Cleaning a well from sand

A well is an alternative to centralized water supply. It solves problems with watering and is used for household needs. But from time to time it is necessary to carry out preventive work to ensure the cleanliness of the well and the serviceability of the system.

Therefore, many site owners are wondering how to clean sand from a well. Many people want to do the work themselves, while saving their money.

Causes of siltation

An alarm that should alert the owner of the device is a decrease in water pressure. After this, a brief stagnation usually occurs, accompanied by a characteristic gurgling sound, then muddy water is released and eventually the system stops working.

Siltation occurs for several reasons:

- When drilling a well, the pipe was installed incorrectly. The place where water enters the device is not located in the aquifer or weakly aquiferous layer - a defect during drilling.

- The internal arrangement of the structure also plays a big role. Due to the leakage of the casing pipes, grains of sand enter the source from the side and from above through cracks. Thus, the source is filled with sand.

- There is a small flow of water from the well. Siltation occurs due to the settling of silt, small particles of clay and rust from the pipe at the bottom of the system; they gradually become compacted, which reduces the well's flow rate. If the water consumption is large and frequent use, the risk of siltation decreases.

- If it is not possible to pump water continuously throughout the year, it is recommended to use the well as much as possible in the summer. Perhaps for this purpose it is necessary to turn on the pump for a long time, which will allow the water to circulate, freeing the well from clay and rust. But we should not forget that fine sand particles can only slightly affect the operation of the well; coarse sand particles do not have such an effect on the quality of its operation.

Advice: If during the year it is not possible to increase the frequency of pumping out water, then in the summer it is necessary to pump out more of it.

- To supply water, rotary pumps are used, which draw water; if the depth is not more than 8 meters, this leads to the settling of small particles below this level. To clean such a well, you need to periodically use a vibration pump, and it must be gradually lowered to the very bottom while pumping the device.

- The presence of a filter with a smaller diameter than the main pipe. As a result of this, the pump can drop 20 - 30 centimeters higher than the upper edge of the filter. Over time, the filter fills with sediments that poorly allow water to pass through. Cleaning of this design is done with a vibration pump, which has a smaller diameter and has a lower water intake.

- The use of a vibration pump with an upper water intake.

- Any well must have a filter, which is small holes located in the layer from which water comes. Most often, this is at the bottom of the first pipe. This filter allows solid particles passing through these holes and water to pass through.

- Sometimes specially made filters for wells are installed, which are two pipes of different diameters with holes drilled in them. The wire spiral is wound tightly between the pipes. The disadvantage of such a device is that the internal diameter of the main barrel is larger than the internal diameter of the filter, which does not allow a vibration pump to be lowered to the bottom, and makes it difficult to clean it with such a device having standard dimensions.

Before cleaning the well, you need to determine the causes of breakdowns.

They may be:

- Sand began to come out of the well, which is the first sign of siltation, but it can appear in large quantities in the water for other reasons.

- The flow rate and its potential have decreased. This is the volume of water restored in the well per hour.

- The water became cloudy and an unpleasant odor arose.

- Problems can arise due to irregular operation or errors made during drilling and construction. A change in the direction of the aquifer veins, then the cause will be natural.

- Lack of defense mechanisms. In this case, debris may enter the mouth.

- Reasons may include lack of maintenance or improper pump operation.

There are two main types:

- With filter.

- With a straight barrel.

You can set up the operation of the structure in the following ways:

- Rinse.

- Pump up.

- Blow it out.

Where does sand come from in a well?

For many, water contamination comes as an unpleasant surprise, and they ask the understandable question of why it happened that when drilling at great depths, where artesian layers lie, sand and water flow.

It is important to note that a small amount of it is allowed by sanitary standards and is not considered a tragedy. If it does not exceed 0.1 -1 g/l, such water is suitable for use and will not cause harm to health.

The presence of fractions of foreign solid particles in the water mass supplied by the pump may explain why sand and water come from a new well. It must be taken into account that the horizons of the formations are located directly next to the sandy horizons. Passing through them, masses of water capture a small amount of sand, and the pump delivers it upward.

Well cleaning

A water intake with a straight barrel is more convenient to clean. In this case, the equipment can sink to the bottom, which eliminates the risk of rapid siltation.

A circuit with a mesh filter

How to clean with a bailer

Although this method of cleaning a well is labor-intensive, it is reliable. Using bailers, you can clean a completely idle well to its original state, remove not only silt, but also fairly coarse sand and small stones.

The procedure for cleaning a well from sand and silt with a bailer is as follows:

- The bailer for the well is lowered to the bottom, raised by 30 - 50 centimeters and then abruptly released.

- The element falls to the bottom under its own weight.

- The ball stays in place due to potential energy and opens the lower hole.

- Water with agitated sand and silt enters here.

- After this, the ball lowers under its own weight and closes the hole.

- Three to four movements are enough for the bailer to fill halfway.

- Without jerking, the bailer smoothly rises to the surface and sand and silt are poured out along with the water. A bailer can capture from 250 to 500 grams of sand and silt in one lift, which is about three centimeters high in a 108 mm diameter casing, water is not taken into account. Using such indicators, you can calculate the frequency of cleaning in the future to maintain it in working order.

Tip: A tripod gate can make lifting the bailer easier.

Scheme of the bailer device

Let's talk about how to make a ball yourself:

- You need to buy a rubber or PVC ball from a toy store, but make sure it is the appropriate size.

- Then you buy shot of any caliber at a hunting store.

- We cut the ball in half, fill its parts with shot mixed with glue, which is waterproof.

- When both halves are dry, they need to be sanded and glued again with glue. The quality of the glue you use will determine how strong your ball will be.

If you have followed it in accordance with all the recommendations, it will play its role efficiently: block the bailer hole for a long time. If it was not possible to purchase shot, it can be successfully replaced with balls from bearings.

How to clean a well using a vibration pump with a nozzle

A more progressive method that does not require physical labor is the method that uses a vibration pump, the general view of which is shown in the photo. Its disadvantage is the inability to accurately determine the bottom, but this is not always important.

Vibration pump

Any type can be cleaned in this way, but it is more effective with a narrowed barrel of the device, when cleaning with a conventional vibration pump is impossible. Cleaning of silt deposits in the narrowed part of the well can be done with a vibration pump, “Malysh” type; water is taken from below.

In this case:

- A rubber or durite hose is put on the protruding body of the water intake and secured with a clamp to the pump body.

- Insurance is required in case the hose slips. A long metal, PVC tube or thick hose of the required length is inserted inside it and the connection is securely fixed. A small weight is attached to the lower end of the hose so that the hose cannot float when lowered into the well.

- The pump is lowered until the lower end of the nozzle touches the muddy level, then it is raised 5 - 10 cm and turned on.

- The productivity of this method of cleaning a well is 10 times higher than using a bailer.

The disadvantages of this method include the inability to lift large particles and wear on the working valve of the vibration pump.

How to perform mechanized well cleaning

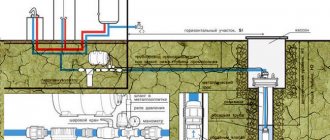

Deep wells are best suited to mechanized cleaning using two pumps working in pairs:

- Deep with a lower fence.

- Self-priming type “Kama”, supplying water to the well.

In this case, the water supply pressure will not be very strong, which increases the cleaning time of the structure, but slow mulching of the water increases the operating time of the deep-well pump - it does not become clogged with silt and sand.

Mechanized cleaning scheme

Work instructions include:

- A container with a volume of approximately 200 liters is installed near the well.

- At the top of the container, an old bucket is installed at the bottom, with a mesh located at the bottom.

- A hose is lowered into the bucket, through which water is supplied from the Kama pump.

- The second end of the hose, with a weight attached to it, is lowered to the bottom.

- The deep pump is lowered and fixed 10 - 30 centimeters above the sludge level.

Tip: To do this, the pump is first lowered into the ground until it stops, and then raised and secured at the required height.

- Before clearing sand from the water from the well, the pump is turned on and the container is filled with water to the upper level.

- The pump that supplies water to the well is turned on to stir and cloud the top layer of silt.

- If the flow rate is small, you need to first fill the container with water, then turn on both pumps at the same time or first the external one. This will ensure a timely supply of water to the well, and the pump will operate for a long time.

- Periodically you need to move the water supply hose, and lower it as sand or silt is pumped out.

How to clean a well using a fire truck

Using a high-pressure hose, the well is cleaned in ten minutes. But the cost of this cleaning method is high, and it is not safe; filters and system components can be damaged. It should only be used when it is very dirty.

How to clean with a deep-well pump

This method is used when it is not possible to use any other. Although the process is average in duration and labor-intensive, it is quite simple.

Its essence is as follows:

- You need to stir up the water and everything in it at the bottom.

- A small metal ripper is attached to a long cable or cord and lowered to the bottom of the device.

- The device must be raised and lowered several times, which leads to loosening of sand and silt.

- The vibration pump lowers.

- The water is pumped out until it is completely clean.

Can liquid be used with sand?

Theoretically, such water is allowed to be used for economic purposes - watering gardens, car washing, etc., but only after its high-quality mechanical cleaning. However, it is worth remembering that completely ridding the liquid of sand requires large costs for installing filtration systems and the need to use a drainage pump to pump and lift dirty water. Such expenses may be considered unreasonable. It is better to completely get rid of sand in the well by taking appropriate measures.

Precautions during well cleaning

In order to prevent damage to the system during cleaning, you must follow basic rules:

- Do not use equipment for cleaning that is not designed for this work.

- During the cleaning process, you need to constantly monitor it and not leave the well and equipment unattended.

- Stop pumping immediately if large particles of metal or plastic appear.

The video will tell you what other cleaning methods exist. This article gives only some recommendations for cleaning from silt and sand. Periodic cleaning will increase the life of the pumping equipment and keep the system clean and tidy.

Briefly about the main thing

There are many reasons why sand comes out of the well or muddy water appears in the well; what to do depends on the factors that caused the system to become polluted. When selecting the most effective method for solving a problem, it is important to establish the cause of contamination. You can clean the water extraction system using mechanical methods, including the use of pumps, bailers, and filters. But if the manipulations carried out did not bring the expected results, there is a possibility of depletion of the aquifer, in which case the only way out of the situation is the construction of a new well.

Ratings 0

Preventive measures

To prevent the well from producing sand over time and causing trouble to its owner, it is important to take a number of preventive measures.

- Completely pump (flush) the source after drilling it. It is important to do this until the water comes out completely clean.

- Correctly calculate the fraction of filter mesh cells based on the size of sand grains. This can be done by experienced professionals.

- Monitor the strength and reliability of all connections of the casing pipe during its installation.

- Use a pump whose technical characteristics correspond to the performance of the source. A unit that is too powerful will either deplete the well or drive sand.

- Operate the hydraulic structure regularly (even in winter). Seasonal downtime leads to silting of the filter. If it is impossible to avoid seasonal operation of the well, it is advisable to come to the site once a month and pump out at least 100-150 liters of water.

It is always easier to prevent a problem than to solve it later.

Source of the article: https://strojdvor.ru/vodosnabzhenie/iz-skvaziny-idet-voda-s-peskom-cto-delat/

Effective cleaning methods

Well cleaning bailer

The simplest option for dealing with a silted bottom is to use a bailer: a piece of steel pipe with teeth on one side and special flaps there. The principle of its operation is that when it free falls from a height of 0.6-0.8 meters, it crashes into a layer of sand deposits with its weight. At this moment, the bailer flaps open and sludge enters the pipe cavity. When it rises, the blades close, preventing dirt from flowing back into the casing space.

As soon as the volumes of lifted sludge are very low, a stream of water under high pressure should be applied to the bottom of the shaft. This will help wash away any remaining dirt in the filter area. The dirty liquid is pumped out with a powerful pump until a clean water resource appears.

Using a bailer you can clean wells up to 15 meters deep. If it is longer, the master will no longer be able to cope with the problem.

Mechanical flushing

Well cleaning using two pumps

Here you need to use two pumps - one powerful one to supply water under pressure to the siltation zone, the second drainage one to pump dirty liquid upward. Both units must operate simultaneously.

The supply hose is equipped with a special weight so that it does not rise to the top under the pressure of incoming water. It is lowered approximately 20-25 cm from the silt layer. The intake hose is placed a little higher (30-40 cm from the bottom). Turn on both pumps and start working. The incoming liquid will break up the sludge deposits, and the drainage pump will pump them upward.

It is advisable to prepare a special barrel or other reservoir for dirty water. A bucket without a bottom, covered with fine mesh underneath, is attached to its upper edge. Water will pass through such a homemade coarse filter and be cleared of grains of sand.

How to prevent clogging of a well?

There are no “eternal” wells for water supply. Unfortunately, sooner or later, the owner of an individual water source will face problems. It’s bad if the aquifer has dried up, you’ll have to drill again or deepen the existing excavation. This is difficult and very expensive.

It’s a different matter if a well becomes clogged—it’s easier and cheaper to prevent it than to “treat it.”

Extending the service life of the source is facilitated by following several operating rules:

- Strictly adhere to the selected drilling technology . Carefully monitor the tightness of the casing pipe and the integrity of the filter.

- Immediately after completion of drilling work, flush the source until clean water appears.

- Protect the well from the penetration of surface water and pollution by installing a caisson and cap. As a temporary solution, simply seal the top of the casing.

- Before starting operation, select the correct submersible pump and install it at the required height , always taking into account the flow rate of the well.

- It is advisable not to use a vibration pump to supply water . Vibrating in the casing, depending on the type of soil, it, to a greater or lesser extent, provokes the penetration of sand into the well or contributes to siltation of the adjacent soil. A cheap and simple vibration generator can be used for a short time; for continuous operation you need a centrifugal pump.

- The well should not stand idle without drawing water . The ideal operating mode is daily pumping of several tens or hundreds of liters of water. It is provided if people live in the house permanently. If this is not possible, you should regularly, at least once every 2 months, pump out at least 100 liters of water from the well.

Following these recommendations, of course, will not avoid clogging of the well in the future. However, it will delay this trouble by ensuring the maximum possible resource for efficient operation for a given source.

Proper construction of a well is the key to its longevity. It is necessary to install a special head on the casing pipe, which seals it and serves for reliable installation of equipment

Conclusions and useful video on the topic

In conclusion, here is a useful video that shows step by step the available method for flushing a clogged well:

Note that cleaning a well from sand and silt can be a very difficult task. And it’s not a fact that you can do this on your own. And by carelessly wielding mechanical projectiles, you can generally cause significant damage to a water source .

At the same time, there is a special technique that very effectively and to a large extent restores the characteristics of wells.

Do you have personal experience in cleaning wells on site? Do you want to share effective methods or ask questions on the topic? Please leave comments - the feedback form is located below.

Grid problem

Sediment in the water in the form of sand or clay is one of the least problems that can arise. It is more difficult to resolve the issue with metal impurities or other substances that may be contained in excess in well water. This problem occurs with sand wells that reach a depth of 80 meters. In some cases, clay can also be pulled from an artesian well, when there are layers of clay in the limestone layers. During installation work, a casing pipe is installed in which the water surface is supported and through which water flows to the pump. Its outer part is wrapped in a mesh, which serves as a coarse filter and should trap various mechanical impurities.

Therefore, if a problem arises, it is necessary to look at the condition of the mesh in the well. If it is chosen incorrectly, then over a few years a layer of sand may accumulate at the bottom of the well, which is lifted by the pump. If its cells are too large, this process may occur somewhat faster. There are other reasons that can lead to this effect. One of them is an error during installation. It leads to damage to the mesh and the umbrella is small, then it collects water with sand or clay. Metal well casings are often used. From constant interaction with liquid, the metal corrodes and may fail. If this happened to the lower part of the casing, then the mesh could also fail.

Another reason is excessive water rise during floods or melting snow. In this case, liquid can enter the well along with particles of soil, clay and sand. After some time, the grains of sand will settle to the bottom to such a level that they will fill the sump, filling the filtration zone. This leads to the fact that the water surface falls, because it cannot flow freely into the casing. Moreover, if the horizon is small, then the water will not have time to replenish the reserves around the pump and you may be left completely without it. When the debit is sufficient, the flow of sand will carry it to the pump, which will damage its impellers, which are most often made of polymer, and cause trouble for consumers. If, after several years of using the well, it was noticed that sand appeared, the fraction of which changes from time to time, then it can be argued that the mesh has broken through and needs to be replaced.

Note! Not only the pump, but also the automation suffers from grains of sand.

If the contacts in it are blocked, the pump will not turn on at all or simply will not turn off, which will lead to overheating or damage to the entire supply system. The result will also be disastrous for the hydraulic accumulator, the bulb of which is designed for a certain pressure and can easily fray due to the presence of sand in it.

Water with sand comes from the well: reasons for the appearance of sand and methods of cleaning

Often various impurities appear in water, to eliminate which it is necessary to identify the cause of their penetration. When water and sand come out of a well, what to do, how to carry out repairs yourself and remove the cause of pollution are the first questions that arise from consumers.