A membrane tank for hot water supply is an extremely important element of the piping of an indirect heating boiler. It is important that it exists at all; it is important to correctly select its volume and initial pressure.

So that you can be convinced of this, I want to tell you a story, then we’ll move on to choosing the parameters of the tank, and after that we’ll look at the main elements of the boiler piping.

The material will be very useful, so download my manual “Membrane expansion tank and main boiler piping elements” for reference.

History of water leak search.

One day I arrived at a customer’s site.

It was necessary to provide heating and water supply for the bathhouse - a guest house with a swimming pool. There are radiators and water heated floors, ventilation and equipment for the pool. In short, if you also involve subcontractors, then the order is monetary. The customer is not stuffy or stingy, excellent. But at the beginning of the conversation, he asks: Sergei Nikolaevich, I have the following problem in my main house: the water consumption has always been 25 - 40 cubic meters, and for some reason the last two months have been more than a hundred. Everywhere in the house is dry. Can you see what the reason is? And I understand: if I find a leak now, I’ll take the order; if I don’t find it, then I’ll lose it in disgrace.

We checked all the taps for consumers - they are closed, the dishwasher and washing machine are turned off, there is no gurgling in the toilets, all the taps in the garden are closed. And the counter is spinning. I went from the meter through the cold water pipe. Cold pipe, already dripping. On the floors there are collectors to water outlets - at room temperature.

Only the pipe to the boiler is cold, up to the safety valve. The valve itself is cold and the rustling of water can be heard in it. From the valve, the discharge tube is carefully directed into the sewer. Also cold and wet. That is, the safety valve does not hold, and cold water flows through it directly into the sewer.

You may ask, what does the membrane tank of the boiler have to do with it? Well, here's the thing: I unscrewed the nipple cap, pressed the rod, and there was silence. There is no air, it has leaked. The tank must compensate for the thermal expansion of hot water in the boiler when heated. When water expands, it goes into the tank, compressing its air part. If the pressure does increase, it will do so slowly and will not exceed the response pressure of the safety valve. But here the air has flowed out, there is nothing to compress. The entire tank is filled with water. When the doyler heats up, the pressure quickly increases beyond 6 bar, and the valve is activated, releasing some of the water. After several dozen such discharges, safety valves often begin to leak. And then the caring installers installed a discharge outlet into the sewer. The user does not understand at all what is happening, some kind of miracles.

In general, the diagnosis took about fifteen minutes. I said that our installer would come tomorrow, replace the valve and pump up the tank. There will be no leaks. We received the order.

The customer asked to install an additional boiler. This 150 liter was not enough to fill the jacuzzi. So there it is! the puzzle is complete. This means that the boiler often had to be heated from minimum to maximum, which means that the water expanded as much as possible when heated. When air leaked out, this inevitably caused an excessive excess of pressure and activation of the relief valve.

Do you understand how important it is that there is enough air in the tank for the system to operate smoothly?

DHW recirculation. A simple solution to the problem

This article will describe a fairly simple technology for solving a common problem - hot water recirculation, or rather, the lack of hot water when you need it. If you live in a compact house and the water heater is located near water consumption points, you are not familiar with this inconvenience. If you live in a large house and the boiler is in the basement, 15 or more meters of water supply may stretch to the last consumer. Owners of large homes are familiar with long waits: they turn on the tap and wait two whole minutes for hot water to flow. This wastes energy and water resources.

As a rule, a series water supply connection is used. The main pipe extends from the heater to the farthest point. Consumers are connected from it using tees - a sink, a bathtub. The disadvantages are obvious - pressure drops if several taps are open at the same time, waiting for hot water. Another option is a balanced system using a collector, where each endpoint is served by a dedicated line from the collector. The price is several times higher than in the first case.

What initial pressure should be created in the tank?

The tanks come from the factory at 2.5 bar.

Some people put it just like that. I have a different approach and I will explain why. Air must be pumped into the tank based on the pressure of cold water. For example, 4 bars come into the house from the central water supply. Create a little more air pressure in the tank, for example 4.2 bar. This is the opinion of at least one more respected author, I agree with him and I will explain why. If the air pressure was 2.5 bar, then after connecting the tank to water, it will compress the air in it to the same four, and the working volume of air will be significantly reduced, by almost half. If the pressure is set to 4.2, then the volume of air for compression will be consumed only with the beginning of the real expansion of water. Look:

Pipelines for the DHW recirculation system

It is worth keeping in mind that DHW recirculation will require significantly more money to be spent on its installation.

In addition to the cost of the plumbing circuit, it is additionally required to provide thermal insulation of the pipes in order to keep heat leakage within normal limits. The pipeline layout itself is quite simple. One part of it, supplying water to water collection points, is sequentially mounted in a continuous line from the thermal unit to each point. However, the pipeline does not end at the last water withdrawal point, but returns back to the heating unit.

Before installation begins, each pipeline segment is placed in a belt insulation made of foamed polyethylene or rubber. Rubber is more suitable for those sections of pipes that will subsequently be walled up. Not only the pipes themselves are insulated, but also the fittings, and all joints in the heat-insulating material must be sealed with metallized tape.

Tank maintenance.

If the safety valve is triggered, it means that air has leaked from the tank, or the membrane has leaked. Unscrew the cap of the tank nipple and press on the stem. If water comes out, then the membrane is torn and the tank needs to be replaced. If nothing comes out, or the air hisses, then you need to pump it up: • release the union nut on the shut-off valve, • open the drain valve (red handle) and drain the water, • pump up the pressure, for example, with a car pump, • close the drain valve. • attach and tighten the union nut.

Operation and mode of operation

After assembly and performance testing, the recirculation system is put into operation. It works continuously.

Some users, trying to save energy and equipment life, turn off the system at night or during a long absence.

This is a completely effective solution, but you will have to get up early in the morning to start the movement of water and raise its temperature. However, you can spend a little money and install a control unit. It will automatically stop the circulation and restart it according to the set program.

In private

For a private home, continuous circulation operation is recommended

This is especially important if the house uses an independent sewer system

Discharging excess water will require frequent pumping of the receiving tank, which will require extra costs and add to your worries.

In a multi-story

DHW recirculation in multi-storey buildings works automatically, without the participation of residents. The system is configured in such a way that all controls are located in the basement (in the boiler room) and do not require outside intervention.

All maintenance, repairs and other work are carried out by employees of the management company. This is convenient for apartment residents, as it relieves them of worrying about the condition of the equipment.

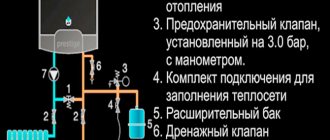

What do you know Installation of an indirect heating boiler:

• Design and principle of operation.

• How to choose the boiler volume. • Simplified wiring diagram for floor-mounted and wall-mounted boilers. • Detailed boiler piping diagram. • Detailed equipment. • How to heat a boiler with a wall-mounted single-circuit gas boiler. • Piping of a wall-mounted single-circuit gas boiler with a boiler. • How to heat a boiler with a floor-standing boiler. • Pump manifold piping diagram for multi-circuit boiler houses with a boiler. • Boiler heating control from its own thermostat. • Boiler heating control by a separate immersion thermostat. • Boiler priority scheme over other consumers. • Application of heating elements and night tariff. • Additional materials. Other articles about membrane tanks:

1. Where in the boiler room should the expansion tank for heating be installed?

2. How to choose a membrane battery tank and set up a water supply system.

All the most common fatal mistakes in installing water heated floors. Sergey Volkov.

Device

How are expansion tanks for water supply arranged?

A membrane tank is a steel container with a pipe for connecting to a water supply or heating system and a spool for pumping. It is divided by an elastic membrane into two compartments - air and water. The air compartment is often filled with nitrogen instead of air, which prevents corrosion from damaging the tank walls.

Construction of a water supply expansion tank: a steel container is divided into two compartments by an elastic membrane

Curious: the expansion tank of a hot water supply or heating system is usually equipped with a membrane with increased heat resistance. There are no other design differences between it and the hydraulic accumulator, so the expansion tank can be safely used as a hydraulic accumulator.

How to do it yourself?

The piping of the boiler of a private house is done in each case according to its own scheme. The reason for this is the large number of projects, different configurations and layouts of houses. In addition, the choice depends on the design of the boiler, its features and volume.

Before starting work, you should draw up a wiring diagram and mark on it the installation points of all consumer devices, pumping equipment and other elements.

Typically two options are used:

- through an indirect heating boiler;

- through a storage boiler.

Let's consider both options in detail.

Through an indirect heating boiler

An indirect heating boiler is a container with a coil installed inside it. It is connected to the heating boiler, and the coolant circulates in a closed loop without mixing with hot domestic water.

This boiler is equipped with five pipes:

- a straight pipe running from the boiler to the coil;

- return pipe through which the return from the coil enters the boiler;

- cold water make-up pipeline;

- straight pipe (supply) of hot water to water collection points;

- return pipe leading to the boiler.

The circulation pump is installed in the return pipeline. This is done to create normal operation of the device and prevent overheating of parts.

The diagram shows a heated towel rail that always remains hot thanks to recirculation. This allows you to ensure a dry and warm microclimate in the bath, eliminating the appearance of dampness or mold.

Through a storage boiler

A storage boiler is a regular container with thermally insulated walls into which hot water flows from the boiler.

The reservoir contains a working volume of hot water sufficient for the household needs of the family. Typically its capacity ranges from 100 to 1000 liters, depending on the number of residents of the house and their needs.

The recirculation connection diagram to the storage boiler is a loop, where T3 is the supply, T4 is the return line.

It enters the make-up pipeline B1, and the entry point is located after the shut-off valve assembly with a check valve. A circular pump is also installed on the return line, along with shut-off and control elements.

The peculiarity of this scheme is that the temperature of H2O in the boiler and the make-up line are different. This is achieved by setting up a mixing unit that connects hot water from the make-up pipe to the cooled return pipe.

In this case, it is necessary to take into account the possibility of mixing layers of water in the container. If the water is made up with water that is not too hot, the temperature in the boiler will be noticeably lower than the standard value.

The specificity of the operation of storage boilers is such that water is heated only by replenishing it during disassembly.

Over a long period of time, a simple drop in temperature is inevitable, and recirculation becomes useless. Therefore, the use of storage tanks is recommended for houses with high and constant consumption of hot water.

Boiler piping with recirculation

Experts consider an indirect heating boiler to be one of the most economical and efficient water heaters for home and garden use. The source of water heating can be gas, electricity or a heat exchanger. It is the heat exchanger that ensures the cost-effectiveness of using a hot water system with an indirect heating boiler.

The further functioning of the entire system depends on the correct piping of the boiler. The concept of piping can be defined as a feature of the installation and connection of a hot water supply system to a water heating source.

When installing the boiler and the entire recirculation system, you need to:

- Set the recirculation point. It is usually located in the center of the heating container;

- Cold water is supplied to the bottom hole of the boiler;

- The hot water outlet must be installed at the top of the boiler;

- The coolant pipe is connected from above and passes downwards (the water circulation of the heat exchanger will pass along a circuit, the inlet of which will be at the top of the boiler, and the outlet at the bottom).

- The supply of pipes to the energy source must be carried out according to the rules for installing materials, and connected using adapters. Valves and taps.

The piping of the recirculation boiler is carried out with a standard set of materials: taps, PVC pipes, adapters, fittings, pumps. You need to choose only high-quality certified products made from durable materials. The use of corrugated hoses and powder metallurgy material is strictly not recommended.