Problems with heating residential premises during the cold period are the most pressing for the bulk of the population of our cities. There is no hope for a qualitative improvement in centralized heating. The process of equipping households with autonomous heating systems is going quite slowly. If we talk about city apartments in old buildings, then the situation here generally looks critical. The desire of residents to install additional heating sources in their apartments is met with prohibitions from regulatory organizations.

Despite the illegality of installation, many residents of apartment buildings are trying to install warm floors in their apartments, a heating system that is recognized as the most effective today. Just the desire to install heated floors in your apartment is not enough. There are a number of technological problems that will have to be solved by those who want to improve the comfort in their own home.

The installation of the heating pipe itself does not raise any special questions. It is important to follow the installation technology here. Another thing is the heating source (heating device). Gas boilers, central heating and hot water supply systems, all these connection options have practical implementation. Against this background, it will be interesting to consider from a technological point of view the possibility of connecting a heated floor from a home boiler.

Is it possible to connect a heated floor to a boiler or not?

When constructing water-heating floors, owners of apartments or private houses should:

- make a structure that will warm the air in the room to the required level;

- choose a profitable option in terms of installation and operation, which will be inexpensive.

First, we suggest that you learn the structure and operating principle of a water heated floor and the possibilities of combining the system with various devices (radiators, three- and two-way valves, etc.)

Gas or electric boilers are used to heat the coolant. More often, gas-fired boilers are installed in private buildings. It will not be possible to install such equipment in apartments with central heating.

In addition, to connect to a common heating system, you must obtain special permission. Therefore, there is a need to find an alternative method - this is the installation of an electric boiler.

Boiler is a device for heating water from electricity for domestic purposes. But it is worth noting that it was not originally intended to heat liquid for underfloor heating. Therefore, this will be an additional load for him, as a result of which the water heater may fail.

However, it is still possible to power the floor from a boiler, but it will not be possible to heat large areas using this method. This option is ideal only for the bathroom or toilet.

For your information! Correctly calculating the load on the electric heater is important.

Operating principle

The operating principle of different types of electric boilers has the main similarity - it increases the temperature of water or other liquid. The differences in the types of equipment lie only in the method of converting electricity into heat.

Boiler with heating element

For boiler equipment with heating elements, an electric current passes through a high resistance wire (tungsten), causing it to heat up.

The resulting heat passes through the quartz sand backfill and the heater body to the water moving inside the boiler tank, then reaching the radiators of the heating systems or the “warm” floor coil.

Electrode boiler

With electrode boilers, everything happens a little differently. A “zero” wire is connected to its cylindrical steel body, and a metal electrode with a connected “phase” is installed inside along the axis.

Inside, with the help of a pump, undistilled water from the heating is forced to move, which is a conductor with a certain electrical resistance. That. When electricity is passed through this liquid, it will heat up. The degree of temperature increase depends only on the duration of exposure to electric current and its strength.

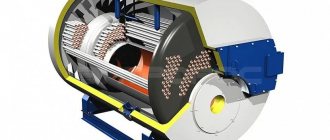

Induction

In an induction boiler, water is heated due to the phenomenon of electromagnetic induction. Electricity is passed through a coil wrapped in wire. At the same time, a metal core is placed inside it. Around the coil so-called eddy currents heating the core array, which in turn is washed by water. This is how the coolant absorbs heat.

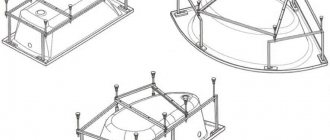

Types of boilers

A water heater is an electric boiler equipped with a tank in which heated liquid accumulates. For domestic purposes, designs up to 100 liters are used, and for industrial purposes up to 300 liters. An industrial type is recommended for installing floor heating.

By design, boilers are either instantaneous or storage.

Flow-through

Flow-through - a compact tank with a square-shaped ten, which is connected to a cold water supply. When turned on, the water heats up almost immediately. The power of such heaters is 6 - 10 kW, so they place a large load on the electrical network.

A tankless water heater is not suitable for heated floors.

Cumulative

A storage heater is a container with two casings, between which there is a protective layer of heat-insulating material (polyurethane foam). The outside body is enameled steel.

The inside of the flask has a coating of glass enamel; the process of its application is spraying, which allows you to obtain a smooth surface on which scale does not form. In addition, the enamel does not react to salts present in water and is not subject to corrosion.

Some models have an internal coating not of glass enamel, but of glass porcelain - the surface is of high quality, but if it is exposed to high temperatures for a long time, cracks can form. However, manufacturers guarantee that the device will operate uninterruptedly for at least 10 years.

Another type of coating that is used for boilers is stainless steel with titanium, which can withstand high temperatures. A water heater with such a coating will last for many years.

A heating element (in the form of a tubular heater) is placed inside the container; it heats the coolant. The ten is placed in a metal pipe, this protects it from scale. In addition, the flask contains a magnetic anode - a rod with positively charged particles that neutralize the negative charge.

This helps reduce corrosion formations. The rod needs periodic replacement, as it wears out quite quickly. The water heater is equipped with pipes through which cold water flows in and hot water comes out.

For your information! Today, models of electric water heaters with a volume of 250 - 300 liters have appeared on the market, which were specially designed for use in heating systems. Their difference is in the location and cross-sectional size of the supply and return openings.

The standard power of storage models is 1.5 - 3 kW. The device is similar to a thermos; the water is heated and then slowly cooled, thereby maintaining a high temperature for a long time.

In addition, these types have a thermostat, which allows you to set the heating temperature required for heated floors. And when the required temperature level is reached, the boiler automatically turns off, which contributes to rational energy consumption.

In shape, boilers can be horizontal or vertical. The vertical design is recommended for arranging heating floors.

It is important to know! To heat 15 liters of water to 60 degrees, you will need a heater with a power of 1 kW, heating time is 1 hour. A 100 liter tank will reach this level in 3 hours, with a power of 3 kW.

How to make a heating element boiler with your own hands?

This type is the most common. Heating elements are used to heat the coolant. They are located in a heat exchanger, which, in essence, is a sealed, heat-insulated container equipped with pipes for coolant input and output.

A heating element is a thin-walled tube made of aluminum, steel or titanium, inside of which there is a nichrome spiral. The walls of the tube and the spiral are separated by a dielectric storage device, usually quartz sand plays its role.

The principle of operation of such equipment is as follows: the spiral heats up because an electric current passes through it, the heat from it is transferred to the sand and the tube, and the tube heats the coolant. The water heats up approximately 15-20 minutes after the equipment starts operating.

To save money and free space, you can make a similar electric boiler yourself. To do this you need to have on hand:

- grinder;

- welding equipment;

- grinding unit;

- thermostat;

- multimeter;

- steel sheet;

- adapters for connecting to the pipeline;

- pipe ø12 cm, and 3-5 tubes of smaller diameter;

- 2 heating elements.

After all the necessary tools and materials are prepared, you can begin work:

- Metal pipes are prepared: three tubes with a diameter of 12.5 mm and two with a diameter of 30 mm. These parts are cut from pre-prepared pipes.

- A piece of large pipe about 65 cm long is needed; it will act as a heating tank. In places that are pre-marked, holes are made by welding for the pipes - supply, return, drain, expansion tank, heaters. Using a grinder, the edges of the holes are polished.

- The pipes are welded to the corresponding holes.

- A circle of sheet steel of the required size is cut out and welded to the bottom of the heating tank. The protrusions are cut off and the connecting seams are sanded.

- A long pipe with a diameter of 12.5 mm is welded to the upper part - a second electric heating element is screwed to it.

- Several holes are made in the bottom for mounting a heating element with a power of 1.5 kW. After the heating element is fixed, the boiler is screwed to the heating system using pipes and the wires are connected.

- Afterwards, a less powerful heating element (about 0.9 kW), which is equipped with a thermostat, is connected to the upper pipe.

- After everything is connected, water is poured into the system. After several hours of operation, the system is checked with a multimeter. In the case when everything is done according to the instructions, the instrument readings will be 70 ° C - this temperature is optimal.

The finishing touches are sanding and painting the boiler.

The disadvantage of such equipment is the likelihood of scale deposits on the heating elements. Which leads to a decrease in operating efficiency or breakdown of the device. When using special liquids or distilled water as a coolant, this problem is prevented.

Operating principle of a water heater

The operating principle of an electric boiler is mixing cold and hot coolant. Heated water rises to the top, and cold water is located below, where it is heated.

The operating process of the water heater is as follows:

- The storage tank is filled with water through a special pipe. The inlet is equipped with a safety valve; it holds the liquid and does not allow it to flow back.

- The thermostat sets the required temperature, but not more than 80 degrees.

- The heater turns on automatically and water heating begins.

- The hot liquid rises upward and exits through the intake tube located on top of the tank.

- The coolant moves through the intake pipe into the floor pipeline.

Characteristics of gas models

Modern modifications of gas boilers must be equipped with electronic controls that regulate temperature parameters, ensuring the safe operation of the system.

In order for the automation and circular pump for a warm water floor to work in the event of a power outage, it is advisable to stock up on a local source. Car batteries will provide several hours of operation. In situations where there is a risk of frequent power outages for several days, you will have to purchase a diesel generator.

The principle of operation of the boiler is based on the circulation of the coolant through the exchanger, during which it is heated by the flue gases produced when the fuel burns. During the transfer of thermal energy, the gases are cooled, and at a certain temperature condensation is formed, causing the appearance of additional heat. This feature significantly increases the efficiency of heating equipment.

Gas boilers function flawlessly under conditions of uninterrupted gas supply, without requiring special routine maintenance techniques. In designs that provide an electronic mechanism for igniting the boiler, the operation of the burner is regulated in accordance with the specified temperature values with the removal of all harmful combustion products through forced ventilation. Boilers with piezo ignition, operating automatically, also stop the flow of gas if the flame goes out, but combustion is restored manually.

Which boiler to choose?

For the construction of warm water floors, the model of a flow-through electric boiler is practically not suitable. The main disadvantage is the significant energy consumption.

The only suitable option for heated floors is a storage water heater. When choosing the type of heater, attention should be paid to the power of the equipment; this determines how intensively and quickly the coolant is heated, as well as its volume.

For your information! Devices with a power of 6 - 10 kW are specially designed for installation in conjunction with heating systems. Their main disadvantage is their high electricity consumption.

When calculating the power of an electrical appliance, you should start from the fact that to heat an area of 10 square meters you need a water heater with a power of 1 kW, so a household boiler model is not suitable for heated floors. It can only be used for small rooms - a bath or toilet.

The second point that you need to pay attention to when purchasing is the volume of the tank. The greater the amount of hot coolant received, the less often the water heater will be turned on periodically, in order to help save resources.

Saving

Options for saving energy, in addition to choosing more economical models and types of heater, are based on the use of thermal inertia of the coolant. For example, if there is a concrete screed, it becomes possible to periodically disconnect the heater from the network.

The concrete layer takes a long time to cool, which allows you to significantly save energy (and money) - up to 30%, and sometimes more. In addition, it would be rational to organize the correct distribution of operating modes of the circuits in different rooms - cooler in the corridors, warmer in the living room or bathroom. This separation will help reduce the heating intensity and save money.

Features of the design of a heated floor connected to a boiler

When designing a floor heating system from a boiler, you need to take into account:

- the size of the pipeline and the number of branches, the longer the circuit, the slower the fluid circulation will be;

- power of the heating element - if the size of the lower threshold of the heated room corresponds to the power of the boiler, then after some time the efficiency of heating the coolant may decrease; the solution is to buy a heater with a power reserve of 20%.

In addition, the system requires constant maintenance - periodic descaling of the storage tank and heater. This procedure will help keep underfloor heating pipes in good condition and increase their service life.

It is recommended to connect the boiler in a bathtub or room located close to the heated room.

And to increase the productivity of the device, the structure must be equipped with a circulation pump.

By observing all of the above points, you can build a hydrofloor that can provide heating for your apartment.

Installing the unit

First you need to install an electric boiler indoors. As we have already said, the unit can be floor-mounted or wall-mounted. In the first case, the kit includes a special stand, on which the “landing” is performed.

In order to hang the boiler on the wall, you need to prepare anchors with dowels and a drill with a suitable drill bit. First, mark the wall using a tape measure and a marker.

The holes must be placed perfectly level in a horizontal plane. Next, we drill out the marked places, drive dowels into them and screw in the anchors. After the anchor is firmly seated inside the wall, you can hang the electric boiler.

We draw your attention to the fact that the installation of the electric boiler must be carried out perfectly level in both horizontal and vertical planes.

Any misalignment can affect the performance and service life of the equipment.

Connection diagrams for heated floors and boilers

There are several schemes for connecting a heated floor to an indirect water heater. Let's look at the simplest ones:

- Using a three-way valve - the essence lies in the interaction of two circuits: a warm floor and a water heater. This valve distributes the coolant between them. It is controlled automatically using a thermostat on the heater. This system promotes rapid heating of water in the boiler, while it is possible to completely shut off the supply of hot water to the floor branches. And when the set temperature is reached, the valve is activated and the supply is resumed. This piping method is suitable for constant use of the boiler.

- With two forced circulation pumps - this option is recommended for intermittent, seasonal use of the device. One is placed on the supply pipe in front of the water heater, and the other on the floor contour.

A thermal relay is used to power the circulation pump, so it functions only when the temperature drops below normal. Heating accelerates, and forced circulation is turned on. In this scheme there is no three-way valve, and the connection is made using tees.

- Using a hydraulic arrow - this method is recommended for boilers with a volume of 200 liters or more, and with several heating branches. A system with a hydraulic distributor makes the circuit simpler, and there is no need to install pumps on each floor circuit. The hydraulic arrow ensures equal coolant pressure in all loops. However, it is difficult to make a harness with your own hands in this way without experience.

Scheme with pump-mixing unit

This scheme also applies to combined systems, when you have both radiators and heated floors at the same time.

However, here, instead of a 3-way valve, a more expensive pumping and mixing unit is used.

Specification of materials

In fact, the cooled return flow is also mixed into the main boiler feed here. But thanks to the balancing valve, cooled water can be mixed in in certain doses and given proportions.

This will ensure the precisely specified temperature of the coolant entering the TP tubes through the manifold.

This is the most effective and most comfortable scheme. The pumping and mixing unit itself can be assembled in various variations.

Depending on your needs and financial capabilities, the following components may be included:

Construction and connection of heated floors to the boiler

For clarity, let’s look at how to make a heated floor from a water heater, using the example of using a 3 kW heater to heat an area of 30 m2, with the installation of a three-way valve.

We will need a recirculating boiler with outlets to connect hoses for hot and cold water supply. The recommended diameter of the pipes is 2.6 centimeters. In addition, you should stock up on the tools that you will need in your work so as not to be distracted during the installation process.

The sequence of construction of hydrofloors from a water heater is as follows:

- Preparing the rough base - it should be leveled and cleared of debris.

- Installation of the collector unit - it must be mounted on the wall, or mounted in a specially equipped metal box.

- Taping damper tape around the perimeter of the room will help maintain the integrity of the concrete screed.

- Hydro and thermal insulation - polyethylene film can be used as a waterproofing material. The choice of thermal insulation material is huge, from ordinary polystyrene foam to polystyrene foam mats with bosses.

- Installation of the water circuit - these can be pipes made of copper, polyethylene or heat-resistant plastic. The heating elements are laid according to the planned pattern and with a set step. The pipes can be attached to the reinforcing mesh, which is laid on the thermal insulation, with plastic clamps, or fixed between the grooves of polystyrene plates.

- Connect the circuit to the distribution manifold - one end to the cold tap, and the other to the hot one.

- The boiler is connected to the distribution unit using metal pipes.

- Installation of a three-way valve with a thermal head on the manifold - to regulate the temperature level of a warm water floor.

- Connecting a circulation pump to a warm floor - it provides the flow and necessary pressure of water in the floor pipeline.

- Installation of an expansion tank - it is necessary to remove excess water from the heating system. It should be mounted on a cold metal pipe near the outlet to the boiler. And in front of it you need to equip a tube for air outlet.

- Checking the system for operability - to identify possible leaks and malfunctions. Pressure testing is carried out during the day under operating pressure.

- Filling the screed - the contour of the floor is poured with concrete mortar. The procedure is done when there is pressure in the pipes. The concrete layer must be allowed to dry thoroughly, this will take about a month.

- Laying the finishing coating - it is laid only on a completely dry concrete base.

You can turn on the water system only when the screed, as well as the tile adhesive if ceramic tiles were used as a floor covering, have dried. The temperature should be raised to operating condition gradually over several days.

The principle of operation of this circuit is to heat water in the tank, then it is discharged through the collector into the floor circuit. The waste coolant is returned through the distribution unit to the return pipeline.

If the water temperature exceeds the required level, the three-way valve automatically shuts off the hot water supply and opens the cold water supply. The mixing process is carried out in a special chamber. When the coolant reaches the desired degree of heating, the thermal head closes the flow of cold water.

The heater and collector are equipped with separate automatic devices for temperature regulation. The device on the collector is responsible for the coolant in the floor line, and on the shade - for the level of water heating.

You can install a heated floor from a boiler both in a house and in an apartment. Installation is not difficult, the main thing is to follow the technological process and instructions. In addition, the low cost of installation is of no small importance, because a water heater costs less than an electric boiler.

However, it should be noted that the operation of such a heating system is accompanied by high energy consumption. Therefore, it’s up to you to decide how to heat your home - with a regular radiator or underfloor heating from a boiler.

Safety regulations

Before we move on to the main part of heating installation, I would like to pay attention to the safety of electrical installation work.

Firstly, the connection of the electric heating boiler must be carried out when the electricity is turned off.

Secondly, it must be installed at a certain distance from other objects, namely:

Thirdly, the network must be three-phase (380 V) in order to reduce the current load on the electrical wiring. When using a single-phase network to connect a powerful boiler, the wiring may not be able to withstand it, resulting in spontaneous combustion and a short circuit.

Fourthly, all wire connections must be sealed and protected from water.

Water ingress onto the contacts can occur when the pipeline is damaged (for example, the coupling connected to the unit bursts) and when condensation drains from the ceiling (in an unheated room).

It is also recommended to protect the cable with corrugation or a cable duct made of self-extinguishing material. If the wires catch fire, these products will prevent the spread of flame.

We are launching

When all wiring elements are connected, it is necessary to check all connection points. There should be no exposed contacts, as well as damaged insulation.

It is also necessary to check all couplings, taps and pipe joints. Only after a high-quality inspection of the heating system can you proceed to its start-up. First, we open the valves connected to the equipment, and then turn on the electric boiler.

Pay attention to the functionality of the temperature and pressure sensors. The nominal values are indicated in the instructions included in the kit. In case of obvious deviations, it is better to call a specialist.

Electric boiler wiring

The piping of electric heating boilers should include the following elements:

- Circulation pump.

This piping element ensures the movement of coolant along the heating circuit, thereby ensuring heat transfer to heating devices.

- Expansion tank.

The key purpose of the expansion tank is to receive excess coolant when it overheats excessively. The absence of a tank can lead to rupture of pipes or damage to elements of the heating system.

- Safety valve.

Using a safety valve, excess coolant is discharged into the sewer.

The valve only works in emergency situations - for example, when water boils when the pump stops or when the tank overflows. The pressure at which the valve operates is usually equal to the maximum pressure in the system.

- Automatic air vent.

This element ensures independent removal of air from the heating system circuit.

In the absence of an air vent, coolant circulation will be difficult, and the system itself will make a lot of noise. Pressure gauge. The presence of a pressure gauge makes it possible to monitor the pressure level in the heating system pipeline. The pressure gauge scale must be designed for at least 4 bar.

The expansion tank, air vent and safety valve are a safety group of the heating boiler. The installation of an electric boiler in a private house must be accompanied by the installation of a security group.

Selecting a circulation pump

For a circulation pump, two parameters are important - pressure and performance. The amount of pressure in most cases is practically irrelevant.

The minimum pressure for the weakest pumps is 2 meters, which is quite enough to ensure normal operation of the heating system of any private home:

Rating of popular manufacturers

PhotoNameRatingPrice

| #1 | Buderus Logamax, E series | ⭐ 97 / 100 | Find out more | |

| #2 | Kospel EKCO | ⭐ 96 / 100 | Find out more | |

| #3 | “Galan”, series “Hearth”, “Geyser” and “Vulcan” | ⭐ 91 / 100 | Find out more | |

| #4 | Ferroli | ⭐ 96 / 100 | Find out more | |

| #5 | RusNIT | ⭐ 97 / 100 | Find out more |

Buderus Logamax, E series

Country of origin: Germany. These are new heating element wall-mounted boilers of various capacities. Eco-friendly heat sources that are used to heat premises for various purposes, including residential ones.

Buderus Logamax, E series

pros

- it is possible to connect to any heating system;

- mounted in closed systems;

- high efficiency;

- The models are easy to install and require a minimum number of additional elements.

Minuses

- high price.

The perfect solution

The most convenient electric boiler for underfloor heating is a single-circuit one. Here the operating scheme is clear and transparent: the device heats water through heating elements, the circulation pump creates pressure on the hydraulic distribution grid of the heating network, and the temperature of the liquid in the structure can be adjusted.

For rationally thinking owners, it is recommended to create separate water treatment and heating systems in the house; for the latter, using your own single-circuit boiler looks optimal.

The use of indirect heating boilers is a convenient solution for those who want to get a controlled, efficient heating system and hot water without complicating the electrical network of a house or apartment. A single-circuit electric boiler is capable of supplying water not directly to the heated floor, but through the heat exchanger of the water heater.

The operation of an indirect heating boiler is stable, therefore, in a system that has entered a stable mode, it is impossible for a situation to arise when hot water consumption sharply reduces room heating performance.

Electric boiler from a boiler

We install protective equipment

When all the input wires are connected to the electric boiler, it will be necessary to additionally protect it with RCD circuit breakers installed in the main panel.

The purpose of the first device is to protect equipment from short circuits and wiring overloads. Connecting an electric boiler through an RCD will protect you from leakage currents.

It is also recommended to connect a voltage stabilizer, since even small surges can damage the unit. I don’t think it’s worth talking about the need to ground an electric boiler. The main requirement is that the ground wire runs directly from the bus to the equipment frame.

Selecting an expansion tank for installation

For closed heating systems, membrane tanks are usually used, in which the compensating cavity is filled with air or gas. Between the cavities of the tank there is a flexible membrane. When the temperature of the coolant increases, its excess enters the tank and compresses the membrane.

To determine the volume of the tank, you can use a simple calculation. First you need to measure the total volume of coolant in the system, for which it is enough to drain it into any container whose volume is known. 10% is taken from this value - and this is the value the tank volume should have.

Electricity consumption

Electricity consumption is determined by the type of heater and its power.

The amount of expected consumption is a very pressing question, since it determines the amount of money that will have to be paid regularly for electricity.

Therefore, before purchasing a boiler, it is useful to calculate its power and determine the consumption parameters.

Attention! The use of more modern designs of electric boilers makes it possible to stabilize and reduce electricity consumption and, accordingly, the cost of paying for it.