Installing a new membrane into the housing

We insert the new membrane into the accumulator housing through the lower hole in the housing.

We push the membrane to its protrusions at the bottom.

Now our task is to straighten the membrane inside the housing and get the threaded fitting into the hole in its upper part. For a larger model, you can use special devices or tie a rope to the fitting in advance and pull it through the hole.

Screw the nut onto the threaded fitting.

There is a recess for a hexagon inside the fitting. Use an adjustable wrench to slightly tighten the nut. If you do not plan to install control automation, a pressure gauge or an air release valve on the hydraulic accumulator, then the upper hole in the flange can be plugged with a metal cap of a suitable diameter. You can use fum tape or flax as a seal.

We wind 5-6 turns of fum tape and install the cap.

First we tighten it by hand, then tighten it with an adjustable wrench.

We install the lower pressure flange on the body. This flange secures the membrane to the body, pressing its edges. Install and tighten the bolts on the flange according to the same rules as for tightening the wheels of a car. Depending on the number of bolts, you can use a “criss-cross” or “star” pattern. We must try to install and tighten the bolts from opposite sides - this way we will achieve uniform pressure on the flange and membrane. When all the bolts are installed, tighten them one by one with a socket wrench.

Fix breakdowns yourself or call a specialist

Repairing a storage tank for people who constantly deal with tools and equipment seems like a simple matter. Removing the nipple and installing a new part with a complete seal requires skill and knowledge. It is easier to unscrew the screws of the old flange and replace the membrane, but without a suitable wrench this will not be possible. The hole in the housing can only be repaired by welding; this work will require a specialist. It is enough for consumers to carry out regular maintenance of the hydraulic tank, and entrust complex repairs to representatives of the service center.

In case of significant damage and wear of the hydraulic accumulator components, it is recommended to purchase new equipment.

Installation nuances

You can carry out the repair procedure yourself, saving about 1,000 rubles - about the same amount you would have to pay to a master for the replacement work, which, in principle, is nothing complicated.

Replacing the membrane in a pumping station in stages is as follows:

- The work is carried out after the water has been pumped out from the tank and the pumping station is de-energized.

- Actually, the front flange is removed from the accumulator tank, and the old membrane is removed.

- If it was not possible to completely remove water from the system, it is better to loosen the flange mounting bolts gradually, and remove the leaking water using improvised means.

- If the membrane is intact, the inner surface of the tank must be absolutely dry. Accordingly, after removing the “pear”, if there is any water left there, the surface needs to be dried as much as possible.

- Then a new one is installed in place of the old container (sometimes it is recommended to additionally treat the junction of the “pear” and the tank with sealant), and the flange is screwed into place.

- After installing the membrane, you need to restore the internal pressure of the accumulator. To do this, using a compressor, air is pumped through the nipple on the back side of the tank (you should achieve the same pressure that was when the pumping station was operating in normal mode, checking the pressure gauge).

After this, the station is connected and a test switch is performed. If the membrane was replaced due to a rupture, there should now be no problems in the operation of the pumping station.

The membrane needs periodic (about once every year or two) replacement, otherwise it may burst during operation, and you will still have to change it.

In addition, with prolonged use, the “pear” greatly stretches and fills the volume of the accumulator tank, which forces the automatic pump to constantly pump up in order to normalize the pressure. This, logically, does not affect its wear for the better.

A sign that repairs are needed and the membrane needs to be replaced can be a situation when the pumping station, for example, suddenly turns on or stops every time the tap is opened, or operates jerkily.

The pressure gauge shows a sharp drop in pressure immediately after reaching the design operating mode.

This usually means the membrane has ruptured. On the back of the tank there is a small valve (a fitting used to pump air if you need to adjust the pressure inside the tank), through which water should not flow when the pumping station is in operation (when nothing is broken).

If this happens (it’s easy to check), the membrane needs to be changed. During normal operation of a hydraulic pump station, water should not get between the walls of the tank and the membrane.

In total, replacement of the membrane is necessary:

- Periodically, to increase the service life of the pumping station;

- If the membrane is damaged.

Timely replacement of a worn-out bulb is a very important and necessary matter. After all, it is precisely the accuracy of its operation that determines the correct maintenance of pressure in the system

For example, if it does not work correctly, the pump may turn on more often unnecessarily, which means it will consume more energy, increase its own wear and create additional load on the pipeline.

Naturally, such consequences are not very useful, so the membrane should be inspected periodically and, if necessary, replaced immediately.

Replacing the heating expansion tank membrane. Replacing the membrane in the expansion tank

Replacing the membrane in the expansion tank is a technically simple process that does not require special skills or knowledge. It is required in the following cases:

- Malfunctions of the pumping unit;

- Leak behind the air valve;

- Intermittent streams from the water supply tap;

- Tank nipple leaking;

- Unnaturally low pressure level in the system.

How to replace the membrane in the expansion tank with your own hands:

Preparation

Replacing the membrane in the expansion tank begins, first of all, with purchasing a new one. It is recommended to purchase high-quality products manufactured by leading European brands, and not cheaper Chinese analogues, which, even with careful use of the storage device, break down extremely quickly. Then you should prepare an expansion tank:

- Shut off the water supply;

- Vent the air;

- Drain off any remaining liquid.

The occurrence of an air lock

If the heating system is filled with liquid or during emergency downtime, it is necessary to constantly bleed the air. Usually it accumulates at the top of the battery or where the highest point of the pipe system is located. Sometimes bleeding air once does not help: tap water is saturated with a large amount of oxygen, and the process of displacing it from the system can last up to two weeks. The air is released using a special Mayevsky tap until the coolant appears.

Popular models of membranes for hydraulic accumulators and average prices

Let’s say right away that there are a great many different models, as well as manufacturers. Therefore, we will give a small rating of only the most popular options for this product. For the convenience of our visitors, all information below is presented in the form of a summary table.

Table. Rating of membranes for hydraulic tanks with approximate prices.

| Name, photo | Short description | Average market price, in rubles per piece |

| 1. UNIPUMP 24 liters (EPDM) | A domestically produced product, the volume of which, as you might guess from the name, is 24 liters. Made of elastic rubber (ethylene/propylene, synthetic origin). | 2200 |

| 2. UNIPUMP 5 liters (EPDM) | The characteristics in this case are almost the same, with the exception of the volume - here it is only 5 liters. | 2100 |

| 3. “Gillex” 24 liters | This hydraulic accumulator membrane is also produced in Russia and can hold up to 24 liters. | 2100 |

| 4. UNIPUMP 300 liters (EPDM) | The description and characteristics are the same as those of the first two options, only the capacity already reaches 300 liters. | 9900 |

| 5. “Gillex” 300 liters | Designed for water temperatures of no more than 99 degrees, can hold up to 300 liters of water. | 8200 |

As you can see, despite the great variety, the products of the two manufacturers mentioned above are the most popular in the country.

Well, we’ve sorted out the features and other introductory points, so let’s move on to the most important thing!

How to check and diagnose faults

Most hydraulic accumulator malfunctions can be corrected independently. All reasons can be divided into several groups.

Table 1. Malfunctions in hydraulic accumulators

To extend the service life of the hydraulic tank, it is necessary to regularly carry out external inspection and diagnostics of the main components, and monitor the pressure level in the system.

Recommendations for servicing hydraulic accumulators:

- Monthly inspection, checking that operating parameters comply with the standard (for each model and system individually).

- Check for corrosion stains on the body and connections.

- Check for leaks and surface moisture at joints.

- If there are malfunctions or malfunctions, correct them immediately.

- Checking the integrity of the membrane (inspection every six months).

- When not in use, store the hydraulic tank in a dry place, avoid contact with heating devices (to avoid drying out and destruction of the membrane material).

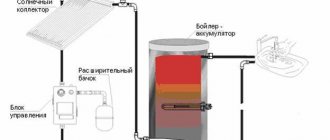

Diagram of the hydraulic accumulator

How to check the initial pressure in the tank:

- Disconnect the tank from the system.

- Drain the water.

- Connect the pressure gauge to the nipple.

- If the readings are lower than the default ones, it is necessary to pump up the pressure to working pressure (with a car compressor, for example).

Functions, purpose, types

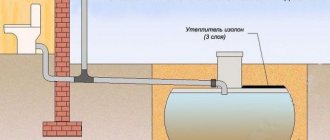

Installation location - in a pit or in a house

In the water supply system of a private house without a hydraulic accumulator, the pump turns on whenever water flows somewhere. These frequent starts lead to wear and tear on the equipment. And not only the pump, but the entire system as a whole. After all, every time there is an abrupt increase in pressure, and this is a water hammer. To reduce the number of pump starts and smooth out water hammer, a hydraulic accumulator is used. The same device is called an expansion or membrane tank, a hydraulic tank.

Purpose

We found out that one of the functions of hydraulic accumulators is to smooth out water hammer. But there are others:

- Reducing the number of pump starts. There is some water in the tank. With a small flow rate - wash your hands, wash yourself - water flows from the tank, the pump does not turn on. It will turn on only when there is very little left.

- Maintaining stable pressure. This function requires one more element - a water pressure switch, but they maintain the pressure within the required limits.

- Create a small supply of water in case of power outage.

It is not surprising that most private water supply systems have this device - there are many advantages from its use.

Kinds

The hydraulic accumulator is a tank made of sheet metal divided into two parts by an elastic membrane. There are two types of membrane - diaphragm and balloon (bulb). The diaphragm is attached across the tank, a pear-shaped cylinder is secured at the inlet around the inlet pipe.

According to their purpose, they are of three types:

- for cold water;

- for hot water;

- for heating systems.

Hydraulic tanks for heating are painted red, tanks for water supply are painted blue. Expansion tanks for heating are usually smaller in size and lower in price. This is due to the membrane material - for water supply it must be neutral, because the water in the pipeline is potable.

Two types of hydraulic accumulators

Depending on the type of arrangement, hydraulic accumulators can be horizontal or vertical. Vertical ones are equipped with legs; some models have plates for hanging on the wall. It is the elongated upward models that are most often used when independently creating water supply systems for a private home - they take up less space. The connection of a hydraulic accumulator of this type is standard - through a 1-inch outlet.

Horizontal models are usually equipped with pumping stations with surface-type pumps. Then the pump is placed on top of the tank. It turns out compact.

Principle of operation

Radial membranes (in the form of a plate) are used mainly in gyroaccumulators for heating systems. For water supply, a rubber bulb is usually installed inside. How does such a system work? As long as there is only air inside, the pressure inside is standard - the one that was set at the factory (1.5 atm) or that you set yourself. The pump turns on, begins to pump water into the tank, and the pear begins to increase in size. Water gradually fills an increasingly larger volume, increasingly compressing the air that is located between the wall of the tank and the membrane. When a certain pressure is reached (usually for one-story houses it is 2.8 - 3 atm), the pump is turned off, and the pressure in the system stabilizes. When you open a tap or other water flow, it comes from the accumulator. It flows until the pressure in the tank drops below a certain level (usually about 1.6-1.8 atm). After which the pump turns on, the cycle repeats again.

The operating principle of a gyroaccumulator with a pear-shaped membrane

If the flow rate is large and constant - you are filling a bathtub, for example - the pump pumps water in transit, without pumping it into the tank. The tank begins to fill after all the taps are closed.

A water pressure switch is responsible for turning the pump on and off at a certain pressure. In most hydraulic accumulator piping schemes, this device is present - such a system operates in optimal mode. We’ll look at connecting the hydraulic accumulator a little lower, but for now let’s talk about the tank itself and its parameters.

Large tanks

The internal structure of hydraulic accumulators with a volume of 100 liters and above is slightly different. The pear is different - it is attached to the body both at the top and at the bottom. With this structure, it becomes possible to fight the air that is present in the water. To do this, there is an outlet in the upper part into which you can connect a valve for automatic air release.

The structure of a large hydraulic accumulator

Main varieties

Today on sale you can find various options for hydraulic tanks, which differ in the principle of their operation, design, installation methods, as well as a number of other operational characteristics.

Depending on the installation option, it is customary to distinguish two main types of hydraulic accumulators:

- horizontal;

- vertical.

The principle of their operation is the same. You just need to take into account the fact that vertical hydraulic accumulators, the volume of which exceeds 50 liters, have an additional special valve on top designed to bleed air. During the operation of such containers, air inevitably accumulates in them, collecting in the upper part of the tank. Without the presence of special valves, complete airing of the entire system and rupture of pipes at the connections may occur. Accordingly, the installation of such a hydraulic accumulator is carried out taking into account the location of the mandatory protective mechanism.

In horizontal devices, a special drain or a small tap is installed specifically for bleeding air, located behind the hydraulic accumulator. The need to install them slightly increases the cost of the equipment used. At the same time, homeowners who do this work on their own often forget about the mandatory use of additional safety taps. This subsequently leads to problems with the operation of the autonomous water supply system.

Depending on the purpose, it is customary to divide three types of hydraulic tanks:

- painted blue - for cold water supply;

- painted red - for hot water supply;

- painted scarlet - tanks for closed autonomous heating systems.

It is customary to distinguish hydraulic tanks by their volume. Such installations can be intended for both a small country house and a full-fledged cottage where several families live simultaneously. The most popular today are hydraulic accumulators for water supply systems, the size and volume of which are 100-200 liters. They are affordable and compact in size. Such installations make it possible to provide high-quality, proper water supply to a private home inhabited by 3-5 people.

Prevention

To prevent a breakdown of the hydraulic accumulator from taking you by surprise, you need to carry out periodic maintenance. It's easy to do:

- once every 3-4 months the tank is inspected for damage;

- Once every six months, you need to check the operation of the pressure gauge, pressure switch, and also check the air pressure level in the tank.

In addition, all experts recommend replacing the membrane in the accumulator every three years. Naturally, subject to its constant and uninterrupted use.

The fact is that the average service life of these products rarely exceeds this figure. Therefore, it is better to replace it in advance - this way you can protect yourself in advance from a sudden breakdown.

Peculiarities

To reduce energy consumption and eliminate pressure level fluctuations in modern pumps with hydraulic accumulators, manufacturers install a special separating element - a membrane.

The shape of the membrane part depends on the volume of the container and comes in two varieties:

- oblong;

- elongated.

The base is rubber or specialized rubber. The material for the manufacture of the membrane must comply with all hygiene standards and sanitary standards. Special rubber that is resistant to mold and mildew can withstand high pressure and a wide temperature range.

Manufacturers produce two types of membranes:

- flat;

- balloon

Device

The hydraulic accumulator membrane is an element that allows the hydraulic accumulator to be divided into an air section and a water section. An elastic membrane is placed in the tank body, forming two spaces that are independent of each other.

The balloon membrane device is filled with water, and in the cavity between its walls and the accumulator shell there is air pumped under high pressure. A flat membrane is attached to the walls of the battery, forming two isolated spaces.

With the help of alluvial systems, water is pumped into the device until the maximum pressure level is formed. Experts set the required level using a relay on the equipment body.

Principle of operation

The principle of operation of the accumulator is to supply water to the membrane by a pump. In the cavity between the walls of the membrane and the coating of the accumulator, the pressure necessary for the operation of the entire water supply system is created.

When the value set on the relay is reached, the pumping system automatically turns off, maintaining internal pressure. This allows you to avoid changes in water pressure and ensure stable operation of the system. After the pressure drops to a minimum level, the pumping unit will automatically begin drawing water and pumping air again.

Restrictions

Manufacturers impose certain restrictions on the use of membrane expansion tanks, which depend on the design and materials used in the manufacture of the device. Manufacturers have clear requirements for the properties and composition of the liquid in the heating system. The content of, for example, ethylene glycol in an antifreeze solution is limited. The use of a membrane expansion tank at pressures exceeding permissible standards is prohibited. It is mandatory to install a safety group that controls and limits the pressure in the tank. The heating systems of autonomous heating apartments and private houses use equipment with an operating pressure of at least 3 bar.

What functions does an expansion tank perform in water supply?

A membrane tank for water supply is a multifunctional device; not a single autonomous system, with the exception of those using expensive submersible electric pumps with frequency control, can do without its use. To answer the question of why a tank is needed in the system, one should consider its design and operating principle.

All membrane tanks consist of two main parts, including a metal tank and an internal elastic membrane with an inlet fitting pressed into the housing cover. When the electric pump operates on closed taps, water enters the internal elastic shell and it stretches (expands); at a certain moment, the water supply stops and the hydraulic tank remains filled.

When the taps are opened, water from the accumulator enters the system with a certain pressure due to the compression of the elastic membrane until the pump is restarted, which again pumps water to fill the tank. The process of turning the electric pump on and off is controlled by a pressure switch; to set it to the response thresholds, a pressure gauge built into the system is used.

Rice. 2 Structural design of a horizontal tank

Expansion tank for water supply as a hydraulic accumulator

From the principle of operation of the hydraulic tank, it is clear that it accumulates (accumulates) a certain volume of water in its internal elastic cylinder or part of the body. Thanks to this, the required pressure is maintained in the system for a certain time, and a certain supply of water is created, which is useful in emergency situations in the event of a short-term power outage, damage to the water supply, or failure of the electric pump.

Some homeowners install large-volume hydraulic tanks inside the house - this allows them to make significant reserves of water resources.

Hydraulic tank to stabilize the pressure in the system

Since a hydraulic tank filled with water releases water resources over a long period of time, depending on its volume and consumption, equal pressure in the water supply is maintained for a long period of time. In the absence of a storage tank, the pipeline would be cleared of water resources faster - this would cause a rapid drop in pressure in the system and frequent activation of the electric pump.

Rice. 3 Operating principle of the hydraulic accumulator

Expansion tank for protection against water hammer

Protection against water hammer is one of the answers to the question why a hydraulic tank is needed. The principle of compensating for water hammer in the system is as follows: when the electric pump is turned off and on, there is an abrupt stop or movement of water flows. At the same time, due to inertia, water has a physical effect on the pipeline shell, shut-off and control valves, transferring its kinetic energy to them. The components and parts of the plumbing system begin to shift, resulting in loosening of threaded and compression connections, pipeline fasteners, and malfunctions in the automation.

An elastic storage tank for a water supply system in the form of a shell inside a hydraulic tank stretches or contracts first when the water flow moves and stops - this helps prevent physical impact on other components of the water supply system.

Hydraulic accumulator to increase the service life of pumping equipment

The principle of operation of the automatic switching on and off of the electric pump is the reaction of the relay to the filling of the hydraulic tank with water - as soon as the inner rubber shell begins to stretch and resist the pressure of the water masses, at a certain moment the pressure switch is activated and turns off the electric pump. It is clear that the longer the inner shell of the hydraulic tank is filled with water, the longer the pump remains on.

Similarly, when drawing water, water leaves the tank more slowly and, accordingly, the relay to turn on the electric pump is activated after a significant period of time.

Rice. 4 Hydraulic tanks for heating systems - popular brands

Step-by-step instruction. Different connection methods

Expanzomat is another name for an expansion membrane tank. It makes more sense if a specialist does the installation. If you decide to install it yourself, then in unclear moments, contact him and get advice. The tank can be installed both on the supply side of the line and on the return side.

Installation sequence and features:

- location of the expansion tank in space. In principle, as already mentioned, the tank can be positioned in any way you like. But from a rational point of view, the air chamber should be located at the top so as not to be affected by gravity. This will increase the already significant impact on the membrane from the coolant and air. Replacement or repair will be required after a shorter period of time than specified in the warranty;

- On the installed diagram of the heating system, select a place free from turbulence. This is usually the section of pipe in front of the recirculation pump. This is the best option;

- attach the tank to the wall and connect it to the system with a flexible hose.

It doesn’t matter where you place the tank: for supply or return, it is important that it is located at a minimum distance from the suction side of the centrifugal pump.