Having realized the dream of purchasing a country house, many buyers are faced with difficulties in choosing a suitable boiler for heating the building. How much power is enough to maintain a comfortable temperature level? What type of boiler will satisfy the buyer's needs? The purchase is important, so when choosing a gas boiler, you should carefully study all its characteristics.

Operating principle, purpose

The operating principle of a gas boiler is quite simple, understandable and boils down to the following algorithm:

- An unheated coolant (water or special liquid) is supplied from the pipeline to the heat exchange circuit using a circulation pump.

- At the same time, the valve opens and gas fuel is supplied to the burner and its subsequent automatic ignition.

- In accordance with the timer settings and temperature sensor readings, an open flame heats the coolant inside the heat exchanger.

- Depending on the intensity of combustion and throughput, passing through the thermal circuit, the coolant, heated to the desired temperature, enters the heat pipe of the heating system and further into the radiators.

- When the system reaches a predetermined heating level, the flame goes out, and then, when cooling, it lights up again, etc. - depending on the settings of the external thermostat.

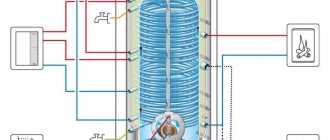

Schematic representation of the operation of a gas boiler Source otoplenie-gid.ru

If the gas unit is intended not only for heating, but also for hot water supply, it includes a second heat exchange circuit. In this case, the boiler is called a double-circuit boiler. At the same time, the additional heat exchanger, which is responsible for supplying hot water to the mixer, differs from the primary one in higher heating rates and water flow throughput.

Note! Some boiler models do not have separate circuits for heating and hot water. Therefore, they can only work in one mode. For example, when you open a tap in the system, the flow sensor is triggered - the heat exchanger begins to work to supply hot water supply. As soon as the water intake stops, it switches to heating mode.

Connection diagram of the heating system and boiler to a gas boiler Source kotlobzor.ru

See also: Catalog of companies that specialize in autonomous gasification of country houses and related work

Protection system

Almost all models of modern gas boilers have a highly effective multi-level protection system. First of all, in the event of a gas supply interruption, the solenoid valve, which is responsible for the flow of fuel into the boiler, automatically closes. However, a significant drawback is that the valve does not open automatically when the gas supply is restored. In this case, the boiler must be restarted manually. If there is a power outage, then after it is restored the system starts up on its own.

Modern models have a long range of protective functions. One of the most important is to protect the system from freezing.

That is, the temperature of the coolant is constantly monitored by special sensors. And if it drops to a critical temperature, the system independently starts the boiler to warm up the coolant. Another extremely important and useful function is that to ensure high-quality performance, the system automatically starts the circulation pump once every certain period of time and “drives” the coolant. Thus, all elements are constantly maintained in working order.

If a malfunction occurs in the system, information about this will immediately be displayed on a special screen located on the control unit. Having discovered a malfunction and calling a service center specialist, you should definitely tell him the error code that appears on the display. Thus, the technician will arrive knowing in advance about the breakdown - and will be able to restore the system to functionality in the shortest possible time.

Gas boilers are quite economical - special equipment allows you to reduce not only fuel consumption, but also the calculation of a gas heating boiler, the energy consumption consumed by the system, and the efficiency of a gas heating boiler is acceptable.

Device, main components

A standard gas fuel heating boiler includes the following main operating units:

- Burner.

Carries out gas combustion and uniform distribution of the generated heat to the heat exchange circuit. It can be conventionally atmospheric or turbocharged - equipped with forced exhaust of combustion products.

- Heat exchanger.

It is a box with a curved tube located inside through which water passes for heating. Divided into single- and double-circuit. Made from copper, steel and cast iron.

- Circulation pump.

Provides constant water pressure in the pipeline for its optimal distribution throughout the system.

- Expansion tank.

Prevents emergency expansion of water and its vapors inside the system.

- Smoke exhaust.

Carries out the removal of combustion products to the outside. It can be conventional - atmospheric, as well as turbocharged - with a fan for forced exhaust of gases to the street.

- Control block.

Provides configuration of system operating parameters. Connects wires, sensors, sensors, electrical circuits.

Gas boiler control module Source stroy-podskazka.ru

- Sensors for automatic control of safety parameters.

Gas automation for boilers monitors the stability of operating parameters and the safety of the system. Prevents the development of an emergency situation for various reasons - overheating, traction shutdown, loss of flame in the burner, etc.

Advice! A standard double-circuit boiler produces up to 8 liters of domestic hot water per minute. If higher consumption is required, it is better to install a single-circuit model combined with a storage water heater. The volume of household boilers varies widely - from 50 to 300 liters. This is quite enough for the everyday needs of a private home.

Boiler powered by a gas boiler Source domkotlov.by

Circulation pump operation

What the performance indicators of the circulation pump will be depends, first of all, on the power at which the boiler operates, and this device does not have much influence on the operation of the entire system. It is very important that the pipes through which the coolant circulates are made of high-quality material, for example, steel or good plastic.

Varieties

The functionality of household gas boiler equipment largely depends on the type of its main parts. There are several types of classification - according to the following criteria:

- Installation method.

They are divided into wall and floor. The former are small in size and have no more than average power. They take up little space and are designed for small spaces. The latter are more productive and are designed for heating spacious houses. For them, you need to equip a reliable boiler room in accordance with all building codes.

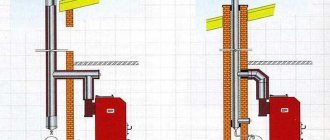

- Type of chimney and combustion chamber.

There are atmospheric and turbocharged ones. In the first case, fuel combustion waste is removed by natural draft, and oxygen is taken into the open-type chamber from the room itself, in the second - by a forced built-in fan, while the flow of oxygen into the closed-type chamber is carried out from the outside through an air duct.

- Number of heat exchangers.

Boilers with one circuit provide heating + a boiler, while those with two circuits provide hot water in addition to heating.

Piping of a 2-circuit gas unit Source szgaz.ru

- Ignition type.

In one version, the flame is ignited manually using a built-in piezoelectric element, in the other, special automation for heating boilers works. At the same time, it allows the boiler to operate without human control.

- Heat removal scheme.

Convection units transfer the heat of the fire directly to the coolant. More advanced condensation models additionally use the energy of water vapor. For this purpose, their design includes a special steam heat exchanger. The efficiency of such installations is significantly higher.

Helpful information! The heat exchange circuit made of cast iron is considered the most durable. However, during transportation and installation, one must take into account its large mass and fragility.

Cast iron heat exchanger for a gas boiler Source gradusplus.com

What is the difference between a floor-standing gas boiler and a wall-mounted one?

In the first case, the units have medium or high power. They differ in greater mass. The power of such a device can exceed 300 kW. The installation is capable of effectively heating residential, domestic and commercial premises of considerable area.

The main design difference between a floor-mounted heating device and a wall-mounted one is the heat exchanger. In the first case, it is larger and more massive. Material: alloy steel or cast iron. The latter has increased fragility, but is resistant to corrosion, has high thermal conductivity, and is durable. At the same time, floor-standing devices can be either completely energy-independent or operate when connected to the mains.

Wall-mounted boilers are equipped with heat exchangers made of steel or copper. The service life of such installations is shorter. They are convenient to use for heating residential premises. They operate quietly, have small dimensions and weight. All wall-mounted units are energy-dependent. For the operation of the pump and fan, which ensure the movement of the coolant, as well as the removal of flue gases, a connection to the electrical network is required.

Installation stages

Installation of a wall-mounted gas boiler is carried out by specialists using the following technology:

- Preparing the room for placing the unit in accordance with regulatory requirements.

- Creation of a ventilation system.

- Installation of fasteners and brackets.

- Installation of the unit.

- Supply and connection of heating system pipes.

- Connecting cold water supply.

- Connecting gas boiler equipment to a gas source.

- Installation of wiring, connection of electrical appliances and automation.

- Installation of a chimney.

- Checking, preparing and test running the boiler.

Important! In the room where the gas boiler is installed, safety regulations must be strictly observed. Wall decoration is allowed only from non-combustible materials. In addition, the presence of an air gas sensor is a mandatory condition for operating the unit.

Boiler power. How to choose it?

The heating power of the boiler is calculated based on the area of the heated building. The generally accepted figure is 1 kW per 10 square meters. This takes into account the power required directly for heating, with compensation for lost efficiency (efficiency factor) due to room ventilation, as well as taking into account a small power reserve. Thus, we can calculate that if the ceiling height is about three meters, then 10 square meters will require 0.6 kW of heat, which with an increase of 30% to compensate for efficiency losses from building ventilation and with a reserve of up to 30% of power will give us the same figure of 1 kW per 10 square meters. Too large a reserve of boiler power is also not desirable in order to save both on resource costs and on the cost of the boiler itself. Accordingly, an area of 200 square meters will require a heating system with a capacity of 20 kW. At the same time, it is worth taking into account the energy efficiency of the room - window area, insulation of walls and floors, as this significantly increases energy costs to create a comfortable temperature in the room.

Features of operation and maintenance

After the installation of wall-mounted boilers or their floor-standing analogues is completed, the period of operational maintenance begins. To avoid breakdowns and emergency situations, equipment must be inspected at certain intervals. In addition to the gas unit itself, the heating system pipelines require no less attention.

Often the cause of an accident is blockage of the line by salt deposits accumulated on the inner surface of the pipes. This problem is especially acute when using hard water in the system. This can be solved by periodically carrying out preventive cleaning - by pumping special reagents into the pipeline.

Recommendation! Smart automatic control systems can significantly extend the operation of a gas unit and increase safety. Modern devices are equipped with sensors for gas pressure, flame intensity, chimney draft, heating and emergency control of the primary circuit, water pressure, safety valve, and hot water leakage. In the event of an emergency, the boiler will be automatically turned off, and the owner will be notified even at a distance - via SMS or the Internet.

Popular manufacturing brands

The efficiency and economy of gas heating is confirmed by the high demand for gas boilers.

A large number of companies produce this type of equipment. European companies are leading in this direction, but manufacturers from Southeast Asia and Russia are practically not lagging behind them. The number of firms is large, which creates serious competition between them.

The most famous companies are::

- Vaillant . A well-known German brand that produces reliable and high-quality gas boilers;

- Buderus . A company from Germany produces high-quality heating equipment of a high level;

- Viessmann . Another German company whose products are highly valued by users all over the world;

- Ariston . The Italian company is currently a subsidiary of Indesit.

- Baxi . Another well-known company from Italy;

- Protherm . Slovak company. Known for naming a series of gas boilers after animals;

- Navien . Korean manufacturer of inexpensive and high-quality gas boilers;

- ZhMZ . The abbreviation “Zhukovsky Machine-Building Plant” is well known in Russia. Non-volatile boilers from this manufacturer are characterized by stable operation and low prices;

- Lemax . The company from Taganrog (Russia) produces gas boilers of high quality and affordable cost.

The list of companies producing gas heating equipment is far from complete.

New companies are constantly emerging, and companies are merging into single holdings . Changing the situation contributes to the development and improvement of equipment, allows us to achieve better performance and reduce prices.

Briefly about the main thing

The design of a natural gas boiler is based on the following working units included in its design:

- Flame former.

- Heat exchange circuit.

- Pump.

- Expansion tank.

- Chimney.

- Control module.

- Automation.

A gas boiler operates on the principle of burning natural gas in a burner and transferring the released energy to the coolant through a heat exchanger. The units differ in the method of installation, smoke exhaust and combustion chamber, number of heat exchange circuits, type of ignition and heat removal scheme. Installation of equipment is carried out by specialists strictly according to technology. Regular inspection is required during operation.

Ratings 0

Selection based on combustion chamber

Boilers can be open or closed. The first uses air directly from the room. In this case, it is necessary to install a chimney. Boilers with an open or atmospheric combustion chamber are mainly installed in separate rooms. Similar types of gas boilers are used in floor-standing installations with a power of more than 35 kW.

In a closed combustion chamber, a coaxial chimney is used to supply air and remove flue gases. This device consists of two pipes of different diameters, the first is inserted into the second. Air is supplied to the burner through one channel, and the combustion product is discharged through the other. The closed type is used mainly in wall-mounted units.