In home plumbing, ball mixers began to be used relatively recently. However, the popularity of this plumbing equipment is growing every day. This can be easily explained by convenience and ease of use. Problems with these faucets are quite rare. And the service life is very long. With faucets of this design you can seriously save on water. Despite its high reliability, problems still occur with this plumbing device in Russian conditions, but everything can be resolved. Let's look at how these faucets work, what can happen to them, and how to repair them.

Ball mixer: the main invention for plumbing

Despite the fact that the ball mixer has been in operation in our country for some two decades, this design was developed a very long time ago. It was created by engineer Alex Manukyan. In 1929, Manukyan created a small company that manufactured various parts for cars and Ford. In 1940, from a small company, this company turned into a large production with a turnover of millions of dollars.

In 1940, a certain inventor from California approached Manukyan and offered to purchase the right to produce a revolutionary crane. The innovation was that instead of the traditional two taps, one was used for hot and cold water. Using it, it was possible to simultaneously adjust both pressure and temperature. The innovation was poorly received and they even laughed at the inventor. But Manukyan looked at one small perspective that everyone else simply missed. The design of the ball mixer is such that it has only one moving element. There are no gaskets or parts subject to rapid wear.

After some time it became clear that, despite the lack of gaskets, the mixer was working fully. And now Alex Manukyan, together with experienced engineers, begins work on finalizing the design. In 1954, the work was completed and a new revolutionary product was released, which is now installed in most bathrooms. By the way, Manukyan made a huge fortune for himself from this.

Advantages of ball mixers

Ten years ago, there were no alternatives to valve devices in the plumbing market. And when the ball mixer appeared, many were faced with a choice - what to install in the bathroom? Sales show that the ball valve design is in great demand. This can be easily explained by the advantages and high performance characteristics of the device. Also, experts in plumbing equipment say that now you can’t find anything on sale that would be more reliable.

Ball bath faucets turned out to be very convenient to use. You no longer need to twist anything to set the optimal water temperature and pressure. To do this, simply set the lever to the desired position. Over time, this becomes almost automatic.

Those who have been using such devices for a long time already know where the handle should be for the appropriate temperature and pressure. And for those who are just planning to install such a device, it is useful to know that the pressure can be adjusted by moving the control handle up or down. The temperature is adjusted by turning to the right or left.

Design of mechanisms with a ball valve

Modern plumbing fixtures, namely ball mixers, like their valve relatives, despite their advanced technology, sometimes fail. There is nothing unusual about this. They are made from the same materials. It's the same metal, the same rubber and plastic. Parts are subject to wear during use. Repairing a ball mixer is not difficult. But in order for everything to work out, you need to understand the device and be able to remove it, if necessary.

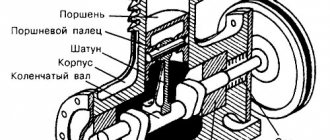

So, the device consists of several elements. This is a rotary handle, or rather a lever. There is also a rod, and its seal is adjusted using the included washer and nut. There is a valve body and a nut. The body contains a ball cartridge along with a rod.

This cartridge is a solid, non-separable element. It has three holes. They are designed for cold, hot water, as well as mixed water of the required temperature and pressure.

Technique for restoring shut-off valve functionality

When planning to restore the functionality of a ball valve, you should ensure not only the availability of the necessary tools, but also good lighting.

When restoring the operation of the faucet, you should first unscrew the self-locking nut (in some cases you should simply unscrew the screw that holds the rotary handle). All this can be easily done using a size 8 or 10 spanner wrench, and an open-end wrench also helps in this matter (everything initially depends on the crane model).

Next, you need to carefully remove the faucet handle. This, as a rule, is not easy, only after its gradual rocking, accomplished by alternating pressure on one or the other side of the structure. In this case, it is important not to knock on it - this will lead to the integrity of the flags and their breakage.

Now you should select the most suitable key, and then try to turn it, alternately changing the direction: first you can try to do it clockwise, and then counterclockwise. When carrying out the described actions, it is important to monitor their amplitude - it should be low, because with great effort there is always a risk of breaking the rod or tearing off the edges.

As soon as movement is noticed, the amplitude of the movements and their scope can be increased. When performing this work, it is very important to ensure that one of your hands holds the head on the rod, and the other turns it.

As soon as the rod moves as freely as possible, at this point you can put on the handle, and then secure it with a screw (or nut). Now you should continue the rocking process until the water supply is completely blocked.

Typical faults

With careful use, without applying any special effort to the device, the product can serve without breakdowns for a long time. However, more often these cranes are operated differently and fail.

Typical malfunctions include a leak when the lever is in a locked position, or low pressure when the pressure in the water supply is normal. Regulations are also often violated. It is impossible to adjust the water to the desired temperature, since mixing is carried out chaotically. Before repairing ball bathroom faucets, you need to determine the cause of the problem.

Types of breakdowns

The ball cartridge is fixed in the housing using rubber seats. There is free space between these elements. If it becomes clogged, it will cause a malfunction. Even a small speck is enough to break the seal. As a result, the rubber seat becomes deformed. The ball mount fails.

Also, one of the most common troubles is a blockage in the shutter. In this case, you can even do without repairs, and the problem can be solved with simple cleaning. But to do this you will have to disassemble the tap. But after assembly, everything will fall into place again and the device will work like new.

Often, all breakdowns occur due to water flowing in the pipes. She's very tough. It does not depend at all on what type of mixer is installed. In order not to change plumbing fixtures frequently, experts recommend installing filter elements. Another nuisance is water that flows from under the rotary handle. Here it is enough to tighten the connection.

Problems during operation

Even high-quality plumbing fixtures fail over time. The service life of the faucet depends on the material from which it is made, the quality of the tap water and the intensity of use. The most common problems that arise when using single-lever models are:

- Cracks on the device body. They arise due to poor quality material and installation errors.

- Aerator clogged. The cause of this malfunction is the poor quality of tap water.

- Wear of rubber gaskets. Seals are consumables; they wear out over time due to the high intensity of use of the device.

Important! No matter how high the quality of the faucet, it needs preventive maintenance. Even if no problems arise during operation, you need to disassemble the device once every 2 years, clean it, and replace the gaskets. After all, even a small speck that gets under the seal can cause a leak.

If water is leaking from underneath the faucet base

This malfunction can be eliminated by replacing the seals. Before you start repairing ball mixers with your own hands, you first need to turn off the water. Then the mixer is dismantled and disconnected. Also unscrew the fixing nut.

A worn gasket must be replaced with the same one, only a new one. If it is selected correctly, then you will need to apply a little force to install it.

Repair features

So, let's look at what needs to be done if repairs are unavoidable. Repairing the device is quite simple - any home craftsman can handle it. For work you will need a standard set of tools:

- Adjustable wrench.

- Hexagons.

- Screwdriver or thin knitting needle.

- Flashlight.

First of all, turn off the water. Next, dismantling is carried out. There is a plug on the device body. She is also being removed. Under this plug there is a hole through which you can access the screw that holds the lever in place. This screw should be unscrewed. Now you can remove the lever. If the device has been standing for a long time and the ball mixer has not been disassembled, some effort may be required.

Now there is access to the dome part of the product and plastic eccentrics. These parts are also removed. The cartridge will be installed under them. All dirt must be carefully removed. Next, the mixer switch is removed from the housing. It should be carefully examined from all sides. If there is damage, the cartridge must be replaced.

Next, check the rubber sealing elements. If their elasticity is reduced or lost, then the parts are replaced with new ones. The seals on which the switch is installed are also replaced (for prevention).

Next, it remains to install all the parts in place and assemble the structure in the reverse order. After this, the product should work normally again. But there can also be a leak under the tap. In this case, it is removed and the seals under the drain are replaced.

General information

A ball valve is a mechanism installed on the main water supply system. It is necessary to block the water supply through the cold or hot water supply pipeline.

The blocking element is a ball with a hole inside. It is installed between 2 elastic seals. The passage of water between it and the internal surfaces is impossible. When the handle of the ball device is turned to the “open” position, water flows through the hole in the blocking element. When closing, the handle rotates the ball and closes the channel.

Kinds

Ball products differ in design, type of connection to the main line and material of manufacture. Manufacturers produce ball locking mechanisms with a collapsible or solid body. The type of design affects the repairability of the product. Based on the type of connection to the pipeline, devices are divided into 4 types:

- Threaded.

- Flanged.

- With solder connectors.

- Combined.

Depending on the material used, ball products can be made of steel, brass and plastic. In domestic conditions, locking elements made of brass are common. They are resistant to the negative effects of moisture and have a long service life.

Product repairability

Products with a solid body cannot be repaired. If they fail, a complete replacement of the unit is required. The functionality of collapsible structures is restored by replacing broken parts. Following the sequence of actions will allow you to properly repair the ball valve.

Shower switch repair

This malfunction occurs quite often. When you try to turn on the water from the spout into the shower hose, the lever switches independently. Liquid flows from the spout and cannot be supplied to the shower. To find the reasons, unscrew the union nut and dismantle the hose. Then remove the top gasket. You may need to pry it up with a thin knitting needle. The gasket is replaced with a new one. The mixer is assembled and checked.

If the device still does not work, then turn off the water again and remove the shower hose. Then remove the adapter, spout and lever. Now remove the eccentric and spool. Next, access to the lower gasket ring opens. It should be replaced. Next, the device is assembled and tested. Before you go to the store for supplies, you should see if you have these gaskets at home. Often several seals are included with the device. If you still don’t have the materials, you can make them yourself. Hard rubber 3-4 millimeters thick is suitable.

Recommendations for carrying out repair work, possible difficulties,

Experienced professionals give the following recommendations:

- Lay a sheet of cardboard or thick cloth in the sink or bathroom. This will prevent small parts from falling into the drain and protect the tub cover from falling heavy tools.

- If the cartridge fastening nut is stuck and the threads are covered with a layer of mineral deposits, you need to moisten them with warm vinegar and leave for a while.

- If the handle turns tightly after assembly, you have overtightened the nut. It should be loosened a little, a quarter of a turn.

It’s better to start disassembling in the morning or afternoon so you can get to the store before closing for spare parts.