Causes of poor circulation

The circulation of water in the system is disrupted due to complete or partial blockage in the riser or in the supply to the heating device, airing of the main line, freezing of the network, or errors in pipe laying. This also leads to deregulation of the central heating system and the appearance of coolant leaks.

Poor pump performance

The purpose of the pump is to maintain the required water pressure in the heating circuit. A well-functioning pump must meet the following requirements:

- A necessary indicator of work productivity;

- Pressure;

- Device pressure;

- Compliance with the type of liquid;

- Matching pipe diameter;

- Dimensions of the device in accordance with the length of the line.

What to consider when choosing a pump

The pump must cope with its load.

But you definitely need to consider whether it will work constantly or will only turn on to replenish the heating system and adjust the pressure. This should be taken into account when choosing pump power. For a pump that operates in constant mode, it is important to take into account the energy consumption indicator. If you choose the wrong pump, it will not “push” the coolant well, and as a result, the battery will heat up unevenly, and the pump itself may burn out from overheating. Poor water circulation will also be noted if the diameter of the components for connection to the system is incorrectly selected.

When the pump is selected correctly, the heating system functions reliably and fully, and the movement of water occurs unhindered.

If you have difficulties choosing a pump, it is better to contact specialists; they will help you choose the appropriate device for a specific heating system.

Wrong pipe diameter

This is also one of the common reasons for poor water circulation in the heating line.

The diameter of the pipes must be selected at the design stage. First of all, it is necessary to take into account that different heating systems have their own rules according to which pipes are selected.

If the heating network is connected to a central heating main, then the diameter of the pipes is chosen in the same way as an apartment heating system. For autonomous heating, these diameters may differ. It all depends on whether there is a circulation pump in the system or whether the work will be carried out due to the natural circulation of water.

The choice is also influenced by:

- Pipe production material;

- Type of coolant used;

- Specific features of heating main wiring;

- Planned pressure in the system;

- The speed of water movement along the highway.

Important! When calculating the diameter, the type of pipe must be taken into account, because the measurement system differs based on the material of manufacture. Steel and cast iron products are marked taking into account the internal diameter, and copper materials according to the outer section. This should definitely be taken into account when planning a pipeline, where several different materials are combined in the pipeline.

System clogged

As already noted, if there is no water circulation in the riser and heating system, then the problem may be due to debris accumulated in the system.

A coarse filter will help get rid of it. Dirt that gets into the pipes is easier to remove by catching it in the filter. First of all, such a filter protects the pump. It is also recommended to install a filter at the boiler inlet. Such a water filter should be placed in front of each plumbing fixture. When installing the device, you must pay attention to the filter housing. There is an arrow on it that indicates which side to install the filter depending on the direction of movement of the coolant.

The filter should be cleaned regularly. To do this, you need to turn off the water, unscrew the cap, take out the mesh, rinse it, put it in place and screw the cap back, after which you can open the taps.

Advice! To prevent clogging of the pipeline, during installation it is necessary to control that there is no debris in the pipes; for this, the ends of the pipes are covered. It is also necessary to check the radiators, since new products may contain factory shavings or other debris.

Airiness of the heating system

If the installation of the pipeline is carried out in violation of the rules, air jams will form. They block the movement of water. To quickly solve this problem, install air vents or a Mayevsky valve. For the central system, where a lot of air accumulates, automatic Mayevsky valves are used. The air is quickly removed and the movement of the coolant through the network is restored.

Do-it-yourself installation recommendations

To lay the main natural circulation lines, it is better to use polypropylene or steel pipes. The reason is the large diameter, polyethylene Ø40 mm and more is too expensive. We make radiator hoses from any convenient material.

Advice. When assembling a gravity heating network made of metal-plastic, do not install compression fittings - they greatly reduce the internal passage.

An example of installing a two-pipe wiring in a garage.

How to make the wiring correctly and withstand all slopes:

- Start with markings. Mark the locations for installing batteries, connection points for connections, and routes for highways.

- Mark the routes on the walls with a pencil, starting from the distant batteries. Adjust the amount of inclination using a long building level.

- Move from the outer radiators to the boiler room. When you draw all the routes, you will understand at what level to install the heat generator. The inlet pipe of the unit (for cooled coolant) must be located at the same level or below the return line.

- If the firebox floor level is too high, try moving all the heaters up. Horizontal pipelines will rise next. As a last resort, make a recess under the boiler.

Laying a return line in a furnace room with a parallel connection to two boilers.

After marking, punch holes in the partitions and cut grooves for a hidden gasket. Then check the routes again, make adjustments and proceed with installation. Follow the same order: first secure the batteries, then lay the pipes towards the combustion chamber. Install an expansion tank with a drain pipe.

The gravity pipeline network is filled without problems; Mayevsky’s taps do not need to be touched. Just slowly pump water through the fill valve at the lowest point, all the air will go into the open tank. If any radiator remains cold after warming up, use a manual air vent.

Natural and forced circulation - what's the difference?

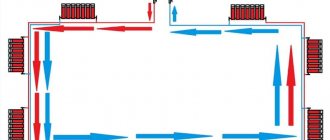

Natural is built on the physical process of heated water rising upward. The density of hot water is less than that of cold water, so warm layers are displaced by less heated layers. This phenomenon occurs without human participation, you just need to create the conditions to start the process.

However, natural circulation is unstable, without the necessary pressure. The speed of movement of layers of water is low; it cannot push the flow through the pipeline. In addition, it is almost impossible to regulate the natural process, just start or stop it.

Forced is the movement of water using special pumping equipment. The process occurs evenly, it can be adjusted, flow parameters changed or stopped as needed. The pump creates pressure that allows water to move through a branched, extended system.

The natural process is used where slow, ineffective mixing of layers of water at different temperatures is sufficient. As a rule, it is used in small water supply systems of a private home, when only a small exchange of layers is needed.

Coarse filter

As mentioned above, one of the reasons that there is no coolant circulation may be the accumulation of debris in the pipeline. To completely avoid this, again, we don’t save on pennies, but install a coarse filter in front of each device:

Using a filter, catching dirt is easier than correcting the consequences of clogged pipelines or boiler heat exchangers.

Conclusion! We place coarse filters in front of each heating system device (pump, boiler, etc.) and in front of each plumbing fixture. We do NOT save pennies to “buy” problems. There are arrows stamped on the filter housing indicating the direction of movement of the coolant or water in the water supply...

Pressure norm

Effective transfer and uniform distribution of coolant for the performance of the entire system with minimal heat loss is possible at normal operating pressure in the pipe lines.

The coolant pressure in the system is divided according to the method of action into types:

- Static. The force of influence of a stationary coolant per unit area.

- Dynamic. Force of action during movement.

- Maximum pressure. Corresponds to the optimal value of liquid pressure in the pipes and is capable of maintaining the operation of all heating devices at a normal level.

According to SNiP, the optimal indicator is 8-9.5 atm, reducing the pressure to 5-5.5 atm. often leads to heating interruptions.

For each specific home, the normal pressure indicator is individual. Its value is influenced by factors:

- power of the pumping system supplying coolant;

- pipeline diameter;

- remoteness of the room from the boiler equipment;

- wear of parts;

- pressure

Pressure control is possible using pressure gauges mounted directly into the pipeline.

Heating systems with forced circulation

A standard forced circulation heating system operates using the same connection methods. The difference is that due to the large extent of this system or the lack of natural conditions to create an inclination of the pipes, it is necessary to include a pump in the system. The circulation pump is mounted to the main pipe - this helps to increase the service life of the heating system. Using a pump helps not only increase heating efficiency, but also reduce the number of lines. A forced circulation system has the ability to heat not just several rooms, but even a house with several floors.

Heating systems with forced circulation

In order to produce high-quality operation of this type of system, a continuous power supply is required. Installation of a circulation pump in the heating system is required in order to create forced circulation of water in a closed loop. In this type of system, the pump is the central component among the equipment. It should be noted that the circulation pump may not have significant performance: its power is only needed to direct the liquid into the supply pipe. The same pressure pushes the water in the opposite direction, since the system is closed.

The circulation pump is necessary to ensure uninterrupted operation of the heating system, therefore it must fully comply with the system into which it is installed. Due to its functionality, this type of pump can be widely used in a wide variety of pipelines.

Possible breakdowns and ways to eliminate them

So, if something goes wrong with your circulation pump and it refuses to work, then we’ll try to repair the unit ourselves.

If the pump makes a hum, but the impeller does not rotate

The reasons may be the following:

- Presence of a foreign object in the impeller area;

- The rotor shaft has oxidized due to long-term downtime of the unit;

- Loss of power supply to the mechanism terminals.

In the first case, you need to carefully remove the pump from the heating system and unscrew the housing in the area of the impeller. If a foreign object is found, remove it and rotate the shaft by hand. When assembling the pump in the reverse order, it is necessary to install a reliable filter on the pipe.

If there is oxidation, then clean it well, lubricate all movable elements of the working unit and reassemble the pump in the reverse order.

If there is a problem with the quality of the power supply, then you will have to check the voltage using a tester. First, completely replace the cable in all sections of the cable and if a break or fault is detected. Then, if the cable is OK, check the voltage at the terminals. If the tester shows infinity, a short circuit has occurred. If it shows less voltage, it means that the winding has broken. In both cases, the terminals are replaced.

If the unit shows no signs of life at all

This can happen if there is no voltage in the network. Using a tester, check the voltage and, if necessary, correct the problem.

By the way, it is recommended to protect the pump from surges in the network by installing a reliable stabilizer. This move will also protect the pump from the combustion of a fuse, which fails as a result of constant pressure drops in the network.

If the pump starts but then stops

The reasons may be:

- Presence of scale between the moving elements of the unit;

- Incorrect pump connection at the terminals.

In the first case, you will have to disassemble the pump and check it for scale. If detected, limescale deposits are removed and all joints between the rotor and stator are lubricated.

If there is no scale, then check the tightness of the fuse on the unit. You should remove it and thoroughly clean all the clamps. Here it is also worth checking that all wires in the terminal box are connected correctly in phases.

If the pump makes a loud noise when turned on

The reason for this is the presence of air in a closed circuit. It is necessary to release all air masses from the pipes, and install a special unit in the upper part of the pipeline to prevent the formation of air locks.

Another reason could be wear on the impeller bearing. In this case, you need to disassemble the unit housing, check the bearing and, if necessary, replace it.

If the pump is noisy and vibrates

Most likely, the issue is insufficient pressure in the system. It is necessary to add water to the pipes or increase the pressure in the area of the pump inlet.

If the pressure is still low

Here it is worth checking the direction of rotation of the working unit in the pump body. If the wheel does not spin correctly, then an error was probably made when connecting the device to the terminals in phases when using a three-phase network.

Another reason for a decrease in pressure may be too high a viscosity of the coolant. Here the impeller experiences a lot of resistance and does not cope with the assigned tasks. You will have to check the condition of the mesh filter and clean it if necessary. It would also be useful to check the cross-section of the inlet and outlet pipes and, if necessary, set the correct operating parameters of the pump.

What it is

If a system with forced circulation requires a pressure difference created by a circulation pump or provided by a connection to the heating main, then the picture is different. Natural circulation heating uses a simple physical effect - the expansion of a liquid when heated.

If we ignore the technical details, the principle of operation is as follows:

- The boiler heats a certain volume of water. So, of course, it expands and, due to its lower density, is forced upward by a colder mass of coolant.

- Having risen to the top point of the heating system, the water, gradually cooling, describes a circle by gravity through the heating system and returns to the boiler. At the same time, it gives off heat to the heating devices and by the time it reaches the heat exchanger again, it has a higher density than at the beginning. Then the cycle repeats.

Useful: of course, nothing prevents you from including a circulation pump in the circuit. In normal mode, it will provide faster circulation of water and uniform heating, and in the absence of electricity, the heating system will operate with natural circulation.

Pump operation in a natural circulation system.

The photo shows how the problem of interaction between the pump and the natural circulation system was solved. When the pump is running, the check valve is activated, and all the water flows through the pump. Once you turn it off, the valve opens and water circulates through the thicker pipe due to thermal expansion.

How to organize yourself?

The circulation diagram of a private house is usually created independently, taking into account the configuration of the premises, the number of water points, branches, and additional lines. The main task is the constant operation of the heated towel rail, which is installed in a gap in the hot water supply line.

If the water cools down, the device will stop heating the room and drying towels, and the bathroom will be damp and cold.

For medium-sized buildings, one bottling is used, but for large cottages, several boilers with their own systems are often installed. Let's look at the most common options.

Through a storage boiler

A storage boiler is a container with insulated walls where hot water is accumulated and supplied as needed.

The circulation system is not important for it, since the return line temperature will be lower than in the main tank. This will require heating or changing the water.

If you refuse circulation, the water in the dead-end lines will completely cool down and the hot water supply mode will be disrupted.

Therefore, to organize the flow movement, perform the following actions:

a direct DHW line is drawn to all consumers and returns to the storage tank;- a circulation pump is installed before entering the container;

- The make-up pipeline from the boiler is connected either with a separate input or connected to the return pipe through a three-way valve.

The tank is recharged only when the pressure in the DHW system drops or when the temperature drops significantly. For the correct operation of such a system, a control unit with a system of sensors is required, which will continuously provide information about the state of the flow.

This scheme requires the use of a separate boiler not connected to the heating system. Therefore, it is used only in the southern regions.

Through an indirect heating boiler

An indirect heating boiler is a heater where the working “body” is a coil with hot coolant. As a rule, it is built into the heating system.

The hot stream passes through the coil at a sufficient speed to ensure that enough thermal energy remains to heat the home. At the same time, the DHW line is always ready to supply water at the required temperature. Circulation is needed only to prevent the water from cooling in dead-end lines.

Assembly order:

- The boiler is connected to the heating system. To do this, it has a separate pair of pipes for supply and exit of coolant. Typically, the boiler is located next to the boiler in order to receive coolant at the maximum temperature.

- The hot water supply line is looped and connected through a circulation pump to the boiler. As a rule, the return flow is connected to the farthest point of water collection and directed to the tank along the most direct path so as not to lose thermal energy.

- Connect the cold water make-up pipeline. It supplies water when the level in the tank drops. The float valve gives the start command.

- They start circulation and adjust the heating mode by changing the speed or volume of coolant supply to the heater.

- They check the system for operability and eliminate any deficiencies found.

The circulation option through an indirect heating boiler is considered the most efficient and stable. In the summer, the heating circuit is turned off and the boiler only works to heat the tank.

Two-story house

In two-story country houses, it is recommended to use a closed heating system with a circulation pump. The list of necessary equipment here includes: a boiler, an expansion tank, a piping system, as well as the required number of heating radiators.

Copper pipes are connected to each other using special silver-based solder. The downside of this material is its high price, but it is distinguished by high quality and reliability. Metal pipes also transfer heat well, but they are often destroyed by corrosion.

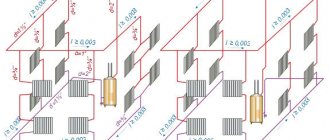

Two-pipe heating system for a two-story house with natural circulation and top wiring

In two-story buildings, three types of wiring can be used: collector, two-pipe or single-pipe. When connecting heating devices using a single-pipe scheme, it is quite difficult to regulate the temperature in the rooms, because the maximum amount of heat will reach the first radiators from the boiler, while the last radiators will heat up much less than the others.

A two-pipe heating system is considered a more suitable option for a two-story country house. Here, two pipes are connected to each of the heating devices: hot water from the boiler flows through one of them, and the liquid that gives off heat flows into the other. The coolant temperature in the main supply line will be the same.

What are the consequences of inefficient operation of heating devices?

The problem of uneven heat distribution in a heating radiator cannot be solved by itself. If you do not pay attention to it, it is fraught with the following consequences:

- The efficiency of heating equipment decreases;

- The apartment becomes cold;

- The risk of a pipe burst increases;

- Economic losses. If in an apartment building the heat meter is common to the building, then the cost of services will be divided among all heat consumers, although the heat output will be low.

- There is a possibility of freezing the heating system. This possibility is unlikely, but such cases occur periodically.

If the air temperature in the room does not meet established standards, then residents will be forced to pay utility bills not for the supplied heat, but for the cold air.

In addition, people connect electric heating devices, which entails increased energy costs. Optimal room temperatures:

- living room and bedroom - from + 18 to + 22°C;

- toilet - + 18°C;

- bathroom - from + 20 to + 25°C;

- corner room - from + 20 to + 24°C.

According to GOST, at night (from 00:00 to 05:00) the temperature can drop by 3 degrees, which is not a deviation.

If the reason for the cold bottom of the radiators is a system failure due to the fault of the heat supplier, you need to write a statement to the management company with a clear description of the problem. The housing office is obliged to send a technician who will measure the temperature of the coolant, air and radiators.

As a result, the heating tariff may be recalculated.

If equipment failure is detected in the apartment, prepare for the following consequences:

- repairs are carried out at the expense of the owner of the house;

- If the equipment is outdated, then replacement is carried out by the owner of the apartment.

If the neighbors are proven guilty, they are obliged to fix the problem.

Checks performed on heating systems in a private home

The easiest to maintain is the open system. Preventive measures when checking it are limited only to monitoring the level of water in the expansion tank. If the system is closed, there is a need for additional checks.

Place of expansion tank in water heating system

Closed water heating system: features of preventive measures and inspections

If water heating in a private house is of a closed type, then the quality of its operation can be ensured only if a greater number of actions and operations are performed. The sequence of actions may be as follows:

- First, the pressure in the expansion tank is checked, for which a pressure gauge mounted on the pipeline is used. The ideal pressure level is 1-1.5 Bar. If the level is lower, the volume of water in the tank should be increased and the probable cause of its leak determined (all connections are checked);

The pressure in the heating system should be about 1-1.5 Bar

- then air is removed from the system, for which all radiator taps are opened in turn. If water starts flowing from the taps, we can conclude that there is no more air in the system;

There is no air in the heating system if water starts flowing from the tap

- Next, the expansion tanks are checked by connecting a pump with a pressure gauge to the radiator valves. Low pressure requires pumping air into the tanks.

Checking the circulation pump of the water heating system

If water heating in a private house includes a circulation pump, it is necessary to ensure its serviceability and efficiency. The operation of the pump should be silent and there should be no excessive resistance during its operation. If there is any deviation, you should invite a specialist to determine the cause and solve the problem.

The circulation pump installed in the heating system should operate almost silently

The filter located in front of the pump may become clogged if it gets into it with wood chips, sawdust or other debris that may have been in the pipes before they were installed. The filter is cleaned after turning off the water. To do this, the filter is removed and washed under running water.

The filter at the inlet of the circulation pump must be cleaned regularly

By performing these simple and fairly few operations, you can ensure trouble-free operation of the water heating system and the necessary comfort in your home.

Design features

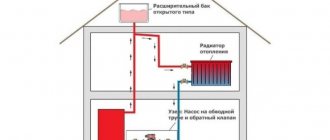

For a gravity system to work effectively, the following requirements must be met:

- the heat source is any non-volatile heat generator with outlet pipes with a diameter of 40-50 mm;

- at the outlet of a boiler or stove with a water circuit, an accelerating riser is immediately installed - a vertical pipe through which the heated coolant rises;

- the riser ends with an open-type expansion tank installed in the attic or under the ceiling of the upper floor (depending on the type of wiring and the design of the private house);

- tank capacity – 10% of the coolant volume;

- by gravity, it is advisable to choose heating devices with large internal channels - cast iron, aluminum, bimetallic;

- for better heat transfer, heating radiators are connected according to a versatile pattern - bottom or diagonal;

- special full-bore valves with thermal heads (supply) and balancing valves (return) are installed on the radiator connections;

- It is better to equip batteries with manual air vents - Mayevsky taps;

- replenishment of the heating network is organized at the lowest point - near the boiler;

- all horizontal sections of pipes are laid with slopes, the minimum is 2 mm per linear meter, the average is 5 mm/1 m.

On the left in the photo is the coolant supply riser from a floor-standing boiler with a pump on the bypass, on the right is the return line connection

Note. Slopes perform 2 functions - they help the coolant flow in the desired direction, and the air rises through the pipelines and leaves through the open expansion tank. A caveat regarding the radiators used: if the system is built correctly, steel panels also heat well.

Gravity heating systems are made open and operated at atmospheric pressure. But will gravity flow work in a closed circuit with a membrane tank? We answer: yes, natural circulation will continue, but the speed of the coolant will decrease and efficiency will drop.

It is not difficult to substantiate the answer; it is enough to mention the change in the physical properties of liquids under excess pressure. With a pressure in the system of 1.5 Bar, the boiling point of water will shift to 110 °C, and its density will also increase. The circulation will slow down due to the small difference in the masses of the hot and cooled flow.

Simplified gravity flow diagrams with an open and membrane expansion tank