Let's look at why a wooden shield made of boards at the bottom of a well is needed, and what kind of wood is best to make it from. Despite all sorts of myths that aspen, oak, and larch do not rot in water, this is not true. All types of wood are subject to rotting! It is possible that they will not completely rot, but superficial rot will definitely occur, which will be quite enough for the water to acquire an odor. Its manifestations are possible within a year. The smell is most noticeable when heating water and spraying it, for example in a shower.

What is the bottom

Regardless of the type of structure, it is mandatory to install the bottoms of the wells. The bottom must be concreted to prevent groundwater from entering the structure. This is especially true where water is collected. Wells must also be protected from liquid penetration.

Not only the quality of the water, but also the durability of the object, how reliable the operation will be, and the importance of preserving communications and equipment located inside depend on how well the material is installed.

The bottoms of the wells must be strong, since they will constantly be subject to heavy loads. In some cases, they must withstand the entire mass of all reinforced concrete rings that press on the bottom of the well. To support all this mass, heavy concrete and very strong steel are laid.

In order to extend the service life of the well bottoms, during the work process, vibration pressing is used to connect the components using an innovative method. Using this method, very smooth concrete with high strength can be obtained. Thus, a dense reinforced concrete structure emerges. There are no gaps between the bottom ring and the bottom.

Today, factories have mastered and successfully used the technology for producing high-quality products of several types of rings, as well as well bottoms.

Due to various circumstances, builders cannot always place monolithic products at the bottom of a well.

Before laying materials on the bottom of the well, you need to pay attention to the parameters of the bottom. This is necessary in order to calculate the largest load. Moreover, they must be combined with the standard parameters of the rings.

Properly laid well bottoms should be in the form of a monolithic slab of reinforced concrete materials. The shape should be round, and for installation there should be three loops. The diameter of the slabs may vary, but the thickness is standard and is 14 cm.

Such parameters are not random; they are prescribed in state standards and are strictly regulated. Studies were carried out, during which it was established that this particular thickness has a sufficient margin of safety and can withstand high pressure of reinforced concrete products, as well as incoming water, resist soil mobility and the influence of groundwater. The design must be selected together with other details.

What is quicksand in a well and how to get rid of it?

Imagine: you start digging a hole for household needs, digging a well, or preparing the ground for a foundation. You are standing, although not on solid ground (the ground after all), but on a fairly solid surface... and suddenly you suddenly fall down. It was you who ran into quicksand.

Starting from a certain depth, quicksand can appear anywhere in your area. Until you start digging or do a geological examination, you will never know where it is. The quicksand has the ability to move. Having learned about the presence of quicksand in the ground, people are afraid to build capital. And sometimes, the owners don’t even realize that their entire land is covered in quicksand, they simply don’t encounter them. It depends on your luck.

Quicksand is a layer of soil saturated with water, measuring from 2 to 10 meters, which is capable of moving underground in a vertical direction. It can be found at a depth of a meter or less. Quicksand is a sealed object (until you touch it). The smallest particles of soil from which it consists, due to their saturation with water, act as a lubricant along the edges of the quicksand, which is why it moves so easily underground.

Quicksands are classified as:

- True. They contain the smallest particles of clay, sand and organic matter, which, on the one hand, seem to glue the soil into that very “amoeba”, and on the other hand, provide it with greater mobility, and as a result the result is slippery and unpredictable, which is extremely problematic for land owners. mass underground. The soils in which true quicksand are found are mainly clayey sands, sandy loams, and loams.

- False. They consist only of sand and water. If such quicksand is touched or damaged, the liquid it contains begins to come out along with the sand. Not as destructive as in the first case, but still causes significant problems during construction.

Until now, even scientists do not have a clear answer as to why quicksand is formed. It is logical that most of them are detected in places with water-saturated soils. However, our man basically begins to be interested in the “life” of quicksand exactly from the moment when he needs to go deeper into the ground.

Kinds

Well bottoms must be selected in such a way that the diameter is no less than the diameter of the rings. During the production process, it is imperative to indicate its dimensions, what volume, and also what operational properties it has.

The most common types of products are marked PD-10, PD-15, and PD-20. They differ in weight and diameter.

bottom of well PD-10

There are products designed for collector wells. They have a high level of water resistance, are resistant to low temperatures, while maintaining their qualities. This slab is rectangular, there are elements for connection.

river sand

This is a fine-grained material with a high content of quartz and a small amount of clay or other impurities. Before filling into the bottom part of a well shaft, river sand must be washed with water several times. This will allow you to almost completely remove any unwanted suspended matter from the filter system.

Features of the bottoms

The slab has a large mass and does not allow the well structure to sag. In addition, it does not allow it to move over many years, provided that the installation is done correctly. Since it is made from high-quality concrete with high-strength steel, it has a high level of durability.

Today you can buy products at various specialized sales points. The staff will provide all the information you need and help you make the right choice. The cost of such plates will pleasantly surprise you.

Such a product is very important when arranging a structure. Previously, slabs were concreted, but now it is possible to buy them at a favorable price. Thus, the process of arranging the bottom was significantly simplified.

The slab is used to support the entire structure and also to prevent water from affecting the rings. At the moment, during manufacturing they are installed separately, and a structural module is placed on top. This industry is developing at a rapid pace, so products have appeared on which a bottom plate is installed. They may not always be used, it all depends on the design of the well.

Slabs are used not only in ring wells, but also in wood and brick.

Reviews

Sometimes you can find reviews online that constructing a bottom filter is a useless procedure. This version is supported by the following arguments:

- the water in the well can be cleared after settling;

- Do not scrape water out of the structure too intensively;

- If the water flow is low, it is recommended to pump the well.

However, along with this, an aspen shield is considered the best device for wells on quicksand. It allows you to control the quicksand and protect the hydraulic structure from being pulled in. A more expensive way to combat quicksand is to deepen the well to the clay layer, which is always located under the quicksand. At the same time, many users agreed that installing a bottom filter without a shield on quicksand is generally impractical.

Advice: the best way to protect yourself from getting caught in quicksand and having to build a filter is exploratory drilling before choosing a place to build a well. In this case, your well is guaranteed to provide you with clean, high-quality water.

Video instructions for constructing a bottom filter:

What are the requirements?

To make the structure, it is imperative to use heavy concrete. To secure them, a special frame is installed. Products are manufactured in strict accordance with state standards. The main features are:

- strength;

- a special type of water permeability;

- is not subject to corrosion processes;

- resistant to low temperatures;

- quality is maintained even in high humidity conditions.

Despite the large mass, the installation process, as a rule, does not cause any problems, thanks to the presence of three hinges on top. They are also easy to transport. When choosing a product, pay attention to the parameters. The diameter should not be less than the diameter of the well. This is necessary in order to ensure the maximum level of tightness.

One of the main requirements for a slab is high mechanical strength. The stability of the entire well depends on this. It is imperative that there are no chips, cracks, or protrusions on the surface; it must be smooth and even. There should be no gaps between the components; the structure must be monolithic. The flat surface allows the use of modern approaches to the arrangement process.

Aspen panel design

A round aspen panel consists of boards fastened together. Its design is simple - the basis is an edged/unedged board or slab, which is fastened with crossbars made of slats or bars, preferably with wooden wedges, chopiks (wooden dowels), since metal nails and screws have no place in the water. 1-2 mm gaps are left between the boards for swelling; there is no need to drill holes, although in practice we have also encountered perforated boards. Such a shield is lowered to the bottom and covered with gravel on top or pressed down with a large rubble.

Determination of the level of occurrence of hot water

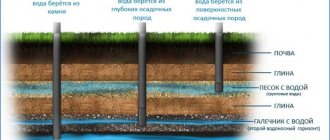

Before you begin any excavation work and create a sewer system, you should find out exactly what water level is on the site. Options for doing this:

- Look into the well on the site, if there is one. The water level in it will be the approximate depth of soil water.

- Find out from neighbors in the area. If they have lived in this area for a long time, then they know exactly the characteristics of the soil.

- To conduct an experiment. Its essence is to make a hole in the soil; a garden drill will help with this to the water level or 1.5-2 meters. You need to make 3-4 such holes throughout the area at different points. Leave them for a day, then check the level.

- Carefully consider what plants are on the site. If moisture-loving plants predominate and grow vigorously, then this indicates a high groundwater level.

Determination of groundwater level

The reasons for higher groundwater level are:

- Swamps and ponds nearby.

- Violation of norms for the use of subsoil.

- Large amounts of precipitation, floods.

- Streams and springs on the site. Moreover, in this case, the neighbors’ level will be normal.

Creation of an alpine slide

If there is a lot of clay left, but there are no ideas for use, it can be used on the site to build an alpine slide. This will solve two issues: remove the unnecessary mountain of remaining soil and decorate your garden.

Gardeners know that it is very difficult to maintain an alpine hill in its original form for several years. Since the soil settles due to temperature changes and precipitation, every year you have to do everything all over again: lift the stones and add soil.

In this case, you can use clay left over after digging a well or septic tank.

The quality of the soil itself is not important in this case; large inclusions will only be beneficial. To create an alpine slide you need:

- add sand and gravel to the mixture;

- compact the resulting material, giving it the selected shape;

- pour water 3-4 times, without allowing the prepared mixture to dry completely;

- Having made sure that the composition is well compacted, install stones to decorate the alpine slide and water again;

- Pour a small layer of fertile soil between large stones and plant plants.

In the same way you can make rockeries, rocky garden design, edging the sides of paths and beds.

Methods for installing such a filter

There are two ways to install a bottom filter: direct and reverse. They differ in the sequence of layers.

- When laying directly, the largest stones are placed at the bottom, then the medium ones, and small pebbles are at the top. This method is also used when using a shield that protects against quicksand.

- When laid back, the largest stones are on top, and the smallest ones are at the bottom. Sometimes the bottom is covered with a layer of coarse quartz sand.

The thickness of the layers (using any method) is 10-15 cm, and the “filler” fraction in each differs by approximately 5-6 times.

Decorating an old well

The site of the old well will not be suitable for construction for several years, so it will have to be used somehow. In principle, there are many options. The simplest is a flower garden or platform. But there are more decorative options. One of them is a small artificial pond. It can be built if part of the well trunk remains protruding above the surface of the earth. In this case, it is necessary to seal the bottom of the reservoir, strengthen it and line it with flat stones from the inside. For example, in the photo below such a pond is shown as one of the options.

Artificial reservoir in place of an old well

Instead of a pond, you can create a flower bed by lining the trunk sticking out of the ground with natural decorative material. For example, a stone. That is, by turning on your imagination, you can get a beautiful and functional object on a suburban area. Although many summer residents simply level the place, adapting it to other needs.

Why is a blind area necessary?

The blind area is arranged for several reasons. The first thing the owner thinks about is how to ensure access to a source of water regardless of the weather. You don’t want mud squelching under your feet or getting tangled in the grass. A level area around the well will eliminate these problems. In addition, it gives the building a beautiful finished look. The second reason is functional. The top of the well is covered with a lid to prevent leaves and dust from getting in. But it also needs protection at ground level. A special threat is rain and melted spring water. When they are mixed with drinking water, it becomes cloudy and tasteless. Additionally, there is a high probability of pathogenic bacteria entering, which then affects the residents. The blind area is necessary because adds beauty to the structure, creates convenience in using the well, and protects the health of everyone who consumes water from the source.

Crushed stone

Stone of medium and relatively large sizes is obtained through the process of crushing certain types of rocks. Coarse backfill is used at the very top of the bottom of the well or at the bottom of the structure.

When choosing this filter material, you must ensure that there are no increased levels of radioactivity.

How to properly prepare concrete mortar

Concrete mortar is prepared in two types - saturated (7 parts crushed stone and 2 parts Portland cement) and unsaturated (6 parts crushed stone and part cement). Both solutions must be kept in the fresh air so that they harden slightly, which will prevent the mixture from being washed away by water: the first solution is kept for 5 hours, the second – 3. Placed under a canopy or covered with something.

In order not to disturb the solidity of the structure, you need to monitor the consistency of the solutions. So, the next layer can only be poured onto a semi-liquid solution that has not yet hardened. Otherwise, the structure will not be strong and cracks may appear.

Crushed stone in the bottom filter

The design of the bottom filter is simple and ingenious. Essentially, this is a repetition of nature's natural method of filtering liquid. Water passes through several layers of bulk materials, which retain small particles and impurities. They absorb everything extraneous. In the classic version, there are three layers in which the grain size of the stone successively increases: the first layer is sand, then small fractions of crushed stone, and at the end they are filled with a large fraction, usually 40–70 mm. Sometimes two or four additional layers are poured.

Direct backfilling is necessary when placing a well on quicksand or loose soil. Backfilling is effective if there is sand at the bottom of the well and the water comes in slowly. Sooner or later, such filters become clogged. Experts recommend cleaning them every three to four years.

Crushed stone is placed in a well for two reasons. The first is to provide additional filtration when using several fractions. Sand traps dirt and other particles. The crushed stone layer is designed to retain sand and all other impurities. In addition, it protects the well from agitation.

Concreting the site

concreting the area around the well

diagram of the concrete blind area around the well

The durability of the structure ensures proper preparation of the solution. Cement-sand is not suitable, because... After a few months, the surface will crack and begin to crumble. To prepare high-quality concrete, take clean sand without foreign inclusions, fine crushed stone and cement, mix dry in a ratio of 5:3:1. Add water and mix until a homogeneous, creamy consistency is formed. Step-by-step instructions will help you properly concrete the site:

- They are preparing a trench. Take out the soil to a depth of 30 cm, arrange a sand cushion with a layer of 15 cm. It is moistened with water and compacted well.

- Fill in 10 cm of fine crushed stone and compact it. Lay reinforcement or mesh, placing stones so that it is in the concrete layer.

- A formwork made of boards is installed around it. The entire space is divided into segments - this will protect the blind area from destruction in frosty weather. They use slats, which are removed after the concrete has set, and the voids are filled with mortar.

- The site is planned with a slight slope from the rings. The level is set using slats.

- Fill with mortar, tamp to remove voids, then level. Cement is scattered over the wet mortar and smoothed. The procedure is repeated several times - this strengthens the surface layer.

- The area is covered with wet burlap and left. Make sure that the material does not dry out and moisten it regularly.

Some care tips

The bottom filter, after proper assembly, does not require special attention, but if it is not cleaned in a timely manner, the quality of the water will deteriorate significantly.

- Inspect the filter once every six months. If plaque has formed on its upper layers, it is time to clean and rinse the barrier.

- Once a year, stones (especially shungite) must be washed with citric acid or calcined (~300 C).

- Every five years, it is imperative to replace all layers and components of the filter, especially the shield (if it is made of wood).

- After installing the filter, you cannot immediately use the source. Better to let it sit for a day or two.

Pebbles

Pebbles are used as backfill for medium or large fractions. Such material is represented by differently rounded rock fragments, the diameter of which varies between 1–15 cm. Sea pebbles, as a rule, have a flatter shape compared to river stone. Before backfilling, the material is washed.

Crushed stone or gravel?

In construction, it is customary to distinguish between the destruction products of various rocks - gravel and crushed stone. But the first one is the result of a natural process, and crushed stone is obtained artificially, by crushing rocks using special mechanisms.

Crushed stone is in demand in construction

The gravel turns out smoother, its dimensions do not exceed 20 mm. The crushed stone is much cleaner, without foreign inclusions, acute-angled, reaching 200 mm.

Thanks to this shape, the binding capacity of the stone increases significantly. It is added to concrete and reinforced concrete products to increase strength.

For the same reason, it is needed in the filtration layer of wells, drainage systems, and cesspools. The filtration layer of crushed stone is better than gravel at any compaction density.