Self-installation of a boiler is considered a responsible undertaking that requires maximum compliance with the rules and regulations of connection. A safety group must be involved in piping the water heater, which includes a safety valve for the boiler - a small but functionally important device.

In this article we will consider the types of safety valves and their design features. After all, in order to install the heater without errors, you need to understand the structure and operating principle of the valve.

We will also provide instructions for piping the boiler and tips for installing a safety valve, and give useful recommendations on choosing suitable equipment.

What is it needed for

Installing a safety valve prevents the pressure inside the device from increasing above the standard value. What causes blood pressure to rise? As you know, when heated, water expands, increasing in volume. Since the boiler is a sealed device, there is nowhere for the excess to go - the taps are closed, and there is usually a check valve at the supply. Therefore, heating the water leads to an increase in pressure. It may well happen that it exceeds the tensile strength of the device. Then the tank will explode. To prevent this from happening, they install a safety valve for the water heater.

This is what an installed pressure relief valve looks like in a water heater

Maybe there is no need to install a safety valve, but simply remove the non-return valve? At a sufficiently high and stable pressure in the water supply, such a system will work for some time. But the solution is fundamentally wrong, and here’s why: the pressure in the water supply is rarely stable. There are often situations when water barely flows from the tap. Then the hot water from the boiler is forced out into the water supply system. In this case, the heating elements will be exposed. They will heat the air for some time and then burn out.

But burnt-out heating elements are not the worst thing. It’s much worse if they get hot, and at this time the pressure in the water supply rises sharply. The water that gets on the hot heaters evaporates, a sharp increase in pressure occurs - with a jerk - which leads to a guaranteed rupture of the boiler flask. At the same time, a decent volume of scalding water and steam escapes into the room under high pressure. What this could mean is clear.

What it is?

A dry technical definition says: an overpressure valve is a fitting that automatically releases excess water when excess pressure occurs.

It is a direct-acting device because it reacts directly to the influence of a heated medium (water or other coolant).

As a rule, an overpressure valve is included in the basic package of all compact water heating devices.

Sometimes an overpressure valve is confused with a check valve. Often both devices are placed in a single housing, which is why confusion arises. However, these devices are used to perform different tasks and are fundamentally different from each other .

How does it work

It would be more correct to call a safety valve for a water heater a valve system, since there are two of them in the device.

They are located in a brass or nickel-plated case, which looks like an inverted letter “T” (see photo). At the bottom of the housing there is a check valve that prevents the outflow of water from the water heater when the pressure in the system decreases. In the perpendicular branch there is another valve, which, if the pressure is exceeded, allows some of the water to be released through the fitting.

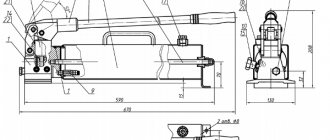

Safety valve device for boiler

The working mechanism is as follows:

- While the pressure in the boiler is less than that in the water supply (when filling or when the tap is open), the check valve plate is pressed out by the flow of water. As soon as the pressure is equalized, the spring presses the plate against the protrusions of the body, blocking the flow of water.

- When the heating is turned on, the water temperature gradually increases, and with it the pressure also increases. As long as it does not exceed the limit, nothing happens.

- When the threshold level is reached, the pressure compresses the safety valve spring, and the outlet to the fitting opens. Some of the water from the boiler is released through the fitting. When the pressure drops to normal, the spring closes the passage and the water stops flowing.

Based on the principle of operation, it is clear that water will constantly drip from the fitting. This happens when the water heats up and the pressure in the water supply decreases. If you periodically see water on the fitting, then everything is working normally. But the draining liquid must be drained. To do this, put a tube of a suitable diameter on the pipe and secure it with a clamp. The normal operating pressure of the boiler is from 6 Bar to 10 Bar. Without mechanical fastening, the tube will be torn off in no time, so we select a high-quality clamp and tighten it well. Place the tube into the nearest sewer drain.

One more point: the tube for the fitting needs to be transparent and preferably reinforced (the so-called “herringbone”). Why reinforced is understandable - because of pressure, and transparent - to be able to monitor the performance of the device.

Installation diagram of the device on the boiler

There are few requirements for correct installation of the valve device:

- The safety valve is always installed in the gap in the cold water line between the shut-off valve and the inlet to the boiler; no other devices should be placed in this gap;

- The maximum distance from the inlet pipe on the boiler to the valve fuse is 180-220 cm;

- For most models, the device is installed vertically, with water flowing from bottom to top. The direction of movement of the water flow is indicated by an arrow on the body.

The drain fitting on the safety valve must be connected by a transparent PVC pipe to the sewer line. The transparent tube is very convenient to use - you can clearly see how the safety valve works.

In order not to drill or cut the sewer pipe, you can use a special tee for washing machines, as in the video

Before installation, the body is carefully purged with air to avoid a loose fit of the plate to the seat due to debris or scraps of packing tape accidentally getting inside. The valve is assembled according to the traditional scheme - the threads are wound up with a hammer in the direction of tightening the union nut and twisted with the inlet or underwater hoses.

Before starting the boiler, the cold connection is pressurized under operating pressure. If no water droplets appear at the joints within 5-7 minutes, it means the installation was completed correctly.

After filling the boiler, it is necessary to check the operation of the safety and check valves. The test is carried out “cold”. The correct adjustment of the emergency water discharge can be checked with a flag. With a slight pressure, about 1/5 of the full stroke, the first drops should appear, and with full pressure the water runs in a stream. This means that the factory settings are correct.

The operation of the check valve can be checked as follows. It is necessary to fill the boiler completely, then close the shut-off valve at the entrance to the tank and the central inlet. When you open the tap in the bathroom and kitchen, water will run out of the pipes for the first couple of minutes. If the flow does not stop even after 5 minutes, it means that the “return” does not hold and requires adjustment. The flow of water from the boiler can be indirectly monitored by the pressure drop on the pressure gauge.

Only dismountable valve models can be adjusted directly. For this, special thin metal washers with a thickness of 0.2-0.3 mm are used. They are placed under sagging springs, and thereby the elasticity of the part is experimentally selected. Non-separable valves are replaced with new ones.

Types and varieties

If we are talking about conventional safety valves for a water heater, then they look almost the same, only the nuances differ. But it is these small details that are responsible for the convenience and safety of operation.

Safety valve for boiler with forced pressure release option

The photo above shows two safety valves with release levers. They are needed for periodic performance checks. The lever flag is lifted up. It pulls the spring behind it, freeing it to release water. This check should be carried out approximately once a month. You can also empty the boiler tank by raising the flag and waiting for everything to drain.

Design Features

The difference in the presented models is that the model in the photo on the left has a lever secured with a screw. This eliminates the possibility of accidental opening and complete discharge of water.

Two more differences are striking. This is an arrow on the body indicating the direction of water movement, and an inscription showing what pressure the device is designed for. Seemingly minor details. But if you can figure out the direction of water movement (look in which direction the poppet valve is turned), then the nominal value is more difficult. How to distinguish, for example, whether it is 6 Bar or 10 Bar? Only checks. How will sellers differentiate them? No way. By boxes. What if they put it in the wrong box? In general, it is better not to take a valve without markings on the body. These are usually the cheapest of the Chinese designs, but the difference in price is not so great that it is worth the risk.

Safety valves - serviceable and not

Also pay attention to the shape of the water discharge fitting. The model on the left has a long fitting and has a non-linear shape. The hose fits on it quite easily and is long enough to install a clamp. The shape of the fitting on the model on the right is different - with an extension towards the end, but more importantly, the fitting is short. You can still pull the hose onto it, but the clamp is questionable. Unless you crimp it with wire...

The following photo shows the safety valves without a forced pressure release flag. The one on the left has a threaded cap at the top. This is a serviceable model. If necessary, you can unscrew the lid to remove clogs, scale and other contaminants.

The model on the right is the worst option. No markings, forced resets or maintenance. These are usually the cheapest available, but this is their only advantage.

For large volume boilers

All of the above models are suitable for water heaters with a volume of up to 50-60 liters. Larger boilers come with other models, many of which have built-in additional devices. Typically this is a ball valve and/or pressure gauge to control pressure.

For boilers up to 200 liters

The water drain fitting here has a standard thread, so there will be no problems with fastening reliability. Such devices already have a fairly high price, but their quality and reliability are much higher.

With pressure gauge and original

Not everyone likes the appearance of these devices. For those who attach great importance to aesthetics, very attractive devices are produced. Their price, however, is comparable to the price of an expensive water heater, but it’s beautiful.

Main types of water heater breakdowns

A diagram of all components of the safe operation of water heaters. The main types of breakdowns of water heaters are as follows:

- It makes a lot of noise - the first sign of scale on the heating element. The noise is created as a result of the fact that initially it is necessary to warm up the lime deposit, and then the water. In such a situation, excessive consumption of electricity occurs. If the problem is not corrected, the heating element will soon fail.

- Presence of scale on internal elements. The first sign of such a problem is rusty water. It is enough to carry out routine cleaning of the internal elements.

- The water does not heat up - this indicates a malfunction of the heating element. The solution is to replace the heating element.

- Water overheating indicates that the thermostat is not performing its functions. The part cannot be repaired and requires replacement.

- Electric shock. The problem appears in the event of a voltage breakdown on the housing, if the shell of the heating element is damaged and the heating element begins to come into direct contact with water. To solve it, it is enough to replace the heating element.

- Water leaking from the tank. It mainly occurs when the storage tank is damaged by corrosion. A worn-out container should be replaced, but if a leak is observed from under the plastic cover, then the boiler must be completely replaced.

- The device does not turn on or off. To determine the cause of this problem, you will need to diagnose the device.

To make minor repairs, which include replacing external parts, just read the instructions for the water heater and you can get to work. But if the problem lies inside the device, then it is better not to conduct experiments and contact a service center to receive qualified assistance.

Is it possible to install other valves?

Sometimes, instead of a special safety valve for a boiler, a blast valve is installed, which is intended for the emergency release of heating water. Although their functions are similar, the main mode of operation is fundamentally different. The demolition device should only be used in emergency situations. It is designed for volley discharge of a large volume of liquid. It is not suitable for constantly bleeding small portions of water. Accordingly, it will not work correctly.

Another case is to install only a check valve. It will not allow water to drain when the pressure in the water supply decreases, but it will not save you from increasing pressure in the boiler. So this option doesn't work either.

Complaints regarding the operation of the safety valve

In fact, abnormal operation of the valve device may have very specific reasons:

- Low quality product;

- Abnormally high pressure in the water supply;

- Incorrect installation and adjustment of the valve mechanism.

As a rule, high water pressure is typical for the first floors of apartment buildings. When installing professionally, technicians are always interested in water pressure. It is impossible to install a boiler and connect it to a water supply with water at 5-6 bar. Therefore, they try to regulate the pressure using an inlet valve or recommend installing a reduction gearbox, which will immediately solve half the problems.

The first and third cases are much more complex and dangerous than high blood pressure. As a rule, manufacturers of well-known brand boilers complete their products with very good, high-quality safety valves. When purchasing, few people check exactly what additional components and materials are included with the boiler, so branded devices are replaced during pre-sale preparation by those that are the same size, but cheaper. Therefore, when purchasing or installing, it is worth checking the operation of the device again, so as not to be surprised later that the safety valve on the boiler is leaking.

High valve quality can be determined by the following characteristics:

- The body is made of cast brass alloy, possibly with nickel plating. Cheaper iron-aluminum or copper-aluminum alloys will be lighter, with thinner body walls;

- Plastic valve plates, when pressed on the stem, touch the inner walls of the body or become wedged in an extreme state;

- The mechanism inside the valve does not ensure reliable closure of the flow even at low pressures. To check, you can press the valve stem with your finger and blow into it. If there is no reliable locking, then it is better to replace the safety valve. Moreover, if the boiler drips from the safety valve, this does not mean that the device is faulty. Most likely, the locking plate is clogged with sediment, but the mechanism itself is in working order and does not require additional adjustment.

If there is no water at all, or the water flows in a stream, this indicates that the valve plate is jammed in one of the extreme positions. The device will require dismantling, cleaning and adjustment.

But even if the boiler and safety valve are selected correctly and of the required quality, there remains a risk of improper installation and adjustment of the system by craftsmen. For example, it is not uncommon for a hot water safety valve to be installed on a boiler. To avoid finding yourself in a similar situation, it is enough to have at least a general understanding of how to install and adjust the safety valve.

How to choose and install

Select a safety valve for a water heater based on the pressure for which the unit is designed. This number is in the passport. The volume of the tank also influences the choice. They produce devices with operating limits of 6, 7, 8, 10 Bar. Basically, all units are designed for this pressure. So everything is simple here.

Installation is simple: flax tow or fum tape is wound onto the threads, after which the valve is screwed onto the pipe. Twist it all the way by hand, then another one or two turns using keys. It is much more important to choose the right place to install it. When installing a water heater, this valve is installed directly on the cold water inlet pipe.

Installation example

Next there may be a check valve, which is also called a shut-off valve. But this is already reinsurance - the same device is available in the safety device, and often after the water meter at the inlet. The installation diagram is shown below. This is one of the normal options.

Installation diagram of a safety valve for a boiler

The diagram shows a ball valve. It is necessary to empty the tank before storing it for the winter (at dachas) or before dismantling it for prevention and repair. But more often they put it on a tee, which is screwed directly onto the inlet pipe of the water heater. A safety valve is screwed onto the tee from below, and a ball valve is placed in the side outlet.

Installing a safety valve after a tee

Actually, these are all normal options.

Professional installation advice

Even such a simple procedure as installing shut-off valves is based on the implementation of certain rules. For example, the design of a room often requires camouflage of the pipeline and security group.

You can hide devices, but subject to three conditions:

- the length of the flexible line or pipe from the fuse to the tank should not exceed 2 m, otherwise there will be excessive additional pressure on the valve spring;

- the ideal installation of the fuse is directly to the boiler fitting, and if this does not work, then installing a tee is still excluded;

- To service the fittings, a technical hatch should be equipped.

Many people worry when they see drops of water on the valve connection. This is a normal phenomenon and indicates that the device is working properly.

From time to time, small pressure surges occur in the line, which provoke a minimal discharge of liquid. You need to worry when water either does not appear at all or pours continuously.

The line length between the water heater and the fuse should be minimal. This is necessary not for aesthetic reasons, but so as not to create additional pressure in the pipes

It should be remembered that independent modernization of safety devices is strictly prohibited. If you need a 0.8 MPa valve, then you need to purchase just such a new product, and not try to somehow remake or adjust the 0.7 MPa device.

If there is any doubt about the functionality of the safety valve, you should dismantle it and check whether the spring or seal is clogged. Are you having problems with your water heater itself and don’t know what to do? We recommend that you familiarize yourself with common boiler breakdowns and repairs. If you lack skills, invite a specialist from the service center.

Breakdowns, causes, elimination

In principle, the safety valve for a water heater has only two failures: water either often flows from it or does not flow at all.

First of all, it must be said that bleeding of water when heating is the norm. This is how the system is supposed to work. Water may also be released when the boiler is turned off, if the pressure in the cold water supply pipes is higher than the valve response limit. For example, the valve is 6 bar, and the water supply is 7 bar. Until the pressure drops, the water will be released. If this situation repeats often, it is necessary to install a reducer, and it is best to use water in an apartment or house, but there are compact models of reducers that can be installed at the entrance to the boiler.

Boiler piping with safety valve and reducer

How to check the serviceability of the valve? If there is an emergency reset lever, this is easy to do. With the boiler turned off, you need to lift the lever several times to release excess pressure. After this, the dripping stops and does not resume until heating begins.

If water continues to drain, the spring may be clogged. If the model is serviceable, the device is disassembled, cleaned, and then put back in place. If the model is not collapsible, you just need to buy a new valve and install it.

This is what the reducer looks like - to stabilize the pressure on the boiler

Constantly dripping water is unpleasant and hurts your wallet, but not dangerous. It is much worse if, when heating the water, you never see water in the pipe. The reason is that the valve is clogged or the outlet fitting is clogged. Check both options. If it doesn’t help, change the valve.

Check valve for water heater: detailed description

The constant availability of hot water in a house or apartment has long become a familiar norm for most people, without which it is difficult to imagine a normal, comfortable life. If a water supply is installed to the housing or an autonomous uninterrupted water supply is organized, for example, from a well or well, then there is nothing to think about - you need to install a water heater of one type or another.

Check valve for water heater

Probably the leading position in popularity among water heating devices for domestic needs are electric boilers. They are extremely easy to use; their installation does not require any additional approval procedures or drawing up separate projects. Installation of such a boiler is quite feasible even for independent installation. That is why the information that will be presented in this publication is necessary - each of the home craftsmen should clearly understand how important a safety check valve is for a water heater.

No matter how the workers of the housing and communal services, emergency and rescue services, the state technical supervision authorities warn, no matter what stories with the consequences of accidents are shown on television, there are still “smart guys” with alarming regularity who benefit from all these technical recommendations and just good advice - not a decree, they themselves “know what is simpler and better.” Alas, ignoring a very small, inexpensive, easy-to-install, and at the same time extremely important object for piping an electric water heater can result in very big troubles, and, it is possible, even a tragedy.

Design and principle of operation of the valve

First of all, it is necessary to immediately make a very important disclaimer. Despite the fact that very often, in order to obtain information, interested people enter the search query “check valve for a water heater,” it would be much more accurate and correct to talk about a safety valve that combines several functions. These devices have a certain similarity, but there is also a huge difference, which determines the main task - ensuring the safe operation of the electric heater.

For comparison, consider the device of a conventional check valve:

This is how a regular check valve works. But it’s not enough for a boiler!

This is a metal cylinder, on both sides of which there are threaded sections for “packing” into a straight section of pipe of the appropriate diameter. A poppet valve is stopped inside - a disk with a rubber seal around its circumference, on the central axis - a rod (shown in the figure with a green arrow). The disk is constantly in a spring-loaded state, blocking the internal channel for the passage of water.

When water is supplied in the direction of the arrow (the direction of the permissible liquid flow is always indicated on the valve body - this mark is shown with a red arrow in the figure), the pressure in the pipe through the “plate” compresses the spring and slightly opens the passage. As soon as the pressure decreases, the valve automatically returns to the closed state.

This precaution is, of course, necessary to ensure that the tank in the water heater is constantly filled, under any circumstances. However, such a measure is clearly not enough to ensure safety - this will be discussed below.

The safety valve is somewhat more complicated:

Safety valve device for water heater

Essentially, these are two valves in one body, placed perpendicular to one another.

In the larger cylinder (item 1), which follows the flow of water, the same valve is installed, preventing the reverse flow of water. On the supply side there is a male threaded section (item 2) for insertion into the water supply system (in particular, it will be convenient to connect a flexible water supply hose here). On the opposite side there is a female threaded coupling (item 3), which in some cases is screwed directly onto the standard cold water supply pipe in the electric heater.

The figure clearly shows the check valve “plate” (item 4) with a sealing ring around the circumference, and the spring (item 5) that holds the valve closed.

Now here is the main difference. Perpendicular to the cylinder with a check valve there is another one, somewhat smaller in size (item 7). In fact, it contains the same poppet valve, but its spring is much more powerful - this is the same safety “breakdown” valve. Normal and even slightly increased pressure in the water supply system will not be able to compress the spring and open it - this requires much more serious efforts.

In the cylinder cavity behind the safety valve “plate” there is necessarily a hole with a pipe (pos. 8), where excess liquid will be discharged when the valve is activated.

A cylinder with a safety “break” valve can be completely plugged, and sometimes it ends with a threaded plug (plug), behind which there is an adjusting screw (usually with an “internal” hexagon). But the most common safety valves are those with an additional lever:

Many valve models are equipped with a lever for manual bleeding of fluid

The figure clearly shows the features of such a device. The lever (pos. 9) is intended for manual opening of the safety valve with water discharge through the pipe (pos. 8). Please note that the pipe may have a special relief design, which allows you to put thin hoses on it to drain water into the drainage (sewer). The manual valve control function can be convenient, for example, for draining the contents of a boiler during repair or maintenance work. However, you should not get carried away with using such manual control - this can in some cases even be dangerous (this will be discussed below).

Any safety valve always has an arrow indicating the direction of cold water flow towards the electric water heater. (there is a red arrow in the diagram). Very often, the maximum operating pressure of the “stall” valve is indicated on the body - in this case it is 0.7 MPa or 7 atmospheres (yellow circle in the figure).

How does a safety valve work in different situations?

To fully understand the importance of a safety valve, it is best to consider the cases in which it operates, as well as the situations that may arise if for some reason the valve is missing or faulty.

For clarity, once again - the simplest, but also the most understandable scheme for piping a boiler with a safety valve. The blue and red arrows show the direction of flow of cold and hot water, respectively. The green arrow points to the installation location of the safety valve.

Typical safety valve installation diagram

1. After the electric water heater is installed and completely “wired”, it should be filled. To do this, simply open the cold water supply and the hot tap on one of the mixers. There is enough pressure in the water pipe to open the check valve to allow unimpeded flow. As the volume of the water heater tank fills, air is displaced. As soon as water flows from the mixer, the entire container is filled to the upper intake pipe, the supply can be turned off.

The pressure in the boiler at this moment is approximately equal to the pressure in the cold water main - it is, as it were, “propped up” by it. However, it may even be a little higher - due to the remaining compressed small volume of air in the upper part of the tank. Plus, when the power is turned on, the water begins to heat up - and this, of course, also leads to an increase in pressure.

2. Let's imagine a situation where the check valve is not installed or is in a faulty condition. The equilibrium that was achieved when filling the boiler tank is sooner or later disturbed, since the pressure becomes higher than the pressure in the pipe. The “hot” taps on the mixers are closed, which means that the heated water will look for an outlet in a different direction. This can lead to hot water suddenly starting to flow from a “cold” tap, or to filling the toilet flush tank with it. Meanwhile, the boiler thermostat cannot understand the situation and does not give a signal to turn off the heating elements. Expensive electrical energy is completely wasted.

3. But this is not the saddest thing. It is no secret that the pressure in the water main, especially in multi-storey buildings, often drops to critical values (the tap, as they say, barely flows), or even disappears completely. There are a great many reasons for this, for example, an accident on the highway, maintenance work, a planned reduction in pressure, for example, at night, etc. What happens if the check valve is missing or faulty? Nothing good - the boiler will simply empty, since all the water from it will completely flow into the supply pipes.

It’s good if the boiler has protection against “dry” heating, and it will work quickly! And if not? Powerful heating elements will idle heat the air in a closed volume, and this will end either in their burnout or cracking of the enamel - in any case, nothing good can be expected in such a situation.

4. A reasonable question may arise - is it possible to limit ourselves to installing this same check valve? It would seem, judging by the description, that he is able to solve all problems.

Do not consider it an exaggeration: such an installation is like a bomb planted in your home!

No, under no circumstances is it possible. The installation of a complex valve that combines both non-return and safety valves is a prerequisite for the safe operation of the water heater.

If somewhere the reader comes across a similar picture - only a check valve at the inlet, then he should understand that this is comparable to a planted powerful bomb, which is not known when it will explode.

Another example of “suicidal creativity”

Let's look at the situation in detail. When the boiler is turned on, heating begins, and as the temperature rises, according to the laws of thermodynamics, the pressure in a closed volume begins to increase.

Designers of household appliances include a certain operational resource in each water heater, allowing the device to operate up to certain pressure values in the tank - usually this value is indicated in the technical documentation. Typically, all boilers are very balanced thermodynamic systems, in which the optimal ratios of permissible temperatures and pressure levels are very accurately calculated. However, anything can happen. And as soon as the pressure level, for some reason, begins to approach the permissible upper mark, the spring on the safety valve is compressed, and the resulting excess liquid is discharged into the drain pipe. As a result, the system again enters a state of dynamic equilibrium.

Water coming out of the drain pipe is normal.

Now let’s try to imagine what can happen in a situation where there is no emergency valve, and everything is limited only by the return

Water heating should be limited by a thermostatic regulator, but quite often these electromechanical devices are far from perfect and can simply fail. In this case, heating continues uncontrollably.

The pressure inside the boiler tank is growing, but there is no way out - the mixers are closed, and the check valve has reliably shut off the supply line. It would seem that the temperature will only reach 100 degrees, to the boiling point of water? Nothing like this! As the pressure in a closed volume increases, the boiling point of the liquid also increases sharply. For example, the data is shown in the table:

| Pressure in a closed volume, atm (MPa) | Water boiling point, °Ċ |

| 1.0 (0.1) | 99.09 |

| 1.033 (0.1) | 100.0 |

| 1.5 (0.15) | 110.79 |

| 2.0 (0.2) | 119.62 |

| 2.5 (0.25) | 126.79 |

| 3.0 (3.0) | 132.88 |

| 4.0 (0.4) | 142.92 |

| 5.0 (0.5) | 151.11 |

| 6.0 (0.6) | 158.08 |

| 7.0 (0.7) | 164.17 |

| 8.0 (0.8) | 169.61 |

| 9.0 (0.9) | 174.53 |

| 10.0 (1.0) | 179.04 |

| 20.0 (2.0) | 211.38 |

| 25.0 (2.5) | 222.90 |

| 50.0 (5.0) | 262.70 |

| 100.0 (10.0) | 309.53 |

When the word “bomb” was mentioned above, this is not at all an exaggeration! In such circumstances, the water heater actually turns into an explosive device of terrible destructive power.

Already at 4 - 5 atmospheres of pressure, the boiling point reaches almost 150 ° C, and continues to rise. An increase in pressure on the walls can lead to their deformation, chipping of the enamel or ceramic coating - but this will be the least of all possible evils. Another scary circumstance is a sharp drop in pressure in this closed system, and this can happen when a crack appears in a weld, when a rubber seal breaks, or even simply when a hot water tap on a mixer is opened.

A sharp decrease in pressure leads to a corresponding sharp decrease in the boiling point of water. As a result, the entire volume of liquid (imagine all 50, 80 or 100 liters at the same time!) instantly boils, which, of course, is accompanied by the release of a colossal amount of steam. No one, even the most durable building, can withstand this - a powerful explosion follows, which is capable of demolishing everything in its path, including even brick interior walls. There are many clear examples of this on the Internet.

It's hard to believe, but these are the consequences of an explosion of an ordinary electric boiler

So, let's briefly summarize the issue of the need for a safety valve.

— It prevents reverse leakage of water from the tank into the supply pipeline in the event of a decrease in pressure.

-The presence of a valve at the inlet creates additional protection for the boiler from possible strong pressure surges in the water supply system and from water hammer.

— The safety valve will eliminate possible shortcomings in other safety levels - it will maintain the temperature-pressure regime in the boiler within acceptable values.

— A safety valve equipped with a lever also allows water to be drained from the boiler if necessary.

Video: Is it necessary to install a safety valve on the boiler?

Prices for popular models of indirect heating boilers

Indirect heating boiler

Recommendations for selecting and installing a safety valve

Selecting the right valve is not difficult. Most often, boilers (especially from leading manufacturers) go on sale complete with a valve of the required rating. You will need to focus on the same value if for some reason you have to change the valve in the future.

The maximum pressure value in the boiler tank must also be indicated in the technical documentation of the product. If the water heater is not equipped with a valve, you will have to purchase it yourself, based on the value indicated in the passport. It is important to choose the right rating here - if you install a valve that is too “weak”, water will leak from it almost continuously. A valve with too strong a spring will not create absolutely safe operating conditions.

The valve can be “packed” directly onto the boiler pipe for cold water (always has a corresponding blue color marking. For reliable sealing during installation, it is best to use flax tow with modern sealing pastes. When tightening, 3–4 full turns are usually sufficient. If there is a flexible liner underneath , then a rubber sealing gasket is sufficient.

A drain valve between the valve and the boiler is quite acceptable, but only on a tee

Sometimes a drain valve is inserted between the valve and the boiler itself - this greatly facilitates periodic maintenance work. Such an installation is quite acceptable, but only under one condition - the valve must be located at the outlet of the tee, but in no case should it interrupt the direct channel from the water heater to the valve. Any shut-off valves on this straight section are strictly prohibited!

Step-by-step instructions for wiring an electric water heater

It makes sense to consider step by step how you can independently connect an electric boiler to the water supply system. The table below shows two options as examples. Despite some differences, in both cases it will still be clearly demonstrated that the safety valve is a mandatory element of the piping of such a water heater.

| Illustration | Brief description of the operation performed |

| To begin with, a few words about installing the water heater itself on the wall. Of course, the location is thought out in advance, before purchasing the device, so that the boiler fits in the space allocated to it and does not interfere with the normal operation of the room. A power cable connected to a separate machine is usually installed in advance at the installation site. Insertion points into the water supply system are also immediately provided. To accurately hang the boiler on the wall, its height is measured. | |

| Knowing the height of the water heater, it is easy to determine the lowest point of the position of the device that it will occupy after installation. | |

| On the back side of the water heater body there are devices for mounting on the wall. In this case, it is a regular mounting strip (bracket) that will cling to the hooks. There may be other options - the device’s instruction manual usually describes all this, and often 1:1 templates are also included to simplify the marking process. | |

| In this case, it is necessary to determine the location of the line on the wall along which the hooks will be mounted. To do this, measure the distance from the lower end of the water heater to the mounting plate. | |

| The same distance is marked on the wall vertically from the previously designated point of the planned lower edge of the boiler. | |

| With control over the building level, a horizontal line is drawn along which the hooks will be located. | |

| The next step is to measure the required distance between the hooks. In this case, 200 mm will be optimal - the hooks will be placed closer to the edges of the mounting strip, but there will still be the possibility of a slight play left and right to align the water heater. | |

| This distance is transferred to the intended horizontal line - the centers of the holes for the hooks are marked. In the example shown, they landed rather poorly - exactly on the seams between the ceramic tiles. If there is such a possibility, then it is better to mark the holes away from the edge of the tile - the likelihood of a crack appearing when drilling holes is much less. | |

| Powerful hooks were chosen to hang the boiler: the outer diameter of the polymer dowel plug is 14 mm, the length of the dowel is 80 mm, the diameter of the metal hook is 8 mm. Often, the electric water heater kit already includes the fasteners recommended for installation. | |

| At the designated points, the corresponding holes are drilled with a hammer drill, into which dowel plugs are driven. Then the hooks themselves are screwed in. | |

| The hooks are screwed in to such a depth that a reliable, stable fit of the water heater is ensured, without play, but also without jamming. | |

| That's it, the boiler is hung on the wall. From below you can clearly see two pipes through which the device will be connected to the home water supply system. The pipes are color coded: blue – cold water supply, red – hot water outlet. | |

| The appropriate connection has already been made into the water supply system - here are two polypropylene pipes to which the water heater pipes need to be connected. On the left is the hot water supply pipe, on the right is the cold water supply pipe. | |

| In the example under consideration, the master decided to equip the entrance to the boiler with an optional element - an additional tap, which will be used if it is necessary to empty the boiler. To do this, a tee will be installed on the inlet pipe of the water heater. The recommended preliminary “fitting” is carried out - how many revolutions are needed for the swarm outlet to take the required position. In general, it is advisable to carry out such fittings before assembling any fixed assembly - there is less chance of making a mistake. | |

| After this, the tee is packed onto a tow winding coated with Unipak sealing paste. | |

| The tee is packed and given its intended position. | |

| A compact tap will be mounted on the side branch pipe of the tee. | |

| The tow is wound up and sealing paste is applied. | |

| The tap is screwed in, tightened with a key, at least three turns, and given the planned position for easy access to the handle. | |

| But now it’s time to install a mandatory element - a safety valve. Be sure to pay attention to the arrow showing the direction of water flow. | |

| The safety valve will be installed on the lower pipe of the already installed tee. The basic rule is fully observed - there are no locking devices between the valve and the water heater. The valve installed on the side branch of the tee does not have any effect on the safety of operation of the device. | |

| The valve is packed onto a tee - in the illustration this entire assembly is assembled. | |

| It is advisable to make the boiler piping dismountable - this will make it possible to turn off the device to remove it, for example, for maintenance or to replace the heating element or anode rod. Therefore, the foreman decided to install shut-off ball valves with an “American” union nut at both inputs. An example of such a tap is shown in the illustration. | |

| The tap itself will be tightly packed onto the lower branch pipe of the safety valve. And a fitting for transition to a polypropylene pipe will be mounted on the fitting with the union nut itself. That is, it will not be difficult to disconnect the boiler from the pipes. | |

| A second similar tap is installed for hot water, but directly on the outlet pipe of the water heater. And it is also assumed that a fitting for transition to a polypropylene pipe will be packaged with the removable fitting with the “American” one. | |

| Here the fitting mounted to the tap fitting is tried on at the installation site. In this case, a 90-degree elbow fitting was used to immediately lead the pipe closer to the wall. | |

| Next, another bend will be welded in - and the pipe will go down along the wall. | |

| A regular fitting for switching to polypropylene is mounted on the fitting of the second tap for hot water. But this was done solely for reasons of aesthetics in the appearance of the piping - so that the “step” of transition to a level closer to the wall on both pipes is located at the same height. Next, the usual welding and installation work with polypropylene pipes is carried out. | |

| This is how neat the overall water heater piping unit turned out to be. | |

| And this illustration shows how the supply pipes are welded into the previously left water supply pipes. The water heater installation is complete. You can open all the taps (except the drain), fill the boiler with water, and connect to the power supply. If there is a need and opportunity, a transparent PVC pipe is placed on the drainage pipe of the safety valve, which is diverted into the sewer, toilet flush tank or some container - the excess water released will not fall on the floor. | |

| Now let's consider a possible option for piping the boiler with the installation of a flexible line. The illustration shows that the water heater is already hung on the wall. The arrow shows one of the “water outlets” - pipes hidden in the wall under the finishing of cold and hot water pipes. | |

| Conventional ball stop valves will be packaged onto these connections. In this case, there is no particular need to use taps with a union nut - the piping will be dismountable due to the use of a flexible connection. | |

| The nozzle is wound with flax tow. Some craftsmen use FUM tape, but there are still many more supporters of reliable sealing using tow. | |

| The winding is coated on top with Unipak sealing paste. | |

| Then the tap itself is screwed on - first it is baited by hand... | |

| ...and after that, it is tightened with a wrench, so that the “lamb” is located in a place convenient for use – at the top. | |

| A similar operation is completely repeated with the second tap. That's it for now. | |

| Let's move on to operations directly on the boiler itself. Its two pipes are ready for further installation. | |

| A sealing winding is performed at the inlet pipe - a safety valve will be installed here. | |

| In this case, the master decided to limit himself to only the valve, that is, to do without installing a drain valve on the tee. A completely normal solution - you can drain the water from the boiler through the valve - a special lever is provided for this. Draining will take a little longer, but installation is simpler and cheaper, and you still don’t have to resort to emptying the boiler very often. | |

| The valve is screwed on and then tightened with a wrench so that the lever and drain pipe are in a position convenient for the user. In fact, this was the last connecting node, requiring winding of tow. | |

| The safety valve is installed in its original place. | |

| Flexible hoses are connected. In this case, the master used high-quality corrugated stainless steel hoses, which, according to their characteristics, are considered “eternal.” A flexible hose made of a rubber or plastic hose in a metal braid is, of course, significantly inferior in reliability, and is attractive only due to its low price. The installation principle is completely identical. Hoses in length are purchased taking into account the distance from the boiler to the “water outlets”. The gasket that comes with it is inserted into the union nut of the hose, then the nut is inserted onto the thread of the pipe (in this case, the outlet). No winding is necessary if the end of the pipe along the entire circumference is in normal condition - the gasket will provide the required level of sealing of the connection. The union nut is first screwed on by hand until it stops... | |

| ...and then tightened literally another ¼ ÷ ½ turn with a wrench. There is no point in over-tightening the connection - you can pinch the gasket and thereby achieve just the opposite result. | |

| The second end of the flexible hose is connected in the same order to the threaded pipe of the faucet on the corresponding “water outlet”. | |

| The installation of the second hose is carried out in a similar way, with the only difference being that its upper end is connected to the safety valve branch pipe. Now you can turn on the water and check all connections for leaks. If a “tear” is detected, you can slightly tighten the connection with a wrench, without applying much force - the leak should disappear. | |

| If there are no leaks, you can proceed to full operation of the water heater. The illustration shows the “lower node” of the boiler piping: a flexible line is connected to the taps of the “water outlets”. | |

| And these are the same hoses, but connected from above to the safety valve (for cold water) and to the hot water outlet pipe. The boiler installation is complete. |

Video - Check valve on a water heater

Frequently asked questions (FAQ)

And finally, it makes sense to answer some of the most frequently asked questions about the operation of boilers with a safety valve.

- People often ask how to deal with annoying drops of water protruding from the drain pipe?

But there is no need to fight them - they only indicate that the valve is functioning normally. The easiest way is to put a transparent tube on the pipe (so that you can visually control it) and lead it either into a sewer pipe or, for example, into a toilet flush cistern.

- Is it possible to place the valve so that it is not visible?

By and large, if he’s so annoying, then it’s okay. But at the same time, certain conditions must be met:

— No additional elements are allowed between the valve and the boiler - shut-off valves, tees, etc.

— The length of the section from the valve to the entrance to the boiler should not exceed one and a half to two meters. The fact is that the vertical column of water in the pipe will put additional pressure on the safety valve spring, and it will begin to work incorrectly, with severe undercutting.

- Leakage from the valve is too frequent and abundant, even at low water heating temperatures. What can be done?

The reasons for this phenomenon may be different.

— The valve rating does not correspond to the characteristics of the water heater.

— the spring in the valve simply weakened over time.

In both cases, the valve should be replaced with a new one with the required actuation force.

Another reason may lie in the instability of pressure in the water supply system. For example, frequent pressure surges with a large amplitude lead to valve activation even in the absence of heating. In this case, it is recommended to install a pressure reducer at the entrance of the water supply to the house (apartment).

- Can I try to adjust the valve myself using adjusting screws?

Definitely no! Adjusting such devices requires “calibrated” pressure, and carrying out such procedures on your own is prohibited. The valve is not such an expensive product that it is impossible to purchase a new one of the required rating.

- I never saw even a drop of water come out of the valve. This is fine?

But this is a very alarming sign. Who knows, perhaps the valve is simply “calming” with its appearance, but is completely inoperative. For example, the chamber behind the disc spring is overgrown or clogged with scale, the pipe is clogged, etc. If the valve is equipped with a lever, then you can try to check it manually (only better - at low heating temperatures, about 40 degrees, so as not to get burned).

It is possible that the valve rating is too high - it does not correspond to the water heater model. In addition, manufacturing defects cannot be completely ruled out.

The best way out of this situation remains the same - replacing the safety valve with a new one.

It will be calmer this way!

Never skimp on your own safety!

Video - Tricks for connecting an indirect heating boiler

Design and operating principle

Safety valve design

The safety valve has a simple design and is a combination of two spring mechanisms housed in a common metal body.

There is no fundamental difference between brass and steel products, but brass is a little more expensive and lasts longer. The springs inside the case are made of chrome-plated steel.

Operating principle of the device

Both cylinders, located perpendicularly, have a similar design, but different purposes. The part located along the flow of water has a spring inside and a “plate” with an o-ring.

The spring keeps the mechanism closed and prevents liquid from returning into the pipeline. The end parts of the cylinder are equipped with male-female threads for insertion into the cold water supply system and connection to the boiler fitting.

A more powerful spring is installed inside the second cylinder, which is in a neutral state even with a slight increase in pressure.

Consequences of absence

When heated, the liquid increases its volume (expands) by 3% .

This means that a heater with a working volume of 10 liters will have an additional 0.3 liters. If the container is not sized to accommodate additional volumes of water (and this is most often the case), the heater body will be destroyed. Then a crack will appear into which water will begin to leak.

Most heaters are designed in such a way that a decrease in pressure in the working tank is immediately compensated by replenishment from the network. Therefore, the leak will be constant until the container is replaced or repaired .

Device and principle of operation

The device for preventing a serious accident looks surprisingly simple, and its dimensions are small - it fits in the palm of your hand. It is a small mechanism consisting of two perpendicularly located spring-loaded valves, enclosed in one metal body. Essentially, these are two cylinders (tubes), one of which is slightly larger than the other.

The first larger diameter tube, usually 1/2 inch, with two threads at the ends, has a check valve installed that allows fluid to flow in only one direction. The flap in it is located across the pipe and can move along it by several millimeters, opening or closing the passage.

Under the influence of pressure directed towards the water heater, the flap opens, compressing the spring. As soon as the pressure in the pipeline and behind the valve is equalized, the valve closes under the action of a spring.

In a tube of smaller diameter, located perpendicular to the first, a second valve is installed, the spring of which is adjusted to open at a certain pressure, exceeding the pressure for the first valve. This is a fuse that protects against explosion.

Thus, when the pressure rises and the check valve does not allow water to escape into the cold supply pipe, the second valve opens and it is discharged through the drain pipe.

The nozzle may have special notches that make it easy to put on a hose of a suitable diameter. This hose must be secured with a clamp and led either into the sewer or into a container that will have to be emptied from time to time. This will have to be done infrequently, since the amount of water squeezed out during operation of the water heater will be small.

Very often, a plastic flag is provided in the design to force the opening of the drain device. You can use it to check the functionality of the fuse. To do this, you just need to open it and make sure that the piston stroke is free, it is not clogged with rust and scale, and the spring force is enough to return the valve to the closed state.

The safety valve body is often marked with an arrow indicating the direction of water flow to facilitate installation. The small pipe is usually marked with a marking indicating the pressure in pascals at which the emergency valve opens.

Proper installation of the boiler: selection and installation of a pressure reducer

Which pressure reducer should be purchased is up to the owner of the water heater to decide. These devices differ:

- According to the permissible level of water temperature (low temperature - 0-40°C, high temperature - up to 130°C).

- By type (diaphragm or piston).

- According to the level of inlet water pressure (up to 15, 25, 30 or 60 bar).

- If it is possible or impossible to calibrate and adjust them (adjustable pressure reducers are adjusted by rotating a screw).

- Based on the presence or absence of space for a pressure gauge (and the presence of the pressure gauge itself in the kit).

- By case material (brass or its alloys) and manufacturer.

How to check the serviceability of the pressure relief valve

In order for the boiler to operate without posing a threat to the residents of the house, it is necessary to periodically check the quality of the protective system. How to assess the condition of the PCV:

- Turn on the boiler without opening the hot water tap.

- Wait until the water heats up to maximum.

- If everything is in order, water will soon start dripping from the fuse system.

Reasons for PCV failure:

- The hot water tap is broken.

- The thermostat is set to +30…+40°C. In this case, the water will not heat up to such an extent that the pressure inside the tank reaches its limit.

- The operating pressure of the PCV is too high and does not correspond to the boiler capacity. This situation can lead to the most dangerous consequences.

The safety mechanism must correspond to the boiler in terms of design parameters and functionality, otherwise the operation of the latter will be not only ineffective, but also dangerous. Valve performance checks should be carried out monthly.

Choice

Most often, all modern water heating devices are sold with an already installed protection system in the form of a safety valve with certain parameters. When purchasing a device yourself, you should pay close attention to the features of the threaded part, as well as the maximum operating pressure.

Installed valve

Each valve is designed for a certain pressure level, which must be indicated in the technical data sheet of the equipment. The total volume of the tank must also be taken into account. Manufactured protective systems can have a response threshold from 6 to 10 Bar.

If the safety valve is incorrectly selected or installed incorrectly, constant leakage of liquid or very strong overheating of the water heating equipment may occur.

Tips for choosing a valve model

As mentioned above, water heaters are sold with a safety valve. In this regard, when purchasing a new model, especially a branded one, you do not need to worry about selecting parts.

The need to purchase arises in three cases:

- you received a used boiler without piping elements;

- the fuse was lost during a move;

- the valve is broken or worn.

Knowing the boiler model, you can easily select a new element. In the equipment operating instructions you can find the maximum pressure parameters - the same ones should be stamped on the body of the new part.

There is no need to buy a valve with a lower maximum pressure value or, on the contrary, a product with a reserve. In the first case, you will observe a constant leak from the tank, in the second, the valve simply will not work if an emergency occurs

The thread diameter must match the dimensions of the mounting fitting and the cold water pipeline. In addition to the device itself, you will need a linen thread for the pipe or a rubber gasket if a flexible liner is used.

Sometimes a valve is installed between the boiler pipe and the fuse to drain the water. This is an acceptable, permitted piping scheme, but under one condition - the valve must be mounted on a horizontal outlet from the water supply main. There should be no shut-off devices between the safety valve and the water heater.

Service

During use, depending on the intensity of hot water consumption, it is necessary to flush the safety valve for the boiler from scale, rust fragments from pipes and other foreign matter in the water. To do this, you just need to sometimes open the emergency discharge channel of excess liquid using a lever.

This mechanism should not be used to empty the water heater. Particles settling at the bottom of the tank passing through the bleed spring will get stuck and interfere with its further normal operation.

By following all the rules for using the water heater and ensuring that the safety valve is working properly, you will confidently and safely use hot water.

Source