Most of the requirements for installing a boiler are described in detail in the passport or recommendations for heating equipment. For a careful and diligent worker, it is almost impossible to make a mistake. Another thing is the installation of the heating circuit.

It is not so easy to piping a boiler with polypropylene. General recommendations, as a rule, are not enough, because you have to take into account the characteristics of the premises. And the boiler piping schemes with polypropylene differ for different types of boilers.

What is boiler piping with polypropylene

In a simplified interpretation, piping a boiler with polypropylene is considered to be a set of control devices with the distribution of heating pipes from the outlet on the boiler heat exchanger, along the circuit, through all the heated rooms of the house or apartment. The quality of the system depends on how correctly the piping scheme is chosen.

What's included in the harness:

- Security group. It includes a pressure gauge, air valve, thermostat. Depending on whether the water will circulate naturally or using a pump, a flow meter and an emergency valve may be included in the group.

- Propylene pipes designed for hot water supply or heating.

- Expansion tank.

- Taps and valves that allow you to regulate the amount of hot water for a specific branch of the piping.

- Dirt filter.

It is generally accepted that the expansion tank is an attribute of all existing boiler piping schemes. But it is not so. Modern gas boilers already have a built-in compensation tank for 1.5-3 liters of water. If the boiler heats a small room, then the built-in tank will suffice.

The use of polypropylene pipes requires the installation of an emergency or steam valve. The essence of the problem is that water heated by the boiler can boil, most often at the entrance to the heating circuit. If this happens, then boiling water and steam will flow further through the pipe, it will reach a section with a tank with an air release valve, and that will be the end of it.

But before the vapor-air plug leaves the system, it will melt the polypropylene. Therefore, when piping a boiler with polypropylene, the valve is installed before water enters the pipes. This is usually a problem with solid fuel boilers, since coal and wood fireboxes have high thermal inertia. If overheating occurs, then it will not be possible to stop the process in seconds.

A large number of joints

Another disadvantage in organizing heating with polypropylene pipes is the large number of joints. The average house can sometimes have 200-300 joints and most of them are hidden in the screed and walls. And every junction is a human factor that can play a cruel joke. At any moment, any joint can leak. It's good if he's outside. But as practice shows, quite often the joint begins to leak inside.

And taking into account the constant linear expansion of the pipe, the joint may also lose its tightness. It would be correct to note that such situations do not always occur.

Types and characteristics of pipe products for heating systems

For heating systems, two types of PN25 pipes are used:

- with an internal reinforcing layer of polypropylene and fiberglass;

- with an additional inner shell of aluminum foil.

For piping a boiler with natural circulation, polypropylene reinforced with a mixture of polyethylene and fiberglass is usually used. The pressure is almost equal to atmospheric pressure, the outlet temperature usually does not exceed 80-85 ℃. Therefore, using more expensive pipes with an internal foil lining may be a waste of money.

For gas and electric boilers, the piping can be made from PN25 pipe with any type of reinforcement. Glass-reinforced polyethylene has a lower coefficient of thermal expansion. Polypropylene with aluminum foil is less deformed and sag due to heating.

When soldering with fittings, the foil has to be peeled off, so the labor intensity of assembling the boiler piping is higher.

There is no need to skimp on materials for lining heating boilers with polypropylene in a private home. Firstly, unlike hot water supply, the pipes and fittings of the heating system are constantly under load, which means the risk of leaks in the event of a defect increases sharply.

Secondly, any accident and its elimination with resoldering of polypropylene will cost much more than the benefit from conditional savings on materials. The rupture of polypropylene can cause failure of boiler equipment.

PN25 pipes with aluminum foil can be operated at temperatures up to 95 ℃, the maximum pressure should not exceed 10 atm, operating pressure - 2.5 atm. For the water injection supply line, unreinforced PN10 PPR polyethylene pipe can be used.

Soldering plastic pipes for heating

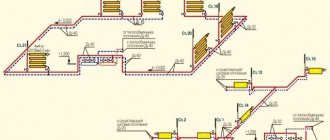

soldering diagram

The most critical stage of the technological process of installing a heating system is pipe welding.

Soldering is carried out in the following sequence:

- Cutting pipeline parts to the required length.

- preparation .

- Heating and joining of pipes.

- Maintaining a still state.

First of all, large sections should be welded, which will later be placed in the designated location.

The connecting elements are placed in the iron attachment. In this case, the part that will be placed in the other is heated from the outside (the nozzle is put on it with the side intended for external heating). In another fragment, for heating from the inside, the nozzle is placed with the “cap” side.

Please note that it is necessary to put the parts on the nozzle and join them together until they stop.

Over the course of 7-10 minutes, the parts cool down completely motionless, resulting in a reliable connection.

The soldering depth is determined according to the diameter of the pipes:

- at 16-25 mm – the depth is 13-15 mm;

- 32-50 mm – 16-20 mm;

- 63-110 mm – 24-32 mm;

The heating duration is also set according to the diameter of the product:

- 16-20 mm – 5 seconds;

- 25 mm – 7 seconds;

- 32 mm – 8 seconds;

- 40 mm – 12 seconds;

- 50 mm – 18 seconds;

- 63 mm – 24 seconds;

What to choose

It is believed that the choice of PN25 pipes should correspond to the cost of boiler equipment. For cheap wood burning, you can use Chinese pipes. But not the first ones that come to hand, but those that are produced in China under a license from one of the European Union countries, made from imported raw materials using original equipment. For example, the “BLUE OCEAN” brand.

To piping a double-circuit boiler with polypropylene, you can use German products from Banninger or Italian pipes from Valtec. Among the cheaper ones, we can recommend high-quality polypropylene from. They are not capricious during installation and tolerate low temperatures well. Vesbo is the best Turkish pipe for piping.

Did you choose the pipes for piping the boiler yourself?

What materials are they made from?

For the manufacture of plastic pipes, inorganic material based on high-viscosity polymers of artificial or natural origin is used:

- Polypropylene.

- Polyethylene.

- Polybutylene.

- Polyvinyl chloride.

To increase strength, plastic is reinforced by connecting polymer layers with metal foil with a special glue or by adding fiberglass threads to the melt.

Options for piping boiler equipment

When choosing a scheme, you will need to pay attention to the design of two separate parts of the heating system:

- boiler equipment safety groups;

- diagram of pipe distribution and heat delivery to the premises.

The safety group configuration depends on the type of boiler. The manufacturer of boiler equipment indicates in the product passport the minimum set of devices that ensure the operation of the unit. He even gives a recommended wiring diagram for the outlet and inlet of the heat exchanger. You just need to install the devices correctly.

You will have to plan the wiring diagram yourself, choose the type of circulation and the method of equalizing pressure throughout the heating system. For low-power boilers, leveling can be done by including bypass valves in the piping. For powerful heating systems, balancing is performed in an intermediate tank - a hydraulic collector or, in other words, a hydraulic arrow.

Forced circulation circuits

The system uses pumping of the coolant, so the heating circuit quickly and evenly warms up to operating temperature. It is best to solder the line from glass-reinforced polypropylene; it gives a relatively small elongation of the pipes, so there will be no problems with deformation of the pipelines.

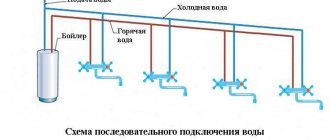

For apartments and private houses with a small number of rooms, polypropylene piping is often performed using a linear single-pipe scheme. Thanks to the pump supply, hot water moves through the pipe at high speed, so all radiators are heated more or less evenly.

The batteries are connected to the circuit in series one after another. In this case, the supply from the boiler to the radiators and the gaps are made of glass-reinforced polypropylene PN25. The return can be made with a PN20 pipe.

For large rooms and private houses on two floors, piping is often performed by dividing the heating system into several lines. In this case, a distribution manifold is used. The main circulation pump pumps hot water through the boiler heat exchanger and hydrocollector. Due to the high pressure and temperature, both units, supply and return pipes are made of steel.

On the other hand, dedicated hot water supply lines to radiators, heated floors or boilers are connected to the distribution manifold. This part of the harness is made of PN25 polypropylene. Each line is equipped with its own tap and circulation pump.

You can find piping options with a distribution manifold made of polypropylene or metal-plastic. Such schemes are used for heating apartments, for example, in houses for several owners with one boiler and a hot water boiler.

With natural circulation

In private houses and apartments with individual heating, old schemes without forced water circulation can be used. The boiler piping is carried out in the form of a closed loop of two pipes - direct supply and return. Batteries or tubular registers are connected between them.

The direct supply line is often made of steel pipe. The coolant temperature can reach 95-98 ℃. Therefore, polypropylene is not used for piping the boiler outlet. Hot water is directed through the top pipe and returns through a line laid at the level of the boiler heat exchanger inlet fitting. Cooled water is collected in the return, the temperature of which rarely exceeds 60 ℃, so you can install PN20 polypropylene without any problems.

The piping of a heating system with natural circulation must include an expansion tank. According to the diagram, it is installed above the boiler, on a vertical steel pipe with a height of at least 180-200 cm.

A heating system with natural circulation of coolant is also called gravity, but this is not entirely correct. It would be more correct to call it impulse.

The water in the heat exchanger is heated to a high temperature, steam appears under slight excess pressure. The steam flow pushes water up the steel pipe to the level of the expansion tank, lifting it and at the same time saturating it with microbubbles.

In this section of the piping, the microbubbles cool and turn into a liquid state, releasing additional heat and heating the water. The coolant becomes hot and heavy, so due to the difference in levels, the boiling water squeezes out colder water and returns to be heated by the boiler.

An expansion tank must be present in any heating boiler piping scheme, but with a natural circulation scheme, this device additionally ensures the pumping of hot water through the heating circuit.

Final conclusions

There is no clear answer to the question of what is better to use for heating – polypropylene or metal-plastic. Much depends on the circumstances and capabilities of the homeowner. The following conclusions suggest themselves:

- By choosing propylene, you save a lot of money, but you must achieve high-quality installation by all means. With a large number of connections, invisible defects may still occur.

- You will have to pay decent money for metal-plastic - this is the main disadvantage. If we can overcome it, then otherwise you won’t have any problems.

Finally, an important note: remember that “crooked” craftsmen are able to ruin any material, even the most expensive and high-quality one. Pay special attention to the contractors you choose for the heating installation in your home. Otherwise, you will subsequently get leaks described in the video:

Criteria for choosing a wiring diagram

The selection of a suitable option begins with determining the type of circulation and the method of replenishing the circuit with water. For a private home, both natural and forced coolant circulation can be used.

If there are no problems with power outages, and the house has a central water supply, then the best option would be a gas boiler with:

- piping made of polypropylene;

- pumping coolant;

- replenishing the system with a drain from the water supply network.

Thanks to the use of a pump and the low temperature of the hot water, there is no need to cut into steel sections. It will be enough to piping polypropylene pipes. The piping of the boiler and radiators is carried out according to a two-pipe scheme.

Strapping for large apartments and houses

For buildings with a heated attic, piping can be done according to a natural circulation scheme. It will be necessary to raise the water tank to the second floor under the attic ceiling. You will need to install washers in the pipework of the upper and lower pipes, preferably taps that regulate the flow of hot water. Otherwise, it will be difficult to balance coolant flows on different floors.

In such schemes, the use of polypropylene in the boiler piping improves the quality of heating, since the internal walls of polypropylene pipes are always smoother than those of steel pipelines.

If in an apartment or house, in addition to heating, the boiler is used as a heat source for a hot water boiler, heating a bathhouse, heating a heated floor, then it is better to choose a piping scheme with a hydraulic arrow.

The same piping scheme can be used for a solid fuel boiler. The security group that controls temperature and pressure will change. It will also be necessary to replace the polypropylene with steel or copper in the area from the boiler outlet to the inlet fitting of the water gun.

Country option

In holiday villages there are always problems with electricity. Either they turn off the lights for several days, or the voltage in the network is clearly not enough for the boiler automation to work, and most importantly, it is possible to start the pump. While it is still possible to install an uninterruptible power supply unit for the combustion front control system, it is difficult to select such a device for the pump, and it is expensive.

In such conditions, wiring is done for a system with natural circulation of water, but with a bypass pump included in the circuit. On smooth propylene pipes, heating with natural circulation will work efficiently, only slightly inferior to schemes with pump supply.

Typically, a pump is needed to quickly warm up a room or remove air from the system. It is turned off at night, since the hum from the running engine can be heard even if the boiler is in the summer kitchen.

Large linear extension

If you are planning to use polypropylene pipes for heating, then immediately plan to use them only in hidden installation. You will need to hide all pipes in the walls and screed, and preferably in insulation.

The main problem with polypropylene is its linear expansion. It is approximately 2.5 mm per linear meter. If you have installed straight pipes, then during operation they will definitely “float” somewhere. Even if you fasten them often. If these pipes are located outside, then you are unlikely to appreciate such a picture.

Nuances and piping options for different types of boilers

Most of the problems that arise in the operation of boiler equipment are associated with improper installation of the equipment in the boiler piping. Often, efficient operation is hindered by the wrong type of taps. For example, instead of ball metal ones, installers like to install cheaper models made of polypropylene.

What is the difference? Taps made of polypropylene, especially on the hot water branch, become tightly “welded” after a year, and it is impossible to turn the valve.

Gas equipment

For heating using domestic gas, two types of boilers are used, floor-mounted and wall-mounted. The first type of gas boiler is not much different from classic coal or wood-burning models. Additionally, automatic control of the gas combustion front and a chimney draft presence sensor are installed.

The piping, which should be located on the same level as the heat exchanger, must have an air release valve, a pressure sensor, and a water make-up valve.

Regardless of the model and power of the floor-standing gas boiler, an expansion tank is included in the piping. Especially if the heating circuit is built using a hydraulic arrow. In this case, the expansion tank is placed immediately at the outlet of the boiler heat exchanger.

The relatively low water temperature makes it possible to pipe the premises with polypropylene pipes. Moreover, the distribution manifold is also often assembled by soldering polypropylene tees.

For wall-mounted single- and double-circuit boilers, it is advisable to install expansion tanks, regardless of whether a compensating tank is present in the design. Moreover, a tank is placed in the harness, both on the heating line and on the hot water supply line. Experts advise embedding an air release valve into a polypropylene pipe; this is done at the highest point of the heating circuit.

When assembling the piping, the heating circuit feed line from the water supply is equipped with a dirt filter and a pressure reducer. It is believed that polypropylene, unlike steel, does not produce debris particles, but it is better to include a filter on the piping, since the make-up water may be of poor quality.

Electric heater

Unlike gas boiler equipment, an electric boiler operating in a “heating-pumping” cycle can operate in both cyclic and constant heating modes. The use of polypropylene for piping an electric heater turns out to be even more profitable than steel pipes.

Firstly, polypropylene does not conduct current, so the heating circuit is isolated from the electric heater. We are talking about pipes with fiberglass reinforcement.

Secondly, polypropylene pipelines have a lower thermal conductivity coefficient than steel ones, so less heat is lost. This means that in the bathroom, where there is a heater, a manifold and all the fittings, there will be no “tropics”, while in the rest of the rooms it will be cool.

Only the distribution manifold and the safety group installed in front of it with an air and emergency relief valve are made of metal in the piping. There should not be any other elements except the pressure gauge. If for technological reasons it is necessary to place cranes in front of the group, then after completion of the assembly work the valves are opened and the rotary handles are removed or blocked.

Connecting pipes to each other

socket welding

There are 2 methods of connecting plastic pipes to each other:

- Socket welding.

- Welding using connecting elements.

Socket welding technology involves the use of a manual machine. The essence of its application is that when the material is heated, the process of diffusion of molecules occurs (the molecules of one component combine with the molecules of another, resulting in the formation of a seamless shell).

With this welding method, one end of the product is placed into the pre-expanded end of the other.

To carry out soldering using fittings, the end of the pipe and the coupling are inserted into a soldering iron nozzle of the appropriate size and heated at a temperature of 260 degrees.

The temperature can be set on the iron's thermostat. After the required time has passed for heating the material, the components are removed from the nozzle and then combined.

Products with a diameter of more than 63 mm are connected by butt welding.

Requirements for a room with two boilers

In the case when the same type of heating sources are selected, the requirements for the furnace are applied to the specific type of fuel used: gas, coal, pallets or electric heating.

The boiler room in the house needs to be treated with due attention

If units operating on different types of energy carriers are selected, the premises must comply with both, and the larger indicator is selected.

Requirements for units using solid fuel:

- The floor area of the combustion room is selected according to the total thermal power of the devices: up to 32 kW, 7.50 m2 is required, up to 62 kW - 13.50 m2, up to 200 kW - 15.0 m2.

- A unit of more than 30 kW is installed in the center of the combustion chamber to ensure reliable circulation of air masses.

- The surface elements of the combustion chamber: floor, walls, ceiling and partitions are made of fire-resistant building materials, using waterproofing protection.

- The boiler is installed on a reliable foundation made of fire-resistant building materials.

- For units up to 30 kW, the requirements for fire resistance of the floor are lower; it is enough to cover it with a steel sheet.

- The supply of solid fuel is stored in a separate dry room, and the daily supply can be located in the boiler room at a distance of at least 1 m from the boiler.

- The furnace room must have a door and windows installed that can provide reliable air circulation three times based on the existing volume of the room.

Requirements for furnace units with gas-fired boilers:

- Gas boilers with a total power of up to 30 kW can be installed in non-residential premises of a house where there are windows and doors that can provide 3 times air circulation.

- When the power of the gas source is more than 30 kW, a separate furnace room is required with a ceiling height of at least 2.5 m and a total area of more than 7.5 m2.

- If this equipment will be installed in a kitchen in which a gas stove operates, then the room must be at least 15 m2.

Design

The production of fittings, according to GOST 13846-84, involves the use of tee and cross type schemes.

The device consists of:

data-ad-client=»ca-pub-8514915293567855″ data-ad-slot=»1955705077″>

- pipe head;

- fountain tree;

- manually operated locking devices;

- chokes.

The pipe head is used to hang several rows of tubing and seal them. In addition, the pipe head takes part in technological operations, which include: development, operation and repair of the well.

Hanging of columns is carried out (on a thread):

- if a single-row elevator - on the coil thread;

- if there is a two-row elevator: the inner column is on the thread of the coil, the outer column is on the thread of the crosspiece of the pipe head.

The pipe head requires replacement of its side valves. This process is carried out using special blind plugs, which are installed in the threaded holes of the housing.

Shut-off devices on fountain fittings with manual control

Christmas tree functions:

- directs product to the flow line;

- takes part in the installation of special devices;

- measurements of pressure and temperature of the environment;

- lowering downhole instruments for pipe cleaning.

Shut-off devices are presented in the form of straight-through plug valves and direct-flow valves with a lubricant supply. Their main purpose is to cover passage holes.

Column heads serve as casing hanger, sealing and pressure control between pipe strings. to menu

Technical requirements for design

GOST 13846-89 defines a Christmas tree as a device designed to seal wells, shut off the medium and direct it to the manifold, and carry out other technological operations.

According to GOST 16350-80, fountain fittings can be used in temperate and cold macroclimatic regions. Placement is carried out according to category 1 (GOST 15150-69).

Optimal ambient temperature: from -60ºC to +40ºC.

High-quality fittings are durable and can withstand atmospheric loads

GOST 51365-2009 established the use of a certain material and the level of technical requirements that are most suitable for operating conditions.

The production of parts can be designed according to individual orders, taking into account that all operating conditions and the choice of component materials will comply with established standards. to menu

Designation AFK

- AF – fountain fittings;

- K – method of hanging the pipeline according to GOST 13846-84;

- n – scheme according to GOST 13846-84 (n = 1-6);

- E – cable entry;

- 65×21 – nominal diameter and working pressure in MPa;

- HL – climatic versions of the product;

- K1 – corrosion resistance category.

Typical schemes according to GOST 13846-89:

- AF1, AFK 1;

- AF2, AFK 2;

- AF3, AFK 3;

- AF4, AFK 4;

- AF5, AFK 5;

- AF6, AFK 6.

to menu

Application of buffer tank

The wiring diagram for a solid fuel boiler with a battery tank is not widely used. It is quite cumbersome, but allows for more correct heating operation. Its advantages:

- Stabilization of temperature in the system due to the increased volume of water in the circuit;

- Possibility of reducing the number of approaches for adding fuel to the boiler furnace due to the accumulation of excess heat in the storage tank;

- Possibility of accumulating clearly unnecessary excess thermal energy when using too powerful a boiler or excessive stacking of firewood.

The heat accumulator circuit has one drawback - it is necessary to allocate space for the device itself. The volume of the container used reaches several hundred liters, so you will need free space to place the tank.

There are many schemes for connecting buffer tanks. The simplest of them involve the use of the same coolant in the boiler and in the heating system. A more efficient scheme is using a three-way valve with a thermostat, which ensures a more uniform and economical consumption of thermal energy from the buffer tank.

Schemes with two circuits are also used. In this case, heat accumulators of heating systems are equipped with heat exchangers connected to solid fuel boilers. Heat exchangers heat the water in the tank, which is the coolant of the heating circuit. This option is distinguished by its efficiency and more uniform heating.

How to choose

Criteria for choosing plastic pipes for a future heating system:

- Design diameter and wall thickness size.

- Acceptable operating parameters.

- The degree of flexibility of pipe products.

- Features of installation (open and hidden type of installation).

It is advisable to select plastic fittings from the same manufacturer.

The products of the German companies Rehau, Banninger and Wefatherm have proven themselves well. Products from these companies can be used for assembling heat supply routes and heating systems with the following coolant performance characteristics:

- Temperature conditions up to 130 ºС.

- Pressure up to 25 bar.

Materials from Czech companies Ekoplastik, FV-Plast and Wavin are to some extent inferior in quality to German products, but Russian builders willingly purchase them. The lower price segment is occupied by plastic products from Turkey and China. However, their operating temperature limit is +95 ºС.

The cost of domestic plastic products is significantly lower than that of foreign analogues. At the same time, in terms of strength and heat resistance, they are not inferior to them, and even superior.

Common problems and errors

Low efficiency and frequent breakdowns of heating equipment are a clear sign of mistakes made during its installation.

Mistake #1. Most often, problems arise due to insufficient heating of the coolant. As a result, this leads to the appearance of a large amount of tar or soot.

Mistake #2. Incorrect adjustment or lack of protection against boiling water is one of the most common problems. Because of this, the coolant heats up excessively, which negatively affects heating appliances, pipes and other equipment.

Mistake #3

If the heating system is not highly efficient, then you should pay attention to the quality of the sealing. To do this, you need to check whether the boiler and other structural parts of the system are reliably insulated

Indirect water heaters

An indirect water heater will ensure stable and efficient operation of the entire heating system.

The wiring diagram for a solid fuel heating boiler using an indirect heating boiler is not the simplest, but not the most complex either. Here, consumers are faced with the task of ensuring the supply of hot coolant from the heating circuit to the coil. To do this, a hydraulic arrow is installed in the system, distributing flows into two or more directions. Two pipes extend from the arrow - one goes to the batteries, and the second to the boiler.

Two circulation pumps are installed behind the hydraulic switch - the complexity of the piping scheme gradually increases. One pump sends coolant to the radiators, and the second pumps it to the boiler. The operation of the second pump is regulated by a thermoregulation system built into the water heater. This ensures the maintenance of a stable temperature in the DHW circuit.

General installation instructions

Before purchasing a heating unit, you need to determine where it will be installed. The furnace room is designed for this, but often there is not enough free space in it, since it is occupied by an existing gas or other heater. Then the installation of a solid fuel boiler in a private house can be done behind the wall of the furnace room, in an extension. A frame made of metal structures is installed and covered with sandwich panels or profiled sheets with insulation. This option is convenient for those who plan to burn with coal; there will be no dirt inside the house.

All inexpensive solid fuel boilers for low-power homes can be placed directly on the rough floor screed. They are light in weight and do not exert vibration loads on the base, since they are not equipped with a fan or screw conveyor for feeding pellets. For units with a power of over 50 kW, it is recommended to build a concrete foundation, which should rest on the ground and compacted crushed stone bedding. The foundation is made 80-100 mm above the level of the screed, and it should not be connected to it. Foundation devices also require long-burning boilers, which have a mechanism for lifting and lowering heavy loads.

Projects for private houses usually provide for the installation of a chimney shaft in the thickness of the wall with a pipe exiting through the roof. If the shaft is missing or occupied by an existing gas heater, you will need to install a chimney for a solid fuel boiler. To do this, it is better to use metal double-walled chimneys with insulation. They are lightweight, assembled from sections of the required length and are easily attached to the wall of the house. For turns and branches, the same double-walled tees and bends are made. Methods for installing chimneys with and without an exhaust shaft can be seen in the figure.

Chimney installation

The furnace room must have natural exhaust ventilation. When heating boilers are installed in a private house, the exhaust is provided through a shaft in the wall. The shaft is parallel to the chimney, only with a smaller cross-section. If it is not available, a transfer grille is installed in the outer wall; it should be located under the ceiling of the room. The role of the hood is as follows:

- A vacuum is created in the furnace room, as a result of which fresh air from other rooms is sucked in and used for combustion. Boiler systems with a power of 50 kW and above require the organization of separate supply ventilation.

- Removing combustion products that accidentally entered the room.

The approximate layout of the equipment and the installation diagram of a solid fuel heating boiler are shown in the figure.

Solid fuel boiler installation diagram

Often in boiler rooms of country houses there is no sewerage outlet. This is not entirely correct, since sometimes it is necessary to empty the system or the water jacket of the boiler. The safety valve discharge is directed into the same drain.

Installation procedure

To perform the work, the following instructions for installing solid fuel boilers are proposed:

- Release the product from its original packaging.

- If there is not enough space in the furnace room, then it is better to assemble the product outside. Install all doors and ash pan drawer, as well as other elements supplied separately. There is no need to install a fan and automation devices; this is done after installing the boiler.

- Move the unit indoors and install it on the foundation or floor so that the gas outlet pipe is on the same axis with the chimney pipe. At home, installing a solid fuel boiler yourself must be done with an assistant; the weight of the equipment is rarely less than 50 kg.

- Secure the boiler to the foundation or screed so that there are no distortions.

- Connect the chimney, install a fan with a control unit and a safety group.

- Connect the boiler to the heating system according to the selected scheme.

Safety valves

They are not used when the heating system is open. The purpose of the valve is to protect the boiler from damage in the event of a sudden increase in pressure.

Usually the valve is forgotten or a model or safety group with different characteristics is installed. When the valve responds, some of the water flows out of the system, providing pressure relief and protection. You should not insert the drain tube into the sewer, since the reason for the decrease in pressure will not be clear. You can get by with a funnel. By the way, there is no need to throw the septic tank into the coolant.

Air vent

. The part must be installed immediately after installing the boiler to avoid “airing”. Often they simply forget to open it. This is also typical for wall-mounted options with a factory function. By the way, the circulation pump is also ventilated.

The air vent must stand strictly vertically upward. When it starts to leak, there is a shut-off valve in front of it, so replacing it with a new one will take a couple of minutes.

Circulation pump

. The pump will operate properly only when the axis is in a horizontal position, and this position will significantly extend the “life” of the bearings.

It is advisable to protect the mechanism from dirt and debris from the outside. Strainers sold separately

Radiators.

Disadvantages when connecting a panel radiator to the coolant. The radiator design involves connecting the supply pipe to the internal vent, located almost in the center, and to the outermost one - in the return pipe. The reverse connection order will reduce the heat transfer of the radiator by half. By the way, decorative screens disrupt heat transfer by 10-20%.

Proper installation and correct power calculations will help create maximum comfort for living in a country house at any time of the year.

Christmas tree fittings - tee type

The tee-type fountain fittings have two tees: the upper one is the working one, the lower one is the backup one.

The tee-type Christmas tree fittings have nominal bores of 50 and 90 mm.

The tee-type fountain fittings have two tees: the upper one is working, the lower one is a backup one, which is used only during repair or replacement of the upper one. Reinforcement of this type has a large height (up to 5 m from the ground surface), is inconvenient to maintain, and is unbalanced. It is used in particularly difficult well operating conditions - in the presence of solid suspensions in the gas flow that cause abrasive wear of equipment, gaseous or liquid corrosive agents (carbon dioxide, hydrogen sulfide, propionic, butyric or other fatty acids), with sharp fluctuations in pressure and temperature.

The wellhead is equipped with a special twin tee-type Christmas tree with two-string flow lines for each formation. There are a number of modifications of well equipment according to the fountain-gushing scheme, adapted for various operating conditions.

| Scheme of cross fountain fittings. |

In sand production wells, a tee-type X-mas tree is used. Instead of a cross 7, a tee (not shown in the figure) with a spare flow line is installed on the central valve 6, then an intermediate valve and a tee with a working flow line.

The well's surface equipment is a special double X-mas tree of the tee type with nominal bores of 50 and 40 mm in diameter and with two-string discharges for each formation (Fig. XIII. The fittings are designed for an operating pressure of 20 0 MPa. Equipment with parallel placement of tubing pipes is used in wells with a production casing with a diameter of 168 mm or more.

Deep gas-condensate wells are equipped with an AF-60-300 tee-type (two-string) Xmas tree in a flanged design, designed for GOO am test pressure and 300 am operating pressure.

To test a well equipped with a tee-type X-mas tree, a line must be laid from the bottom string of the valve for installing a diaphragm critical flow meter (prover), and a purge line must be laid from the top string.

To test a well equipped with a tee-type Xmas tree, a line for installing the prover must be laid from the bottom string of the fixture, and a purge line must be laid from the top string. If the fountain fittings are of the cross type, then a line must be laid from one string, and a blow-off line from the other.

In accordance with GOST 13846 - 89, tee-type Christmas tree fittings are produced for operating pressures of 14, 21, 35, 70 and 105 MPa. Christmas trees with bore diameters of 100 - 150 mm are designed for high-yield oil and gas wells.

After completing the well killing work, the AFT2 - 21/2x320 tee type Xmas tree should be dismantled, having previously disconnected it from the pipeline. At the wellhead, install a preventer installation in accordance with Scheme 2 according to GOST 13862 - 90 and remove the lift string from the well, inspect the pumping and compressor pipes.

| Wellhead piping and location of surface equipment during well development in the Stavropolneftegaz association. |

When developing wells with a depth of 1000 - 1500 m, a Christmas tree with a bore of 50 mm is used - 1AFT50, 2AFT50, etc., in Fig. IV.10 shows a diagram of the piping of the wellhead with the 2AFT50 Xmas tree and the location of ground equipment during the development and exploration of wells in the Pyatigorsk geological prospecting expedition of the Stavropolneftegaz association. At the wellhead, a tee-type christmas tree with a pressure of 12–5 MPa is installed. The upper string is directed to the gas separator and to the torch, and the lower string is directed only to the torch. From the gas separator, the liquid enters the measuring tank, and the gas, after measuring using a prover, goes to the torch. The upper string contains a fitting chamber, a rock collector, a pressure gauge and a pocket for a thermometer. The gas separator is installed at a distance of 50 m from the Christmas tree fittings.

| Wellhead piping and location of surface equipment during well development in the Stavropolneftegaz association. |

Simple formulas - for an apartment

Residents of multi-storey buildings can use fairly simple calculation methods that are completely unsuitable for a private home. The simplest calculation of heating radiators is not highly accurate, but it is suitable for apartments with standard ceilings no higher than 2.6 m. Please note that for each room a separate calculation of the number of sections is carried out.

The basis is the statement that heating a square meter of room requires 100 W of radiator thermal power. Accordingly, in order to calculate the amount of heat required for a room, we multiply its area by 100 W. So, for a room with an area of 25 m2, it is necessary to purchase sections with a total power of 2500 W or 2.5 kW. Manufacturers always indicate the heat output of sections on the packaging, for example, 150 W. Surely you already understand what to do next: 2500/150 = 16.6 sections

You should also take into account possible heat loss depending on the location of the room. For example, if this is a room located on the corner of a building, then the thermal power of the batteries can be safely increased by 20% (17 * 1.2 = 20.4 sections); the same number of sections will be needed for a room with a balcony. Please note that if you intend to hide the radiators in a niche or hide them behind a beautiful screen, then you automatically lose up to 20% of the thermal power, which will have to be compensated by the number of sections.