What does elastic putty consist of?

Elastic putty consists of a number of components. These are mainly polymer resins and fiberglass. Acrylic elastic putty retains all the properties of standard putty. The difference is increased adhesive abilities. The elasticity of this material practically eliminates shrinkage of the material and the formation of cracks. On the market you can see elastic putty based on silicone. A different composition from the previous one allows you to create a grainy surface. The first option makes the surface smooth.

The elastic putty is white with a milky tint. The consistency is viscous and resembles a paste. For some manufacturers, the color of elastic putty may be gray.

Compound

Manufacturers add the following components to the silicone mixture:

- liquid potassium glass;

- silicone resins;

- marble chips;

- titanium dioxide.

Acrylic putty is made on the basis of:

- water;

- acrylates;

- plasticizers;

- modifiers.

Preparing to work with elastic putty

To work you will need:

- Elastic putty. The quantity is calculated by surface area;

- Tools for work. Spatula, trowel, trowel, reinforcing mesh;

- Prepared work surface. The wall must be cleaned of dust and dirt. If they have deep revivals, they must be eliminated. For better adhesion, a primer is applied.

How to work with elastic putty

Elastic putty is sold ready-made. It is applied with specialized tools. If elastic putty is used in hard-to-reach places or corners, use reinforcing mesh. When applying, a certain temperature must be maintained. From 4 to 32 degrees Celsius.

If something doesn’t work out for you, you can wash off the putty layer with water. This should be done until it dries. After drying, the surface can also be adjusted. Dried putty can be sanded. This way you will get rid of roughness and excess.

Automotive putty. How to apply it correctly?

Rare body repairs are completed without putty. Even in garage repair conditions, at an amateur level. Below we will consider the general aspects of using automotive putty.

How to divorce?

Automotive putties are sold in two-component form: putty mass (or base) and hardener. The base is a plastic substance that has good adhesion and pliability under external mechanical influence. The hardener is used to convert liquid putty into a solid mass.

The vast majority of modern putties are diluted according to the same scheme: 2-4 grams of hardener per 100 grams of putty. In this case, the choice of the exact proportion depends on weather conditions and requirements for hardening speed. In dry, hot weather, 2 grams is enough. If the weather is humid and cool, or accelerated curing is required, the proportion can be increased to 4-5 grams per 0.1 kg portion of base.

Mix the base with the hardener slowly, with soft plastic movements and always by hand. Do not beat car putty using mechanized means. This can saturate it with air, which will weaken the frozen layer on the workpiece.

If, after adding the hardener and mixing, the putty has acquired a noticeable reddish tint, you should not use it. It's better to prepare a new portion. Excess hardener may cause a red tint to appear through the paint.

How long does it take for car putty with hardener to dry?

The drying speed of automotive putty is influenced by many factors:

- brand of putty;

- amount of hardener;

- ambient temperature;

- air humidity;

- etc.

On average, one layer of putty dries for about 20 minutes until it gains strength sufficient for abrasive processing. However, when applying several layers, the drying time can be reduced. The final strength is gained in 2-6 hours.

You can also speed up the polymerization process of the putty with a hairdryer or incandescent lamp. But there is one caveat here: it is categorically impossible to dry the first layer artificially, as this can subsequently lead to its cracking and peeling. And subsequent layers should sit for at least 10 minutes after application without external influences. Only after the initial polymerization has taken place is the putty allowed to dry a little.

How long does it take for car putty with fiberglass to dry?

Fiberglass fillers are typically used to smooth out deep uneven surfaces. They have high tensile strength and resist cracking well. Therefore, even a thick layer of putty with glass, unlike other types, is less likely to peel off from the treated surface.

Due to thicker layers, putty with glass requires longer drying. Different manufacturers talk about different hardening speeds for their products. But on average, bodybuilders can withstand fiberglass fillers 50% longer.

How to apply car putty correctly?

There are simply no universal answers to the question of how to putty correctly. Each master works in his own style. However, there are a few general recommendations that most bodybuilders adhere to.

- Work out in advance the question of which putty is best to eliminate the defect in your specific case.

- You need to prepare as much putty at a time as is required to treat one element or one defect. The hardener will turn the putty into a wax-like mass unsuitable for application in 5-7 minutes.

- Choose a spatula that is suitable for a particular case. There is no point in using a large wide spatula to stretch an area 3 times smaller than the spatula itself. The same applies to large areas of treatment: you should not try to pull them out with small spatulas.

- There is no need to try to immediately bring the surface to the ideal using only spatulas. The main thing is to fill the defective area well and carefully. And micro-irregularities and “snot” will be removed with sandpaper.

What kind of material is this

Elastic putty is a synthetic mixture that contains a polymer resin and various types of fillers.

- strength;

- durability;

- protection against mold and mildew;

- does not crack;

- provides the best performance characteristics.

- ready-made mixtures;

- dry powdery.

Types of elastic putties

There are special compositions for finishing wooden surfaces on sale. The product can be applied to furniture, frames, parquet floors, door frames and other types of structures.

Working with material

Before starting application, prepare the necessary tools and materials.

Preparing for work

An important stage of finishing is preparing the surface: remove dust, dirt, and thoroughly dry the wall. This will ensure a strong connection of the new layer with the base and reduce the risk of cracks.

After this, they begin priming the surface. The mixture creates a transparent and vapor-permeable coating, increases adhesion and ensures proper drying of the new layer. The primer contains resins that bind the loose elements of the base and strengthen its structure.

After the primer has dried, begin applying elastic putty.

How to work with putty

The finished mixture can be applied to the wall or ceiling immediately after opening the package. Powdered putty is mixed with water, following the manufacturer's instructions. Most often, about 0.35 liters of water are consumed per 1 kg of substance.

After combining the ingredients and obtaining the required consistency, wait a few minutes (the mixture is used within an hour). Immediately before application, the mass is mixed again. The elastic material can be applied by hand or by machine.

Putty for sealing cracks

After preparing the solution, finishing begins. Apply a layer 2 mm thick. The room temperature should not be lower than +5°C and not higher than +30°C. The drying time of the putty depends on air humidity, type of composition and other factors. Further work is carried out approximately 48 hours after applying the mixture.

How to use putty materials

Let's consider the main areas of application of this material. This is the elimination of defects on a wooden floor, sealing various kinds of cracks, imitation of wood texture on the surface.

Putty for wooden floors

Putty for wooden floors must contain components that will prevent the material from quickly wearing out from mechanical stress.

If you try to save money, then after 2-3 years the sealed surface will deteriorate and crack

Aqueous, paste-like and gel-like compositions are suitable for the floor. If the product contains fiber fiber, then the durability of the finished coating is guaranteed.

Nitro-based putty will also be stable. In the composition you need to look for cellulose ether components, acetone, resins. Products containing wood flour have a high level of adhesion to any type of wood. Nitro putties, for all their positive qualities, have a rather pungent odor.

Homemade compounds mixed with wood flour ideally fill cracks and seams on wooden floors

Wood putty: what to use to fill cracks

A small gap in a wooden floor is sealed either with a putty of a suitable color, or with a composition of any shade, followed by priming and painting the floor.

Cracks 3-4 mm in size are sealed with acrylic products; larger defects should not be touched, as the finished material will crumble and fall out.

The solvent-based product is well suited for sealing cracks up to 1 cm, and can even eliminate defects on heated floors.

Oil compositions for eliminating narrow cracks should be mixed with chalk, and for wide flaws - with wood dust.

Imitation of wood from putty as a way to decorate the surface

To make imitation wood, a number of tools are required. You need to get a palette knife, a textured roller, a roller with a picture of a wood cut, several types of rubber spatula, and a stencil.

Acrylic, gypsum and silicone bases are suitable for interior finishing.

Beautiful imitation wood made of putty

Cost of putty

Other formulations

Putty for walls Stuc-O-Flex (16 thousand rubles / 19 l) is intended for leveling surfaces and sealing joints and cracks. Suitable for indoor and outdoor use. Advantages of the product: the mixture is easy to work with, adheres well to rough and porous surfaces (even without the use of a primer), and forms a smooth surface. The putty can be applied to gypsum, concrete, brick, plasterboard, cement, wood and other coatings.

Presto putty (RUB 2500-2800/12 l) is a two-component mixture of polyester resins and various minerals. Suitable for repairing small and medium cracks and various deformations. The product can be applied to plastic, wood, metal and concrete surfaces.

- elastic;

- soft;

- pasty;

- forms an even layer;

- easy to sand;

- dries quickly;

- has good adhesion.

- density: 1.89 g/dm³;

- heat resistance: 120°C.

To prepare the solution, 2-4% hardener is required.

Source

Liquid putty for car body

- Characteristic

- Manufacturers

Putty is used as a base to correct uneven spots and dents on the car and prepare its surface for applying primer. Its liquid version is a composition that can restore the ideal smoothness of the body.

After application with a spray gun, the product is dried under ultraviolet light and then sanded with fine-grained sandpaper.

Applying liquid putty to a car using a spray gun

Using this mixture has the following advantages:

- masks even deep dents and paint chips;

- fills micropores and small cracks, preventing the development of corrosion;

- prevents peeling of the paint layer applied on top, which means it saves money and effort that you will need during painting work to improve your car.

The adhesion of the mixture determines the final appearance of the car, however, liquid filling compounds are characterized by increased adhesion to both metals (steel, aluminum) and various types of plastic. Before applying the product, make sure that the temperature conditions correspond to those indicated on the package. Also note that putties, paints and primers purchased from the same manufacturer often have better adhesion and work well together.

Applying liquid putty to the car body

Characteristic

Mostly on the market you can find two-component putty. It is applied to different types of materials and is based on polyesters or acrylic resins, and is supplemented with various fillers to give strength and quick drying.

A two-component composition is sold complete with an activator, which is added in a ratio of 3 to 7% of the base and ensures hardening of the material. Excess or lack of activator makes the polymerization process impossible and reduces the effectiveness of the applied base.

The mixture should be applied within a few minutes (up to half an hour) as it will dry extremely quickly. Polyester mixtures shrink less than epoxy mixtures, which, among other things, are quite difficult to sand.

Manufacturers

On the market you can buy putty for your car from the following manufacturers:

- Carfit . This two-component composition is used on passenger cars and other types of cars. Creates a non-porous surface when drying quickly. Apply a layer of up to 35 microns. Cannot be applied over epoxy primer. Mixes with hardener in a ratio of 3.5:100 and dries up to 5 hours;

Liquid putty CARFit Spray

- A80 with Roberlo activator . It has a good ability to fill microcracks and finish the body to a perfectly smooth state. It is characterized by the absence of spreading and is often used when applied to welding seams. This material must be processed with a filler that is appropriate in technology;

A-80 Liquid putty with catalyst Roberlo, 1 l

- 791R . A two-component composition based on peroxide resins is intended for finishing the surface. A peroxide hardener is included in the kit. It grinds well and is applied to steel, creating a film with a high thickness and a uniform structure. It is not recommended to use putty on the surface of a car where a one-component or etching primer has been applied. It is also not recommended to apply thermoplastic paints or primers on top of such a base;

Spray putty (liquid) DuPont 799R + 791R

- Novol . It is applied using a spray gun to fill all sorts of imperfections in the car. Serves as an excellent insulator for metal, preventing moisture penetration. Diluted with 6 or 7% hardener. Applicable to metal and plastic and easy to sand;

NOVOL Spray putty (liquid) 1.2 kg + hardener

- Sprint . This liquid putty for metal based on polyesters quickly undergoes the polymerization process even when applied in thick layers. Helps fill large and microscopic pores, leveling hard-to-reach car surfaces. Another advantage of the mixture is thixotropy (no spreading when applied to vertical surfaces). High elasticity allows for easy sanding. It is recommended to use this mixture when filling a large surface;

Liquid putty Sprint 2K HS Spray

- Chamaleon . It has good filler properties, elasticity, and less weight compared to conventional putty. Dries up to 5 hours naturally and up to 1 hour at 60 degrees.

CHAMALEON 407 liquid putty for cars

Elastic putty for seams

Elastic putty is a composition created specifically for work when preparing internal surfaces for applying the finishing coating.

It is indispensable when repairing foundations that are characterized by mobility and the ability to deform. The main condition for performing quality work is not to use this composition as a leveling mixture on the outside of the building. This type of putty is widely used when filling joints between two different materials. For example, it can be used to fill seams and joints between metal and concrete, wood and brick.

Features of the composition

Elastic putty is used as a material that allows not only to efficiently hide joints between surfaces with different properties, but also to ensure a high level of strength of the top layer of coating.

After the composition hardens, a durable film is formed on its surface, and the inner layer retains its elasticity, withstanding the loads that arise when the structure deforms.

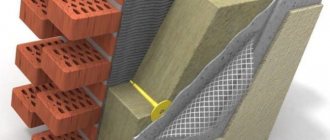

When constructing a thermal insulation layer, many craftsmen install polystyrene foam boards, and fill the seams between them with polyurethane foam. In most cases, puttying must be done before finishing.

The joints of polystyrene foam boards can be properly and reliably closed using elastic putty.

Modern manufacturers produce two types of such compositions, which differ from each other in their basis. A polymer is used as a base, on which the quality of the resulting surface depends.

Acrylic elastic putties are used to create a flat and absolutely smooth surface in preparation for painting or wallpapering.

Silicone - allows you to create a grainy, rough surface suitable for laying tiles.

Features of elastic putty:

- applied to all types of substrates;

- used when filling joints of various materials;

- has high elasticity.

It does not flow off the spatula and easily lays on the wall, providing a high level of moisture and vapor permeability. Most often, this material is used when working on wooden, concrete, and metal coatings, since it is in such conditions that elastic putty shows all its best qualities.

When choosing one or another composition, you should carefully study the recommendations and instructions for use. This is due to the fact that some products can be used at a certain temperature and humidity.

Universal formulations

Products that can be used both indoors and outdoors are less common. Typically, this quality characterizes plasters for concrete and brick. But in the case of wood, you can find worthy analogues. When choosing such compositions, you should pay attention to the presence of a water-repellent effect, high adhesion and strength. Universal putty for wood can be either oil-based or water-based - the main thing is that it does not crumble and is flexible. Another important quality of such solutions is the anti-frost effect, which prevents the coating from cracking in extreme cold conditions.

Preparation and execution of work

Careful surface preparation is carried out regardless of what kind of mixture will be applied. First of all, you need to remove all contaminants and get rid of dust. Of great importance in preparation is the high-quality filling of all detected cracks and cracks.

The deepest ones can be filled with polyurethane foam or cement-sand mixture. After hardening, excess foam is cut off with a stationery knife and priming begins.

When choosing a primer, it is necessary to pay attention to compositions that have a high level of penetrating ability and contain antiseptic substances. This will reliably protect the treated surface from mold and mildew.

The primer is applied in two layers. The drying time of the first one is from 2 to 4 hours; you can start puttying 12 hours after the formation of a thin and durable film.

On such a surface, the elastic putty is distributed evenly and laid down in a thin layer. This will not only enhance the adhesion of the putty to the surface, but also reduce material consumption, avoiding unnecessary material costs.

To perform the work, either a ready-made solution or a dry mixture can be selected. In any case, the composition should be thoroughly mixed before starting manipulations. Do not neglect this advice. Refusal of additional mixing will cause the loss of some qualities and main properties of the mixture.

Types of automotive putties and their application

Types of automotive putties and their application.

Good afternoon. In this article I will talk about the main types of automotive putties and their applications. Those. what they are for and how to work with them.

Since my practice is handicraft car repair, I do not use very expensive materials; mainly in stores in the Russian Federation, products of the Polish company NOVOL are presented; it is on the putties of this manufacturer that I will talk about the types of polyester putties and their use.

I agree - NOVOL is not the best product , but this particular manufacturer is everywhere.

Attention - when rubbing putty, be sure to use a respirator; if dust gets into your lungs, it can cause dangerous diseases!

Types and advantages of putty for cars

The procedure for leveling a car body consists of two main stages - filling and finishing. First, preliminary careful leveling of metal and plastic surfaces is carried out, filling in all irregularities and visible defects, then final leveling.

Based on the above, automotive putties are divided into two groups:

- Fillers - designed to fill visible defects, giving the car body element mechanical strength and hardness. Filling compounds have a coarse-grained structure, and therefore belong to the category of primary putties.

- Lapping pastes - pastes with a fine-grained structure, are used to give a smooth, even surface to previously leveled body elements.

The following types of putty are available on the market of modern materials for automotive repairs:

- Fiberglass. It has high mechanical strength and good filling ability. The paste is used to strengthen stretched areas of the body, eliminate deep defects, through cracks and areas of corrosion, places of metal rupture and other serious damage. It is applied only to hard areas and elements of the body, since when the vehicle is moving it can crack and burst due to vibration (on the hood, roof, middle part of the doors).

- Universal. Putty with high adhesion to various surfaces - steel, aluminum, galvanized, stainless steel, galvanized, fiberglass, and plastic. The high strength and uniformity of the paste allows it to be used to fill various defects and finish leveling the surface of a car body.

- Rude. Used to repair serious body damage. The high filling capacity of the composition is achieved due to the inclusion of metal shavings in the composition. Rough putty for cars gives minimal shrinkage, can be sanded and is highly resistant to temperature changes.

- Finish (thin). It has a fine-grained structure and is used at the last stage of body leveling to create a perfectly flat and smooth surface for painting.

- On plastic. Putty of increased elasticity, used on plastic elements of the car that are subject to vibration.

- Liquid. It is used at service stations and auto repair shops, since application requires the use of a special sprayer. Suitable for filling minor defects and damage - scratches, pores, unevenness, etc. When applied, it allows you to create a perfectly flat surface, which becomes highly rigid after 2-3 hours.

Composition and technical characteristics

Automotive putty is used to eliminate damage and unevenness on the surface of metal and plastic parts, so it must have a viscous consistency.

Features of the work

To prepare a high-quality solution from a dry mixture, you will need to strictly follow the manufacturer’s recommendations and the proportions specified in the instructions on the package.

First, cold water is poured into the container, and the dry composition is introduced into it in small portions. To obtain a solution, mix the components using a construction mixer or drill equipped with a special attachment. Its blades are installed so that during the mixing process the solution rises from bottom to top.

After the first mixing, the composition should sit for 10-15 minutes, the mixer is again immersed in the container and the steps are repeated. Again, the composition is allowed to sit for at least 15 minutes and only after that they begin to work. For more information on how to putty walls, watch this video:

Application to the surface is carried out using a small spatula to apply the composition to the main tool, which is either a large spatula or a trowel (trowel, malka).

The composition is distributed over the surface from the far corner, from bottom to top. If one person is working and covering the bottom half of the wall first, sand the edge to eliminate any noticeable transition before starting to putty the top half.

Complete drying will occur no earlier than after three days. After this, the surface is treated with sandpaper, if necessary, and painting begins.

Source

Useful tips

- When treating fences, walls of houses and other buildings, as well as outbuildings made of wood, it is best to give preference to oil-based compounds. Moreover, they can be used after the wood has been impregnated with compounds against rotting and insects, but before painting;

- Treating parquet and other wooden surfaces that we often come into contact with is best done with safe water-based compounds. Yes, they take longer to dry, but their price is more affordable;

- Regardless of the surface, acrylic options are the most attractive. They can be successfully used both indoors and outdoors. It must be remembered that the composition of such putties is white, and therefore it is necessary to apply paint over them, otherwise the place will stand out strongly.

If the composition needs to be diluted, then this should be done until it becomes sour cream. The work is best done with a drill with a special attachment. It should be remembered that the composition dries quickly, so mixing large quantities of putty at once is not recommended.

vote

Article rating