Despite the fact that today a bathhouse made of aerated concrete is a popular construction, some people have controversial questions about its quality and reliability. One of the main questions is why timber and logs were replaced with blocks? Why are they better? The main reasons are the rise in price of wood, the complexity of processing, labor intensity, and fragility. The decisive arguments in favor of aerated concrete blocks were affordability, ease of installation, and high speed of construction.

Historical note: In ancient Rome, one of the popular building materials was concrete. Baths were often built from it. Most of which can still be seen today. A modern aerated concrete block is as similar as possible to the concrete of that time. The only difference is that it contains additives that improve the properties of the material. To the question “are bathhouses built from aerated concrete”? The answer is obvious, of course yes.

Is it possible to build a bathhouse from aerated concrete?

Building a bathhouse from aerated concrete is an excellent solution for those who want to save budget and time. Technical progress does not stand still, but the documentation for some types of wall blocks requires revision. According to GOST, cellular concrete cannot be used for the construction of buildings with high humidity - for example, bathhouses, swimming pools, boiler rooms. But, knowing about the excellent physical qualities of the aerated block, which are in many ways similar to those of wood, most experts refute this point in GOST.

What's the matter then? Why is the use of wood for rooms with high humidity not prohibited? Its water absorption coefficient is an order of magnitude higher than that of aerated blocks. It is also not safe, since it supports combustion. Rodents love it; mold, bacteria, and fungi grow and reproduce well on it. When wet, the geometry, etc. is seriously disrupted. The only advantage of wood over aerated concrete is aesthetics, as well as a pleasant smell.

It is important to think through high-quality hydro- and vapor barrier at the initial stage of construction. And the problem with waterlogging is solved. When insulating a bathhouse made of aerated concrete, it is important to follow the principle: increasing the vapor permeability of the wall materials when viewing it from the inside out.

Features of materials

Interesting features of various materials:

- Foil can be replaced with liquid glass . But it must be used immediately after the waterproofing layer.

- Linden is a very beautiful material with a pleasant smell. But it requires careful and timely care, as it very quickly loses its appearance.

- Alder has a pleasant appearance and emits a cognac aroma . But you will have to pay a lot of money for such material.

- Aspen is not an acquired taste material. Although it has a beautiful appearance, not every visitor to the bathhouse may like the bitterness in the smell.

Choosing material for interior decoration is the most enjoyable process. There are many types of wood on the market.

How to properly build a bathhouse from aerated concrete blocks with your own hands

Before the start of construction work on the bani, a project for the future construction is drawn up and an estimate is agreed upon. Building a bathhouse from aerated concrete with your own hands - consider in the form of a table the acceptable and undesirable places for construction.

| Allowed | Not recommended |

| We build a bathhouse from aerated concrete 15-25 m from the reservoir | Windward placement |

| Ravine placement | Select wetlands |

| Orientation relative to existing buildings | Build on the first line near the reservoir |

| Must be visible from the windows of the house | Place waste pipes directly into water |

| Entrance from the south side of the building (due to climatic conditions) | Build close to the neighbor's fence. |

| Installation of windows from the west, southwest for maximum natural light |

Next, we will consider what a bathhouse made of aerated concrete is, the pros and cons of this building material.

Specifics of aerated concrete

Aerated concrete is a building material from the cellular concrete family. It was created about 100 years ago with the goal of obtaining a light and warm material for the construction of economical housing. The creators of aerated concrete managed to fulfill their task. They managed to obtain a material with low thermal conductivity and low weight, which allows saving on the foundation and heating of the house. These advantages appeared due to the porous structure. The mass of aerated concrete is replete with small (2-4 mm) air-gas cavities, which give the material all its working qualities, both positive and negative. The material is soft and friable and does not withstand compression and tension loads. In addition, aerated concrete is hygroscopic and easily absorbs moisture. This property is typical for all types of concrete, but gas silicate not only absorbs, but accumulates moisture inside air bubbles.

This is a dangerous property, since in winter the water freezes, expands and ruptures the material from the inside, like an explosion stretched over several months or years. This is the most undesirable scenario for the development of events, but less dangerous options are little better - wet gas silicate is not able to retain heat, it becomes heavier and begins to overload the supporting structures.

Because of these qualities, aerated concrete must be protected from contact with moisture by all available methods. The outside of the material is finished with plaster, cladding and cladding are installed. The inside is plastered and painted, and covered with wallpaper. The specifics of these works differ little from the general rules that require the possibility of drying the material. To do this, it is necessary that the permeability of the finishing layers inside is minimal, and outside - maximum. This is the only option that ensures normal removal of moisture from the walls. Otherwise, water will begin to accumulate inside the pores of aerated concrete and create conditions for the destruction of the building.

Pros and cons of building a bathhouse from aerated concrete

Anyone can build a bathhouse from aerated concrete with their own hands. The main thing is to study all the nuances of the gas block. It retains heat well and has excellent performance properties. Banya warms up much faster compared to the same brick one. The cost of a bathhouse made of aerated concrete is noticeably lower than the price of logs; the same timber costs 2 times more, brick – 1.5 times. The percentage of building shrinkage is minimal. This advantage is especially appreciated when carrying out interior finishing work. Aerated concrete blocks are a non-flammable material and are highly resistant to biological attack. Working with him is easy and simple. The blocks are lightweight, so there are no strict requirements for the foundation. The construction of the structure is carried out in record time.

The main, and perhaps the only drawback is hygroscopicity, that is, the ability of the material to absorb moisture. This minus should definitely be taken into account and avoided in the future. The best option for interior decoration of a bathhouse is lining, and for exterior decoration - facing bricks. Disadvantages can be found in absolutely any building material. In the case of aerated concrete blocks, their operational and technical indicators are fully covered by their advantages. More and more often you can find a positive review of a bathhouse made of aerated concrete blocks rather than wood.

Steam room insulation

The steam room is the hottest and most humid room in the bathhouse. Here it is necessary not only to insulate the walls from contact with hot air, but also to cut them off from the absorption of steam. As a rule, thermal insulation of a steam room is implemented in the form of a continuous insulating box along the planes of the walls and ceiling. The insulation is installed in a continuous layer over all surfaces, filling the cracks with foam. The best option is to install polyethylene foam with the foil side facing the inside of the room. This will reflect the infrared rays back into the steam room and retain thermal energy.

Horizontal planks are installed on top of the thermal insulation material on the wall and wooden sheathing is mounted. It is also an element of insulation, since wood has low thermal conductivity. In addition, the cladding creates an additional barrier to water vapor (wood is impermeable to moisture, although it tends to absorb it). Not only the walls are sheathed, but also the ceiling. Here it is necessary to carry out the electrical wiring in advance, sealing the points where the cable passes through the heat-insulating material. As a rule, lamps are placed on walls or ceilings. In addition, you need to take care of the laying of air ducts (if forced ventilation is used). This is an important point, since it is impossible to carry out ventilation after installing thermal insulation and sheathing on the walls - the external arrangement of the pipes looks sloppy. In addition, the air ducts become very hot and become dangerous for users.

The floor is insulated during the construction process, since it is necessary to lay the floor covering (tiles) with a slope to drain the water. Therefore, insulation of the floor in the steam room is carried out according to the usual scheme for all rooms of the bathhouse. Sometimes it is made of wood, so as not to use a platform, but to walk directly on the boardwalk. This option is convenient and practical, but it becomes more difficult to dry such a floor - the underside of the boards gives off moisture worse, which can cause rotting.

Stages of work, from a to z

You can calculate the project yourself on our website in the section: Online aerated concrete block calculator

- Let's calculate the project

The construction of any building should always begin with a well-designed project. It is in it that data on areas, number of rooms, wall heights, materials, their quantity, etc. is displayed. If there is no project, then at a minimum there should be sketches with data on the future structure. Besides:

- It is important to consider the input and distribution of electricity, water, and sewerage systems. This will allow you to create a more accurate estimate for upcoming expenses.

- To select the right type of foundation and what thickness of the walls of aerated concrete bathhouse will be most optimal, you can use ready-made design solutions on construction sites. Even if, instead of a bathhouse, there are calculations for a guest house with an attic, this data can be taken as the basis for calculations.

- The thickness of aerated concrete for a bathhouse, namely the walls themselves, is 300-400 mm for residents of central Russia

- Preference is most often given to a foundation made of a monolithic slab. This is considered the simplest and least labor-intensive option.

A popular version of a bathhouse is a building measuring 3*4 m, with 3 rooms (dressing room, washing room and steam room) and two windows.

Projects

Currently, the bathhouse is a multifunctional space that is used not only for washing, but also for complete relaxation. Based on these goals, modern projects of block baths are being developed. In addition to the main premises (steam room, wash room), this building may contain a cozy relaxation room, a small terrace, an attic or a swimming pool. The size of the latter largely depends on the dimensions of the structure itself.

The most common are attractive bathhouse designs that include a relaxation room.

Most often, the relaxation zone is larger in area than the rest of the premises. This is because in the rest room it is necessary to place a table, armchairs or chairs and other necessary pieces of furniture that need enough free space.

The most common types of projects include the following options.

When building a block bathhouse with a rest room, be sure to take into account that the building must have a vestibule or a small dressing room separating the internal and external parts of the structure. Thanks to such additions, cold and frosty air will not penetrate into the room during the winter season.

Most often, this decision is made if there are no other residential spaces on the land plot. Also, similar structures are often used when designing a plot in a dacha. The attic is a great place to spend the night after being in the recreation area.

When developing a bathhouse project with dimensions of 3 by 5 m, it is necessary to organize several isolated rooms. Without them, the resulting design will be incomplete.

The first room a person enters may be a dressing room. It should be such that you can leave clothes in it. In the interior of such a bath it is necessary to place a small closet in which there is free space for storing all things. Many owners install an additional box in such baths, in which they separately store fuel (wood or coal).

Even in projects of very small baths it is necessary to provide this room. In a 3x5 m building, you can put a small table and a few chairs in the relaxation room.

Immediately behind the rest room you should organize a sink or shower. These spaces are necessary so that sauna users can cool down after steaming their bodies. These rooms should have a simple and uncomplicated interior design. They can accommodate several small benches, a shower and a clean container filled with water. Currently, many owners choose one shower stall to furnish such spaces, abandoning the classic sink.

The main room of the bathhouse is the steam room. Here you need to place a stove, as well as comfortable wooden benches. All listed rooms must be located in any bathhouse. In addition, the building with dimensions of 3x5 m also allows for the installation of a small terrace or attic.

Immediately after the dressing room, you can organize a small relaxation room and place a compact table in it, as well as a couple of chairs. You can get by with a not too large sofa and place a coffee table in front of it. This area should be separated from the rest of the space by a partition, and behind it a spacious steam room should be arranged. It can be divided by another partition and equipped with a washing space in the resulting small corner. In such conditions, a narrow shower stall will look best.

A partition should be placed behind it to close the three remaining zones - shower, steam room and toilet (if you want to install it in a bathhouse).

All bathhouse projects are similar to each other. Any building should have a washing room, steam room and rest room. Additionally, the building can be equipped with a spacious attic or a neat terrace. Some owners even combine such structures with a garage. In this case, it is recommended to contact specialists who can competently draw up correct drawings of such buildings.

How to calculate the number of gas blocks per bathhouse

Now let's proceed directly to the calculations themselves. After you have chosen the thickness of the walls and partitions, we proceed to counting the required number of blocks. Let's consider an example: for external walls we take a block with dimensions of 600 * 300 * 200 mm, and for internal walls 600 * 75 * 200 mm. The sizes of the blocks are the same, the only difference is the width, so we carry out the calculations separately.

- Let's take the size of the bathhouse 3*5 m. We get the perimeter of the walls = 16 linear meters. The height of the walls is 2.5 m. From here we calculate the area = 40 m2.

- Next, we subtract the area of the openings (we have two windows and a door). The size of the windows is 100*50 cm and 50*50 cm, the doors - 200*90 cm. We calculate the area, add it up and get the final result - 2.55 m2, which we then subtract from the total square footage. Total= 40m2-2.55m2=37.45m2

- For our region, the wall thickness is 30 cm. Multiply 37.45 m2 * 0.3 = 11.235 m3. We add 5% of the material supply to the estimate. Total = 11.835 m3 of wall material.

- Now we calculate the number of blocks for the internal walls. The algorithm is similar, the only thing in point 3 is that instead of 0.3 we substitute 0.075m.

Depending on the chosen solution for the design of the armored belt, you have two options: buy ready-made U-blocks or regular ones.

Gas blocks: dimensions and characteristics

Dimensions refer to the height and length of the blocks themselves. These data are standard 625*250, but the width may differ and vary from 100 to 600 mm. The wider the wall and the higher the grade of aerated concrete, the higher you can build a house, and also use monolithic concrete floors. The thinner the wall, the less stable it is.

Density

Marked with a letter and a number, for example, D300. The higher the density, the higher the strength and thermal conductivity of the material. For the construction of a bathhouse, blocks with density and strength indicators D400 and B2.5, respectively, are suitable.

Thermal conductivity

This is the property of a material to release thermal energy. The advantage is low thermal conductivity. The average is 0.14 W/m*S. Heat transfer resistance d500. The higher this indicator, the better the layers of aerated block resist heat transfer. For example, with a wall thickness of 300 mm, this figure is 2.67 m²*C/W, while for a brick wall this parameter is only 1.09 m²*C/W.

Heat capacity

This parameter shows how quickly it is possible to heat a bathhouse. Since we are considering which bathhouse made of aerated concrete or wood is better, we will compare these two indicators. The heat capacity of a gas block is 0.84 kJ/kg*C, wood - 2.4 kJ/kg*C. It follows that a wooden bathhouse takes much longer to warm up. First the walls heat up, and only then the air in the room.

Internal insulation with tight installation of the insulator to the wall

Internal insulation of a bathhouse made of gas silicate blocks is carried out in different ways. The most common option is to install thermal insulation material close to the wall. This method saves internal space, simplifies and speeds up work.

As a rule, the material is installed directly on a wall made of aerated concrete. They use adhesive compositions (adhesive for laying aerated concrete or tile adhesive is suitable), as well as mechanical fastening with dowels and screws. The first option is more labor-intensive, but effective and reliable. The absence of a gap between the wall and the insulator prevents moisture from entering from the air, condensation and wetting of the aerated concrete. Fastening with screws is less dense and can cause moisture to enter the gas blocks. In practice, they usually combine both options - stick the insulator on the wall and fix it with screws so as not to delay the work.

If an impermeable material is used, a vapor barrier can be dispensed with. Sheets of foam plastic (penoplex) or strips of foamed polyethylene are installed tightly to each other, the cracks are filled with polyurethane foam and taped with aluminum tape. However, it is necessary to remember the numerous points of passage of pipes, wires, brackets and other structural elements. Each area must be carefully sealed using foam or silicone plumbing sealant.

How thick are the blocks needed to build a bathhouse?

Having examined the characteristics, let’s return to the question of how to make a bathhouse from aerated concrete, namely, what wall thickness to choose. Since the bathhouse is not intended for year-round use, and it is heated only periodically, precise calculations are not required in this case. The reference point is the region of residence. For example, for the southern strip, a wall thickness of 30 cm is sufficient. Or you can make it smaller, 20 cm, provided that thermal efficiency is maintained by increasing the thickness of the insulation. Is it necessary to insulate a bathhouse made of aerated concrete? The answer is yes, regardless of your region of residence. This is necessary for faster and better heating.

On a note! It is possible to carry out facing work without insulation, but in compliance with the ventilation gap. If brick is chosen as the exterior decoration, then it is necessary to organize ventilation.

For temperate climates, the thickness of aerated concrete walls is 37.5-40 cm, and for regions with a harsh climate, 50 cm. Thermal insulation of external walls is mandatory. An alternative to standard insulation can be the gas block itself. How to insulate a bathhouse made of aerated concrete in this case? A block with lower density values is selected. This insulation option is considered the most durable.

External insulation, dew point

When considering the removal of steam from porous walls, it is necessary to understand the physical essence of the processes occurring. If moisture in a gaseous state is absorbed into aerated concrete from the inside, then liquid water evaporates from the outside. This occurs due to a decrease in the temperature of the outer layers of the wall. There is a concept - dew point. This is a conditional plane inside the walls in which the transition of steam into a liquid state occurs. It is called a point, since the very appearance of the term is associated with graphic images of walls in section, where the transition area is displayed as a point.

Water vapor, absorbed from the inside, spreads throughout the entire volume and reaches a region of low temperature, at which condensation occurs and liquid forms. This is a common occurrence, but for external walls it does not bode well. Removing liquid moisture is more difficult and takes more time. At the same time, steam flows from inside as usual. Water begins to accumulate, the wall becomes wet and ceases to perform heat-insulating functions. In winter, another area appears - the zero point. In it, water turns into a solid state, that is, it freezes. An insurmountable barrier arises, the removal of moisture from the walls stops, creating conditions for the destruction of the wall material.

If there is no external insulation, dew and zero points appear inside the walls. However, if a layer of thermal insulation is installed outside, both planes move outward. When installing a sufficiently thick layer of insulation, both areas are outside the aerated concrete, the material retains its working qualities.

Material for external insulation

It is important that the thermal insulation is permeable to water vapor and does not interfere with the drying of the outer surface of the walls. For this purpose, mineral wool is used; it is the only fairly effective and inexpensive vapor-permeable insulator. There are a lot of videos online that demonstrate external insulation using polystyrene foam or penoplex. This is the wrong approach since both materials are impervious to moisture. They trap steam inside the walls and contribute to their getting wet, which sooner or later will lead to dire consequences (destruction of materials). At the same time, it is necessary to take into account that visual monitoring of the condition of gas silicate blocks will be impossible - they are covered on both sides with several layers of thermal insulation and finishing. Therefore, it is possible to detect the results of an incorrect choice of thermal insulation only in the final stage, when the walls require major repairs.

If an impenetrable heat insulator has already been installed on the outside, there is no need to rush to dismantle it. the problem can be solved in another way - by installing a reliable cutoff of the walls from moisture from the inside, as well as organizing high-quality ventilation of the interior. Here you will need the help of specialists who can calculate the standard air exchange and select equipment with the ability to heat the supply flow.

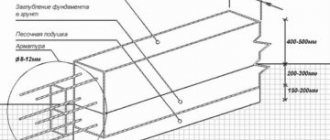

Foundation for a bathhouse made of aerated concrete

Since the gas block is lightweight, it is recommended to install a strip foundation. An important determining criterion is the type of soil. Where it is unstable, preference is given to a strip foundation on piles. Only a specialist can determine which foundation for an aerated concrete bathhouse is suitable for your site.

Ventilation in aerated concrete bath

As a rule, dense cold air masses tend downward (they are quite heavy), while warm ones are displaced by them and tend to rise. In this way, air moves in the building where there is a heating installation. If there is no influx of fresh air, then renewal does not occur. Air masses simply move in a circle. The simplest option is natural ventilation in a bathhouse made of aerated concrete. This is when holes are made at the bottom and top of the wall. Fresh air comes in through the bottom, and out through the top. This type of ventilation is quite sufficient for a small bathhouse. The main thing is to choose the right places to make holes.

Technology and features of wall masonry

The first step is to carry out external markings and install a boundary rope. Deviations in the height of the foundation of more than 4 cm are not allowed. The construction of walls begins with the formation of corners. The blocks are laid using special glue using a trowel. The first row is laid on a concrete composition, and the blocks themselves are placed together on an adhesive solution. After laying the 1st row, you must wait 5 hours for the concrete composition to gain strength and the blocks to become motionless.

The laying of subsequent rows is carried out using an adhesive composition with an optimal percentage of block displacement of 50%. Just like the first row, the masonry starts from the corner. To level the surface, use a sanding board.

Preparation of materials and tools

After drawing up the drawing, you can calculate the exact amount of required consumables. You need to add another 10% to the resulting amount to avoid unnecessary trips to the hardware store. Tools and materials:

- for the foundation - boards for formwork, concrete mixer, buckets, reinforcement, tying wire, sand, crushed stone, cement;

- for the floor - logs, boards for rough and finishing flooring;

- for the roof - rafters, cross beams, battens for sheathing, roofing material;

- for walls - gas blocks with masonry mortar;

- shovels, trowel, trowel, containers for mortar;

- drill with whisk attachment, screwdriver with bits;

- hacksaw for wood, saw for gas blocks;

- miter saw, rubber mallet;

- marking tool, tape measure, building level;

- vapor barrier film, insulation.

Waterproofing the base for masonry walls

Once the base has dried, inspection is carried out using a level. All defects are eliminated with masonry composition. Waterproofing aerated concrete in a bathhouse is a very important stage. You will need bitumen mastic and roofing felt. Overlapping of the rolled material is allowed up to 15 cm.

On a note! Previously, the foundation and masonry were separated by ceramic bricks. After time, it turned out that the brick did not create a protective “shell” against cracking of the walls, and also did not impart strength to the building. Conclusion: this step is optional.

Partitions

What should be the partition in a bathhouse made of aerated concrete, or rather its thickness? For the construction of partitions up to 3 m in height, it is recommended to choose blocks of a grade not lower than D 400. The most optimal option is D 500-D 600. The higher the grade, the better the load-bearing capacity. The thickness of the internal walls is chosen based on whether it is load-bearing or not. If the partition is load-bearing, then it is necessary to carry out calculations according to the mind. If the wall is not load-bearing, then another indicator is used - height. When constructing a partition up to 3 m high, it is sufficient to use blocks 10 cm wide; over 3 m and up to 5 m, the block width will be 20 cm.

Ceiling in a bathhouse made of aerated concrete

The ceiling in a bathhouse made of aerated concrete can be made in several versions. It all depends on the intended purpose. If the attic of the bathhouse will be used as an attic, the household. premises, etc., then the ceiling structure must withstand serious loads. Simply put, be highly reliable. Even if the attic space is not planned for further use, the ceiling structure must support its weight and a layer of thermal insulation. In order not to heat the street, you should choose high-quality thermal insulation that is not afraid of moisture and high temperatures. For example, the use of certain tree species together with special means to extend the life of wood.

Gas block during the construction of a bathhouse

A bathhouse built from aerated block, with the correct construction technology and high-quality insulation, can be used for many years - up to 85-90. Time has shown that you can save a lot of money on gas blocks, installation work takes little time, and the technological indicators of using a gas block in conditions of elevated temperatures and moisture are quite high.

Advantages

Using a gas block has many advantages.

- The gas block is made from natural material, which when heated does not release toxic substances into the environment. This indicates its environmental friendliness and safety in use.

- The building material has a porous structure and is lightweight. To build a bathhouse, you do not need an overly massive foundation; a shallow, strip foundation will do.

- The gas block holds heat well. Additional heat and waterproofing during finishing improve these indicators.

- Building a gas-block bathhouse is 3-4 times more economical than using traditional timber, and approximately 10 times faster.

- The material lends itself well to processing - sawing, cutting, drilling, gating.

- The gas block is not flammable, which meets fire safety requirements.

- The gas block does not rot and is resistant to chemical and mechanical influence.

An important advantage for a bathhouse is that microorganisms, bugs and rodents do not settle in the gas block

Flaws

Like any material, aerated block has weaknesses.

- The aerated block easily absorbs moisture and takes a long time to dry, so additional waterproofing of walls (both internal and external) and a forced ventilation system are required.

- With additional waterproofing, the walls will be less breathable, which can affect the microclimate in the bathhouse.

- The walls of the bathhouse will breathe less, which means the climate will not be as comfortable. Excessive condensation may occur.

- In a bathhouse made of aerated concrete, interior finishing is required, which means additional costs and extra time for construction.

- There will never be a special woody spirit in a gas-block bathhouse, as happens in a Russian bathhouse made of timber.

Warning! The aerated block easily absorbs and draws moisture from the soil, so a foundation made of this material must be waterproofed on all sides.

Bathhouse roof made of aerated concrete

Often the roof of a bathhouse made of aerated concrete is gable. The most popular finishing material is metal tiles. When calculating the material, the type of roof, the length of the base and width, the length of the overhangs, and the height of the roof are taken into account. The height and angle of inclination of the slopes are formed by gables made of aerated concrete. But often the end of the bathhouse roof is covered with a board. Insulation is carried out over the ceiling. A membrane is installed on top of the rafters. The rafter system depends on the type of roof and the roofing material itself.

Installation of roof truss system

The next stage is the arrangement of the rafter system for the gable roof. The work package includes the following:

- Installation of the base, rafter and transom for the finished structure. For the rafter system, an edged board is used (dimensions 100 × 40 mm).

- Installation of triangles for gables.

- Installation of wooden sheathing from beams with a step width from 60 to 100 cm.

- Arrangement of the attic floor base in compliance with technological gaps for ventilation.

- Gable trim.

- Installation of waterproofing material on wooden sheathing.

- Laying roofing material.

Bathhouse made of aerated concrete or wood

If we consider whether it is better to build a bathhouse from wood or aerated concrete, then the advantages of the second material option, namely aerated concrete, are noticeably greater. This is due to the fact that wood must be periodically treated with special antiseptic agents to protect against mold, fungi, and rodents. Mandatory sealing of the joints between logs/beams is also required. This event must be repeated several times. And caulking joints is still fun. Another compelling argument why it is worth building a bathhouse from aerated concrete blocks rather than wood - a wooden bathhouse is always an increased source of fire hazard.

What is better for a bathhouse: aerated concrete or foam concrete?

What is better to choose for building a bathhouse? The weight, hardness and specific strength coefficients of these two materials are approximately equal. But as for performance indicators, there are noticeable differences (see table below).

How do we see the question “what is better for a bathhouse, aerated concrete or foam concrete”? – definitely the first option. As for convenience in construction, the geometry of the material, the gas block is manufactured at the factory, but the foam block is made in semi-handicraft conditions, so the geometric parameters of the foam block can noticeably suffer.

Foam block bathhouse after 10 years

According to numerous reviews, you can find ones where owners note shortcomings that they personally encountered. After some time, delamination and cracking of the foam block was observed. This is due to temperature fluctuations. The second popular negative review is the formation of mold. Most likely, the reasons for these shortcomings are non-compliance with the construction technology of a foam block bathhouse, the wrong time of year for constructing the structure, an ill-thought-out ventilation system, etc.

Price of aerated concrete bath

How much a bathhouse made of aerated concrete will cost depends on many factors, for example, area, number of rooms, roofing material, type of finishing, etc. Will you draw up a project yourself or build according to a standard solution?

Where to buy Bonolit products - Dealers and partners Bonolit Club

If you have a choice to build a bathhouse from wood or aerated concrete blocks, then it is more profitable, easier and faster to build a structure from aerated concrete blocks.

Start of operation after construction

You have built a bathhouse and you can take a steam bath - unfortunately, this does not apply to buildings made of wood. This is due to the fact that the tree needs time to stand, dry and shrink as required. If you pass by this stage, there is a high probability of cracks appearing. And, as a result, destruction of the finish on all sides. For example: radial shrinkage of pine – 6%. This suggests that the frame of a bathhouse with a height of 2.5 meters will shrink by about 13-15 cm. And if finishing is also done, then get ready to seal the gaps.

On a note! Absolutely any type of tree can dry out.

Compared to wood, aerated block has a minimal shrinkage coefficient of about 0.4%. This way you can start finishing work almost immediately. This means that as soon as the finishing work is completed, the bathhouse can be put into direct operation.

Internal or external insulation?

Many users often have a question: what type of bath insulation to choose, from the inside or the outside. The question is not idle, since the bathhouse is different from residential premises, it is used periodically and is not heated constantly. Installation of thermal insulation material from the inside in this case is mandatory. Is it also necessary to insulate the outside if the walls are still excluded from the thermal contour of the building?

Various sources claim that the best option would be to simultaneously insulate the walls from the inside and outside. This option will provide maximum heat saving efficiency and will save fuel for heating the bath. However, experienced bathhouse owners claim that this method is only good for large buildings with recreation rooms, swimming pools and other departments. They have a large wall area with high heat loss. For a small bathhouse, it is quite enough to properly insulate the walls from the inside, and on the outside you can simply install sheathing with a ventilated gap. Thermal insulation in this case is excessive; there is nothing to protect the cold walls from. Therefore, you need to be guided by the size of the bath and the mode of its use.

Conclusion on the article

Is it possible to build a bathhouse from aerated concrete? The construction of a bathhouse from an aerated block requires significantly less expenditure compared to the same timber or log. The sauna warms up much faster and retains heat well. The building can be quickly erected and operated in the near future. The absence of mold, mildew, and rodents is guaranteed. Most importantly, a sauna made of aerated concrete is fireproof. Perhaps these arguments are enough to say goodbye to the long-standing stereotype that a bathhouse can be built exclusively from wood.