- Types of releases and their features

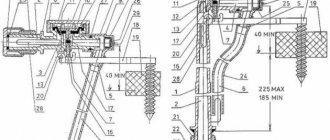

- Features of installing an element with side outlet

- How to choose a side flush toilet?

- How to install a toilet?

Modern plumbing fixtures today are presented in a large number of varieties, and they differ not only in appearance, but also in various parameters and characteristics. That is why it is often not so easy to make the right choice, and for this it is important to first carefully and responsibly approach the study of all the parameters of a particular option. At the same time, not all types can be installed in a certain bathroom, so it is important to initially study the parameters of the room itself where the work is supposed to be performed, and only after that proceed to the direct selection. The fact is that all types of toilets differ in their outlet, but the most popular is a toilet with a side outlet, which involves connecting it to the sewerage system running within the walls of the room.

Toilet with vertical outlet

Features of toilet hoses

Toilet liner

The water supply to the toilet is selected based on the plumbing model. Manufacturers offer options for tanks that differ in size, installation methods and connection to the water supply.

Types of eyeliners

The type of toilet line depends on the size of the toilet, the distance of the water supply pipes, and the type of tank:

- Rigid - tube made of stainless steel, brass, copper. The service life reaches 20 years. The absence of adapters makes installation of the system simple. When purchasing, the type of thread is taken into account.

- Flexible - reinforced hose, bellows tube. Service life from 1 year. Convenient to install in any location of plumbing fixtures.

A rigid product is used infrequently. Mostly in old houses. In new buildings they are connected using flexible hoses.

Popular lines of flexible tubing are made from rubber. Bellows products are made of stainless steel. Resistance to temperature changes, flexibility, and wear resistance make them in demand in the plumbing market.

Parts manufactured using foreign technologies are durable. Products from the German brand Hydraflex are durable and functional. Products of the Italian company PARIGI have good technical qualities. Also, the Turkish plumbing company AYVAZ produces reliable pipes and fittings.

Main types of drainage equipment designs

First of all, they depend on the type of filling and drainage mechanisms. The water drainage functions are performed by lever, push-button and automatic products.

Lever

The float (1) controls the inlet valve (3) through the lever (2). The water level depends on the adjustment of the float lever on the valve lever (4). The water pressure during filling is adjusted at the valve using a set screw.

Lever models were the main models installed on toilets of the last century. They are still used in some places today. Lever devices are distinguished by their simplicity. The first products drained only at the moment of pressing, while the shut-off valve was manually held (by the “pull” - a chain or fishing line). Then came systems that use the siphon effect, which themselves control the flow after activation. But both the first and subsequent models are characterized by increased unregulated water consumption. In addition, such plumbing does not meet current aesthetic requirements.

Push-button

The toilet flush mechanism, made in a push-button version, is installed on most modern plumbing products. The predominant location of the button is at the top, on the covers of compact systems, and can also be on the wall for products installed in building structures. Their advantages, in addition to good aesthetics, lie in the ability to adjust the drain and overflow parameters. Push-button mechanisms also, once activated, hold the shut-off valve open without human intervention. And models with paired buttons allow full or partial discharge of liquid into the toilet.

Automatic

Today, there are rare and expensive products for draining water, which justify themselves when installed in luxury products or used in public places. Their work is controlled by infrared sensors.

Shut-off valves for the toilet, represented by filling mechanisms, work, as many years ago, using the principle of a refill valve, opened and closed by a float. In the classic version, the float transmits force to the valve of a faucet with a side connection through a horizontal rocker arm.

Floats that shut off the water supply through a system of levers.

However, now more often floats are installed that move along a vertical guide, cutting off the water supply through a system of levers for both the side supply and the bottom.

Comparison of known models

Compact toilet with bottom connection

The range of reinforced pipes is distinguished by a variety of braids and hose materials. They have a fixed value. The reliability of the products depends on the compression density of the braid and the tube material.

Features of rubber products:

- low price;

- service life - 1 year.

Rubber products are characterized by:

- wear resistance;

- service period - 5 years.

Aluminum:

- withstands pressure of 5 atmospheres;

- warranty period - 5 years;

- is subject to corrosion in rooms with high humidity.

Nylon:

- withstands pressure of 20 atmospheres;

- operation - 15 years;

- high price.

Stainless steel:

- withstands pressure of 10 atmospheres;

- serves for 10 years;

- does not rust.

Parts made of brass will last longer than those made of plastic and silumin. The material from which the fitting and nuts are made is also of great importance.

The bellows flexible toilet hose is distinguished by a corrugated stainless steel surface. The product can change length if made by crimping.

Eyeliner characteristics:

- withstands pressure from 15 to 35 bar;

- service life up to 25 years;

- dampens vibration of the water supply system;

- not afraid of moisture.

The disadvantages are insufficient flexibility with a small bend radius and high price.

Manufacturers offer a wide range of supply products. The choice depends on cost, functional features, and installation method. Prices for flexible toilet hoses vary from 60 to 3,000 rubles.

Types of installations

The plumbing equipment market offers two types of devices for installing wall-hung toilets:

- block installation. The equipment can be fixed in a niche of the main wall. Installation of the block device is simple, since all the main structural elements are already located in their places;

Ready-made device for fixing the toilet

Equipment for mounting a toilet to any wall

How to choose the right product

Flexible product

The criteria for choosing an eyeliner need to be determined before purchasing it. Necessary:

- measure the distance from the pipe to the plumbing, as well as the diameter of the hose;

- find out the connection method, which depends on the design of the tank;

- take into account the type of thread (external, internal);

- take into account the water pressure in the pipes;

- remember to match the outlet fittings to the threads of the equipment in order to do without adapters;

- give preference to such product materials as silumin, plastic;

- pay attention to the weight of the eyeliner - light weight indicates low quality.

The more information collected, the easier it is to make a choice.

If you liked the article, please share it

Previously on the topic:

Share

Installation, connection and fastening

Before installation, you must check the hose for cracks and scratches. The product should be connected, observing the rule of compatibility of elements (brass-brass, copper-brass). Do not overtighten the nuts and avoid tension on the hose.

Connecting the bathroom to the water supply

This installation option is carried out as follows:

- The cold water supply is turned off. A local water shut-off valve is installed.

- A flexible hose is connected with fittings to the tap on one side, and to the opening of the drain tank on the other.

- The quality of installation is checked. The water is turned on and the connections are inspected.

- The water is drained and filled into the tank 2-3 times.

If there are no leaks, the job is done correctly.

Connection methods

Side eyeliner

The holes are located on the side or bottom of the tank. The connection diagram is simple:

- Lateral water supply to the toilet cistern, when the tubes are attached to the right or left side. Pros: easy installation, repairable by replacing parts. Cons: the water is noisy when filling, the side hoses are visible.

- Bottom water supply to the toilet: the hole for connecting the water supply is located at the bottom of the tank. Pros: tubes are hidden, low noise level. Cons: difficult to install; during repairs, the system changes completely.

A number of container models have a universal connection type, when the excess hole is closed with a plug.

Types of fastenings

When connecting to a water pipeline, a fitting or union nut is used. The second end is connected to the tank. A plastic pipe is installed inside the container and secured with nuts. From the outside, the pipe is connected to the inlet hole of the sleeve with union nuts.

Brass fittings and nuts are durable, and rubber gaskets and sealant will make the connection more reliable.

A flexible toilet line, compared to a rigid one, has a number of advantages: it can be installed quickly, and can be installed in hard-to-reach places.

Selection rules

In order to choose a high-quality bellows liner, many parameters should be taken into account:

- The liner sleeve must be appropriate for the temperature and pressure. If you can use any type for a dishwasher, then for a boiler only a special hose with a mark for hot water. The color designation on the pipe or fittings will show which water (hot or cold) the liner is used with: blue exclusively for cold water, red or two-color for cold and hot water.

- The bellows is selected in such a way that its inlet fittings are threaded directly to the connected machines and equipment, without various adapters. For this purpose, liners with fittings and fittings of various sizes are produced.

- You should buy a product with greater flexibility, which can be determined in a simple way by holding the pipe horizontally and comparing the angle of inclination.

- Fittings and union nuts must be made only of stainless steel or brass and of sufficient thickness. Fittings made from cheap aluminum indicate a fake and low quality product. The corrugation itself must also be made exclusively of stainless steel. It is quite easy to distinguish it from aluminum, since aluminum is very light in weight.

- If the hose is to be used to supply drinking water, it must be checked for any strong chemical odor. If there is a smell, it means that the product contains materials that can be harmful to human health.

- All other things being equal, the choice should be made on products from well-known European manufacturers, upon sale of which copies of the necessary certificates are provided. You should not purchase eyeliner with defects visible to the naked eye: damaged fittings or nuts, deformed gaskets, poor-quality corrugation. Products made of galvanized steel will inevitably rust within 1-2 years after installation, so they are also not recommended for purchase.

- It is best to choose the length of the hoses with a significant margin, since it is not recommended to stretch the bellows too much: this will reduce its service life. A high-quality product must be sold complete with a technical passport and a warranty card for a period of at least one year.

- Although the bellows liner is considered the most reliable and durable, manufacturers recommend carrying out an inspection at least once every six months for preventive purposes and immediately replacing elements on which any defects are found.

For more information about bellows water liner, see the following video.

Reviews

Vasily, Salekhard : “The bathroom was renovated. When the new tank was installed, all the hoses were replaced. We settled on a corrugated pipe. It was not difficult to let her down. We were attracted by the service life and material (stainless steel). 3 years have passed. It doesn't leak anywhere. I'm pleased."

Andrey, Krasnodar : “When 2 years ago the old pipe rusted and started leaking, we had to change it. There is not enough space for the toilet. Connecting communications is inconvenient. A reinforced flexible hose came to the rescue. Installing the side water supply to the toilet took 15 minutes. There was no leak. I took it in a metal braid, the fitting nut was made of brass.”

External damage

Such breakdowns occur due to incorrect installation or non-compliance with the operating rules of the device. Let's look at the most common problems and their solutions.

You may be interested in the article “Soldering polypropylene pipes: temperature table, installation instructions + top best pp systems” Go>>

Crack in the base of the toilet

If you pour hot water into the toilet or drop something heavy, the toilet bowl may crack.

How to repair such a crack if it is at the base of the toilet:

- Prevent crack enlargement. Use a small drill to make small indentations along the edges of the crack.

- Sand the edges of the crack with sandpaper.

- Glue the earthenware with epoxy resin or use two-contact glue.

- Do not use the device until it is completely dry.

- If the glue fails, you will have to replace the bathroom.

The fasteners are not tightened tightly enough

If, shortly after installing the toilet, drops of water appear at the connection between the tank and the bowl, then the clamping nuts may not be tightened tightly. Therefore, the tank did not move much.

Tighten the nuts. By lightly rocking the drain tank, check whether they are screwed on well.

The toilet bowl burst

If you stand on the toilet bowl with your feet, large cracks may appear. Water will begin to leak through the cracks. In this case, repairs will not be possible; you will have to replace the toilet with a new one.

Types of installations

The plumbing equipment market offers two types of devices for installing wall-hung toilets:

- block installation. The equipment can be fixed in a niche of the main wall. Installation of the block device is simple, since all the main structural elements are already located in their places;

Ready-made device for fixing the toilet

Equipment for mounting a toilet to any wall