02.12.2020

Water

Editorial staff of the “New Place” website

Share

From this article you will learn

:

- Types of wells for a private house

- Selecting a scheme for supplying water to a private house from a well

- Arrangement of a caisson when carrying water from a well

- Laying pipes when carrying water to a private house from a well

How to supply water to a private house from a well so that the system functions without unnecessary hassle and supplies all household members with clean water in sufficient quantities? It all starts with finding water. And it may take several months before the water supply is connected to the house.

Autonomy in water supply is convenient; the cost of laying communications quickly pays off with an uninterrupted supply of clean water under good pressure. Below we describe in detail how to supply water to a private house from a well.

Types of wells for water supply to a private house

Well on sand

Water is pumped from the surface sand layer. The depth of such a well is 20-40 m. A sand well has low productivity (up to 1.5 m3/hour) and is suitable for a small private house. During installation, the water supply system must be equipped with an additional filter to remove sand from the water.

Well for limestone (artesian well)

Water is taken from a deep limestone layer. The well depth reaches 200 m. Thanks to this, it has high productivity (up to 10 m3/hour) and is suitable for water supply to several areas or even a small village. In this case, the water from the limestone soil comes out clean and does not require additional treatment.

Drilling a limestone well is expensive. And you also need to obtain a license to use artesian waters, since they are the property of the state.

The choice of well type depends on the depth of the aquifer. Before constructing a well, test drilling is done to calculate the depth.

Abyssinian well

It is a stainless steel pipe with a tip and a mesh filter. The pipe is driven into the ground to the aquifer, 10-15 meters. A hand pump is connected to the outer end of the pipe. The Abyssinian well is rare, so we will not dwell on it in detail; we are more interested in water supply with a submersible pump.

Main characteristics of the well:

- Well depth.

Equal to the depth at which the aquifer lies. - Static level.

The highest level to which the well is filled. - Dynamic level.

The lowest level to which the pump can pump water. The water does not fall below it. - Well flow rate.

Well productivity, that is, its filling in 1 hour (m3/hour).

The characteristics of the well are indicated in the data sheet; they are necessary for selecting water supply equipment.

Which sand filter is better to install?

In order to choose the right design specifically for your case, it is necessary to analyze the quality of the drinking liquid (the presence of impurities and the content of various substances). This is the most reliable way to determine which device is best for you - according to your case. Having determined the level of impurity contamination, you can install equipment whose power will be sufficient to solve your problems. This will allow you not only not to overpay for an expensive device, but also not to make a mistake with your choice.

Water filter for sand in the country: which one to choose

The hole or mesh type devices mentioned above are best suited here. Small stones, gravel, clay, sand particles will be retained with their help at the very beginning of the fence.

Industrial version

The main difference between household devices and industrial devices is power. Industrial equipment is designed to process large quantities of water, but in its design and functional use it is not much different from conventional equipment. However, it all depends on the specific purposes of use. Sometimes there are more complex options than those used to purify drinking liquid on a household scale.

Casing pipes for water supply wells

For wells, pipes made of plastic (HDPE, PVC) or metal are used. Plastic pipes are used more often because they are more cost-effective, do not corrode and are easier to install. However, plastic is subject to deformation and the pipe can be compressed by soil, so for wells longer than 60 meters metal pipes are used.

The most common sizes of plastic pipes:

- 113 mm (5 mm wall) is suitable for installing a 3-inch pump together with an adapter.

- 125 mm (7.2 mm wall HDPE and 5 mm PVC) with 3" pump and well adapter or 4" pump with head

Metal pipes for water supply can be welded or threaded. It is better to choose pipes with a welded connection, since the threads become loose over time under soil pressure. Metal pipes are durable, but they are more expensive than plastic ones, are susceptible to corrosion and are more difficult to cut out the inlet hole for the pipe - the bimetallic crown must be cooled with water all the time.

Metal pipe sizes:

- 89mm with 2" pump.

- 114mm with 3" pump.

- 127mm with 3" pump and adapter.

- 133 mm (once such pipes were used everywhere, today they are rare). Suitable for installation is a 4-inch pump, both with a head and in the version with an adapter.

Methods for organizing water supply from a well

There are two arrangement schemes: with an adapter and a caisson. The most profitable option is to use an adapter with a 3-inch pump. It is installed quickly and simply: below the freezing depth, a special device (adapter) is cut into the casing, through which water enters the supply pipe 32, and then into the house. To arrange this, pipes with a diameter of 113 mm or more are selected for the well.

Fig.3. Installation diagram of water supply from a well using an adapter

Construction of a well with a caisson will cost much more. On our website, the price of a plastic caisson starts from 39,000 rubles. However, in some cases, a well adapter cannot be used on a site, only a caisson. For example, when the water supply needs to be connected not to one building, but to several objects - to a bathhouse, a guest house or a neighboring dacha.

Fig.4. Scheme of well arrangement with caisson

Storage septic tanks

The second popular method of wastewater disposal is its accumulation and storage with subsequent removal. This method is used even when working with nuclear waste, and human waste is safer in any case.

Accumulation plant is the cheapest and most popular method of wastewater collection

How it works? The sealed container is buried in the ground and periodically, vacuum cleaners are called to pump out the excess mass that has entered the tank. A storage tank is essentially an improved version of a cesspool. Once in it, the wastewater is divided into fractions: heavy substances sink to the bottom, and light substances (such as fat, etc.) rise to the top.

Calling a sewer truck for one yard is expensive and impractical; it is wiser to cooperate with neighbors and order a car for several farmsteads at once.

But even without taking this factor into account, “burying the problem in the ground” has its drawbacks. Firstly, the tank can fill up quite quickly; the wastewater level must be constantly monitored and the tank must not be overfilled. Secondly, vacuum trucks cannot enter any area, so the “accumulation zone” should be located close to the roadway.

Borehole adapter, installation of water supply from a well without a caisson

The adapter is a small connecting device. It allows you to insert the water supply pipe directly into the casing, without a caisson. Roughly speaking, this is an insertion into the casing below the freezing depth.

Downhole adapter device

Fig.8. Water supply diagram from a well to a house with a well adapter

Advantages of a water supply system with a well adapter:

- Low price. The cost of installing the adapter is 4,500 rubles. For comparison, installation of a caisson with a slab and anchoring costs from 25,000 rubles.

- Installation is less labor-intensive than in the case of a caisson. When installing a caisson, it is necessary to pour a concrete slab, anchor the container, sprinkle the central heating system, install the coupling hermetically and remove the pipe.

- Does not take up space on the site, unlike a caisson.

The adapter is not suitable if you need to supply water to several objects at once (sites or buildings on the same site). In such a situation - only a caisson. Besides:

- The adapter occupies approximately 2.5 cm in the pipe. This must be taken into account when selecting a pump by diameter.

- It is difficult to install. Both parts of the adapter need to be connected correctly on both sides of the casing, this requires skill.

More details in our article: caisson or well adapter.

How to install a borehole adapter:

— A hole is made in the casing pipe with a 40-44 mm bimetallic crown;

— One part of the adapter is screwed onto a metal rod, lowered into the pipe and inserted into the hole.

— The second part of the adapter is inserted into the pipe from the outside and screwed to the first through a sealed rubber ring.

— The third part with the pump connected to it is lowered into the well and inserted into the already secured threaded part of the adapter.

Video: Installing a Downhole Adapter

If you are interested in how to conduct water from a well using an adapter, use our guide to installing a well adapter yourself. Also, if you don’t want to do it yourself, we can install the well using a turnkey adapter.

Features of installation and maintenance

One of the most common installation methods is the inlet version.

If the water supply system involves a complex configuration, then installation of individual segments is acceptable.

After the work is done, testing is carried out for possible leaks and errors. If there are any, they will be eliminated.

Conditions that must be observed for installation work:

- filtration equipment is installed in front of the meter - this will help avoid clogging;

- During installation, the sump must be directed downward;

- The direction of flow and the location of the filter element must match.

The frequency of preventive installation work is determined by the degree of contamination of the drinking liquid and the service life of the entire water treatment system.

Selection of a pump for organizing water supply from a well

For water supply from a well, submersible pumps of small diameter are used - 2-4″ (50.8-101.6 mm). The Zagorod company most often installs Belamos TF centrifugal pumps with a diameter of 3″ (76.2 mm) in water supply systems.

Advantages of Belamos TF-3 well pumps:

- The body is made of high quality stainless steel and brass.

- There is a thermal protection system that turns off the engine if it overheats.

- Special seals allow the pump to be lowered 80 m below the water level.

- The pump operates with solids content up to 180 g/m³.

The water supply pump is selected taking into account the diameter of the casing pipe and the installation method. If a PVC pipe with an internal diameter of 107 mm (OD 125 mm, wall 9 mm) is used, then a 4 inch (101.6 mm) pump can be lowered into it. This option is suitable when installed through a caisson. When installed through a well adapter, it takes up approximately 1 inch (25 mm) inside the pipe and a 4-inch pump cannot be lowered into it, so a pump with a 3-inch diameter is installed.

Other popular pumps for water supply to a summer house or country cottage

Grundfos SQ-3.

Pump housing made of stainless steel. Diameter 3". Can pump water containing sand up to 50 g/cu.m. m. Built-in check valve and dry-running protection relay.

Fig. 10. Well pump Grundfos SQ 3-55

Belamos TF.

The body is made of stainless steel. Diameter 4″ (97 mm). Can pump water from a depth of up to 150 m, depending on the model. There is a built-in check valve. A pump with an optimal price-quality ratio.

Fig. 11. Well pump Belamos TF-25

Pumping stations for wells

In addition to submersible pumps, we install surface pumps (pumping stations) for wells. But there are nuances:

- The pumping station lifts water from a depth of no more than 8 meters.

- The pumping station is not used with a drain valve. When installing a caisson, this is not a problem; it can have a separate tap for draining water.

- To start the pumping station, there must be water in the system. It is filled through the station.

- The station creates noise during operation. It is better to install it in a dry, warm basement or in a separate technical room or in a caisson.

Important! Do not use the pumping station if the dynamic water level drops below 8 m. The station will not lift water from such a depth.

The Zagorod company provides water supply with Belamos and Grundfos MQ pumping stations.

Belamos Stations

already come assembled with a hydraulic tank and pressure switch. If the station overheats, it automatically turns off.

Grundfos MQ pumping stations

are equipped with a check valve, a pressure switch and a dry-running protection relay. They also have a built-in hydraulic tank, but it is small, so a hydraulic tank of the required volume is usually installed with the station.

How to minimize pollution?

Sand and lime may appear in the water due to the initial properties of the aquifer or errors during drilling or use of the well.

You can minimize the likelihood of well contamination with sand grains using a set of measures:

When drilling, you need to monitor the condition of the casing pipe.- The new well should be thoroughly flushed.

- A caisson and a cap should be made on top around the outlet hole.

- In sandy soils, vibrating pumps should not be used for pumping.

- Long pauses in work should not be allowed.

Important. It is impossible to completely eliminate the ingress of sand, but it will be possible to delay the occurrence of problems and reduce the mass fraction of solid impurities in deep water using these methods.

In any case, for long-term safe operation of the well, filters will be required.

Automation for water supply wells

Downhole automation is conventionally divided into three generations:

First generation.

The simplest automation. Consists of a hydraulic accumulator, pressure switch and dry running relay (optional).

Second generation.

Control unit and electronic sensors. A hydraulic accumulator is not required.

Third generation.

Programmable systems allow you to control the pump up to adjusting the voltage supply to the motor.

Read more about automation systems for borehole pumps in our article automation for pumping equipment.

The Zagorod company installs first generation automation. It is simple, but inexpensive and reliable. The devices are mounted through a five-pin fitting (five-pin). The following is connected to the connector terminals:

- Pump.

- Internal water supply pipe.

- Pressure gauge.

- Hydraulic accumulator.

- Pressure switch.

Fig. 13. Scheme of water supply from a well with a hydraulic accumulator

Question! Is it possible to do without a hydraulic accumulator in a water supply system?

Yes, you can. To do this, it is necessary to install the appropriate automation (unlike well pumps, well pumps do not have built-in automation). However, comfortable conditions - with a standard of 20-30 starts - can only be achieved by using a hydraulic accumulator. Without a hydraulic tank, the pump will turn on every time the tap is opened, and the automation will not protect against water hammer.

The pressure switch turns the pump on or off when the pressure changes. At the bottom of the relay there is a metal membrane. When the taps are closed, the pressure increases, the membrane bends upward and moves the spring to a given range. When displaced, the circuit opens and the pump turns off. When the tap is opened and the pressure drops, the membrane returns to its original position. The spring opens and closes the circuit. The pump turns on. If there is water in the hydraulic tank, it enters the pipes and compensates for the pressure drop. The pump does not turn on, its working life is saved.

Do-it-yourself connection of a pressure switch in a water supply system from a well

Fig. 16. Electrical diagram for connecting the pump automation

Draining water from a well for the winter

To drain water for the winter, a drain valve is installed in a caisson. If an adapter is installed, an automatic drain valve is installed on the pipe in the well. Important: when using a surface pump (pumping station), the drain valve is not used.

Fig. 17. Operating principle of the drain valve

Watering tap

You can also remove the watering tap. When piping through an adapter, the tap is removed from the house. If a caisson is installed, then the output is made from the caisson. In summer, the tap is used for watering, in winter - for setting up a skating rink or slide on the playground.

Fig. 18. Removing the watering tap from the caisson

Fig. 19. Removing the watering tap from the house

House water supply unit

Entry is made in a technical room or bathroom through a 1” tee and a “1” ½ fitting. Then screw in the gland and clamp the cable. The seal is necessary to ensure tightness.

The input kit is usually three meters (the distance from the tee to the freezing point). In most cases, this is enough even if the house is on stilts.

Water treatment for a private home

Groundwater may contain excess chlorine, iron, manganese, calcium and magnesium. Special filters have been developed to purify water.

A water treatment system is a set of filters with different functions:

- Aeration filters remove iron. It oxidizes and precipitates;

- In filters for mechanical cleaning, large suspensions, sand, and rust particles are deposited;

- Activated carbon filters retain chlorine;

- In ion exchange filters, water is softened;

- pH filters even out the acid-base balance.

Before selecting equipment, you need to determine the chemical composition of the water, that is, find out what it needs to be purified from. It is recommended to immediately do a water analysis after pumping the well. If you buy a water treatment system from our company, we can take the water for analysis. It takes several days. After this, we will select equipment for water treatment. You can do the wiring of the filters according to the diagram yourself; it’s not difficult. We recommend ordering commissioning of the system from us.

Laying water pipes around the house

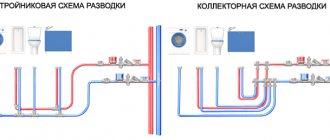

Collector wiring

They install common collectors (combs) for cold and hot water, from which pipes are drawn to each plumbing fixture. Thanks to this, you can use the bathtub, sink and kitchen sink at the same time, without any pressure surges.

Important! There are often errors in diagrams from the Internet. For example, in this diagram, the oblique filter is installed with the mesh facing up. This cannot be done: dirt will not get into the filter, and the pipe will become clogged over time. This must be taken into account when installing yourself.

When to use:

- If there are many water points in the house, you can shut off the water for each point separately.

- If pipes need to be hidden.

This wiring is most popular in cottages from 100 sq.m. made of aerated concrete or wooden frame. In large cottages it is easier to allocate space for collectors, and in the walls and floors of frame and aerated concrete houses it is easy to hide large quantities of pipes.

For collector wiring, pipes made of cross-linked polyethylene or metal-plastic 16 mm are used. Our standard option is a hidden collector distribution with metal-plastic pipes.

Tee wiring

Tee bends are installed on the pipes to the water collection points.

Applies when:

- There is little plumbing in the house.

- If the pipes cannot be laid hidden.

This wiring is cheaper and the system takes up little space. Ideal for houses and cottages with a small number of residents. The peculiarity of this wiring is that if you turn on the water at one water intake point, the pressure at subsequent ones drops.

For tee distribution of water supply, 20 mm polypropylene pipes are used. If there are more than 3 water supply points on one branch, then it is preferable to take a 25 mm PP pipe.

Septic tanks with soil treatment

A cheap, simple and advanced analogue of concrete wells are plastic septic tanks with soil purification. They usually look like barrel-shaped tanks with lids. When choosing a factory septic tank, you should take into account the number of tanks, volume and number of chambers in them. So, with a consumption of 1 cubic meter of water per day, a single-chamber tank is sufficient, with a consumption of 5 cubic meters per day - a two-chamber one, and with a consumption above 8 cubic meters per day - a three-chamber one. The more compartments, the better the quality of wastewater treatment.

Multi-chamber installations provide wastewater treatment for subsequent discharge into ditches

How it works? In the three-chamber model, wastewater first enters the first chamber, and the heavy fractions sink to the bottom. After some time they turn into sludge. Light particles, along with water, enter the second chamber, where they are processed by bacteria. The purified composition is pumped into the third chamber. There, a filter and a special antiseptic mesh with colonies of bacteria await him.

Next, 60-70% purified water enters the filtration field, which is a trench with crushed stone in which perforated pipes or an infiltrator are laid. Here, wastewater is further purified by aerobic bacteria, after which the liquid is drained into a drainage ditch. An integral part of such a treatment system is ventilation pipes (they are needed for air access and maintaining the vital activity of aerobic bacteria).

This is what a septic tank looks like with soil post-treatment in the form of a multi-chamber installation and a filtration field with perforated pipes

What are the benefits of such septic tanks? Due to the fact that the water obtained after cleaning can be poured into drainage ditches (but cannot be used for irrigation or drinking!), the system does not require energy sources for full operation, and the container needs to be cleaned no more than once every 1-3 years.

For a family of 2-3 people, a single-chamber septic tank with a production volume of several cubic meters is sufficient.

The disadvantages of septic tanks with soil post-treatment are:

- inability to use purified water for drinking and irrigation;

- within a radius of 3 m from the filtration field, you cannot grow vegetables or plant fruit trees and shrubs (for a small area this can play a fatal role).

It should also be remembered that in areas with heavy soil or high groundwater levels, such a septic tank will not “work”. For the system to function, you will have to install an additional container with a drainage pump and build a special dome for additional water purification on the soil surface. It will turn out to be very expensive and ineffective.

Thus, wastewater still remains a serious headache for private home owners. There are not many purification methods after which the recycled water can be drunk, and they are not cheap. It’s easier to dispose of wastewater in small doses using modern environmentally friendly technologies.

Hot water supply from a well to the house

To heat water for autonomous water supply, an electric heating boiler (water heater) is used. Such heaters have a storage tank of 50-200 liters. When selecting a water heater, pay attention to the volume of the tank and the power of the unit. The higher the power, the faster the water heats up. Standard power is 1.5-2 kW. With it, 100 liters will heat up in 3 hours.

When installing a boiler, it is imperative to provide for water drainage; for this, a drain valve is installed at the cold water inlet.

If a gas main is laid to the cottage or dacha, then it is beneficial to purchase a gas water heater for hot water supply.

You can also make a water supply from a heating boiler. For example, from a double-circuit gas boiler. But in this option there is a limitation of up to 12 l/s, which is enough if there are up to 3 points in the house where it is supplied. If you need more, you need to use an indirect heating boiler; in this method, you can circulate hot water

Do-it-yourself water supply at home from a well

What will you need for self-installation?

Hot air gun.

If water supply is installed from a well or from a well with a caisson, then the pump is connected through a heat-shrinkable sleeve. To make the clutch seat, it is heated with a hairdryer.

T-shaped installation key.

It is screwed into the adapter with the pump connected. You can buy it at a hardware store for 1000 rubles. or make it yourself from metal or polypropylene pipes.

Mounting key for lowering the adapter with the pump into the well.

You can make it yourself from metal pipes.

L-shaped mounting wrench.

You can also make it yourself from metal pipes. The end must have an external thread.

Bimetallic crown with a diameter of 44 mm.

For drilling a hole when installing a downhole adapter.

Soldering iron (“iron”).

Needed for soldering polypropylene pipes. Average price – 3000 rub.

Apparatus for welding polypropylene pipes.

Press jaws

. Connections through press fittings are one-time, permanent, so they can be hidden under the screed. For installation, special presses are used, manual or electric. Manual press pliers cost about 6,000 rubles, electric ones cost about 50,000 thousand rubles. This must be kept in mind if you plan to install it yourself.

Fitting.

For installation of metal-plastic pipes, crimp or press fittings are used. Compression fittings are tightened with a compression nut. The nut must be tightened from time to time, so the pipeline with such fittings must be visible.

Adjustable wrench.

Required for installation of fittings.

"Swede".

With its help, pipes and other elements without edges are captured.

Sealant.

To seal threaded connections, it is recommended to use plumber's flax and paste (putty), for example, Unipak. Fum tape and other similar materials are highly discouraged.