In order to provide your home or apartment with economical heat and hot water at any time of the year, you can install and connect a double-circuit gas boiler, but only specialists know how to do this correctly. Serious problems can be solved with the help of one element. That is why recently such units have become very popular among owners of country houses. Connecting such an installation is not an easy process, but if you figure it out, you can do everything yourself.

Installation of double-circuit boilers

Modern devices have automation that controls the degree of heating and maintains the temperature of the coolant.

Double-circuit boilers can be called a real home boiler room, since they are capable of not only maintaining a comfortable air temperature in the house, but also providing residents with hot water. However, such devices are complex and therefore are not immune to breakdowns. Natural gas is one of the best fuels, but when using it, you need to follow some rules to prevent it from becoming a source of danger.

When installing, it is important to adhere to the following recommendations:

- The boiler must be installed in a separate room (usually called a boiler room or furnace room). Its area must be at least 4 “squares”. This room should have a fairly wide doorway. It is also mandatory to have at least one window (read: “Rules for installing a gas heating boiler - installation and connection instructions”).

- When decorating the boiler room interior, flammable and fire-hazardous materials must not be used.

- A sufficient amount of fresh air must enter the room, so an unclosed through vent must be created.

- A separate flue is needed for boiler exhaust. The ventilation system should not be used for this purpose, as combustion products will enter the living space, which can lead to unwanted health problems.

- The flue outlet should protrude at least a meter above the roof ridge.

- A durable sheet of metal or other non-flammable material is placed on the floor under the boiler; its area must exceed the dimensions of the equipment, but be at least 1 “square”.

- The double-circuit heating system of a private house must withstand pressure testing of at least 1.8 bar.

All these requirements must be observed, since gas is a dangerous fuel. It is unacceptable to install the boiler in residential premises. Usually a separate extension is built for it so that it does not occupy one of the rooms of the house. If the boiler room is well ventilated, and no flammable materials were used in its finishing, then the heating system will be completely safe.

Gas release

The second part of the start-up is the release of air from the pump, for which the heating regulators are brought to the operating position. The circulation pump turns on, which is accompanied by a faint hum and gurgle of water. To eliminate noise, you need to bleed air from the heating system: the cap in the center of the pump is slightly unscrewed, and when water begins to come out instead of gases, the cap is screwed back.

https://youtube.com/watch?v=taQJKUjiso8

After this, the noise will stop, the electric burner will start working, and the boiler will start working. You should also check the pressure and add more water if necessary. To set up a working system, you need to screw the batteries closest to the boiler, and start the distant ones using control valves, which are located in the water supply section to the radiators.

You also need to take care of the sewage system: during installation, you need to calculate the volume of condensate at the rate of 1 liter per 1 kW of equipment power per day.

Ventilation is located 25 cm from the ceiling with a diameter of 10 cm. Date: September 25, 2021

Calculation of boiler power and boiler volume

The power of double-circuit and single-circuit equipment with the same heated area is different.

In addition, the calculation of the power of a heating boiler is also influenced by the fact that double-circuit boilers are also used to heat water for domestic purposes. But it is worth considering that the power should not be too high either. If the boiler power is calculated correctly, the temperature in the combustion chamber will not exceed 90 degrees, and the durability of the equipment will increase. For example, for a house with an area of 100 square meters, the boiler power should not exceed 38 kW.

The power of the heating boiler depends on its operating conditions. Most often there are two numbers on it, the first indicates how much energy it consumes in heating mode, and the second - when heating water quickly.

The boiler capacity is also calculated based on the conditions of its use. So, 10 liters is enough for washing dishes, 30 is enough for a quick shower, and 100 liters is enough for washing and taking a hot bath.

If gas double-circuit heating is used, the diagram involves connecting gas meters. This device must be taken into account when planning work.

What to do if the diameter of the gas pipeline does not match the boiler pipe

Sometimes the inlet on the boiler may not match the diameter of the gas pipeline. For example, the gas pipe of a Navien floor-standing boiler is 1/2″, and the gas pipeline is 3/4″. Is it possible to connect the device using a DU-15 1/2″ bellows connection instead of 3/4″? Such a transition is permissible, since it is local and does not provide significant resistance.

It is impossible to imagine a modern private house, and especially an apartment in an apartment building, without gas equipment. This could be a stove, a heating boiler, a heating boiler, or other household appliances.

Gas is supplied to a house or apartment through a pipeline system, and from it to each individual consumer via flexible connections. Flexible gas supply can be made in several versions at once.

Connecting gas equipment in a double-circuit heating system

You can install the heating system yourself, but the gas connection must be done by a specialist.

Even if you have the necessary knowledge, you still cannot work with gas equipment without special permission, since if the work is done incorrectly, there will be a danger to the lives of the residents of the house. If you make the connection yourself and correctly, you will have to pay a large fine when putting the equipment into operation. To obtain a permit you need:

- Contact the BTI so that changes can be made to the registration certificate of the house. On the plan it is necessary to indicate the room allocated for the boiler room and make the appropriate notes.

- Submit an application to the gas service and attach to it the registration certificate of the purchased equipment. At this point, you need to purchase everything you need to install the heating system.

- Install the equipment without connecting a double-circuit boiler - the diagram is indicated in the instructions (read also: “Which heating radiator connection diagram is optimal”).

- Invite a specialist from the gas service to connect the device. At the same time, an application is submitted to put the equipment into operation.

- Obtain permission from the gas inspector. Before this, he will check the correctness of the connection and then issue the required documents. Only after this will gas be supplied to the equipment.

Premises requirements

There are several rules that must be followed when choosing a room to install the unit:

- The presence of a window that can open at any time.

- Functional ventilation.

- The room must have outlets for all necessary pipelines to which the home boiler will be connected. Particular attention should be paid to the gas pipe. It must have a counter.

Usually the connection of similar devices is the same. The only thing that may differ is the location of the pipes. But this does not happen often.

Installation of gas equipment

When a double-circuit heating system is installed, the diagram must be followed exactly - only in this case will the equipment work correctly and efficiently.

The body of the heating unit should not be adjacent to the wall, nor should it be installed in niches.

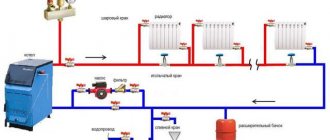

When tying, three systems are connected at once:

- electrical;

- hydraulic;

- gas

You can do the electrical and hydraulic piping yourself, but a specialist will do the gas piping (more details: “Pidding of a wall-mounted double-circuit gas boiler”).

Many gas boilers have a similar connection system. For this, a middle pipe is used, on the sides of which there are tubes for cold and hot water supply (read also: “How to calculate the power of a gas boiler”). The outer pipes are necessary to connect the equipment to the heating system. On the left, hot water flows into the batteries, and on the right, cooled water returns for heating. Thus, connecting a double-circuit heating boiler is quite simple; you just need to follow the recommendations of specialists.

A coarse filter must be installed on the return pipe connection - this is necessary in order to protect the boiler from debris and rust that will accumulate in the pipes. If it is not installed, the service life of the equipment will be significantly reduced. Screw the filter to the pipe in the direction of the arrow to the boiler.

The water supply and return pipes are equipped with taps, with the help of which, in the event of a heating unit breakdown, the water can be turned off. If this is not done, then before starting the repair you will have to drain the coolant from the heating system, and this will take time.

The water supply circuit is connected in approximately the same way; a filter is installed on the cold water supply to prevent the device from becoming clogged with debris.

To cut off the pipeline circuit, it is also necessary to install taps. When installing a double-circuit heating boiler, several conditions must be observed. Before starting the system, you need to make sure that the cold and hot water taps have not been mixed up. A mistake in this can lead to dire consequences - even an explosion of the gas boiler, so you should not take connecting the equipment lightly.

Next, the expansion tank is installed. It is needed to compensate for the expansion of the heating system due to increased pressure. The volume of the tank should be approximately equal to 10% of the amount of coolant in the entire system. Most often, the tank is installed between the boiler and the circulation pump, but it can also be placed in another place where it will not interfere. It will also come in handy if the pressure in a double-circuit boiler drops.

With bithermic heat exchanger

The bithermal heat exchanger is designed on the “pipe-in-pipe” principle. The internal structure may be different - companies try to improve their products and try different options. One thing remains unchanged: one large pipe is divided into parts - lengthwise. They are separated by metal partitions, sealed and do not communicate.

One of the options for a bithermal heat exchanger for double-circuit gas heating boilers

How does a double-circuit boiler with a bithermal heat exchanger work? One part of the pipe—the outer part—circulates coolant, which is supplied to the heating system. In the second part - the internal one - water appears only after a hot water tap has been opened somewhere. The previously operating heating circuit is closed (by a signal from the control board), all the heat is used to prepare hot water. All this time the circulation pump does not work.

Construction of a double-circuit boiler with a bithermic heat exchanger

When the flow of hot water stops (the tap is closed), the circulation pump turns on, and the coolant is heated again, which circulates through the heating pipes. As you can see, the design of double-circuit boilers with bithermal heat exchangers is simpler - there are fewer parts, sensors, and, accordingly, easier control. This is reflected in the price - they are slightly cheaper. At the same time, the efficiency of such boilers in water heating mode is slightly higher (on average 93.4% versus 91.7%).

There are also disadvantages - bithermic heat exchangers clog more often. In the DHW water heating mode, there is no circulation in the coolant circuit. This is not a problem if the system is sealed (as it should be) and does not require constant recharge.

This is how a bithermic heat exchanger overgrows

But if there is a leak somewhere and in order to maintain the operating pressure in the heating system it is necessary to constantly add water, the lumen of the part of the pipe through which the coolant circulates gradually becomes overgrown. When this gap is clogged with salts, the part that conducts water for hot water heating is more active. This leads to the fact that it begins to become clogged with salts and this part, the boiler, simply stops working.

Both circuits of the bithermal heat exchanger are subject to scale deposits

Radiator installation

The main elements of the heating system in the premises of the house are radiators.

Currently, many experts have begun to advise not to purchase traditional cast iron batteries, since they are heavy and have significantly worse properties than products made from a bimetallic alloy. In addition, the latest products look much more aesthetically pleasing and have good heat dissipation. Most often, radiators are installed under windows, making sure that there is free space between them and the window sills. Before this, old pipes and fasteners are dismantled, since they are not suitable for new systems. The wall is marked with a pencil in such a way that at least 10 centimeters remain from the radiator to the floor. Normal heat exchange between the battery and the room is ensured if it moves away from the wall by at least 5 centimeters.

There are several types of radiator wiring

The most common is the lateral one-way connection. In this case, the inlet pipe is connected to the upper branch pipe, and the outlet pipe to the lower one. Thanks to this, maximum heat transfer is achieved, and when connected in reverse, the power is reduced by approximately 10%.

The main advantage of the bottom connection is aesthetics - in this case, both pipes are hidden behind the baseboard. The pipes are located at the bottom of the pipe and face the floor.

Diagonal connection is mainly used for multi-section radiators.

As a result, hot water is supplied from one side into the upper pipe, and on the other, it is discharged through the lower one. Radiators are connected in two ways: in series and in parallel. With a parallel connection, water moves under pressure inside the entire system, and if one battery breaks down, all heating is turned off until the repair is completed. With a parallel connection, radiators can be changed without turning off the heating system.

The number of sections of the device must be calculated depending on the specific situation. This largely depends on the climate of the region and the quality of insulation of the house. But according to the standard, 1 radiator section is capable of heating 2 “squares” of area if the ceiling height is no more than 2.7 m. This formula can be considered conditional, since it is important to take into account other parameters: the thickness of the walls and their material, type and insulation parameters (for more details: “How to choose insulation for heating pipes and whether it is needed”), heater power, climatic features of the region. Double-circuit heating boilers should be selected taking into account the area of the room, but the heating efficiency largely depends on the area of the house and the type of radiators.

What is a bellows eyeliner and what are its advantages?

A bellows gas hose is a corrugated pipe made of stainless steel. Special fittings are installed at the ends of the hose to create a strong and safe connection. The connection to the pipes and equipment is secured using union nuts made of the same material. To increase the level of tightness, metal or plastic sealing rings are installed at the joint.

As a rule, sealing gaskets are included in the flexible hose kit.

Eyeliner kit

The advantages of a bellows hose over other types of flexible hoses designed for connecting gas equipment are:

- strength and rigidity. According to manufacturers' requests, the service life of the bellows is up to 25 years;

- possibility of correct operation at different temperatures;

- not exposed to direct sunlight;

- ability to withstand high pressure;

- possibility of stretching, and when the length increases to 50%, the strength of the liner does not decrease.

The disadvantages include the cost of the equipment, which is 2–3 times higher than the price of rubber analogues.

Pipe selection

Currently, the most common are polypropylene and metal-plastic pipes for heating, as they have considerable advantages over products made from other materials.

Polypropylene is considered one of the most durable materials; if installed correctly, pipes made from this material can last for decades. Their cost is not high, but for installation you will have to spend money on special tools and fasteners. During installation, the pipe must not be overheated; it must be quickly fixed in the desired position. This work requires special skills, so it is better to invite a specialist.

Metal-plastic pipes can be installed independently; their installation does not require special elements, except for compression fittings.

But at the same time, they last less, and in addition, a serious drawback of metal-plastic pipes is the rubber seal, which quickly collapses. But they are still a better option than copper and steel, which deteriorate even faster (for more details: “Polypropylene or metal-plastic for heating - comparison of pipes”). Gas and diesel double-circuit heating boilers are currently enjoying considerable popularity, but they are dangerous if connected incorrectly. Therefore, without having experience in installing such equipment, it is better to seek help from specialists who can perform all the work correctly.

Double-circuit heating system made of polypropylene on video:

Conclusions and useful video on the topic

Some useful tips for installing a gas boiler will help you check the correct installation of the equipment.

With all the perfection of gas equipment, with the presence of automation and serious technological protection, connecting the system requires compliance with established rules and regulations. Without this, it is impossible to guarantee the reliable operation of gas boilers.

Do you have anything to add, or do you have any questions about connecting a double-circuit gas boiler? You can leave comments on the publication and participate in discussions about the material presented. The feedback block is below.

This is a must know valuable advice

Before purchasing a flexible hose, it is necessary to check the size of the thread at the outlet of the plate, its classification and whether it is straight or angular. If the outlet is of a direct type (directed into the wall), you must purchase a sleeve with a square at the end.

The gas hose should not be painted - this will accelerate its cracking. A more attractive look can be created by covering it with special paper or oilcloth.

It is also strictly forbidden to tightly seal gas communications with false plasterboard panels and other structures - this will make it difficult to carry out service work on individual elements.

To camouflage the gas supply system, a collapsible box is used, which can be easily dismantled if necessary. In this case, there will be constant access to all structural elements of the gas system.

It is forbidden to use unnecessary connections. Independent complication of a gas structure, according to technical regulations, may entail a fine or disconnection from gas supply

If a technician was called to connect the gas stove, it is necessary to check that the work was performed correctly: the excess tap from the tap at the lower end should be unscrewed, the flexible line should be directly connected exclusively to the tap located on the branch pipe, and its other end - only to the outlet of the gas stove.

It is also possible to use an adapter. Any additional installations are prohibited.