Drainage, water supply, external sewerage and stormwater systems include various well structures. Previously, they were built from wood, then from brick and reinforced concrete. But now polymer and composite materials are being used more and more.

One of these options is a polymer sand well made from prefabricated elements. Why is it so good, is it possible to assemble it with your own hands? It is these questions that we will examine in detail in our article.

We will also consider the components of a polymer sand well, the features of its use, the main pros and cons.

Types and areas of use

The classification of polymer wells is quite broad.

Thus, products are divided according to access restrictions into wells with and without free access. The first option is used for repair work and inspection. The second option allows you to perform maintenance only from above. Texture classification:

- Smooth single-wall products;

- Smooth devices are double-walled;

- Corrugated with one wall;

- Corrugated with two walls;

- Combined options.

Polymer wells do not contain harmful substances

According to their intended purpose, polymer wells can be inspection, sewer, or drainage. Also distinguished are options of storm or sedimentary type, differential, caissons. You can find collector and telecommunication wells.

The storm type is designed to collect rainwater. It requires cleansing from sediment. Drainage devices are used as rotating and connecting elements in the drainage system. The pipes are placed at the bottom.

Differential devices are used to change the level of the pipeline. They are available with a vertical pipe, with a stepped pipe and with a cutting tip. Collector wells are used to connect separate systems. To prevent waste from entering the drainage system, check valves are installed.

Pumps or electrical devices are installed in caissons at a certain depth. They are additionally insulated. The telecommunication type is used to control connection points. Additionally, a pipe is used to protect the cable. Wells can be prefabricated or welded.

Polymer-based sand wells can be used to replace reinforced concrete or brick products. The scope of their application is quite wide. With their help, both wells and sewer systems are equipped.

Kinds

Before we talk about the types of wells, let's take a closer look at their structure. As a rule, they consist of the following parts:

- bottom (base);

- set of ring walls;

- transition cone;

- lid.

All polymer wells are primarily distinguished by size. This affects sewage disposal per day. In addition, they differ depending on the purpose:

- prefabricated inspection room - for storm and utility sewerage;

- sedimentary type - used to purify water from precipitation;

- storm drains – used to collect storm water;

- collector - for connecting drainage and sewer systems;

- drainage - used in the drainage system as rotating or connecting elements.

Polymer wells can also differ in their texture; in this case, the following categories can be distinguished:

- single-walled smooth;

- double-walled smooth;

- single-wall corrugated;

- double-wall corrugated;

- combined.

In addition, there is another division - according to the material from which the structure is made.

- Made from polypropylene. They are perhaps the most popular due to the large selection of diameters and the availability of double- and single-layer pipes.

- Made from polyethylene. They are characterized by high tightness and resistance to corrosion. As a rule, they are used for storm and domestic sewer systems.

- Polymer sand. This material appeared relatively recently, but has already gained some popularity due to a number of advantages.

In appearance, two more varieties can be distinguished:

- prefabricated ones, which consist of rings;

- welded - one-piece structures.

There is another type of well that is worth noting - polymer cable. Cable drainage consists of pipes and wells; it is used for laying power and low-current wires underground. Cables can be replaced and repaired without much effort or digging up the soil if the pipeline is built correctly.

Polymers have another function in the field of well installation. During the drilling process, there is a need to strengthen the walls of the wells, especially in cases with loose soils. In these cases, polymer mixtures of several components are used, they are diluted with water in the required proportion and poured into the borehole. Such solutions not only prevent wall shedding and promote stabilization, but also reduce absorption and wear of the drilling tool.

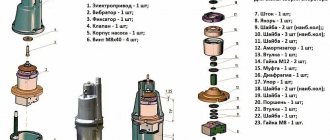

Complete set of a well made of polymer sand rings

A set of type-built wells made of polymer materials (sand composite) consists of the following components:

- set of rings;

- bottom;

- cone;

- Luke.

The main parts of the kit are sand rings for the well, from which the shaft is assembled. The technical parameters of these products are not standardized, so manufacturers adhere to their own specifications.

The most common rings are 1000 mm in diameter. Products with a diameter of 850 mm, 1100 mm and other diameters are also produced.

The strength characteristics of rings for polymer-sand prefabricated wells are determined by their thickness, which usually ranges from 20 mm to 50 mm. The height of the ring is usually 20 cm. The required depth of the shaft is achieved by assembling the required number of components that are connected to each other.

The bottom is a flat round part whose diameter corresponds to the diameter of the shaft. It serves as the base of the well, and must withstand the load from the weight of the structure itself and from the weight of the liquid in the tank. The thickness of the bottom wall is 45-50 mm.

The neck is a transitional element in the shape of a truncated cone, which is necessary to form the upper part of the shaft. Through the neck, access is provided to the well shaft for inspection, maintenance and repair. The dimensions of the cone for a polymer sand well are selected in accordance with the dimensions of the rings.

The neck is closed from above with an inspection hatch, which is also made of composite. The cover can be designed for different maximum loads. Depending on this parameter, hatches are of the following types:

- lightweight – permissible load up to 3 tons;

- medium – permissible load up to 5-6 tons;

- heavy – permissible load up to 12 tons;

- super heavy – permissible load up to 25 tons.

Depending on the type, the scope of application of the hatch is determined. Thus, light and medium hatches are used in areas of country houses or in local areas, in park areas. Heavy and extra-heavy hatches can be used on city streets and highways.

All elements of the well are prefabricated. They are mated to each other using a tongue-and-groove connection. Due to this, a strong, displacement-resistant joint with high tightness is formed.

What it is

Already from the name it is clear that we will talk about products made of composite material: plastic and sand. The product is a prefabricated well consisting of rings, a bottom, a cone-shaped lid and a hatch. The necessary rigidity is ensured by inclusions of sand in a matrix of polymer material. Due to the latter, the best tightness indicators are achieved. The rings, 1 m in diameter and 0.2 m wide, are relatively light, weighing approximately 60 kg. By varying their number, you can obtain the capacity of the calculated volume. All parts of the well are tightly connected into a tongue-and-groove lock.

Benefits of use

In terms of ease of use and performance characteristics, the subject of our article can be compared with concrete rings, from which septic tanks are often made (read about the latter here). Compared to them, polymer-sand wells:

- lighter. Two strong men can handle the installation;

- more compact. If desired, the container can be collected in the basement. The process of self-delivery is simplified;

- more airtight. Composite material does not allow water to pass through. The weak point may be the connection points of the well elements

These are the most significant features that really deserve attention. In terms of product durability and prices, they are approximately the same. But more on that below.

Installation

Polymer sand wells can be used as components of single- or multi-section septic tanks. as an economical option for a caisson, sewer pump station housing, etc. As we said above, the products are durable and airtight. The only weak point is the joints between the individual rings, the bottom, and the lid. Despite the presence of a locking connection, it is impossible to guarantee complete waterproofness of these parts of the well. Therefore, before installation, they are coated with bitumen mastic or special sealants. The future of the structure depends on the quality of this work.

Installation work is carried out in several stages:

- digging trenches for the pipeline (to the freezing depth or in accordance with design data) and a pit for the well (according to the dimensions of the structure, taking into account the information below);

- preparing the base for the container, including filling a 20 cm layer of sand, compacting it and then pouring a concrete slab 20-30 cm thick;

- installing the bottom of the well, coating the joints with bitumen mastic;

- installation of rings, in which the joints must be coated with mastic;

- drilling holes for pipes, sealing with rubber seals mounted on bitumen;

- pipeline connection;

- installation of the cover and hatch;

- backfilling with sand or soil, compaction. Here it is necessary to take into account the nature of the soil on the site. If it is unstable, then it is better to protect the tank with a sarcophagus made of a cement-sand mixture

Prices

Prices for these products may vary depending on the capacity of the manufacturer, the technologies used and a number of other factors. Today, the production of polymer-sand products has been mastered at a number of large factories specializing in the production of plastic containers. Average market prices for well components are presented in the table below.

Cost of well components

Judging by people's reviews, such wells can be used as an alternative to reinforced concrete rings in the manufacture of simple settling tanks. But they are not suitable as containers for storing drinking water, because... The polymer composition is obtained from recycled materials.

As we said above, the only problem area of the finished container is the joints between its components. Despite the fact that the existing fastening prevents lateral displacement of the rings, it does not in any way prevent displacement in the vertical plane. This results in the formation of cracks and a violation of the tightness of the product. For this reason, polymer-sand containers are not recommended for use in conditions of high groundwater levels. In such cases, it is more reliable to use solid tanks made of fiberglass, HDPE, stainless steel, etc.

Finally

Despite the above, polymer sand wells are already an excellent alternative to the use of reinforced concrete rings. Perhaps in the future their cost will drop to levels that will allow them to conquer the market. In the meantime, many prefer to trust traditional solutions.

https://oseptike.ru

Several recommendations for choosing polymer rings for wells

Before choosing and purchasing one or another version of plastic rings, you should consider some recommendations:

If the choice has already been made in favor of a certain model of polymer rings, then before purchasing them you should independently calculate the required depth of the well, the pit for its assembly, the required number of products to build the well shaft, their dimensions, the thickness of their walls, as well as other parameters of both rings and and additional elements. It is best to draw up a project in which all the necessary quantities will be included.

For example, for a septic tank, the calculation is based on the number of people living in the house and its equipment with plumbing fixtures. It can also be taken into account simply the volume of the storage tank required, say, to store water reserves for various needs.

By the way, if you have to base your calculations on the already known (calculated) volume of a storage well or septic tank chamber, then you can use the following online calculator:

Calculator for calculating the working height of the septic tank chamber and the number of rings for its construction

It's simple: you substitute known values and get the result. The only important nuance is that it is necessary to calculate the working height of the well, that is, up to the height where the supply pipe or overflow pipe into the next chamber enters the shaft.

Above this point to the surface of the earth there may be the same rings in small quantities or a conical transition to the neck with a hatch.

- If finances allow, then it is best to opt for double-layer corrugated HDPE pipes. They will ensure the absolute tightness of the structure, since it only has a joint with the bottom part. This version of the plastic product is also suitable as an insert when repairing a concrete well.

- When sealing the joints of the rings (if standard seals are not provided there), moisture-resistant sealants or high-quality welding should be used. Otherwise, through the gaps that may form on the seams over time, groundwater will penetrate into the mine, carrying a lot of contaminants, which will inevitably lead to the need to clean and disinfect the well. And this is a very troublesome matter.

Purchased plastic products must have certificates of compliance with all sanitary and technological standards

It is especially important to check the documents when purchasing rings or pipes for constructing a well for drinking water. When carrying out installation work, it is imperative to strictly adhere to safety regulations. Even if the well is shallow, only one and a half to two meters, the rings, before handing them over to the receiving master located in the pit, must be tied to a stable, fixed support with a strong rope

This simple device will help prevent injuries, since insurance will be provided by the remaining workers at the top. Even a light object falling on your head from above can cause a lot of trouble. And the weight of some polymer-sand rings reaches up to 50 ÷ 60 kilograms!

Why does blockage occur?

In most cases, we ourselves are to blame:

- When using the kitchen sink, we drain food residues, trimmings and dirt into it. In addition, during the dishwashing process, a lot of grease from the residue on the plates ends up in the drain. Gradually, fatty and limescale deposits are deposited inside. And the larger it is, the narrower the gap in the pipes, and as a result, a plug forms in it.

- In the bathroom, the problem is often caused by hair and animal fur that ends up in the drain after bathing.

- In the toilet, trouble can happen due to the ingress of certain hygiene products, cotton wool, paper, floor rags and other unwanted things that clog the pipe.

- In some cases, the cause of the trouble is improper installation of pipes (this happens especially often with modern plastic pipes) and violations during their installation - kinks, slopes. However, this shortcoming is revealed quite quickly after the start of operation, and it will not be possible to eliminate it on your own.

- In older houses, the cause of the blockage may be cast iron sewer pipes. Over time, corrosion appears on their inner walls, they become uneven with a strong coating of rust. In such places, and this is most often the section of pipe from the sink to the bathtub outlet, blockage is common.

- Lack of proper care and preventive cleaning of pipes.

If you notice that an unpleasant odor has appeared from the sink in the kitchen or in the bathtub, the rate of water flow through the drain has decreased, or the rise of water in the toilet bowl is often noticeable after flushing - it’s time to take action before the problem goes too far and you completely lose the ability to use them.

Manufacturing of polymer-sand rings

The raw material for the manufacture of such products is a composite material with the addition of sand filler. A composite is a type of plastic that is endowed with various properties using a variety of additives.

The instructions, according to which well rings are made from this raw material, provide for their creation by pressing under high temperature conditions.

During the manufacturing process, all powdered components are mixed under high pressure. The resulting solution is baked, transforming into low-porosity and high-strength sand-polymer rings for wells.

Polymer ring for a well

Resistance to aggressive substances

Together with water from the ground, aggressive substances reach the surface of the wells, destroying the structure of concrete, and if the well is a sewer, then the reactions of biomass decomposition will “spoil” it from the inside. To make these processes weaker, reinforced concrete rings are lubricated with special antiseptics and waterproofing mastics.

The polymer product is not afraid of aggressive environments. The composite material does not react with substances, therefore it is not afraid of salts, acids and alkalis and does not require additional processing.

Definition and purpose of plastic sewer rings

Construction of a plastic sewer well

Products made from various plastics are used for household needs. Of these they install:

- drinking water tanks, into which water is pumped using a pump;

- wells, in the base of which a device is installed - a thrower, with holes for water outlet;

- absorption or drainage structures, a filter layer of sand and crushed stone is poured onto their bottom;

- rainwater containers;

- chambers for placing energy cables, couplings and fiber optic equipment;

- inspection sewer wells, which are installed in places of branches, turns, changes in slopes and diameters;

- settling tanks.

Elements made of polymers are widely used in the construction of septic tanks and drainage systems, as they are durable, elastic and are not a source of environmental pollution. All products are manufactured in accordance with GOST. Technical specifications depend on intended use. To prevent the elements from deforming under soil pressure, they have stiffening ribs on the outside. Various additives make the plastic resistant to negative temperatures.

Plastic rings are divided into several types, depending on service options:

- examination rooms;

- inspection;

- operational;

- served.

External waterproofing

The main purpose is to prevent negative environmental impacts. The most convenient implementation is when similar processing is used while laying the rings. Otherwise, you will then have to manually dig out the finished trunk. Inspection and sewer wells are completely exposed. For drinking water you need 50 centimeters from the water level mark. Work is carried out at an air temperature of +5 degrees. A caisson for a well requires the same conditions.

Materials are applied only to dry substrates, then everything will stick well. If the well is operational, it must first be drained. In any case, the outer walls are cleaned of dirt and dust, and any defects on the surface.

A separate stage is impregnation using a primer. It depends on the type of well which brand should be used in a particular case. And what kind of caisson is being installed for the well.

Leveling the outer surface of the rings and laying waterproofing are the last stages. External seams are also covered with additional materials. The rings are covered with earth on top when the products are completely dry.

Prices

The price for a complete set of wells consists of the cost of segments to achieve a given depth, a hatch and a ring. The overall cost is significantly influenced by the version of the ground part. Therefore, to present the overall picture, let’s consider the prices for segments of the underground part of the well:

| City | Company | Price, rub/piece |

| Stupino | Titanium | 1550 |

| Ulyanovsk | Incom | 880 |

| Cheboksary | Gaztrubkomplekt | 780 |

| Naberezhnye Chelny | Niguez | 1200 |

| Moscow | IP Nikishkin | 940 |

As can be seen from the table, prices in different cities of our country differ. Another factor influencing the cost of the product is the use of recycled plastic, which helps to significantly save on raw materials.

Installation and connection

The process does not involve complex technological steps. It is quite possible to do the work yourself, without involving specialists. CM. below in the video. Thus, the installation of set rings for a well made of polymer sand is carried out in the following sequence:

- At the first stage, a pit is dug to install the structure and lay water supply or other communications. The depth of the trench is below the soil freezing level.

- A sand cushion 200 mm thick is made. The poured sand is carefully compacted, and a layer of concrete up to 300 mm is poured on top.

- After the concrete has hardened, the bottom of the well is installed.

- Before installing the ring, all joints are treated with a special sealant and mastic.

- As you progress, holes are drilled for the outlet/input of water supply or sewerage pipes.

- Each pipe outlet at the cut hole is sealed with a rubber seal and sealant.

- Water supply is connected.

- Finally, a top ring with a hole for a lid or hatch is installed.

- After completion of the work, the empty space is filled with soil and compacted around the entire perimeter.

Installation work

Polymer floors

The process of installing polymer wells begins with digging a pit for the structure and a trench for the pipeline. When calculating the depth of the pit, you should take into account the need to fill in a layer of sand with a layer of 20 cm and pour concrete with an approximate thickness of 30 cm. The trench for the water supply should be located at a depth below freezing of the soil, so that during the cold season there are no difficulties with supplying water to the house.

The bottom of the polymer well is installed on the prepared concrete base, the joints of which must be coated with bitumen mastic in advance. Next, the rings are installed. Their joints also need to be coated with mastic to improve the sealing properties.

A hole is drilled in the ring located at the level of the pipeline trench, lubricated with bitumen, and sealed with a rubber seal. After connecting the pipes and laying all the rings, install the neck and hatch of the well. At the end, the structure is backfilled and compacted with earth or sand. If the soil on the site is unstable, then for these purposes it is better to use a mixture of sand and cement.

Polymer sand structures can be used not only for the construction of drinking wells, but also for inspection, sewer, and drainage wells. In addition, due to the tightness of the reservoir created by fastening polymer rings, it is often used for telephone communications equipment and electrical networks.

➤

Concrete rings for sewerage: sizes, prices and varieties

In private and suburban construction, sewer systems based on concrete rings are often used. This type of sewage system is considered one of the most economical. After all, the price of concrete rings for sewerage is low, and the process of their installation does not require a lot of time. As a result, the owner of a summer cottage has the opportunity to create comfortable conditions for living outside the city.

Concrete ring with a solid bottom

Along with bricks and polymer rings, concrete elements are also used for the construction of sewage systems in the country without pumping. Each of these materials is characterized by its own advantages and disadvantages, however, concrete structures significantly exceed the parameters of other system options.

Brick is less durable and requires a significant amount of time to make masonry, in contrast to ready-made elements that just need to be placed on the bottom of the pit and fixed. In addition, it is extremely difficult to make deep wells based on brickwork. The turnkey price of a sewer system made of concrete rings is not much higher than the cost of manufacturing a brick system. Taking into account the simplicity of installation work and the minimal time spent, such a small overpayment is completely justified.

Prices for turnkey installation of sewerage from concrete rings:

| Number of rings | Capacity, m³ | Number of consumers | price, rub. |

| 3+2 | 3,5 | 1-3 | 35990 |

| 3+3 | 4,2 | 2-4 | 39990 |

| 4+2 | 4,2 | 3-4 | 39900 |

| 4+3 | 4,9 | 3-5 | 45990 |

| 4+4 | 5,6 | 4-6 | 49900 |

| 3+3+3 | 6,3 | 4-6 | 59990 |

| Installation of a septic tank in areas with high groundwater levels | |||

| 2+2 | 2,8 | 1-2 | 30990 |

| 2+2+2 | 4,2 | 3-4 | 43990 |

Advantages and disadvantages of using concrete wells for sewerage

Many summer residents prefer to buy concrete rings for sewerage for arranging a system on their summer cottage; the prices of these products are far from the only advantage that confirms the benefits of such a purchase.

Advantages of concrete structures:

- the possibility of installation in areas with any type of soil (due to the increased safety factor, concrete rings are able to withstand the natural pressure that is formed during the displacement of groundwater or seasonal movement of soil);

- it is possible to use any materials to perform waterproofing;

Concrete ring for sewerage with stairs

- even if you plan to do the installation work yourself, this process will not take too much time;

- due to the smooth internal surface, the speed and quality of cleaning concrete wells increases;

- the material is more accessible than brick or stone;

- long service life without the need for repair work.

A wide variety of sizes and prices of concrete rings for sewerage allows you to create septic tanks of any capacity and depth. This type of material is highly hygroscopic, so contaminated wastewater can partially seep through the walls into the surrounding soil. However, this problem can be easily solved with waterproofing.

Main types and general sizes of sewer rings

There are two types of concrete products for sale for sewer construction:

- Additional (from 670 rub.).

- Wall (from 990 rub.).

Wall sewer rings

Wall-type elements are used to form the neck of the structure. Additional product options have an expanded range of sizes, and non-standard ones. They are used in cases where the height of storage tanks according to the project cannot be formed from elements with standard dimensions. With the help of additional rings, you can adjust the height of any septic tank structure.

Concrete rings used for the construction of country sewer systems are elements of a regular round shape. The internal diameter of the products ranges from 70 to 200 cm. The standard wall thickness is 70-100 microns. Most often, for the manufacture of drainage pits and country septic tanks, a size of 1-1.5 m is used; the price of concrete rings of this diameter is 1500-2500 rubles. per product.

To make rings, manufacturers use metal reinforcement and grades of concrete with different characteristics. Metal, as a reinforcing component, increases the strength of products and reliability. In addition, the possibility of stretching a structure made of rings is eliminated. In turn, concrete provides corrosion protection to the metal. As a result, the septic tank design is not subject to deformation changes under the influence of compressive loads.

Dimensions of wall concrete rings

Specifications

Thanks to the selected composition of the components of the polymer-sand mixture, excellent technical characteristics are achieved. Up to 80% of the mixture is sand, which ensures rigidity and strength of the products. The plastic is used as a binder and, when hardened, forms a waterproof monolith.

In terms of technical parameters, polymer rings for wells are significantly superior to reinforced concrete rings. The table shows a comparison of their main characteristics:

| Parameter | Polymer sand rings | Reinforced concrete rings |

| Density, kg/m3 | before 1750 | up to 2400 |

| Bending strength, MPa | 17-25 | 6-7 |

| Compressive strength, MPa | 17-18 | 40-50 |

| Frost resistance, number of cycles | over 500 | up to 350 |

| Water absorption, mass% | 0,15 | up to 4.5 |

| Abrasion, kg/cm2 | 0,05-0,1 | 0,3-0,4 |

The table shows that composite rings are superior to reinforced concrete in terms of strength, water resistance, and frost resistance. They resist abrasion better and weigh much less. In addition, polymer sand wells are characterized by increased chemical resistance. They easily tolerate the effects of aggressive substances, including those contained in domestic and industrial sewage. They can be washed using any detergent.

Warranty period

Manufacturers provide a guarantee of about 50 years for reinforced concrete products, but indicate that these parameters relate only to basic technical characteristics. Those. the ring will definitely not fall apart or become thinner. But they cannot give a guarantee for the tightness of the joints, so even the most durable factory wells can silt up in a couple of years if the installation was carried out incorrectly.

With polymer sand wells such incidents are excluded. Therefore, manufacturers provide a guarantee of up to 100 years, although plastics in nature decompose over 400 years, and the sand included in the raw material is eternal.

Source: aqua-rmnt.com/kanalizaciya/kanal-kolodcy/polimerpeschanyj-kolodec.html

Parameters of modern plastic rings for wells: sizes, prices

Examples with exact numbers are given below in the market overview. However, we can note general factors that have a significant impact on the price increase:

- Rings for wells, the sizes of which do not match the standard parameters, are more expensive. Some companies create such products to order.

- The choice of material matters. The cost increases with the addition of special components that improve resistance to high temperatures and other external influences.

- To increase strength, the wall thickness is increased and additional stiffeners are installed. The walls are created using several different polymers. Air chambers are made inside for thermal insulation. Design complications also increase the cost.

Diameters of plastic rings for wells

If the advertisement states “plastic well 800”, then we are talking about the internal diameter. There are exceptions, but there is no point in creating excessively large holes, so 800, 900, 950, 1000, 1200 mm are usually used. Holes that are too small are difficult to maintain.

The method of construction and design features, as well as the geological features of the site, are of certain importance. The typical method is to dig a shaft by hand. In dense soils, the integrity of the walls is maintained at great depths. After completing the excavation work, a backfill of crushed stone is made at the bottom. Plastic well rings are installed sequentially and twisted. The free gap between the outer surface and the walls of the shaft is filled with sand or other granular material. A lid, a “house” and a caisson with equipment are installed on top.

In this option, it is not difficult to calculate what the width of the shaft should be. The external dimensions of the pipe should be taken into account. Depending on the material and design, the wall thickness can range from 10 to 20 mm or more. The outer diameter of the well ring changes accordingly: 810-820, 910-920 mm, etc.

Similar calculations are also used when building in loose soil. But to ensure the stability of the walls, they dig a shaft no deeper than a meter. They lower a plastic well ring there. Carefully select the soil, gradually lowering this fastener. The following structural components are screwed in as necessary. In this case, products with a large internal diameter are used to facilitate work operations.

Such a source can be restored

To reduce costs and prevent problems from occurring after pumping out the old water, only the old backfill is replaced. If necessary, make a recess. Plastic well rings are inserted inside. The gap to the walls is filled with bulk material. Here, the diameter of the elements is determined by the parameters of the existing structure. For this reason, rings of 600-800 mm are used.

Height of plastic rings

There is a wide selection from manufacturers. As a rule, the height of the ring for a well is from 40 to 150 cm. At the maximum size, the weight of the product does not exceed 30-40 kg, which allows you to perform work alone, without the use of cranes and other special equipment. Larger items are more difficult to transport.

It should be noted that some plastic well rings (from spiral pipes, for example) can be cut to the desired length if the need arises. To fasten joints, not only sealants are used, but also heat treatment of the seams and heat-shrink tape. These are relatively simple technologies that are not accompanied by excessive difficulties.

Any change in the height of the plastic well ring is a significant advantage. For comparison, below is a table with the parameters of standard concrete products. This variety is determined, in part, by the fact that it will not be possible to adjust the sizes.

| Parameter | Value, mm | |||||||

| Wall thickness | 12 | 8 | 8 | 8 | 8 | 10 | 8 | 8 |

| Height | 7 | 10 | 15 | 35 | 50 | 60 | 90 | 100 |

Area of use

Plastic wells have many advantages. The most important thing is that they are hermetically sealed, do not enter into a chemical reaction with the environment, and slowly change their properties. Light weight adds an advantage (it can also be a disadvantage). But installing plastic rings for a well is not always easy and they cost a lot.

Shape and size are selected depending on the purpose

Polymer wells can be used for various needs - from storing drinking water to organizing drainage and sewerage. Special plastic is used and its characteristics are selected for the area of application. So, here's where you can use plastic well rings:

- Storm drainage.

- Drainage system: inspection;

- differential;

- prefabricated

Sewerage (storage and filtration wells). Plumbing systems. For the construction of cable ducts. Plastic cable wells allow you to gain access to power and communication cables laid in the ground.

Polymer sand well ring h-200mm d-1000mm

The principle of assembling a sealed plastic well. In addition to the rings, the kit includes a bottom, cone and hatch

What are the advantages of using plastic for wells? First, moisture in any form does not get inside the solid body. This is true for drinking water

For wastewater collection, this is also important, as is the fact that the contents will not leak into the surrounding soil in any form. If we talk about stormwater and drainage, the important thing here is that the walls of the container are smooth and easy to clean

And one more thing - plastic does not react with either the contents or the environment.

To organize sewerage on the site, it is more convenient to use a prefabricated plastic sewer well

Another area where plastic well rings can be useful is restoration. The task is difficult and dangerous. Working in a dilapidated well, when the logs are almost rotten or the concrete rings have moved, is the height of recklessness. It is much safer and easier to restore it using an insert of food grade plastic rings. The disadvantage of this solution is the high price and reduction in useful volume. After all, the insert should be of a smaller diameter, plus they are made with stiffeners.

Customer Reviews

Consumer opinions about these products can be found on the forums using the links below:

- forumhouse.ru;

- forumhouse.ru 2;

- seti.guru;

Wells of this type are controversial among their users.

In the reviews, almost everyone notes the ease of installation.

Negative reviews are the result of purchasing handicraft rings .

You must understand that good production equipment costs money; only large companies can afford it.

Decent technological capabilities presuppose the quality of the finished product. The strength of the locking connection also depends on the capabilities of industrial machines. Therefore, here it is worth separating bona fide large manufacturers and small companies.

Consumers are also wary of using recycled plastic drinking water wells . The concern is caused by the possibility of foreign chemicals entering. In this case, it is more rational to install wells made from pure primary raw materials for drinking water.

The use of recycled materials is possible for sewer and distribution wells, because the recycled polymer does not lose chemical resistance, and is also resistant to aggressive environments and in this case does not have a negative effect on humans.

A limitation for the installation of polymer sand wells may be the characteristics of the soil . High layers of groundwater and intense horizontal soil movements are undesirable conditions for laying wells made of polymer sand.

Deepening an existing well

Water flow is constantly changing, and not always for the better. If there is not enough water in the well, they try to deepen it. This is easier to do with plastic rings.

You can get rid of leaks in the drinking well by installing a plastic tab

Made of concrete, log

Plastic rings can even be used to deepen a well made of concrete rings. We remove the soil only in the center so that the concrete walls do not move down. They remain at the same depth. We deepen only the middle. The size of the “middle” should be larger than the outer dimensions of the repair rings. The disadvantage of this method is that the rings need a smaller diameter. That is, again, the water reserves will be smaller, but there is no need to dig a new well.

We raise the soil to the surface until there is sufficient water flow. Next, we clean the bottom, lay a layer of geotextile, and place its edges on the walls. We pour crushed stone, level it, and place the rings of the required height assembled on the surface on this pillow. Next, we install a bottom filter at the bottom, as in a regular well.

Here's an idea

Since plastic is lighter than water, the installed repair plastic rings must be weighted. For this purpose, any load is suitable, contact with which is not dangerous for water. Ideally, stainless steel chocks and large gravel boulders. This load can be removed in 6-9 months - during this time the soil will “squeeze” the rings and they will no longer rise under any conditions.

This method of deepening a well is safer, but it is not ideal. The result is that the water will be in the plastic insert. It's a little narrower, but it's better than nothing. Everything goes much easier than when trying to add concrete rings. They must be placed on top, and if the existing ones settle, it is unclear how the entire column will behave.

How to make a plastic well deeper

If your well is made of plastic, it is usually of small diameter and working inside is difficult and inconvenient. If you need to make it deeper, the plastic sleeve is taken out of the hole. Next, you will have to clean out the crushed stone that has fallen to the bottom, which filled the gap between the walls of the pit and the sleeve. Then they remove the bottom filter and begin to remove the soil to the required depth. In the future, the actions “inside” are no different: we remove the soil until the amount of incoming water becomes sufficient.

Polymer sand rings are used for sewerage and rainwater collection

On the surface, the required number of plastic rings are added to the finished body and the whole thing is installed in the shaft on a bed of crushed stone. The next steps are already known: we make a bottom filter, pour gravel between the walls. In general, not too difficult, apart from the ground work.

The disadvantage of this method is that if the soil is loose, this trick will not work. By removing the plastic sleeve from the well, you will deprive the wall of support. This can lead to complete or partial shedding. In this case, it may be more justified to install a well.

Soil development

It is recommended to dig one pit, no matter what type of septic tank is chosen. If the septic tank consists of several chambers, then they also dig a common pit, just large enough to accommodate all the planned chambers

You can dig manually, or you can call specialized equipment. The first option is cheaper. Suitable for those who want to save money. You can dig yourself, or you can hire one or more people to do this work. The second option is quite expensive. But its advantage is that if in the first case it would take at least one day to dig a pit, then here it will take 2-3 hours, no more.

Within the framework of the law, as already written above, a septic tank of any type must necessarily have a concrete base and waterproofing in order to avoid seepage or leakage of fractions and wastewater into the ground. Therefore, the order of work is as follows. The bottom of the cesspool must be compacted. Then a layer of roofing material is laid - this is waterproofing. And a concrete pedestal is poured on top of it.

But the location of the filtration well, on the contrary, does not need to be compacted. There must be free soil here so that the liquid can easily seep down. Part of the soil is replaced with crushed stone, forming a so-called cushion at least half a meter high. The pillow acts as a filter that performs two functions. On the one hand, it allows the water to drain out, and on the other hand, it allows it to freely go into the ground.

At the same time, a trench is being dug for a sewer pipe that runs from the house to the septic tank. The depth of the trench should be greater than the freezing depth in a particular area of the country. If for some reason the trench is dug to a shallower depth, then a heating cable is laid, thanks to which the drains in the pipe will not freeze

It is important to consider that the pipe is laid at a slope of 2 cm per meter of pipe. If the slope is not made, then the drains will not flow freely, which means the entire system will not function

If there is a road above the place where the pipe is laid where cars drive, then the pipe must be placed in a sleeve. The sleeve can be concrete or metal. This measure is necessary to avoid mixing the pipe, since mixing it can lead to damage to the sewerage system.

Wells made of sand-polymer rings

Rings are the parts from which, like a constructor, a well is assembled. In addition to them, a hatch with a cover and a neck adapter in the form of a cone tapering upward are used for its construction. If the container must be completely sealed, then the kit also includes a bottom.

Prefabricated well design

Installation is simple and easy to do with your own hands: the individual elements are simply attached to each other using grooves and ridges on the end part. The assembled structure can be used as a water supply, sewer, drainage, storm, inspection and any other type of well. It allows you to protect underground equipment of electrical and telephone networks from moisture. In a word, the scope of application of polymer sand wells is not limited.

Exploitation

Manufacturers provide a hundred-year guarantee on products made from polymer sand. Moreover, this applies to all joints of the well, the tightness of which is also guaranteed thanks to a special joining technology (groove-protrusion). The tightness of the container ensures absolute dryness. Therefore, wells are used for laying telephone and electrical cables.

Maintenance necessarily includes periodic pumping out of liquid (if the well is used as a storage tank).

Which manufacturer should you prefer?

Modern manufacturers offer rings and other elements for wells in a wide variety. As a rule, all products are manufactured in accordance with the standards regulated by GOST and SNiP. But product prices may vary, as can the range.

The choice always remains with the client, who must pay attention to the quality of the elements themselves: external inspection, the presence of certificates confirming compliance with production requirements, availability of equipment and compliance of the product with the specified technical characteristics. Today, about 250 companies produce rings and other products in Russia; proven and reliable ones are presented below

Today, about 250 companies produce rings and other products in Russia; proven and reliable ones are presented below.

Well-established manufacturers of concrete rings on the market:

- “Plant of Industrial Construction Parts” has been operating on the market for more than 45 years, a large manufacturer of reinforced concrete products in the Tyumen region. We have our own accredited construction laboratory that monitors product quality.

- "MasterStroy" - operates near Moscow in Voznesensk, despite the fact that it specializes in the sale of bulk cement, and also produces pressure pipes and reinforced concrete rings.

- "MonolitStroy" - the company operates in the Moscow region, producing and selling concrete products since 2007. The range includes composite and bridge piles, bottom slabs, FBS, wall rings, well covers, etc.

- "Trading Company Vira" - the production line of the enterprise is located in St. Petersburg. The company produces non-pressure pipes and reinforced concrete rings. Products are checked very carefully through a multi-stage control process.

- GazoBloki is a company from Voronezh that produces ready-mixed concrete, facing and sand-lime bricks, as well as a range of sizes for concrete rings and additional elements.

A large number of companies supply reinforced concrete rings throughout the country. The above guarantee compliance with all standards and declared properties, but in any case, everything must be checked very carefully when purchasing, focusing on calculations and the project.

Flaws

When choosing reinforced concrete rings, the dimensions of which make such products universal, you should also consider their disadvantages. There are few of them, but it’s worth familiarizing yourself with them before purchasing.

The presented products are characterized by significant weight. Some rings can weigh around 2500 kg. Therefore, installation will require the use of special equipment (and it is not always convenient to use on site). In addition to special equipment, you will need to resort to the help of several workers. This is also a significant drawback.

Although the cost of concrete rings is small, transporting them is not cheap. After all, such a heavy product must be loaded and removed from the car. To do this you have to hire movers. However, these disadvantages pale in comparison to the numerous advantages.

Features of polymer sand rings

The desire to build a well that will not need repair or reconstruction for many years is quite understandable. But to implement it, it is necessary to carefully think through and design the structure and not skimp on materials and professional installation work. The price of the described products is higher than that of analogues made of reinforced concrete, but it justifies itself.

Preparation method

In the manufacture of well rings, polymers (plastic with various additives that give the material the required properties) and sand are used. All components enter production in powder form. They are mixed in certain proportions, after which they are pressed under pressure and exposed to high temperatures.

Mixing sand and polymer powder

As a result of hot pressing, sand-polymer rings for wells acquire the desired shape and a durable, low-porosity structure.

Pigments added to the mass allow you to obtain products of different colors

Do-it-yourself concreting of a mine

The easiest way for a beginner to work is with concrete rings. Apart from physical fitness, no other specialized knowledge or skills are required. It is much more difficult to install a monolithic structure. If it is not possible to use special equipment, you can concrete the well using formwork.

Monolithic walls have a number of advantages over rings. They are more hygienic and durable. The walls are smoother and, due to the lack of joints, more airtight. Cleaning is easier and disinfection is more effective.

To install a monolithic concrete well, additional materials will be required. They are easy to find in any hardware store and the price is quite affordable.

In order for the well structure to last as long as possible, it is important to choose the right materials

- The material must be purchased before construction; improper storage conditions can lead to a deterioration in the quality of the material.

- Portland cement grade 400 has proven itself well.

- Cement is mixed with sand (quartz is preferred), gravel and crushed stone, all of which is mixed in water.

- River and sea sand shows the best adhesion to cement. Mountain sand contains more clay.

- Gravel is also chosen from river or sea gravel, since it contains rough stones.

- It is strictly not recommended to use crushed brick.