prepare a diagram of the heating circuits, drawn on the provided plan of your house (apartment). This will greatly facilitate installation and help you buy the right amount of materials.

Sequence of actions when installing water heating with two-pipe bottom wiring

It all starts with the choice of energy resource. If you use a gas boiler as the main one in the same scheme, and an electric or solid fuel boiler as a backup, then you can make the heating system energy-independent.

Next, you should contact the competent authority to develop and approve the project. Only after completing all the necessary documentation and purchasing equipment and consumables does the installation of the heating system begin.

Boiler room equipment

The boiler room should be spacious enough, with a high ceiling and good ventilation. Sections of walls and floors located in the immediate vicinity of the boiler are lined with fireproof materials.

The boiler is installed according to the operating instructions. The chimney is led out into the street through a special opening.

Manifold cabinet

This element is a compartment within which the pump, distribution manifold, regulators and meters will be located.

Pipe installation

The pipes are installed as straight as possible, without bends. If necessary, holes are made in the walls, which are subsequently carefully covered with cement mortar. To connect pipes, welding (metal) or a special iron (polypropylene) is used.

Battery Installation

Heating elements are located under the window sill. The installation requirements for the wall, floor and window sill are the same as for installing a single-pipe system. The length of the radiator (number of sections) should, if possible, correspond to the width of the window opening. Temperature regulator valves are installed at the coolant inlet and outlet areas.

The final stage of installation of water heating with bottom wiring is crimping. The first start-up of the boiler is carried out only in the presence of employees of the relevant service.

Theoretical horseshoeing - how gravity flow works

The natural circulation of water in heating systems operates due to gravity. How does this happen:

- Take an open vessel, fill it with water and start heating it. The most primitive option is a saucepan on a gas stove.

- The temperature of the lower layer of liquid increases, the density decreases. The water becomes lighter.

- Under the influence of gravity, the upper heavier layer sinks to the bottom, displacing less dense hot water. Natural circulation of liquid begins, called convection.

Example: if you heat 1 m³ of water from 50 to 70 degrees, it will become 10.26 kg lighter (see below for a table of densities at different temperatures). If we continue heating to 90 °C, then the cube of liquid will already lose 12.47 kg, although the temperature delta remains the same - 20 °C. Conclusion: the closer the water is to the boiling point, the more active the circulation occurs.

In a similar way, the coolant circulates by gravity through the home heating network. The water heated by the boiler loses weight and is pushed upward by the cooled coolant returning from the radiators. The flow speed at a temperature difference of 20–25 °C is only 0.1…0.25 m/s versus 0.7…1 m/s in modern pumping systems.

Low speed of fluid movement through pipelines and heating devices causes the following consequences:

- The batteries have time to give off more heat, and the coolant has time to cool by 20–30 °C. In a conventional heating network with a pump and a membrane expansion tank, the temperature drops by 10–15 degrees.

- Accordingly, the boiler must produce more thermal energy after the burner starts. It is pointless to keep the generator at a temperature of 40 °C - the flow will slow down to the limit, the batteries will become cold.

- To deliver the required amount of heat to the radiators, it is necessary to increase the flow area of the pipes.

- Fittings and fittings with high hydraulic resistance can worsen or even stop gravity flow. This includes check valves, three-way valves, sharp 90° turns and pipe reductions.

- The roughness of the internal walls of pipelines does not play a big role (within reasonable limits). Low fluid speed means low frictional resistance.

- A solid fuel boiler + gravity heating system can safely operate without a heat accumulator and a mixing unit. Due to the slow flow of water, condensation does not form in the firebox.

As you can see, there are positive and negative aspects in the convection movement of the coolant. The former should be used, the latter should be minimized.

Dependent

This connection scheme, as a rule, provides for the presence of in-house heating points, often equipped with elevators. In the mixing unit of the heating station, superheated water from the main external network is mixed with the return water, thereby acquiring a sufficient temperature (about 100°C). Thus, the internal heating system of the house is completely dependent on external heat supply.

Advantages

The main feature of this scheme is that it provides for the supply of water to the heating and water supply systems directly from the heating main, and the price pays off quite quickly.

- subscriber input equipment is simple and inexpensive;

- heating systems can withstand large temperature changes;

- the diameter of the pipeline is smaller;

- the circuit reduces coolant consumption;

- low operating costs.

Flaws

Along with the advantages, such a connection also has some disadvantages:

- uneconomical;

- temperature control is significantly difficult during weather changes;

- overconsumption of energy resources.

Connection methods

Connection can be made in several ways:

- through direct connection;

- with elevator;

- with pump on jumper;

- with a pump on the return or supply lines;

- mixed method (pump and elevator).