Law of Hydraulics: Any flowing fluid chooses the path of least resistance. In the heating network of a private house, the rule works like this: the coolant pushed by the pump tends to pass through the first radiator or the shortest circuit of heated floors. As a result, remote rooms of the building warm up much less well. To ensure uniform distribution of flows, hydraulic balancing of the heating system is necessary. We'll tell you how to adjust radiators and underfloor heating hinges with your own hands.

The concept of balancing

For a heating system to operate as efficiently as possible, it is important that it releases heat in such a way that it warms all rooms evenly. This will not only provide warmth and comfort in the house, but will also help reduce heating costs.

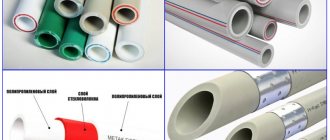

Heating systems can be divided into two types:

- Single-pipe or double-pipe. In them, the heated coolant moves through pipes from the heating boiler, giving off some of the heat to each radiator. Then the liquid that has lost heat enters the boiler again. After this, the cycle described here is repeated again.

- System with manifold connection. It has a distribution device, from which pipes go separately to each radiator. The adjustment occurs for each of them independently.

The last category includes heating systems that use not only radiators, but also heated floors.

The general principle of balancing is similar in different cases. Each radiator has an inlet valve. If they are all fully deployed, then the greatest heat loss in the first category of systems will occur in the first device. Further, increasingly cooled water will flow. To prevent this from happening, a valve is tightened in the initial batteries. Thus, the heat consumption will decrease and it will be enough for other heating devices.

Two-pipe system with heated floors Source eurosantehnik.ru

This procedure must be done in several steps to achieve the desired result. Between attempts, the batteries are given time to warm up properly.

For heating systems, regulation occurs by regulating the volume of incoming heated liquid. There should be so much of it that it is enough to heat each room.

The floors are adjusted in the same way, increasing or decreasing the heat supply. If the floors use heating based on the use of electrical energy, adjustment is made according to different rules, simply changing the settings.

Flow regulators, bypass valves, control valves, and pressure regulators are used to carry out adjustments. The layout of their installation depends on the specific type of heating system.

Thermostats occupy a special place. They have the most complete functionality. The device contains an electronic temperature sensor. The work takes place under the control of an electronic circuit. There is a simple and intuitive control panel.

The use of such electronic devices allows adjustments to be made at minimal cost. If necessary, it is possible to program the heating operation. For example, it is possible to reduce the heating temperature if the family is absent from the house for several days.

Water heated floors Source teplyiypol.ru

Warm floors and radiant wiring

Since the underfloor heating circuits and radiator radiators are connected to a common comb, balancing is carried out directly on the collector. The setting method depends on the availability of rotameters - transparent flow meter flasks installed on the supply or return lines.

To correctly configure the coolant supply using rotameters, you should calculate the water flow through each loop using the formula:

The power of one floor circuit Q is determined based on the heat demand of a separate room. The parameter is calculated according to the specific ratio of 100 W/m² of room area or according to the method of calculating the heating load. The flowmeter scales are marked in l/min, which means the result must be divided by 60.

Calculation example. Heating a room with an area of 10 square meters requires 1 kW of heat. Coolant consumption will be 0.86 x 1000 / 10 = 86 kg/h or 86 / 60 ≈ 1.43 l/min.

Clarification. If a large area is divided into 2 identical heating monoliths with separate water loops, we also divide the calculated flow rate in half.

Further balancing of underfloor heating loops is carried out according to the instructions:

Reference. On manifolds from different manufacturers, flow meters are installed on the supply or return manifold (they also differ in design). To adjust the maximum flow, the location of the rotameters does not matter.

Beam batteries are balanced in a similar way. To be sure, you can combine 2 options - according to the calculated flow rate and the temperature of the radiator surface (the method is described in the previous section).

fastening plastic pipes to the wall with clips

Scheme of flow control with a rotameter. The flow rate through each circuit is shown by control washers in transparent flasks, the unit of measurement is liters per minute

If, in order to save money, you managed to buy a collector without rotameters, the setup will take several days. The goal is to achieve the same temperature in the return pipelines of all loops. That is, the initial installation is made approximately according to the power and length of the circuit, then the return temperature is measured and the flow rate is adjusted.

To check the balancing of the heated floor, you need to start the heating boiler. Negative point: after adjusting the flow rate, you will have to wait several hours until the thickness of the concrete warms up and the temperature of the return lines stabilizes.

Adjustment methods

When balancing the heating system in a private home, you can use temperature readings or coolant flow data as a basis. Each of them has its pros and cons.

First way

The installation implies that all necessary calculations for coolant flow have been previously carried out for the project. It is necessary not only to have control valves, but also measuring devices. Here it is possible to control the volume of coolant pumped through the system and make the necessary settings if necessary.

The advantage of using this method is the high quality of heat control in various rooms. The disadvantage of this approach is the relatively high cost of installing such a system.

Heat distribution in a room Source thebridgestudio.ru

Second way

It is suitable in situations where no preliminary calculations were made when installing the heating system. Then the heating system is adjusted as follows. In such cases, thermometer readings are used for adjustment. At the same time, they try to make the heat consumption approximately equal for each radiator. If the battery is installed in a large room, then it is adjusted so that the heating is proportionally higher.

The simplicity of the procedure is the main advantage of the process. The disadvantages include: insufficiently precise adjustment of heat consumption, the duration of the balancing procedure.

System with collector distribution Source gidrotermika.ru

Recommended radiator thermostat settings for different rooms.

The comfortable temperature for different rooms differs; the table shows the recommended thermostatic head settings for each of them.

| Position on regulator | Room temperature | Mode or type of room |

| * | 7℃ | Frost protection |

| 1 | 15℃ | Staircases and halls |

| 2 | 18℃ | Bedrooms |

| 3 | 21℃ | Living rooms |

| 4 | 24℃ | Bathrooms |

| 5 | 27℃ | Maximum temperature setting |

In what situations is balancing necessary?

In practice, this procedure must be performed in any case. When designing it, a certain level of heat use is planned for each radiator and heated floor. The calculation is performed based on the minimum permissible temperature in this area.

It is important that its distribution in the operating system corresponds to the planned values. After the system has been installed, all valves are first opened fully. Then measurements are taken and balancing is carried out.

A homeowner may need to perform balancing in the following cases:

- One or more radiators are noisier than usual - you can hear the sound of flowing water from them.

- If you touch the radiators in the house, you can easily notice that some radiators get much hotter than others. Moreover, among them there are both hot and barely warm.

- If the house has warm floors, you need to pay attention to the degree of heating of various areas. If you can find clear differences, it makes sense to think about balancing.

- If the apartment owner himself did the heating wiring, he must check how the heat is distributed and make appropriate adjustments.

Successful hydraulic balancing is only permissible if the heating devices and fittings have been selected correctly and there are no air pockets in the system. Otherwise, you must first correctly install the heating system and only then engage in more precise balancing.

How heating works in a private house Source kit-santech.ru

It is necessary to remember that you should not interfere with the operation of the heating system again if it is operating in normal mode. This applies to the following situations.

- When the equipment works flawlessly. Making adjustments is not only pointless, but also dangerous. As a result of the actions of an inexperienced person, the work may deteriorate.

- If technical problems are identified, then balancing the heat dissipation is pointless. First you need to repair the system and only then should you fine-tune the work. This, for example, applies to the following situations: coolant leakage due to a leak in the equipment, air locks, clogged one or more control valves, damage to the expansion tank membrane. Perhaps after finishing work, the heat distribution will become normal.

You should avoid making your own connections to the heating system of an apartment building. They can disrupt heating not only for the owner, but also in other apartments. The only exception to this rule is when individual thermal input is made to each apartment. In a private house there are no such restrictions.

Do not use ball valves to partially restrict the coolant flow. It must be used only in extreme positions, otherwise it quickly becomes faulty due to the influence of the coolant on the surface of the inner ball.

Heating system elements Source septik-pro.com

The most popular manufacturers of thermal heads

The market offers a wide range of thermal heads of various designs. These are liquid and gas thermal heads with a built-in thermoelement; they perfectly perform the main task of regulating the temperature in rooms. They also have an attractive design and original complement to the interior of the room.

Danfoss

The Danish company produces a large range of gas condenser and liquid thermal heads. Gas thermoelements are produced in series from RA 2000 to RA 2991, also available with a remote sensor RA 2992, anti-vandal - RA 2920. The range of temperature settings for these devices is 5-26 ℃, the waiting time is a maximum of 12 minutes. There is a function to protect the coolant from freezing, the ability to limit or block changes in the set temperature scale.

Danfoss RA 2920

Liquid thermoelements from this manufacturer are produced in the following series:

- RAE;

- RAW;

- RAS-C;

- RAS-C2.

Danfoss produces a series of premium thermostats, living eco and living connect, with a backlit display and powered by AA batteries. These thermostats have settings programs that allow you to reduce the room temperature to 17 ℃ at night and during working hours.

Living connect series thermostats are often used as part of intelligent smart home systems. Both series allow you to control the thermostat from your mobile phone via Bluetooth.

Danfoss Living Eco

Oventrop

The German manufacturer positions itself on the market as a manufacturer of high-quality engineering fittings. Exclusive products from Oventrop create special accents in the room. The design and color scheme match the interior, as well as the shape and color of the elegant radiators.

The thermostat for heating batteries "Pinox" not only attracts attention with its design, but also impresses with its functionality. The thermostat is supplied with M 30 x 1.5 thread and clamp connection. It allows you to easily and accurately adjust the temperature in the building. Thanks to its one-piece design, the regulator is impervious to dirt and easy to clean. Works without a power source.

Oventrop Pinox thermostat

The "Uni SH" thermostat with liquid element and threaded connection M 30 x 1.5 is easy to operate and has a clear scale. The thermostat has a raised mark for the visually impaired. The selected setting value can be marked using a memo puck.

Oventrop Thermostat Uni SH

Heimier

Also a well-known German brand, it produces more than 12 types of thermal heads. These are mainly liquid regulators with connection type M30*1.5, M28*1.5, which is most often used in our country.

Liquid thermal head HEIMEIER D

Among them you will find different thermal heads by design:

- with remote sensor;

- with a remote control mechanism;

- anti-vandal for installation in public places.

Heimeier F thermostat with remote adjustment

Preparation for the procedure

Before you start balancing, prepare everything you need for it. To get started, you will need the following:

- A special contact thermometer with which you can accurately determine the degree of heating at various points.

- In order to adjust the balancing valve, you will need a hex wrench.

- If it has been preserved, it is advisable to take a heating wiring diagram. It may not exist if the equipment was installed a long time ago or was done without a diagram prepared in advance.

- You will need paper, pencil and marker.

Instead of a contact thermometer, you can use other models. Professional specialists often use a specialized thermal imager for this purpose. You can also use a remote pyrometer.

If there is no wiring diagram, then you need to sketch out a plan for the location of its elements yourself. First of all, the sequence of connecting the radiators and their distance from the boiler room are noted. Balancing a two-pipe heating system is similar to what is done for a single-pipe one.

When heating balancing begins, the mud trap at the inlet of the heating boiler is cleaned. Then it is necessary to warm up the heating boiler. This must be done up to maximum operating temperature. It doesn’t matter whether the weather outside is cool or hot.

How to heat a private house Source septik-pro.com

Control valves for radiators

To manually regulate the operation of heating devices, special valves are used. Such taps are sold with straight or angular connections. The procedure for regulating heating batteries using these devices manually is as follows.

When the valve is turned, the shut-off cone lowers or rises. In the closed position, the coolant flow is completely blocked. Moving up or down, the cone regulates to a greater or lesser extent the amount of circulating water.

Due to this operating principle, such valves are also called “mechanical temperature controllers”. They are installed on batteries with threads, and connected to pipes with fittings, most often of the crimp type.

The control valve used for heating devices has the following advantages:

- the device is reliable, it is not dangerous from blockages and fine abrasive particles present in the coolant - this applies exclusively to high-quality products in which the valve cone is made of metal and carefully processed;

- the product has an affordable price.

Control valves also have disadvantages - each time you use the device, its position has to be changed manually and for this reason it is quite problematic to maintain a stable temperature regime.

For those who are not satisfied with this procedure and are thinking about how to regulate the temperature of the radiator using another method, the use of automatic products that allow them to control the degree of heating of the radiators is more suitable.

How the balancing procedure is performed

It is important to note that when carrying out it, it is necessary to take into account what kind of heating system is used - it can be single-pipe, two-pipe, with a collector or using heated floors.

Two-pipe heating system

To balance a two-pipe system, you must perform the following steps:

- When the coolant is well heated, all existing valves must be fully opened.

- At the outlet of the heating boiler, the liquid temperature should be maximum. To do this, a contact thermometer is applied to the pipe that leads from the boiler to the first radiator.

- Next, move on to the nearest radiator. It is necessary to measure the temperature of the coolant at the inlet and outlet. If the equipment is working properly, this difference should not exceed 10 degrees. In the case when the specified requirement is met, it is considered that this radiator does not require adjustment.

- A similar procedure is carried out in relation to each radiator installed in the house. At each step, the obtained data must be recorded.

- It is necessary to compare the temperature at the input valves of the first and last radiators. If it is less than 2 degrees, you need to tighten the input valves of the first two batteries by 0.5 or 1 turn. After this, the measurements must be repeated. The temperature difference is expected to increase slightly.

- If the value under consideration is in the range of 3-7 degrees, the inlet control valves of the first two radiators are tightened by 50%-70%, the next two by 30%-40%, and the rest are left unchanged.

- Before taking the temperature again, you need to wait 20-30 minutes. This is required so that the heating equipment warms up in accordance with the new settings. You need to make sure that the difference does not exceed 2 degrees at the inlet taps of the first and last radiator. If the heating main is of considerable length, the difference is allowed to be 3 degrees.

- These procedures must be repeated, tightening the input valves until the goal is achieved. These steps may need to be repeated several more times.

When hydraulic balancing is performed, it is necessary to control the temperature difference between the inlet and outlet valves. If it is more than 10 degrees. The inlet valve will need to be unscrewed slightly. It must be taken into account that precise adjustment occurs individually for each heating system.

Balancing valve for radiator Source termopaneli59.ru

Single pipe heating system

When adjusting a one-pipe system, they usually try to tighten only the valve on the first radiator. Usually after this it is possible to immediately achieve the desired indicators.

Manifold system

This section discusses balancing a system in which pipes are connected to a single node. Such balancing can also be carried out for heating systems that additionally use heated floors. These methods are also used to regulate the operation of heated floors. In this situation, there are two configuration methods.

Balancing valve for radiator Source termopaneli59.ru

How to install a thermostat on a battery: step-by-step instructions

You will need:

- metal-plastic pipe with a diameter of 20 mm;

- 2 tees with 1/2″ thread;

- 6 American metal-plastic compression fittings;

- thermostat;

- ball valve

Procedure:

Unscrew the drive nut with an adjustable wrench and unscrew the old winding.

Clean the threads of the outlet so that the connection between the radiator and the pipe is clearly visible.

Perform the same operation with the lower connection. For ease of installation, remove the radiator and place it on a flat horizontal surface. Hold the radiator cap with one wrench and unscrew the tube with the second.

After this, remove the old seal from the hole, for example, with a screwdriver.

Now you need to assemble a bypass with a thermostat and a ball valve. Coat the threads of the compression fitting with silicone sealant until it fills all cavities.

Take 2 tees and 2 nipples and twist them together.

Screw the thermostat and ball valve to the nipple.

Install transition couplings from metal-plastic to metal into the tee. You should end up with a knot like this.

Screw it into the battery.

Do the same with the bottom connection.

For the bypass, cut off a section of metal-plastic pipe of the required length, after first removing the nuts from the compression fittings and measuring the distance.

Calibrate the edges, that is, remove the chamfers with a calibrator.

Place the nut and ferrule on the pipe and connect it to the ball valve and thermostat.

Do the same with the other end of the pipe. The jumper (bypass) is ready. Connect it to the radiator.

Hang the battery on the old mount and connect it to the riser. To do this, prepare 2 metal-plastic tubes. Don't forget to measure the length at the top and bottom - it often varies.

Remove the bypass from the radiator. Screw the tubes into the upper and lower nodes.

Install the bypass on the radiator, and the tubes in the riser outlets. At the top there is a thermostat for heating.

Below is a ball valve.

Tighten the nuts with an adjustable wrench. The radiator with thermostat can be put into operation.

Features of heating systems

Balancing hydraulic heating systems depends on the design of the system. There are circumstances that make the procedure easier:

- When a private house uses a boiler powerful enough to heat the entire home.

- Three-way valves are installed in the batteries.

- It is possible to carry out forced pumping of the coolant.

- If heating is not very important in certain rooms (such as a basement, garage or similar), then you need to take care of high-quality thermal insulation of pipes. This will reduce wasteful heat consumption.

- When adjusting the heating system, it is desirable that the heating system is turned on. This will allow you not only to carry out balancing, but also to evaluate the result based on your feelings. It is important not only to evenly distribute the heating between the batteries, but also to optimally determine the intensity of their work.

- To ensure efficient system operation, excessive heat loss must be prevented. In this case, it is necessary, for example, to take into account the operation of the ventilation system and the use of air conditioners.

- When making adjustments, it is recommended to pay attention to which room in the house is the coldest. It is recommended to open the valves as much as possible, and adjust the rest taking into account the fact that maximum heat consumption is expected in this room.

- When adjusting, for example, a two-pipe heating system, it is important not only to evaluate the temperature of the coolant, but also to hang thermometers in the rooms to evaluate the result of this work. It is important to consider that the comfortable temperature for different family members can differ significantly. Therefore, before you start balancing, you need to plan. What air temperature in the rooms should be obtained after the settings are completed.

- It is necessary not only to maintain a balance between the batteries, but also to correctly regulate the operation of the heating boiler. It should not work in vain, creating unnecessary additional heating in the house.

Using a steel radiator for heating Source utepleniedoma.com

Applications of three-way valves

One way to regulate heating radiators is to use a three-way valve. True, it is rarely used. Despite the fact that it is designed to solve other problems, such an application is possible.

Install a three-way valve at the junction of the bypass with the supply pipe going to the heating battery. To stabilize the temperature of the working environment, it must be equipped with a thermostatic head.

When the temperature near the head of the three-way valve becomes higher than the set parameter, the flow of liquid moving to the radiator is blocked - it is sent to the bypass. After the coolant cools down, the valve begins to operate in the opposite direction, and the battery heats up again. This connection method is usually implemented in single-pipe heat supply systems, with vertical wiring.

What are the differences between different types of heating systems?

In one-pipe and two-pipe systems, each radiator is connected to two pipes. In a two-pipe system, the waste coolant is directly supplied to the boiler for heating. In a single-pipe system, the incoming pipe is connected to the outgoing pipe right next to the battery. As a result, warm and cold water is mixed.

Balancing valve for heating system Source iobogrev.ru

When using a collector connection, the pipes from each battery are connected separately to a common stand. Sometimes built-in measuring instruments are used to determine the supplied volume of coolant. This device is also used in cases where water heated floors are used.

The efficiency of operation depends on the material from which the radiators are made. If it is made using aluminum, steel or copper, it will quickly heat up and lose body. Cast iron batteries slowly gain temperature and retain it longer. If the owner plans to install a new model, then this must be done before the start of the heating season.

Heating of a private house Source innstroy.ru

In an apartment building, the possibilities for hydraulic balancing of the heating system are very limited. If vertical water supply is used in separate risers, then adjustment becomes impossible. In a private house the situation is completely different. Not only adjustments are available here, but also redevelopment of the heating system.

Needle valve

This device is usually installed in the heating system in front of the pressure gauge. The valve smoothly and effectively changes the flow of coolant, gradually blocking it. The design feature of this device is that the width of the passage in it is half as much.

For example, when installing inch pipes and the same cross-section of a needle valve, its capacity will be only ½ inch. As a result, each device built into the system reduces this parameter. Several products installed in series, for example in a single-pipe design, result in the latter devices being lukewarm or cold.

Since the passage is greatly narrowed, a needle device is not recommended to be installed when solving the problem of how to regulate the temperature of the battery, since its heat transfer is greatly reduced.

You can increase it as follows:

- removing the valve;

- doubling the number of sections;

- by installing a device that has twice as many couplings.

Criterias of choice

A radiator valve is, as a rule, a ball-type device that regulates water flow and connects pipes to the radiator.

Installed on the bypass, risers, at the top of the battery, in places where air accumulates to bleed it. Choosing a suitable faucet is not difficult, just know a few nuances:

- the diameter of the pipes to which it will be connected (DN, in millimeters or inches);

- working pressure (PN, in the range of 15–40 and above);

- type of connection, presence of thread inside or outside, American.

The choice should take into account the purpose of the reinforcement, its location, and the properties of the environment

The ratio of the input and output of the valve in the radiator, their relative position is also important

When choosing, you should consider the characteristics of the cranes:

- Ball valves, although the most common and affordable, are not very effective. It has only two modes: closing/opening;

- a cone valve is a more acceptable option due to the possibility of an intermediate position. Disadvantage: the tap must be returned to its original position and constantly monitored;

- An automatic thermostat is the most efficient, reliable, but also much more expensive than others. When installing it on a one-pipe system, a bypass must be present.

What to consider when installing taps

When installing various taps, it is necessary to take into account, firstly, personal preferences, that is, whether you want to overpay for more precise temperature control, and secondly, the parameters of the room, house, and so on.

The instructions for installing shut-off valves of various types are very similar to each other. It is imperative to check everything for leaks in order to avoid accidents; you also need to take into account the convenience of using such devices. You shouldn’t waste money on a seal; it’s better to choose trusted manufacturers.

If you do not understand anything about installing shut-off valves, then it is better to consult with a professional about what type of faucet you should install in your home.