- How to calculate pump power

- Internal sewerage

Sewage systems for a private home or summer cottage differ from urban ones in their autonomy. And while some country villages have central water supply, they do not have sewerage. Therefore, it is important to think through all the nuances of pipeline installation.

Water supply and sewerage systems in private construction

Water drainage and sewerage in a private house can be done in two ways:

- by connecting to centralized systems;

- by building autonomous systems.

The preferred option is the first, since in this case the external water supply and sewerage system will consist of a pipeline laid from the house to the connection point.

To implement this project, you need to have permission from the relevant organizations to connect to centralized systems (read: “Sewage project in a private house - what needs to be taken into account”). In addition, technical conditions for carrying out work will be required. But not all suburban settlements have central water supply networks and sewage disposal lines. Therefore, many homeowners are forced to build LOS (local treatment facilities) on their property and install equipment for water intake from wells or wells.

Based on the method of transporting liquid, wastewater disposal systems can be either free-flow or pressure. The first of them allow water to move through the pipes by gravity, for which the pipeline is installed at an optimal angle of inclination. In cases where it is not possible to mount the network at the required angle, the design of external water supply and sewerage networks involves the installation of pumps for pumping liquid.

Depending on the location where the equipment will be located, water supply and sewer networks can be internal (inside the building) or external (outside the house).

Features of arrangement of intra-house networks

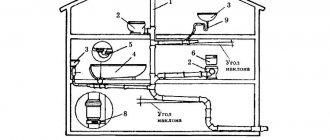

Internal water supply and sewerage networks are pipelines and equipment installed inside the house.

The end point of the in-house sewer line is the place where the pipe exits the building. In turn, for the water supply system, the place where the pipeline enters the house becomes the starting point of the network. The internal plumbing system consists of:

- introducing a pipe into the house;

- starting water metering and dispensing installation;

- source of hot water (this can be a boiler or boiler);

- double pipeline for separate supply of cold and hot water;

- supplies to water intake points;

- water consumers are a kitchen sink, washbasins, toilet, bowl, washing machine and dishwasher.

In-house sewer networks include:

- pipes coming from water intake points;

- sewer riser to which pipes are connected;

- the place where the sewer line is removed from the house.

Design of sewer and water supply networks in the house

Designing water supply and sewerage systems during the construction or modernization of a private household is a complex and responsible process, so this work should be entrusted to professionals. When it is necessary to design a water supply and sewerage system at a summer cottage using simple diagrams, then you can draw up the project yourself. But when building a house with a complex layout for permanent residence, it is still better not to take risks.

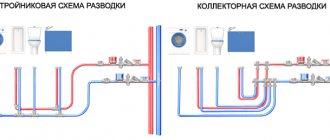

When designing internal water supply and sewerage systems in a private house, the location of water intake points should be taken into account. The simplest option is when the bathroom and kitchen are located next to each other. In this case, you can use the simplest scheme with drainage into a common riser. It is much more difficult to design a house with several floors, each of which has a bathroom.

It is most difficult to develop a project if the water intake points are located in rooms in different parts of the household.

In this case, it is necessary to design a complex system, since the installation of water supply and sewerage will require the installation of several risers and septic tanks. Before you start drawing up a project, you need to do the preparatory work:

- First of all, determine the source from which water will flow into the house. If there is no central water supply in the locality, you need to choose one of the options: deep well, well, springs, etc.

- Geological research is carried out to draw up an engineering-topographic plan of the site in order to determine the type of soil in the area and the depth of groundwater. Therefore, sewage systems with high groundwater levels will be designed according to a completely different scheme.

- Determine how much water needs to be supplied to the house and removed from it during the day. This parameter is directly related to the choice of equipment to purchase.

- A decision is made regarding the type of treatment plant that will be installed on the site. In this case, the distance between the water supply and sewerage is taken into account in accordance with sanitary standards. Most home owners prefer installing factory-made septic tanks. But in some cases, for example, when the groundwater level is high, installing a septic tank may not be possible. In this case, a VOC is installed or a storage tank is installed.

Based on the collected information, appropriate calculations are made, equipment is selected and a design for the future water supply and sewerage system is developed.

How to design water supply from a well

To create an autonomous water supply project, you need to have complete information about the correspondence of the flow rate of the source, the daily need for water at home, and pump performance.

Therefore, design begins with determining the depth of the aquifer, calculating the daily flow rate of the future water intake, minimum and peak water consumption.

Each device has its own water consumption rate

This is the initial data, after receiving which the optimal source location is selected.

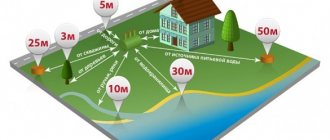

At the same time, the location where the cesspool or septic tank will be built is determined, since the distance between the sewage tank and the drinking well (and other own and neighboring buildings and structures) is strictly regulated.

Installation of internal networks

Construction of the water supply and sewer system begins after the walls and roof of the building are erected.

At the same time, maintain the distance from the sewer to the water supply. Basic rules for installing an internal network:

- The water pipe is inserted into the house no closer than one and a half meters from the sewer main, as well as from the gas pipeline.

- A water metering unit is installed at the entry point behind the outer wall. It can also be made with a bypass line, providing increased water consumption in the event of, for example, a fire or without it.

- Before the water meter, you need to install a departmental valve that shuts off the water, and then a house valve.

- The diameter of the water supply pipes depends on the number of water intake points.

- When installing internal water supply and sewerage in a building, pipelines are usually laid in the basement.

- When there is insufficient water pressure at the inlet, it is necessary to plan the installation of three pumps: two of them will provide water supply in case of minimum or maximum consumption levels, and the third will be a backup.

- When laying internal pipelines, you need to remember the need to observe the slope of the pipes - its size depends on the diameter of the products specified in the design documentation.

Why you can trust us with design

We employ only experienced, qualified employees. We have extensive design experience and are improving our skills, thanks to which we can successfully apply modern design methods when performing work, use the latest technical solutions and create functional, reliable and cost-effective communications.

If you are just thinking about the need to design engineering systems, then you should know that design is the first stage of installing engineering systems at any facility. It is very difficult to create a functional water supply system without preliminary design, so it is better to foresee all the subtleties and nuances before installation begins. From us you can also order an electrical project, a sewerage system project, a heating project, a ventilation project and an air conditioning system project for your facility.

You can pre-calculate the cost of the project using the automatic service calculator.

Installation of external networks

Outside the home, installation of external networks is carried out based on the following rules:

- Pipes are laid at a depth exceeding the freezing depth of the soil.

- If the intersection of water supply and sewerage pipes is designed, the water supply pipeline is located 40 centimeters above the sewer line. When using steel pipes, steel casings are installed at their intersection.

- Pipelines must intersect at right angles.

- When water and sewer pipes are laid in parallel, a distance of at least one and a half meters must be maintained between the walls of pipes with a diameter of less than 200 millimeters.

From all of the above, we can conclude that water supply and sewerage in a private household are a rather complex system (this can be seen in the photo) and their arrangement requires a well-designed project. But they will work effectively provided that all the requirements and rules of technical operation prescribed in SNiP are met.

Materials

What materials do trading companies suggest for installing water supply and sewerage systems?

Here is a list of the most popular solutions:

| Image | Description |

| Galvanized steel pipe (like black steel, it is produced in accordance with GOST 3262-75). Galvanization differs from polymer pipes in durability, but is difficult to install: water pipes are assembled only on threads, because the zinc coating burns out during welding. |

| The copper pipe is assembled into the water supply using compression, press fittings or solder joints. The advantage of the material is an almost unlimited service life, the disadvantage is its high cost (300 or more rubles per linear meter). |

| Corrugated stainless steel also boasts an unlimited service life; at the same time, it costs half as much as copper and is much easier to install on compression fittings tightened with a pair of adjustable wrenches. Disadvantages: the service life of silicone fitting seals is limited to 30 years and large pressure losses due to the specific shape of the pipeline walls. |

| Polypropylene pressure pipe compares favorably with its competitors due to its low cost (from 20 rubles per meter). The material is mounted on equally inexpensive (from 3-5 rubles) fittings for socket welding. For hot water supply, it is customary to use pipes reinforced with fiber or foil: they are more tensile and elongate less when heated. |

| Cross-linked and heat-resistant polyethylene (PEX and PERT) are used primarily for hidden collector water distribution. Despite the relatedness, the materials differ in installation methods: PEX uses mainly fittings with sliding sleeves, while PERT uses socket welding fittings. |

| Metal-plastic water pipes have internal and external shells made of the same modified polyethylene, but an aluminum core that increases tensile strength is glued between them. To install connections, push, press and compression fittings are used. |

| Cast iron sewer pipes and fittings have now been practically replaced by plastic, and deservedly so. It is expensive, heavy and inconvenient to install: the joints are hammered with hemp (tarred hemp) and sealed with cement. |

| PVC sewerage, on the contrary, can please the buyer with a modest price tag, extremely simple cutting and easy installation using socket joints with rubber rings. The only drawback of plastic sewerage is noise: a PVC riser will force you to be aware of your neighbors’ toilet visiting schedule. |

| A polypropylene pipe differs from a polyvinyl chloride pipe only in slightly greater heat resistance (95 degrees versus 80). |

It’s interesting: the range of large manufacturers has long included silent plastic sewerage, which differs from the usual one in a compacted layer with a mineral filler.

Silent sewage system produced by Rehau