Tools for cleaning wells

Devices for cleaning wells are also available in retail stores, but sometimes there is simply no time to purchase them. This can happen on holidays and you just may not want to spend money. You can use a hand grader to clean the well, or there are options to use a homemade bucket to clean the well. For this type of work, you can use various tools and devices. This will be discussed below. He will watch all the work being done both on video and in photos.

How to understand that a well needs to be cleaned

A well in any summer cottage requires periodic cleaning, regardless of the quality of the structure and the characteristics of the soil. You can understand that it’s time to clean the well in the village yourself based on several signs.

The water in the well became cloudy and darkened

It’s time to clean the well with special devices if the water in it has become dark, cloudy-greenish and brownish-yellow. Most often, such signs appear when the seal between concrete rings is broken and cracks appear. The liquid can also turn green and dark from simple stagnation due to long-term non-use.

If the water in the well has changed its smell and color, you should not drink it.

The water is dirty and there is garbage floating in it

If the well is poorly cared for, or it is not made well enough, then gradually fallen leaves, twigs, and other plant debris accumulate in it. Sometimes you can even find dead animals in the water.

The water has an unpleasant odor

If carcasses of mammals get into the well or if the mine is depressurized, the water may acquire a fetid sewer odor. At the first such signs, you need to start cleaning.

Precautionary measures

Wells can be cleaned in different ways, by hand or using pumps. These procedures must be performed with precautions. You should follow these tips:

1. All work should be carried out by three people: if one is inside the mine, two are on backup. If a worker gets sick, they have to pull him out.

2. the worker in the mine must have a helmet, a belt with safety net, a cable is attached to it, by which he can be pulled out.

3.Before starting work in the mine, you should check the level of harmful gases inside. A burning candle, which is in a bucket, is lowered into a shaft without water. When a fire breaks out, it means that there is a lot of flammable gas in the well; when it goes out, there is a lot of carbon dioxide. In this situation, cleaning the structure is prohibited.

4. There is quicksand at the bottom of the structure; it is not recommended to go down to it. A wide platform is attached to the bottom of the stairs to make the base.

5. If an object falls from above, you should press yourself against the wall of the shaft.

6. If the worker is lower than three meters, then there may be a lack of oxygen, and health may deteriorate sharply. It is necessary to monitor the condition, and in case of danger, immediately pull it out.

Sources

- https://SamoDelino.ru/vodosnabzhenie/pochistit-kolodec-svoimi-rukami.html

- https://diz-cafe.com/voda/chistka-kolodca-svoimi-rukami.html

- https://teplogrup.ru/vodosnabzhenie/chistka-kolodca-svoimi-rukami-obzor-luchshih-profilakticheskih-i-kapital-nyh-metodov.html

- https://www.ivd.ru/stroitelstvo-i-remont/vodosnabzenie-i-kanalizacia/kak-samomu-pochistit-kolodec-na-dache-instrukcii-dlya-ruchnoj-i-avtomatizirovannoj-ochistki-60721

- https://ru-canalizator.com/vodosnabzhenie/avtonomnoe/chistka-kolodtsa.html

- https://notperfect.ru/dacha/kak-pochistit-kolodec-na-dache.html

- https://scvazina.ru/grejfer-dlya-chistki-kolodtsa

- https://FokSevmash.ru/servis/samodelnyj-grejfer.html

- https://lkard-lk.ru/dom/kovsh-dlya-chistki-kolodcza-metody-ochistki-kak-stroit-grejfer-i-ispolzovat

- https://vdome.club/materialy/svoimi-rukami/kak-pochistit-kolodets-na-dache-ot-ila-gliny-gryazi-masla-svoimi-rukami.html

- https://bouw.ru/article/chistka-kolodtsa-na-dache-svoimi-rukami

- https://ogorodum.ru/kak-pochistit-kolodec.html

- https://iseptick.ru/vodoprovod/kolodec_dlia_vodi/kak-pravilno-pochistit-kolodec-ot-plyvuna-peska-priznaki-zagryazneniya-etapy-raboty.html

[collapse]

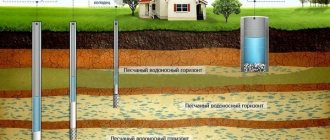

Causes of well contamination

Cleaning the well is a mandatory procedure - it is impossible to use the shaft and not take care of it for many years. There are many causes of pollution, but several main ones can be identified.

Poorly fitting or missing lid

If the mine is constantly open, or its lid does not close tightly, then debris of plant and sometimes animal origin inevitably gets inside. It stagnates and decomposes, which negatively affects the quality of water.

Ideally, it is recommended to equip the well not only with a lid, but also with a canopy

Poorly executed protection against melt water

At the top of any well around the casing ring, a protective layer is required. If it is not there, it is too thin or poorly made, surface water will enter the reservoir every year along with pieces of soil, debris and waste products.

The melt water lock looks like a dense layer of clay around the trunk

Cracks in seam joints

Even if the seams are sealed very well, after the annual frosts they can still crack. Groundwater begins to seep into the well, carrying not only soil particles, but also fertilizers and household waste.

Cracks in well seams inevitably appear; they need to be repaired in a timely manner.

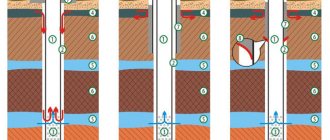

Drainage pumps and their capabilities

Over the years, the well becomes clogged. This leads to a number of adverse consequences. External signs that it is time to clean the well with a drainage pump include:

- lack of transparency;

- presence of odors;

- weak inflow;

- presence of impurities.

As a rule, it is enough to clean the source of sand, clay rocks and solid inclusions once every 36 months so that the liquid returns in sufficient quantity, and the quality of the water allows it to be used for domestic purposes. But if the well is dug in fine-grained sandy soil or dusty soil, then cleaning activities are carried out using a pump at least once a year.

In addition to sucking out dirt, pumping equipment is used for draining reservoirs, pumping liquid out of pools (reservoirs), basements, etc. Using this equipment, you can eliminate the consequences of flooding during seasonal floods and solve a lot of other problems.

How to clean a well from silt, sand or dirt with your own hands

There are several methods and devices for cleaning a well. They allow you to automate and significantly simplify labor-intensive work.

How to clean a well with a pump yourself without going down into it

The easiest way to clean a well made of concrete rings yourself is to use a powerful pump designed for pumping out liquid dirt. When choosing it, you need to pay attention to the performance of the device.

To quickly clean a well with your own hands without helpers, it is better to use two pumps and two containers at once, which are installed on the surface of the earth. One of them is filled with water from a well, and then it is supplied back. The end of the sleeve of a drainage device is lowered into the other, pumping out dirt from the bottom. The jet of water supplied during the cleaning process agitates the sludge and improves the quality of work.

When purchasing a pumping device for cleaning a mine with your own hands, you need to take into account the length of the hose

If the first pump, responsible for backfilling the liquid, is left on the surface, then the drainage device is lowered down and fixed approximately 1 m from the bottom surface. A video about do-it-yourself well cleaning devices recommends taking out the unit from time to time to rinse the filter. When it stops getting dirty, the work can be considered completed.

How to properly clean a well at your dacha with a grab

You can clean a well of clay using a grab, which is the name given to a large bucket that is usually attached to excavators or cranes. In appearance, it looks a little like powerful metal jaws with large teeth. A manual device may look exactly the same as an industrial one, or consist of several “petals” with a similar operating principle.

During use, the grab is securely fixed directly above the well, lowered down on a chain or cable until the jaws hit the ground. When the lifting device is activated, the parts of the device simultaneously close, capturing dirt.

The grab is convenient for removing clay and sand from the well

A manual grab allows you to clean the well yourself in a couple of hours. One person can do the job.

How to clean a well with a bailer

You can clear the drainage well of silt using a bailer. This is the name of a hand-held device that you can construct yourself from an iron pipe, a thick washer and a metal ball. Make the device as follows:

- for the device, select a pipe about 60 cm long; its width should be a couple of centimeters smaller than the well shaft in the narrowest part;

- the bottom of the segment is hermetically sealed with a thick washer, and a grate is welded to the upper part;

- a metal ball of such diameter is placed inside the pipe so that it can completely cover the outlet of the device;

- a handle is welded to the top of the bailer, on which a thin cable can be attached.

Cleaning a narrow well using the device is quite simple. On a cable, the bailer is lowered to the bottom, then raised back about half a meter, and then sharply thrown down again. Do-it-yourself drawings for cleaning wells show that the lower hole of the device will open and water and the sand and silt it carries will enter it. The ball, falling down under its own weight, will block the lower outlet and will not allow the sandy-silt mass to flow back.

Cleaning a well with a bailer with your own hands usually takes at least five hours

To fill the bailer at least halfway when cleaning, you need to lower it with sharp movements several times in a row. After this, the device is pulled out and emptied, and then the procedure is repeated.

Manual cleaning of wells

If special devices are not at hand, or they do not give the desired result, you can only resort to manual cleaning. It is necessary to carry out such work with an assistant who will provide backup.

Manual self-cleaning of a well consists of several stages:

- water is pumped out of the mine using buckets or a pump;

- lower down on a safety rope, simultaneously removing dirt from the walls with scrapers and sponges;

- Clean the bottom of the well using a short shovel, putting the sludge into a prepared bucket.

As the container fills, a second person should lift it to the surface and empty it. Also, during the cleaning process, the incoming water continues to be pumped out; for this, you can use the same bucket if there is no pumping device. Otherwise, the liquid will interfere with the quality of scooping out silt and sand.

Do-it-yourself well cleaning with descent allows you to check the condition of the seams

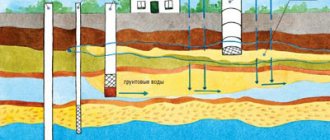

How to clean a well if there is quicksand

In photos of well cleaning you can often see quicksand. This is the name given to a mobile sand or sandy loam layer, saturated with water, which moves and flows under the influence of soil pressure.

You can clean an old well if there is quicksand in the standard way, manually or using devices. But at the final stage of work it is necessary to equip a special bottom shield with your own hands.

To do this, thick wooden boards with infrequent perforations are placed in the well; the device will delay the movement of sand and clay in the water. A special filter is placed on top of the shield - first large, then medium, and then small stones are poured. The overall layer thickness should be at least 15 cm.

When making a shield against quicksand, it is important to remember that it should be slightly smaller in size than the Council mine itself! Since wood decomposes in water over time, the bottom shield will need to be replaced when cleaning approximately every five years.

Cable

If a blockage occurs deep in the pipeline, or in places where it passes (in the wall or between walls), a cable is used for cleaning. It is made of low-carbon steel, the outer surface is coated with a layer of zinc. In appearance, this device for cleaning sewer pipes looks like a perfectly bendable spring, at one end of which there is a special handle - an activator, with the help of which the equipment is set in motion. The other end is equipped with a spiral, with the help of which the layer of deposits in the pipe is broken through.

Clearing the blockage using a cable is carried out as follows:

- To achieve a better result, it is better to remove the siphon from the pipe. The end of the cable with the tip is sent into the pipeline, the second end with the handle should be conveniently placed in the hand.

- To push the device deep into the pipeline, you need to rotate it. It is best to do this clockwise to avoid breaking the flexible shaft as it may come loose. It is rotation that allows the device to go through various bends and curves in the pipe.

- When you find a plug, be sure to start twisting the cable harder, this will allow it to break through, thereby eliminating the blockage. If the cable gets stuck in the pipe, you need to twist it left and right. If the tip is equipped with a hook attachment, then all accumulated debris must be removed from the pipe.

- After completing work with the cable, you need to open hot water and clean the pipes, and the pressure of the water flow should increase over time.

Checking the quality of work using cable sewer cleaning equipment is carried out visually; if the water leaves without problems, then there is no need to repeat the work.

How to clean oil from a well

Oil can get into the well due to a leak in the pumping device, along with groundwater, or as a result of hooligan actions. In any case, if a characteristic film appears on the surface of the water, you must stop using the mine and urgently remove excess impurities from it.

You can do the cleaning yourself in several ways:

- mechanical - oil is collected from the surface of the water using improvised means, for example, ordinary paper, which is subsequently burned;

- chemical - the liquid is treated with adsorbent substances, among which are activated carbon or aluminosilicates;

- biological - the water is saturated with special bacteria that feed on petroleum products.

When using any of the cleaning methods, after removing the oil, you need to rinse the walls of the well under high pressure, while simultaneously pumping out the top layer of liquid.

You can see the oil in the well even without scooping, by the characteristic reflections when illuminated

Equipment needed for a cleaner

If someone doesn’t know, the procedure for cleaning a well from dirt is an unsafe and labor-intensive task.

It is best to work during the day; in this case, darkness is a bad help. It will be nice if two more people come to your aid.

Climbing gear you will need:

- Belay rope and strong cable.

- A ladder on which you can stand comfortably.

- Support bars.

- Wooden swing with a hook.

- Platforms attached to cables.

- High rubber boots.

- Protective helmet.

Having dressed in a rubber suit, boots and a helmet, and having secured a safety rope to your belt, you can slowly lower yourself into the well shaft.

When descending or ascending, you must be sure that there is someone at the top as an insurer.

Before descending to the bottom of the well, make sure that no harmful gases have accumulated there.

This can be done with a lit candle. It is placed in a bucket, which is immersed at the very bottom.

If the candle continues to burn, then there is no danger. When working in a mine, a tool may fall on you from above; to avoid injury, you should try to press yourself against the wall.

When performing work at the bottom, it is not recommended to stand on one leg for a long time; it can be sucked into the muddy soil.

After you go all the way down and visually inspect everything around, it will become clear to you how much work needs to be done and what exactly needs to be repaired.

Which of the following actions may you need to take:

- strengthen and make a control sealing of all seams, this is necessary to prevent groundwater leaks into the well. For this purpose, use a special waterproof sealant;

- clean the bottom filtration system;

- repair wooden structures;

- if necessary, restore the concrete surface with cement mortar.

At the moment, the modern market offers a wide range of cleaning products, in the form of ready-made solutions, for wells.

These compositions contain substances of a stabilizing and disinfecting nature.

You have become familiar with all the possible ways to clean a well with your own hands and know what tools and devices are needed for this.

If you regularly clean the well that is located on your property, you can be sure that your family will be provided with clean and fresh water. Watch the video that was filmed while cleaning a well made of concrete rings.

How to clean a well from bacteria

When a well is contaminated, bacteria inevitably appear in it, changing the color and smell of the water. Usually folk remedies suggest cleaning the bottom of the well with lime. To get started you need:

- remove large debris from the mine using a bucket or other devices;

- pump out all the water;

- clean the walls from soft and hard growths with your own hands;

- seal cracks in the seams between concrete rings;

- remove dirt from the bottom of the shaft manually, using a pump or other special devices.

After this, prepare a 3% bleach solution at the rate of 500 ml of product per 1 m2 of surface. The walls of the well are treated with a thick mixture, and then washed under pressure several times.

Then the water itself is cleaned with chlorine:

- 20 g of 1% lime powder are diluted in 1 liter of cold liquid, the volume of the well is determined and the amount of solution is selected depending on it. On average, 400 ml of product is needed per 1 m3 of water.

- The disinfectant liquid is prepared in the required volume, poured into the well and mixed for ten minutes with a long pole.

- The well is covered with an opaque lid from above and left for 6-10 hours.

After time, the water is completely removed from the well several times with a bucket or pumping device until the specific smell finally goes away.

How to clean a well with potassium permanganate

To clean the well from bacteria, you can use a solution of potassium permanganate. Pour a large spoonful of powder into a bucket of warm water, stir, and then pour into the well and leave for an hour. The walls of the shaft should also be wiped with a brush soaked in potassium permanganate.

After the expiration date, the water is pumped out several times in a row. After the final procedure, a metal sieve with 5 g of manganese powder is lowered to the bottom. A simple device will allow you to make clean water in the well; the product will ensure constant disinfection of the incoming liquid.

When disinfecting a well, it is important to carefully treat the walls; mold and bacteria accumulate on them

Installation of the bottom filter

A properly installed bottom filter is the most important element of rough cleaning, stopping the invasion of sand and clay. To form this protection, only natural materials are used that are not washed away by water. Be sure to place them in several layers to ensure complete safety for those using well water. should be taken into account that in dense soils of clay origin when obtaining water from underground springs, a filter will not be required.

But when the bottom is composed of soft clay and the water flows with significant pressure, the fight against turbid suspension is very important.

Large crushed stone or pebbles laid out in a layer of 0.15-0.2 m will help prevent the bottom from washing out. If the base of the pit is made of sand and water flows in even portions, you will need to lay out the filter yourself. It is also required in cases where there is quicksand below.

The direct type of bottom filter is used where the inflow is relatively small, as well as on top of quicksand. First, material of large fractions is laid out, then medium and small fractions (each layer is 5-6 times finer than the previous one).

The upper filter surface in such a system is made of quartz sand or pebbles. If the bottom is already sandy, reverse filters are used. Their main task is to prevent dirt from entering the water from reaching the bottom of the well. At the same time, owners are protected from contamination of the liquid by grains of sand rising in the flow of spring water. The difference from the direct scheme is that the sequence of layers is reversed; The thickness of each layer is a maximum of 150 mm.

How to clean water in a well

The quality of well water can be seriously affected by impurities in the soil. It is often impossible to eliminate the reasons for the appearance of unnecessary connections inside the well with your own hands. But it is quite possible to clean the liquid using simple devices.

How to remove lime from well water

If water supersaturated with lime comes from a well, the easiest way is to subject it to a settling procedure. Using a bucket or pumping device, the liquid is simply drawn into an open container and left in a calm state for a day. Large fractions will settle to the bottom under their own weight.

Another reliable DIY cleaning method involves running water through a semi-permeable filter. The most inexpensive and effective sorbent is activated carbon. Such a filter in a cleaning device will need to be changed frequently, but it will be able to retain about 95% of excess particles.

The filter system for well water eliminates the need to wait for the liquid to simply settle.

How to clean rusty water in a well

One of the most common problems faced by well owners is the increased iron content in the water. If the element is trivalent, that is, insoluble, then the liquid will initially have a reddish tint.

Rust naturally precipitates, so you can clean cloudy well water in the same way as if you have too much lime. The liquid is first fed into a large container, where it settles for about 12 hours, and only then is used for drinking and household purposes.

Rust in water appears due to the characteristics of the soil - it is impossible to completely eliminate it in a well

You can also use filtration if it is urgent to supply water from a well to communications. In front of the water supply, devices for rough cleaning, cartridge or sorption elements are installed, which will filter out large and small rusty particles.

How to remove iron from well water

Sometimes well water looks completely clean and clear, but has a metallic taste and turns rusty after settling. This means that it contains divalent soluble iron, which becomes noticeable only during the process of gradual oxidation.

To clean water from such an impurity with your own hands, it is necessary to accelerate the transformation of the element into an insoluble precipitate. The most reliable way is aeration:

- A submersible pumping device is installed in the well, pumping liquid into the barrel on the surface, and a plastic bucket with a watering nozzle in the center is fixed on top of the container above the perforated lid.

- Contaminated water under pressure flies out of the watering can, breaking into small drops. Then the liquid flows down the walls of the bucket and through the holes enters the storage barrel, and from there, after cleaning, it enters the water supply system. The iron sediment remains at the bottom of the container.

When leaving the watering can, water with a high iron content is actively saturated with oxygen and oxidized

How to reduce cleaning frequency: practical tips

Any method of removing wastewater from a storage tank requires certain financial and labor costs. Therefore, many are interested in how to reduce the frequency of the treatment process while maintaining the operational characteristics of the local sewerage system. Let us list several popular options for implementing such a task.

Increasing the volume of the well.

The size of the treatment plant is calculated taking into account the number of people living in the house. With an increase in the number of residents, the septic tank will be filled more intensively, which will increase the frequency of calls for vacuum cleaners. The way out of this situation is to increase the total volume of the structure by adding another chamber, which is connected to the operated facility using an overflow pipe.

Application of activated sludge.

Activated sludge is a complex of microorganisms that absorb harmful bacteria and accelerate the biochemical processes occurring in wastewater. By feeding on substances in wastewater, active microorganisms contribute to the rapid processing of suspended particles and more effective water clarification.

Purchase of a biological treatment station.

Without a doubt, this is the most expensive option. However, unlike standard sewer wells, here wastewater treatment occurs at the highest possible level. As a result of the action of aerobic bacteria, almost all harmful substances are removed from the liquid, so purified water can be safely used for watering the area.

The use of a deep cleaning station significantly reduces the frequency of calling vacuum cleaners

Whatever option for arranging an autonomous sewer system is chosen, preventive measures should not be ignored. Timely contact with professionals will prevent emergencies and save money in the family budget.

This is interesting: Pleated blinds

Security measures

When cleaning a well with and without accessories, precautions must be followed. Namely:

- do not go down into the mine without backup and an assistant;

- after pumping out the water, first lower the container with the burning candle; if the latter goes out, there are gases at the bottom that are dangerous to humans, and cleaning must be done in a gas mask;

- perform chemical disinfection with your own hands wearing a respirator, gloves and safety glasses.

Only a person without cardiovascular diseases, hypertension and asthma can clean a silted well. If a well owner suffers from chronic illnesses, he needs a healthy assistant. At the bottom of the mine there is less oxygen in the air than at the surface; during cleaning, this can provoke dangerous attacks of suffocation.

Well cleaning with and without equipment is carried out only during the daytime

Where does waste come from?

In the process of life, every organism that eats and drinks releases some kind of waste, most often biological, into the surrounding world.

Man manages to produce more waste than other living organisms.

- leftover food (when washing dishes);

- fragments of materials (when washing clothes);

- hair and skin discharge (during water procedures);

- other biological secretions of the human body.

Almost all waste products contain solid compounds that have the ability to accumulate, clog the sewer system and interfere with its normal functioning.

Methods for cleaning wells using equipment

The following cleaning methods are currently used:

- cleaning with a suction pump;

- vacuum pumping;

- hydrodynamic cleaning;

- chemical washing;

- thermal washing.

Cleaning with a suction pump

From the point of view of convenience and efficiency, the most optimal option is to use a suction pump. This equipment is intended for sewerage work. Its design includes a tank and a vacuum pump. One of the advantages of this method is the ability to use it in any season. Sludge suckers are widely used for various types of cleaning and preventive work, including for removing sludge from concrete and plastic sewer wells and networks, settling tanks of treatment facilities, septic tanks, as well as for transporting liquid waste.

Cleaning with a suction machine

Vacuum pumping

This method involves cleaning the well and pumping out wastewater using a powerful vacuum pump. After this, the waste is collected and disposed of. This type complies with environmental safety standards and is an effective way to maintain optimal sanitary conditions.

Pro tip:

To ensure stable operation of the sewer system, prevent emergency situations, and maintain the required level of sanitation, it is necessary that sewer wells be pumped out regularly.

Machine for vacuum pumping of sewerage: appearance and diagram

Hydrodynamic cleaning

The operating principle of hydrodynamic cleaning is to wash away waste from the internal walls of a sewer well with strong water pressure. In this way, you can eliminate any blockages of organic and inorganic origin. After flushing is completed, the waste is collected and disposed of.

To carry out such cleaning, one or two machines can be used, depending on the amount of deposits:

- the first is a sewer cleaning machine;

- the second is a silt sucker.

Sewer jetting machine and suction pump

The use of the latter is advisable for large volumes of sludge. To illustrate the need to use a suction pump, consider two examples:

- Example No. 1: a pipe with a diameter of 500 mm and a length of 100 m is heavily clogged. The volume of precipitation averages 200 cubic meters. m. To eliminate them, a suction pump is required.

- Example No. 2: a pipe with a diameter of 150 mm and a length of 100 m contains 2 cubic meters. m of precipitation. Naturally, in this case you can remove the blockage manually.

Pro tip:

Hydrodynamic cleaning is universal, but its effectiveness is achieved only if cleaning work is carried out regularly. This allows you to ensure uninterrupted operation of the system and prevent emergency situations.

Scheme of hydrodynamic cleaning of sewer wells

Chemical washing

This method involves the use of potent chemical reagents. With their help, it is possible to soften and transform condensate deposits of various origins, including salt deposits, into a dissolved state. The process is carried out using special equipment and foamed chemical composition. The latter makes it possible to effectively treat surfaces with a negative plumb and specifically concentrate the impact of reagents. In addition, the foam also creates a mechanical effect.

Chemical cleaning of sewer wells is very effective and environmentally friendly, but due to its high cost it is rarely used.

Chemical wash agent

Thermal wash

In its principle of operation, this method resembles hydrodynamic cleaning. But its fundamental feature is the use of hot water pressure. The water temperature can range from 120 to 160 degrees. An indispensable condition for the effectiveness of this method is its regular implementation. It is noteworthy that in combination with thermal and chemical washing it is possible to increase the efficiency of the latter several times.

Hydrodynamic cleaning

In particularly advanced cases, devices like a plunger will not cope; more effective means and methods will be needed. One of these is hydrodynamic cleaning, which is carried out using a hydrodynamic machine for cleaning sewer pipes.

The operating principle of this method is the mechanical treatment of the inner surface of the pipes with a stream of water under high pressure using this machine. Strong pressure sands the surface and removes blockages.

Design and principle of operation of hydrodynamic equipment

The hydrodynamic machine operates as follows: the working body, which has a nozzle, is placed at the beginning of the cleaning section. The compressor is started - an energy device for increasing pressure. From this device, a powerful jet of water flows through a hose under strong pressure, pushing the hose throughout the cleaning area and breaking up all accumulated debris, thereby cleaning the sewer pipes. In this process, a person only controls the direction of the hose and regulates the flow of water.

Types of nozzles for hydrodynamic cleaning

There are several types of nozzles:

- Universal nozzles used to clear common blockages.

- Punching nozzles used to eliminate old and dense formations.

- Bottom nozzles are used to clean storm drains, leaves, sand, and any branches.

- Chain-carousel are used to eliminate dense tumors that have not been eliminated using other mechanical action.

Machine nozzles have direct and reverse action nozzles. Direct ones launch water forward, and from reverse ones diagonally the water moves backward.

Advantages of the hydrodynamic sewer cleaning method

The following advantages of hydrodynamic cleaning of sewer pipes are highlighted:

- complete cleaning of the internal cavity from foreign debris;

- cleaning takes place along the entire length of the pipeline;

- a high-pressure water jet does not damage the walls of the pipeline;

- hydrodynamic cleaning can be used against blockages of any complexity and age;

- cleaning is quick: in an apartment the process will take no more than an hour, in a private house - about 4-8 hours;

- you can work with any pipeline configuration, because with this method there is access to its most difficult and remote sections;

- the owner of a private house can clean not only his own home sewer, but also the storm drain;

- ice plugs will not interfere with cleaning, because they can be easily destroyed by supplying hot water to the pipeline.

This method has only one disadvantage: the need to buy equipment, which is not cheap.

2How to choose equipment for cleaning the sewer system?

The choice of type of cleaning equipment largely depends on the material from which the pipes are made. Thus, a hydrodynamic machine is most effective for carrying out cleaning work in plastic pipelines and, if necessary, complete thorough cleaning of internal surfaces.

The process of hydrodynamic cleaning of a sewer system consists of supplying a powerful jet of water from a flushing head into the flushed pipeline under the influence of high pressure. This method allows you to completely clean the internal walls of the pipeline and remove almost any blockage.

To clear mechanical blockages - in cases where it is necessary to remove various debris from the pipe - branches, leaves, rags and other clogging elements, it is more effective to use a mechanical cleaning machine.

In mechanical installations, sewer contamination is removed using a cleaning cable. It can be made in the form of long metal rods (rod), a spiral twisted into a drum (drum) or a stacked spiral consisting of various sections (sectional).

BY THE WAY. Additional attachments are a guarantee of expanding the areas of application of the cleaning machine.

In addition to the intended purpose, the nozzles of cleaning machines are also divided by size and materials used for their manufacture.

Selection of equipment: attention to the manufacturer

According to the law, ventilation systems must be cleaned at least once a year. This will ensure a normal level of fire safety in food processing plants and in buildings where dirt and flammable materials accumulate.

Every 5 years, it is necessary to check the condition of the air duct in hotels, restaurants, medical and correctional institutions.

European-made devices

The microclimate in the room and the safety of people depend on the effective operation of the ventilation duct. Thoughtful operation of the system involves regular cleaning of the air duct

When choosing the optimal equipment for cleaning ventilation, you should pay attention to the reliability of manufacturers

The best installations for cleaning ventilation from contaminants are presented on the market by European manufacturers. Market leaders offering a wide range of products are Goodway (USA), Pressovac and AirPower (Finland).

The equipment is of high quality and excellent performance. The downside of the products is their high cost.

Models from domestic manufacturers

A significant portion of consumers choose Russian-made cleaning equipment. It is much cheaper, although the quality of the equipment is impeccable.

When buying Russian equipment for cleaning ventilation, it is better to focus on large manufacturers that offer high-quality, world-class equipment. The products of Equipment for Professionals LLC and Probat Rus LLC are in demand.

Cleaning the air duct does not always help solve the problem; sometimes repairs are required - detailed information on restoring the ventilation system is given in the articles:

- Repair of ventilation systems: analysis of popular faults and ways to eliminate them

- Restoring ventilation: reasons for decreased efficiency and restoration of air ducts

Advantages of plastic products

Despite the disadvantages, plastic pipe products have many advantages. On its walls, deposits begin to accumulate to a much lesser extent compared to similar products made from other materials.

As a result, the drain cleaner may not be needed for a long period. The fact is that plastic products have a low roughness coefficient (resistance to moving flow).

This parameter represents the size of the recesses and protrusions present on the walls of the pipes. For concrete, this characteristic in millimeters is 1.22; for asbestos cement – 1.15; for cast iron – 0.47 and for plastic – 0.02.

Over time, the value of the roughness coefficient changes. After a five-year period of operation of the cast iron system, it can reach 5 millimeters, and after 15 years – about 25 millimeters. This large value is about 50% of the internal diameter of the pipeline. As a result, you have to use the sewer pipe cleaner much more often. But you need to know what type of equipment is best to use in a given situation.