Home / Commissioning

Back

Published: 05/19/2019

Reading time: 6 min

0

5877

To understand why an expansion tank is needed, you should familiarize yourself with the operating principle and main functions of such a tank. Without this information, you may mistakenly think that the item is not of particular value and is simply taking up space in the room. However, in practice, it performs a lot of important tasks and is an indispensable component of the heating system.

- 1 Expansion tank in an open system 1.1 Operating principle

- 1.2 Where to place

- 1.3 What tank volume is required

- 2.1 Design and principle of operation

Is an additional expansion tank needed for a double-circuit wall-mounted boiler?

When replacing a boiler or upgrading a heating system, the owner often has the question “Do I need to install an additional expansion tank?” Let's consider some points.

The expansion tank of a heating system is a capacitive equipment designed to compensate for the expansion of the coolant due to its heating. When water is heated from 10℃ to 100℃, water increases in volume by 4.34%. If there is nowhere for it to expand and the safety valve jams, there will be an uncontrolled increase in pressure and the elements of the heating system may fail. The expansion tank receives excess coolant volume when heating and returns it back to the system when cooling. In addition to compensating for coolant expansion, expansion tanks also:

- soften pressure fluctuations within certain limits;

- protect against air entering the coolant due to pressure drop at the highest point;

- protect pumps, valves, drives from cavitation damage;

- compensate for the missing volume of coolant when removing air from the system

Diaphragm expansion tanks are needed only for closed heating systems. In an open system, the cistern is installed at a high point (often in the attic).

Baxi boiler pressure drops when hot water is turned on

Sometimes, users encounter a problem when the pressure drops when turning on hot water in the baxi boiler. This problem may just be due to insufficient pressure in the expansion tank. The fact is that when the boiler switches to the hot water preparation mode, the circulation pump pumps the liquid in a small circle, i.e. only inside the boiler itself - through a secondary plate heat exchanger. In this case, the heating circuit actually does not heat up and the coolant begins to cool, the volume decreases and in the absence of compensating pressure in the expansion tank, the pressure of the heating system may drop and the boiler will display error E10.

In such a situation, you can also consider the possibility of a breakdown of the heat exchanger itself (a gap between the plates) and water from the heating circuit entering the hot water system, but this is easy to check. To check, you need to shut off the cold water supply to the boiler and open any drain valve. If water comes out of the tap under such conditions, it is obvious that this is coolant from the heating circuit and the heat exchanger needs to be replaced.

Remember, timely maintenance of a gas boiler will help avoid such situations and increase the service life of the unit.

We also recommend watching a video from one of the users, which clearly shows how to pump up pressure in the expansion tank:

One of the most popular models in the Baxi line is the Baxi Eco Four 24 gas boiler. The equipment can be with a closed or open combustion chamber. The power of the unit is 24 kW. The name indicates the letter “F” if the gas boiler has a closed combustion chamber and forced smoke removal. In apartments, turbocharged boilers from Baxi are most often used. Let's look at the design of the expansion tank, breakdowns, pressure drop and how to fill the Baxi expansion tank with air.

Expansion tank for boiler

Expansion tanks for boilers can be external or built-in.

As a rule, manufacturers build tanks into boilers with a power of up to 30-35 kW at the factory. Factory installation ensures greater reliability and compactness of the boiler unit. Usually the built-in expansion tank for a boiler is non-separable, flat, round or rectangular.

The external expansion tank is selected using special formulas (see below). They are floor-mounted and wall-mounted. As a rule, expansion machines with a volume of more than 35 liters are produced only in a floor-standing version.

Do you need an additional tank?

Modern gas wall-mounted boilers are “plug and play” equipment. They are already equipped with an expansion tank, circulation pump, three-way valve, heat exchanger, and safety group. Connect the heating, water supply, gas pipes and start the system. However, there are nuances regarding the additional expansion tank.

The factory membrane expansion tank is selected for the average parameters of a modern system. Yours may be different.

That is, you need to compare the capacity of the factory tank with the calculated value and determine whether an additional expansion tank is needed for heating.

How to calculate the required volume of the expansion tank?

The volume of the expansion tank for heating depends on three parameters:

- heating system volume

- safety valve response pressure

- minimum operating pressure

In this article we will present the easiest way to quickly select an expansion tank without complex calculations for the average one-, two-, three-story house using the REFLEX table. To determine the required volume of the tank, you need to know the volume of the heating system, the preliminary minimum operating pressure, and the response pressure of the safety valve.

The minimum operating pressure in the heating system (P0) is equal to the static pressure plus 0.2 Bar. It should not be less than 1 Bar. Static pressure can be calculated by knowing the height between the top point of the heating system and the mounting point of the expansion tank. For houses up to three floors with ceiling heights up to three meters, the static pressure will not exceed one bar. The minimum operating pressure can be taken equal to 1.2 Bar.

The response pressure of the safety valve for wall-mounted boilers in private houses is usually set at 2.5-3 Bar. Usually they focus on the maximum operating pressure of the boiler.

The volume of a heating system can be determined by summing the volumes of all its components: pipes, heat accumulator, radiators, convectors. All these parameters are indicated in product passports. If the characteristics of the system elements are unknown, but the power and type of devices are known, you can assume 8.5 l/kW for panel radiators, 13.5 l/kW for heating devices of other types. Some manufacturers recommend an average of 15 l/kW for any system.

Knowing the three above parameters from the REFLEX table, you can select the required volume of the expansion tank and understand whether you need an additional one. The volume of the built-in expansion tank can be found in the instructions for the boiler.

An example of the selection and recommendations of the REFLEX manufacturer can be seen below:

Also, many manufacturers indicate in the passport for a wall-mounted gas boiler the maximum volume of the heating system. If the volume of your system is larger, you need to calculate the required volume of the membrane tank for your system and install an additional one. The total volume of built-in and additional volumes must be no less than the calculated volume.

Distinctive features of tanks for hot water supply.

- Certified operating temperature -10 ÷ +100 °C. But I don’t know when the boiler will be minus 10.

- Working pressure 10 bar.

- Factory gas cushion pressure is 2.5 bar.

- They are often white, but not always. This one, as you can see, is unpainted stainless steel.

Good luck. Sergey Volkov.

Source: https://www.youtube.com/watch?v=0FOxZCPnCFc

SaveSavedDeleted 0

Previous

Crushers DR-25. Characteristics and principle of operation.

Next

Crushers DO-1M. Characteristics and principle of operation.

Show full profile

Expansion tanks for gas boilers: design and pressure regulation

- Peculiarities

- How is the system structured and how does it work?

- How to control the system and work with it?

- Possible problems

- Additional Information

Heating equipment is always designed for a certain pressure and pressure in the system. Gas boilers are no exception to this rule. Expansion tanks for gas boilers help them maintain the stability of their parameters.

Advantages

The popularity of electric boilers with a heating pump is explained by the following positive characteristics:

Rich assortment. Models of various capacities are available for sale, which makes it possible to acquire exactly the brand that best suits the operating conditions. In this way, you can choose a heating device for both a country house and an industrial premises: there are always options with suitable parameters in stock.

Economical. Due to the high energy efficiency of modern electric heating boilers (their efficiency is close to 99%), their use allows you to save significant finances. An additional economic effect is facilitated by the use of a circulation pump, which is part of the structure itself. Having low energy consumption, it nevertheless significantly increases the rate of coolant passage through all pipes. As a result, rooms warm up many times faster.

Environmental friendliness. Such a heating system does not emit combustion products during operation. Therefore, there is no need to spend money on organizing a chimney and providing additional air flow. For this reason, electric boilers are widely used in city apartments and office premises.

It is important to remember that the absence of smoke does not mean that the ventilation in the house may be poor.

Ease of management. This is facilitated by maximum optimization of monitoring and control devices

As a result, even an amateur can monitor the operation of heating equipment. Most of the models on the market are equipped with automatic control units: this allows you to resort to adjusting the operation of the system in very rare cases.

Peculiarities

The question of how these tanks should normally operate is related either to operational irregularities or to the need for maintenance. The main purpose of using a tank is to eliminate the expansion effect of heating water. It is getting larger, but the volume of pipes, radiators and storage tanks is finite. In closed heating circuits, 100% filling is required, and this means that the excess coolant mass must be dumped somewhere. The tank becomes a suitable place.

If suddenly there is no way out, the liquid will certainly find a path through which the excess will escape. Safety valves usually become such a place, but still this is rather an emergency equipment. Even if they work exactly as they are supposed to, you will have to remove the spilled water and refill (top up) the system. Installing tanks in advance helps prevent this from happening. And even when the coolant boils, keep everything in perfect order.

How is the system structured and how does it work?

Expansion tanks are tightly closed vessels, which are divided into two fragments using rubber membranes. This is not simple rubber, since it must withstand significant heat while remaining elastic and without losing strength.

Important: the pressure must be determined inside the air cavity entering the empty container, strictly at a temperature of 20 degrees. It is equal to the static pressure of a heating system filled to capacity. This condition makes it possible to achieve an equilibrium state of the membrane and compensate for the pressure exerted by the coolant.

That is, by the time it is put into operation, the tank will be completely empty, and its entire volume can be used to correct the thermal expansion of water or antifreeze. If the gas boiler sensor detects that the pressure in the heating system has dropped to 0.7 bar or less, it gives a command to turn off the heater. And the average value that ensures normal operation is 1.2 bar. Since moving from a non-equilibrium position to an equilibrium one, the membrane can increase the pressure further, its initial level for an empty tank is taken to be 0.3 bar (on average) higher than the standard for a heating system.

Conclusion: with a closed heating circuit with a gas boiler, the pressure should be from 0.8 to 1 bar; the parameters of any system deviating from the standards are calculated individually, taking into account:

- expected volume of water or antifreeze;

- Tank efficiency;

- its required value;

- initial pressure at start-up.

Tanks on Baxi double-circuit boilers, as follows from the instructions, must operate at a pressure of 0.5 bar. However, in reality this figure is minimal, and the same pressure of 0.8 - 1 bar allows you to guarantee the normal functioning of the device. The built-in expander with a capacity of 6 liters works stably with heating systems with a capacity of 75 liters (on water). Or 50 l (with antifreeze).

Whether it is necessary to use an additional expansion tank, or whether standard equipment is enough, is decided only by specialists at the time of preparation of the project.

Choosing the right device

When choosing a model with the necessary functions and volume, take into account the fact that the frequency of pump operation depends on the total volume of the tank.

The leading characteristic for any tank is not its functionality, but its volume.

At the same time, for each water supply system there are criteria that cannot be neglected, namely:

- Number of regular water users. (Daily use).

- Number of points for water intake. (Appliances, taps and other plumbing fixtures).

- Approximate frequency of using water intake points at the same time.

- The “on-off” cycle. You need to know exactly the limit of this cycle per hour for your pump.

Approximate calculation:

When calculating for three regular consumers, install a tank with a total volume of 20-24 liters. However, the pumping equipment should produce approximately 2 cubic meters per hour.

When calculating for four regular users with a reserve, it is better to install equipment of 50 liters or more. The pump productivity in this case is approximately 3.5-3.7 cubic meters per hour.

If there are more than 10 consumers, then a tank of at least 100 liters is required, and pumping equipment with an indicator of more than 5 cubic meters per hour.

To avoid breakdowns and expensive repairs, you need to carefully familiarize yourself with the manufacturer.

In this choice, there is no need to chase a cheaper and dubious brand. Improper savings can lead to breakdowns in the future.

Models with a low retail price inside are made, as a rule, without defects. But consumable parts are always made from the cheapest materials.

It is better to inquire about the material from which the membrane is made. Its environmental friendliness and stability will improve comfort as well as the service life of the system.

How to choose tank volume

You can choose the tank volume arbitrarily. There are no requirements or restrictions. The larger the volume of the tank, the greater the supply of water you will have in case of a shutdown and the less often the pump will turn on.

When choosing a volume, it is worth remembering that the volume that appears in the passport is the size of the entire container. There will be almost half as much water in it. The second thing to keep in mind is the overall dimensions of the container. A 100 liter tank is a decent-sized barrel - about 850 mm high and 450 mm in diameter. You will need to find a place somewhere for it and the harness. Somewhere - this is in the room where the pipe from the pump comes. This is where all the equipment is usually installed.

The volume is selected based on the average flow rate

If you need at least some guidelines to select the volume of a hydraulic accumulator, calculate the average flow rate from each water intake point (there are special tables or you can look at the data sheet for household appliances). Sum up all this data. Get the possible consumption if all consumers work simultaneously. Then figure out how many and which devices can work at the same time, calculate how much water will be consumed in a minute in this case. Most likely by this time you will have already come to some decision.

To make it a little easier, let’s say that the hydraulic tank volume of 25 liters is enough to meet the needs of two people. It will ensure the normal functioning of a very small system: faucet, toilet, sink and small water heater. If you have other household appliances, the capacity must be increased. The good news is that if you decide that the current tank is not enough for you, you can always install an additional one.

Possible problems

It is not always possible to pump the expansion tank to the required number of atmospheres. People who strictly monitor the health of their equipment rarely encounter problems, of course. But carelessness or an irresponsible approach can lead to a number of troubles. Often the pressure gradually decreases, and after a series of boiler top-ups, the tank fails. It even goes so far that the membrane is deformed by the spool when pressed against the wall.

In this case, repair is impossible; the expander can only be replaced completely. It also happens otherwise: the pressure in the heating circuit is at the maximum permissible level, but the tank has not been serviced and remains without pressure. As soon as the heating system stops and begins to cool, the liquid will compress, making it impossible to correct the change in pressure. As a result, the boiler gets into an “accident”. Problems of this kind can be caused by prolonged use of a hot water heater or power outages.

Another likely scenario is that new water has to be supplied systematically and for no apparent reason. For example, the hot water supply circuit is working, and the pressure gauge shows a drop in pressure, the boiler stops working. Since thermal expansion is not compensated, heating of the coolant leads to the release of its excess by safety valves. If you do not notice this situation in time, you can face serious troubles. Therefore, it is necessary to pay maximum attention to the condition of the expansion tank and regularly measure the pressure inside it.

Additional Information

The expander helps to absorb hydraulic shocks created by air pockets and sudden closure of the valve. Tanks can perform this function if they are placed on the return flow of the coolant directly in front of the boiler. Do not assume that the pressure set at the factory will be ideal for practical needs. It is reconfigured using a spool valve.

Important: any pressure gauge, when measuring pressure in the expander, registers only an excess value; to obtain an absolute figure, add 1 bar.

A pumped tank does not work well, since the air will push the coolant out. If everything is configured correctly, but the fuses continue to periodically discharge water, most likely the problem is in the expander being too small. Therefore, it is worth choosing tanks that hold 10% of the total coolant circulating in the system, or even more. Since the tank does not have fittings for pressure gauges, they must be connected to the nipple. It is located on the side opposite to the coolant-filling circuit.

Since car and bicycle pressure gauges measure pressure in MPa, you need to compare their readings with the pressure in the heating system (expressed in bar or kgf/sq. cm). One bar is equal to 100 kPa. When using a car meter, it is recommended to wait 10 minutes after turning off the boiler for the circulation to stop. When the tank is built into the boiler itself, it is necessary to shut off not only the shut-off valves, but also the coolant supply and its return. By following these recommendations, you can significantly simplify your life.

To learn how to check the serviceability of the expansion tank, see the following video.

Distinctive features of an indirect heating boiler

A boiler is a large barrel whose main function is storage. It comes in different volumes and shapes, but its purpose does not change. Without a boiler, a problem may arise when using, for example, two showers or a shower and a kitchen tap at once.

If a household 2-circuit boiler with a power of 24-28 kW produces only 12-13 l/min per flow, and one shower requires 15-17 l/min, then when any additional tap is turned on, there will be a shortage of water supply. The boiler simply does not have enough working capacity to provide hot water to several points.

If a large storage tank is installed in the house, even with several water points turned on at the same time, everyone will be provided with hot water

All storage boilers can be divided into 2 large categories:

- direct heating, creating a supply of hot water using a heating element - for example, an electric heating element;

- indirect heating, heating water with already hot coolant.

There are other types of boilers - for example, conventional storage water heaters. But only volumetric storage devices can indirectly receive energy and heat water.

BKN, unlike energy-dependent equipment running on electric, gas or solid fuel, uses the heat generated by the boiler. Simply put, it does not require additional energy to function.

BKN design. Inside the tank there is a coil - a steel, brass or copper tubular heat exchanger that acts as a heating element. Heat inside the tank is retained according to the principle of a thermos

The storage device fits easily into the DHW system and does not cause problems during operation.

Users see many advantages in using BKN:

- the unit does not require electrical power and benefits from the economic side;

- hot water is always “ready”, there is no need to let cold water pass through and wait for it to heat up;

- Several water distribution points can operate freely;

- stable water temperature that does not drop during consumption.

There are also disadvantages: the high cost of the unit and additional space in the boiler room.

The volume of the storage tank is chosen based on the number of people permanently residing in the house. The smallest boilers are designed for 2 consumers, so when choosing, you can start from a volume of 50 liters

According to all characteristics, the BKN is suitable for use in conjunction with a gas boiler. Moreover, this is one of the best solutions for equipping a hot water preparation system for a private house with a large number of residents.

But boilers are different, so we will consider both acceptable options and those where problems may arise.

Why do you need an expansion tank in a heating system?

To understand why an expansion tank is needed, you should familiarize yourself with the operating principle and main functions of such a tank. Without this information, you may mistakenly think that the item is not of particular value and is simply taking up space in the room. However, in practice, it performs a lot of important tasks and is an indispensable component of the heating system.

- 1 Expansion tank in an open system 1.1 Operating principle

- 1.2 Where to place

- 1.3 What tank volume is required

- 2.1 Design and principle of operation

If you need boiler repair or maintenance, call Profteplo

We work in Kaluga and the region, diagnosing, servicing and repairing systems of any complexity. We carry out both simple tasks of pumping air into an expansion tank, and complex complex repairs of modern systems. We provide a guarantee for all types of work.

If you need advice or want to use the service, just call the number or leave a request directly on the website. The master will arrive on the day of your call and will perform all the necessary types of work.

The expansion tank in a heating boiler performs an important function - it compensates for pressure surges when the temperature values of the coolant change, be it ordinary water or antifreeze. The tank itself consists of two parts, between which there is a membrane. One part contains the coolant, the other contains air, through which the required pressure is created. And for normal operation you need to periodically pump up the tank. Next, you will learn how to pump up the boiler expansion tank and how to detect when you need to do so.

A common situation: you turn on the water and run a bath. At this time, the boiler switches from heating mode to hot water supply mode. While the water is being collected, the coolant gradually cools down, and the expansion tank does not function at this time. And when you turn on the tap, the boiler should start heating again, but this does not happen. The reason is a sharp drop in pressure, as a result of which the automation simply blocked everything. This means it's time to pump up the air and increase the pressure in the tank.

Expansion tank in an open system

Due to ease of installation, affordable cost and high efficiency, the expansion tank in an open-type heating system is very popular.

The advantages of open options are as follows:

- Simplicity of design. In some cases, you do not need to purchase additional materials to install heating, and the working tank can be stored in the garage.

- Open systems do not have the problem of excess pressure, since they are connected to the atmosphere. This eliminates the need to purchase a safety valve.

- Other advantages include the ability to use a tank for air removal.

In addition to the advantages, an open system also has disadvantages. First of all, this is the need to install the tank at the highest point. To do this, it is important to take care of good insulation of the attic floor, otherwise the liquid in the tank will freeze at subzero temperatures.

Principle of operation

To understand why an expansion tank is needed, you should evaluate its performance characteristics, the specifics of its operation and the subtleties of self-installation. In liquid heating systems, water plays the role of coolant.

With the help of special equipment, it moves over long distances and provides full heating of buildings with different number of floors and area. This contributes to an increase in demand for the installation of water systems.

The key advantage of open systems is the ability to operate without pumping devices. The movement of the coolant is carried out according to thermodynamic principles, since hot and cold water have different densities, and the pipes are located at an angle.

The purpose of the expansion tank for heating is to automatically stabilize the liquid pressure and store the remaining heated water.

The tank is mounted above the other components, and the principle of its operation consists of the following stages:

- innings. The heated coolant moves from the electric, solid fuel or gas boiler to the radiators;

- return The remaining warm water enters the tank, begins to cool and returns back to the boiler unit. As a result, the cycle repeats.

If the system is equipped with a single-pipe line, both procedures occur in one pipe. In two-pipe types they are independent.

Where to place

Since the circuit of an open heating system is closed, but not isolated from outside air and not sealed, the problem of excess pressure is eliminated. In this case, the expansion tank must be installed in the correct place - above all other components. If you do not take this rule into account, the coolant will simply pour out.

An even higher placement promotes efficient air removal. The liquid always contains dissolved air, which can turn into a gas and enter into a chemical reaction with metal surfaces in pipes and the heat exchanger.

In some cases, open tanks are combined with a return line, which is due to design features or other layout considerations.

However, they remain at the highest point of the circuit to which the pipe is connected. With this installation, you will need to install special valves for venting gases.

Installation procedure

Most often, installation activities are carried out by professional installers, because... this requires special permission. However, knowing the sequence of operations will not hurt: at a minimum, this will allow you to monitor the work being carried out, ensuring the correct implementation of each stage.

Installation sequence:

- The most difficult thing when connecting an electric heating installation is to provide it with the necessary power. If the existing wiring is able to support the power of the device, then no modification will be required. Otherwise, you have to lay an additional line.

- After the power supply issue is resolved, the meter, electrical panel and RCD (minimum 25 A) are installed.

- Boilers are wall-mounted and floor-mounted. Typically, all the necessary fasteners are included with the system. After the installation of the electric boiler is completed, it is connected to the meter with a cable of optimal cross-section.

- Temperature sensors are connected via separate wiring. Their task is to automatically regulate the switching on and off of heating elements.

- A separate plumbing cabinet is used to install the heat accumulator.

- Some models do not have a built-in circulation pump: in this case, it must be installed separately. This will require an additional wire to supply power to the pump motor.

To connect all the elements into a single system, you will need pipes (metal or metal-plastic). When performing a test run of the circuit, you need to carefully ensure that there are no coolant leaks anywhere. As can be seen from the description, the installation work is quite complex, so a preliminary study of this process will not be superfluous.

Expansion tank for closed heating

The main advantage of a tank for a closed heating system is its compact size and the ability to be installed on any part of the circuit.

When installed in accordance with approved standards, there are no clear restrictions on the choice of installation location. However, in many designs the reservoir is located near the pump.

Due to the tightness of the tank, the pressure inside the circuits can increase to a high level. To protect the structure, it is important to provide a “safety group”.

It consists of the following nodes:

- Safety valve with a specified upper pressure threshold.

- Air vent with automation support.

- Pressure gauge or pressure gauge with thermometer for performing control and measurement tasks.

However, the need to organize a “security group” is not a minus, since it is explained by the specifics of the system.

Design and principle of operation

To determine which expansion tank is needed for heating, you should study the structure and operating principle of structures for a closed heating system. The design of such a tank is quite simple. Depending on the model, it may differ slightly, but the specifics of the operation remain the same. It involves separating a hermetically sealed liquid into 2 chambers using a special elastic partition. One part is connected via a pipe to the system circuit and is called the water part. The second (air) is intended to organize optimal pressure.

The design of the tank provides for the following components:

- Tank body.

- Threaded pipe.

- Nipple or spool.

- Membrane.

- Water and air chambers.

In most cases, a prefabricated stamped cylindrical structure is used as the body (other options are available on the market).

The inner surface of the walls has a protective coating against corrosion and an enamel layer. The body color is red, since stores also offer hydraulic accumulator tanks, which are distinguished by their blue color, indicating the impossibility of working with hot liquid.

On the tank there is a threaded pipe for connecting the tank to the heating circuit. Leading manufacturers supply fittings and an American union nut complete with the tank, which simplifies the installation process.

On the opposite side of the body there is a nipple or spool, reminiscent of a bicycle valve. It is used to pump up the pressure in the air chamber.

The next important component is the membrane, which divides the internal volume of the tank into 2 separate parts. In some cases, an additional membrane tank is installed, which is activated when the main membrane fails. According to this principle, an expansion membrane tank is required.

To manufacture this part, elastic materials with a minimum diffusion rate are used. For a long time, rubber played their role, but due to its fragility, it lost its popularity. In modern devices, it is customary to fix ethylene-propylene or butyl elements.

The role of the air chamber is to create excess pressure, which pushes the membrane down and ensures the minimum volume of the water chamber until it is completely filled.

When the system is filled with liquid and put into operation, the circuit builds up pressure, and the surface of the membrane begins to bend - this indicates an increase in the volume of the water chamber.

Depending on the heating intensity, the degree of expansion may vary. Excess coolant moves into the water chamber of the tank, where it cools down, acquires its previous volume, and the membrane is pressed down. As a result of such actions, an optimal pressure balance is ensured.

Often the membrane may have an unconventional shape. Thus, balloon-type tanks are available for sale, where it is an elastic cylinder with hermetically sealed edges.

This tank acts as a water chamber, and the remaining space is used as an air chamber with a given pressure. If the liquid expands, the walls of the membrane begin to stretch, and it becomes like a pear. In this case, the volume of the air chambers decreases, and the pressure values continue to increase.

What volume should the expansion tank have in a closed heating system?

On the market you can find whole series of tanks with different working volumes. To find the most optimal option, you need to carry out some calculations using the following formula: Vb = Vc × k / D.

The value Vb indicates the minimum volume of the tank, Vc indicates the total volume of the heating system, and k is an indicator of the coefficient of expansion of the liquid.

D is the tank efficiency coefficient, which can be determined using the following formula: D = (1m - Qb)/(Qm + 1).

Qm is the upper indicator of the permissible pressure in the heating system and determines the actuation force of the valve from the “safety group”.

Qb indicates the pre-created pressure in the air-type chamber. If there is built-in paging, a similar indicator will be indicated in the technical documentation. Sometimes the pressure level is regulated by a car pump with a pressure gauge.

To simplify the process of calculating volume, you can use special online calculators.

Gas heating equipment + BKN

At a dacha for a summer holiday it is not necessary to install a complex communications system, whereas for a cottage of permanent residence it is simply necessary. There is no point in wondering whether an additional boiler is needed for a gas boiler - of course, it will turn out to be a very useful acquisition, significantly increasing the comfort of living in the house.

We will review the basic BKN connection diagrams in order to prevent errors that are possible when installing the equipment yourself.

Connection diagram to a 1-circuit boiler

Single-circuit units perform one of the functions declared by the manufacturer: either provide water heating for hot water supply, or heat the house - and the second option is used much more often in everyday life.

The combined solution - a 1-circuit gas boiler + BKN - is one of the best for a small cottage.

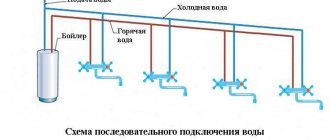

Connection diagram of BKN to a gas boiler. Heating of water for heating and hot water supply occurs synchronously, after which it is distributed into two branches - to the heating radiators and the boiler

The heating process occurs according to the following scheme:

- cold water enters the boiler, where it is heated to the required temperature (for example, +80°C) by a gas burner;

- the heated coolant enters the heating circuit - to the radiators - and into the heat exchanger of the storage water heater, i.e. boiler;

- By increasing the temperature of the heat exchanger, the water in the boiler is heated and when the water taps are turned on, it flows to the consumer.

When implementing this scheme of a gas 1-circuit boiler with an indirect boiler, the main importance is the technical data - power and coolant supply rate.

According to average indicators, the water in the boiler, if it has not previously functioned, heats up from zero to an acceptable temperature in 5-15 minutes, that is, the wait will not last long. Usually the unit is in working condition, so there is always access to heated water.

Let's look at the features of the strapping of the devices in question.

First, you need to choose the most convenient installation location - most often it is a boiler room, a separate non-residential premises. It is better to place the units at a close distance from each other - this way the heating process occurs faster, and less materials are consumed.

Floor mounting requires installation in such a way that the distance to the nearest obstacles or devices is at least 0.5 m - this will be required for maintenance or inspection of the unit

The piping occurs on two sides: loading and water supply.

At the outlet of the boiler, it is recommended to install a membrane expansion tank, which compensates for thermal expansion and stabilizes the operation of the system. All circuits must be equipped with ball valves and check valves that regulate the direction of coolant flows.

It would not be superfluous to install filters - the water supplied to the system is different, and during an accident sand or other debris can get in, which can contaminate the coolant and damage the equipment.

A mandatory element is a circular pump that supplies water at the required pressure. It is mounted on a pipe between the boiler and the boiler, and it is controlled in one of the following ways: either by a storage thermostat, or by a temperature sensor in the boiler

Shut-off valves are installed on both sides of the pump. The same tap is at the cold water inlet to the boiler.

A tee with a drain valve is installed on the boiler pipe, and shut-off valves are installed on both pipes so that the unit can always be cut off from the boiler for cleaning or other maintenance. On the supply, in front of the shut-off valve, you need to place an air vent.

The best option is to connect using a three-way thermostatic valve, which organizes the coolant exiting the boiler and dividing it into two flows - into the boiler and the heating sector. With its help, you can regulate the temperature: if heating up to + 80-90 ° C is suitable for radiators, then for heated floors it is better to limit it to + 45 ° C.

If there is no three-way valve, then two circulation pumps are installed, one of which serves the BKN, the other is intended for the heating branch.

Diagram of connecting the boiler to the solar system. Interaction with the solar collector requires the installation of a separate closed circuit with a heat exchanger and temperature sensors

Sometimes circuits with coolant recirculation are used - for example, to constantly maintain a heated towel rail in “working” condition. Heated water circulates in a closed circuit, preventing the pipe from cooling. A circulation pump is a mandatory element, but a check valve is not needed. The disadvantage of such a system in the summer is excessive energy consumption.

When the operation of the gas boiler switches to “summer mode,” the heating circuit is simply cut off - the gas burner heats the coolant for the boiler. But there is another way out - simply turn off the gas boiler and use only the boiler. This is possible if the storage device is additionally equipped with an autonomous heating source - a heating element.

Two application options with a 2-circuit boiler

Owners of gas heating equipment are also interested in how an indirect heating boiler with a 2-circuit gas boiler works. Experts believe that interaction between the units is possible, but the result depends on the connection diagram: with one of them they are simply not designed to work with each other.

Introduction of a boiler into the DHW circuit

First, let's consider the option when the boiler is integrated into the DHW circuit. From a hydraulic point of view everything looks correct. A three-contact mechanical thermostat, placed in the boiler body, closes the power supply circuit to the pump when the temperature drops.

That, in turn, begins to pump water, which circulates along the circuit between two heat exchangers: it is heated by a gas burner, and then moves to the BKN coil.

Simply put, both devices perform their functions: the boiler stops heating and begins to heat water for hot water supply, and the boiler tries to heat the contents of its “storage” due to the increased temperature of the hot water.

The problem arises precisely because of the mismatch of temperature parameters. Let's assume that the initial filling temperature of the boiler is +15˚С, and the recommended temperature for heating water in the boiler is +60˚С - the automatic limiter no longer allows.

The difference between the two set parameters of 45˚ is significant, so the heat exchange in the boiler occurs quite intensively. But the temperature begins to rise, and when it reaches +40˚С, the difference is much smaller - only 20˚. Accordingly, heat transfer slows down.

Don't forget that water continues to circulate between the two devices. The gas burner of the boiler begins to receive not a 15-degree coolant from the cold water system, as recommended by the manufacturer, but a 40- and then 50-degree heated liquid from the boiler.

As a result, the temperature of the liquid instantly soars to +60˚С, the sensor is triggered, the burner turns off, as it is programmed for parameters that are safe for consumers

The water in the boiler begins to cool - the sensor turns on again and the circulation process resumes. And so on all the time. This leads to the fact that the water in the boiler does not reach the required temperature, but remains insufficiently hot, which is not suitable for domestic hot water use.

The process of interaction between the two units could take place if the boiler burner heated the coolant to +80˚C, but this is prohibited by the instructions to protect users from burns.

Another reason not to use the BKN and DHW circuit of a gas boiler in steam lies in the inability to heat the water in the boiler to a temperature exceeding +60˚C. This is due to sanitary standards.

About once a week, the device is filled with hot water at about 70-75˚C, so that the legionella bacterium, whose colonies resemble mucus, does not multiply in the tank. A large number of bacteria in water leads to the development of allergies and other diseases

It can be concluded that due to only two, but significant reasons, the scheme of combining a gas boiler and BKN through a hot water supply circuit was recognized as ineffective and unsafe. If you already have a double-circuit boiler, just use it for its intended purpose: use one circuit for the heating system, the second for DHW.

Interaction of BKN with the heating circuit

The second option is the interaction of the BKN with the heating circuit. The technical solution works great if the performance of the gas boiler is not enough, and this is the only effective way to connect the BKN to a 2-circuit boiler.

We do not touch the hot water circuit, but use only the branch responsible for heating - that is, going to the radiators and the “warm floor” system. The pipe leading to the boiler must be connected immediately under the boiler, after the tap

With electronic control, you need to set the boiler to heat water at +70°C - this is the coolant that will flow into the boiler, where further temperature adjustment will take place. The thermostat located in the boiler will turn on the pump when the temperature drops, and turn it off when the required value is reached.

With mechanical control of a gas boiler, everything happens differently. A second thermostat, the boiler, is connected to the boiler thermostat, and then the first device can be controlled using the second. For example, if you set the temperature on the second one to +80°C, then the first one, the worker, will require heating the water to +80°C, regardless of what temperature it is set to.

When the water in the boiler heats up to the required temperature, the second thermostat breaks the circuit, and the first one, located on the boiler, again becomes the “main” thermostat. If at this moment the temperature is set to +40°C, then it will drop to 40.

Heating expansion tank

The expansion tank in double-circuit gas boilers has a volume of 6-8 liters. As a rule, this is enough for its operation under normal conditions. But if you have a large heated area, there are a lot of radiators, and they are also non-standard; more liquid is required to fill them. It happens that the volume of the tank installed in a gas heater may not be enough.

In this case, excess heated water will fill the expansion tank completely, but the pressure in the batteries will still increase, since there is a lot of liquid. Then there will be an emergency release from the boiler until the pressure in the radiators stabilizes.

Then, when the temperature drops and the liquid cools, it will come out of the tank. But since an emergency release has occurred, the pressure will drop to a level at which the boiler will not be able to automatically start working. If you do not replenish the heating system with water in time, and the outside temperature is low, it may defrost and be destroyed.

To prevent such a negative scenario from happening, an additional expansion tank for heating is installed in the system. In the event that water fills a standard tank installed in the boiler, there will be no emergency discharge; now the liquid will go into an additional container and then return to the radiators. Thus, the volume of liquid in the system will be constant.

Wall mount

Instantaneous water heaters are lighter, so they are easier to mount on the wall in an apartment. But heavy boilers, which are designed for a water volume of 50 to 200 liters, must be very well attached to the wall.

This is where the installation of the boiler with your own hands begins. Installation can only be carried out using anchor hooks or bolts. Such fastening will be reliable on concrete panel walls or solid brick walls.

But if the wall does not inspire confidence in you: wooden or old brick, then you need to drill through the wall and screw it onto steel strips from behind. Or make a metal frame on the wall and attach it to it using hooks welded to the frame. Well, in general, such a boiler cannot be hung on a plasterboard wall in an apartment.

When installing any water heaters, you must hang them strictly vertically, determining the accuracy of the mounting level. If the boiler hangs unevenly, with a slope, then there will be problems with its operation.

Another nuance that must be taken into account when installing it yourself is that the distance from the shelf to the boiler lid must be left about 15 centimeters.

The video shows in detail how to install a boiler with your own hands:

EXPANSION TANK FOR HEATING

1. Turn off the double-circuit boiler from the network.

2. Close the water supply taps to the heating device.

3. Let's drain the water from the batteries.

4. Let's prepare the expansion tank for heating for operation. Our system is assembled from polypropylene pipes. Accordingly, to connect it, you will need a device for soldering them and several corners, couplings and fittings. So that later you can remove the container for repair or replacement, we use a special fitting, the so-called “American”.

5. Having made sure that there is no water in the heating system, we proceed to the installation of polypropylene pipes.

Let's turn on the polypropylene soldering machine and set it to the desired temperature.

6. Connect the tank by screwing the “American” on it. We will install it on the floor, in a corner, near a wall, so that there is easy access to it.

7. While there is no liquid in the pipes, unscrew the coarse water filter and rinse it.

8. At the same time, we will replace the cartridge in the main filter, which is installed immediately after the water supply pumping station.

9. Having installed everything in place, open the liquid supply taps and fill the radiators until the pressure is 1.2-1.3 kPa.

10. Let's bleed the air from the pipes and close the Mayevsky taps.

11. Turn on the boiler and heat the room.

The tank is set to a working pressure of 1.8 kPa. If it increases in the system and exceeds the value of 1.8, the tank valve will open and excess water will flow into it, and, conversely, when the pressure decreases, water will flow into the batteries. Thus, we ensured stable operation of the system by installing an additional expansion tank for heating.

Checking the operation of the tank is very simple. Let's pump it up with air to a pressure of 1.6 atm and provide access to the nipple. Let's turn on the gas boiler. Let's bring the pressure in the heating system to 1.5 Atm. Using the nipple, we will begin to bleed air from the tank. As soon as it drops below 1.5 Atm, water from the system will begin to flow into the tank, and the needle on the boiler pressure gauge will begin to fall. This means that the expansion tank is working and connected correctly.

If you liked the article, share it on social networks.