The issue of improving energy efficiency and increasing the service life of insulation materials is relevant not only for those involved in private construction, but also for residents of ordinary apartments who want to provide high-quality thermal insulation for their home. Fortunately, a relatively wide range of such materials allows you to choose the most optimal option depending on your financial capabilities and area of application. Very often, polystyrene foam or mineral wool are used for insulation, which are affordable, but not without their drawbacks. Unique technology and the use of an equally unique material called PIR boards made it possible to produce an ideal insulation material, which is used even in rocket science. Today we will understand the basics of choosing PIR panels (PIR panels) and take a detailed look at their characteristics, the largest manufacturers in the Russian construction market and prices for the material.

Section Contents

1. Sandwich panels made of polyisocyanurate foam (PIR) 1.1 What is polyisocyanurate foam? 1.2 Technical characteristics of PIR sandwich panels 1.3 Fire safety indicators of polyisocyanurate foam 1.4 Comparison of polyisocyanurate foam with mineral wool 1.5 Main advantages of sandwich panels with PIR insulation 1.6 Area of use of PIR panels 1.7 Prices for PIR sandwich panels 1.7.1 Cost of wall sandwich panels PIR 1.7. 2 Cost of PIR roofing sandwich panels 2. Polyurethane foam sandwich panels (PUR, PUR) 2.1 Technical characteristics of PUR sandwich panels 2.2 Scope of PUR panels 2.3 Prices for PUR sandwich panels 2.3.1 Cost of PUR wall sandwich panels 2.3 .2 Cost of PPU (PUR) roofing sandwich panels 3. Dimensions of PIR/PUR panels 4. Locking connection of PIR/PUR wall panels 5. Locking connection of PIR/PUR roofing panels 6. Covering of PIR/PUR sandwich panels 7. Sandwich packaging PIR/PUR panels 8. PIR/PUR sandwich panels to order

VITRA

- Possibility of interest-free installments and purchases on credit

- Found it cheaper? We'll lower the price even lower!

- Door warranty 12 months

- All doors are in stock

- Metal thickness:

1.5 mm. - Sheet thickness: 140 mm MDF

- Box thickness: 130 mm

- Thermal expansion: on the box, on the canvas - 24 mm (special 2-chamber plastic insert)

- Decor:

MDF 12 mm outside and 12 mm inside + double glazing + forging - 3 Seal circuits:

3 circuits - Filling: PIR

board - Locks: Border Professional 4 classes, cylinder + lever + night bolt

- Manufacture: Russia

- Door

- Installation

- Free wooden door dismantling

- are common

- technical

- DECOR

- Manufacturer:

Ferroni - Country of origin:

RUSSIA - Burglar resistance level:

4 - Warranty (years):

1 - Possible use:

indoors - Availability:

In stock - Standard dimensions:

860*2050mm; 960*2050 mm. - Custom sizes:

no

- Steel thickness:

1.5 mm - Sheet thickness:

130 mm - Box thickness:

140 mm - Opening:

180 degrees - Box:

solid-bent open with platbands - Hinges:

External on sealed bearings - Seal circuits:

3 circuits - Locks:

Border Professional 4 classes - Overlays:

Decorative overlay for a lever lock with curtains - Anti-cutting:

Anti-removal hex pins - Filling:

PIR board - door weight:

130 kg

- Metal color:

Black Moiré - Exterior decor:

MDF 12 mm Vinorite - Interior decor:

MDF 12 mm Vinorite - Double-glazed window:

2-chamber double-glazed window + forging

We use cookies. Read more in our privacy policy.

- IP Bindeman Sergey Vadimovich

- INN 701713802375

- OGRN 313701725200221

- Privacy Policy

- Personal data processing policy

- We will make an accurate measurement of the door

- You will freeze the current price

- Submitting an application does not obligate you to purchase

- We will make an accurate measurement of the door

- You will freeze the current price

- Submitting an application does not obligate you to purchase

- You will freeze the current price

- Submitting an application does not obligate you to purchase

- You will freeze the current price

- Submitting an application does not obligate you to purchase

- We will make an accurate measurement of the door

- You will freeze the current price

- Submitting an application does not obligate you to purchase

- We will make an accurate measurement of the door

- You will freeze the current price

- Submitting an application does not obligate you to purchase

- We will make an accurate measurement of the door

- You will freeze the current price

- Submitting an application does not obligate you to purchase

- We will make an accurate measurement of the door

- You will freeze the current price

- Submitting an application does not obligate you to purchase

- We will make an accurate measurement of the door

- You will freeze the current price

- Submitting an application does not obligate you to purchase

- We will make an accurate measurement of the door

- You will freeze the current price

- Submitting an application does not obligate you to purchase

Sandwich panels made of polyisocyanurate foam (PIR)

PIR sandwich panels are a reliable building material, which is distinguished by its three-layer structure and low weight. Its main advantage is fire resistance .

Also, the main advantages of this insulation are its low thermal conductivity coefficient and good load-bearing capacity .

Therefore, this insulation is used in the production of sandwich panels as one of the main ones.

1.1 What is polyisocyanurate foam?

Polyisocyanurate foam (PIR) is a modified polyurethane foam (PPU) , which has a number of serious advantages over its predecessor.

PIR is also made on the basis of the reaction of a polyol and isocyanate, however, the presence of fire retardants in its structure makes the insulation self-extinguishing after the combustion source is removed.

In addition, PIR works much better in tension-compression . It can be used in places where these characteristics are subject to special requirements, for example, structures experiencing increased wind loads.

1.2 Technical characteristics of PIR sandwich panels

| Indicator name | Meaning | |||||||||||

| Filler type | polyisocyanurate foam (PIR) | |||||||||||

| Average density, kg/m3 | 42 | |||||||||||

| Weight, kg/m2 with metal thickness 0.5 mm | wall | 9,5 | 11,6 | 12,4 | 13,2 | 14,5 | 16,6 | |||||

| roofing | 9,8 | 11,5 | 12,3 | 13,1 | 14,4 | |||||||

| Metal thickness, mm | 0,50-0,70 | |||||||||||

| Metal surface, mm | profiled or smooth | |||||||||||

| Standard version | RAL 9003 or Zn (galvanized sheet) | |||||||||||

| Thermal conductivity coefficient, W/m K | 0,022 | |||||||||||

| Thermal resistance coefficient | Wall | 1,9 | 3,81 | 4,76 | 5,71 | 7,14 | 9,52 | |||||

| Roofing | 2,0 | 3,9 | 4,86 | 5,81 | 7,24 | |||||||

| Sound insulation, dB | 35 | |||||||||||

1.3 Fire safety indicators of polyisocyanurate foam

| Indicator name | Filler | 40 | 60 | 80-120 | 150-200 | Standard |

| Fire resistance limit of wall panels | PUR | EI15 | GOST 30247.1-94 | |||

| PIR | EI15 | EI30 | EI45 | GOST 30247.0-94 | ||

| Fire resistance limit of roofing panels | PIR | RE15 | RE30 | RE30 | GOST 30247.0-94 GOST 30247.1-94 | |

| Fire hazard class | PIR | K1 (15) | GOST 30403-96 | |||

| Flammability group | PIR | G1 | GOST 30244-94 | |||

| Flammability group | PIR | IN 1 | GOST 30402-96 | |||

| Smoke generating ability | PIR | D3 | GOST 12.1.044-89 | |||

| Combustion Products Toxicity Group | PIR | T2 | GOST 12.1.044-89 | |||

| Surface flame propagation group | PIR | RP1 | GOST R 51032-97 | |||

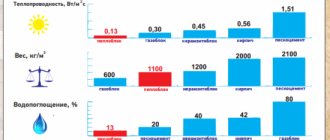

1.4 Comparison of polyisocyanurate foam with mineral wool

| Properties | FEAST | Mineral wool |

| Density, kg/m3 | 40-50 | 115-200 |

| Thermal conductivity coefficient, W/m°C | 0,022 | up to 0.052 |

| Moisture absorption in 24 hours at 96% relative humidity, volume % | 0,01 | > 0,2 |

1.5 Main advantages of sandwich panels with PIR insulation

- Good fire resistance of PIR sandwich panels - they can be used at elevated temperatures (max t for PPU – +100°C, max t for PIR – +150°C).

- Easy to install PIR sandwich panels due to their low weight. The reduction in the weight of the insulation is ensured by the thermal insulation properties of the material, which make it possible to minimize its thickness.

- High strength characteristics and load-bearing capacity. PIR is excellent for insulating structures that experience high loads (for example, concrete-cement screed).

- Low thermal conductivity coefficient (0.022 W/m*K). In this indicator, polyisocyanurate foam greatly outperforms many similar materials.

- Environmental Safety. Polyisocyanurate foam does not emit hazardous substances and does not provoke allergic reactions.

1.6 Area of use of PIR panels

Sandwich panels with polyisocyanurate foam insulation are successfully used for wall installation in buildings for a wide variety of purposes:

- Shopping and entertainment centers;

- Car washes;

- Food or any other “clean” production premises;

- Swimming pools, sports grounds;

- Warehouses, hangars;

- Storage facilities for hazardous substances;

- Industrial workshops;

- Etc.

1.7 Prices for PIR sandwich panels

1.7.1 Cost of PIR wall sandwich panels, rubles. per square meter, depending on the thickness and type of polymer coating of the metal

| Coating material | Panel thickness, mm / Joint type (tongue and groove) | ||||||||

| single | double | triple | |||||||

| Side A | Side B | 40 | 50 | 60 | 80 | 100 | 120 | 150 | 200 |

| Fire resistance limit | EI15 | EI30 | EI45 | ||||||

| Ral | |||||||||

| Ral | 1472 | 1575 | 1674 | 1873 | 2068 | 2282 | 2589 | 3147 | |

| Zn | 1452 | 1555 | 1654 | 1853 | 2048 | 2262 | 2569 | 3127 | |

| Aisi 304 | 2752 | 2855 | 2954 | 3153 | 3348 | 3562 | 3869 | 4427 | |

| AISI 430 | 2272 | 2375 | 2474 | 2673 | 2868 | 3082 | 3389 | 3947 | |

| PVDF | 1682 | 1785 | 1884 | 2083 | 2278 | 2492 | 2799 | 3357 | |

| PuralFarm | 1897 | 2000 | 2099 | 2298 | 2493 | 2707 | 3014 | 3572 | |

| granite farm | 1897 | 2000 | 2099 | 2298 | 2493 | 2707 | 3014 | 3572 | |

| Food Safe | 2072 | 2175 | 2274 | 2473 | 2668 | 2882 | 3189 | 3747 | |

| Zn | |||||||||

| Ral | 1452 | 1555 | 1654 | 1853 | 2048 | 2262 | 2569 | 3127 | |

| Zn | 1432 | 1535 | 1634 | 1833 | 2028 | 2242 | 2549 | 3107 | |

| Aisi 304 | 2732 | 2835 | 2934 | 3133 | 3328 | 3542 | 3849 | 4407 | |

| AISI 430 | 2252 | 2355 | 2454 | 2653 | 2848 | 3062 | 3369 | 3927 | |

| PVDF | 1662 | 1765 | 1864 | 2063 | 2258 | 2472 | 2779 | 3337 | |

| PuralFarm | 1877 | 1980 | 2079 | 2278 | 2473 | 2687 | 2994 | 3552 | |

| granite farm | 1877 | 1980 | 2079 | 2278 | 2473 | 2687 | 2994 | 3552 | |

| Food Safe | 2052 | 2155 | 2254 | 2453 | 2648 | 2862 | 3169 | 3727 | |

| Aisi 304 | |||||||||

| Ral | 2752 | 2855 | 2954 | 3153 | 3348 | 3562 | 3869 | 4427 | |

| Zn | 2732 | 2835 | 2934 | 3133 | 3328 | 3542 | 3849 | 4407 | |

| Aisi 304 | 4032 | 4135 | 4234 | 4433 | 4628 | 4842 | 5149 | 5707 | |

| AISI 430 | 3552 | 3655 | 3754 | 3953 | 4148 | 4362 | 4669 | 5227 | |

| PVDF | 2962 | 3065 | 3164 | 3363 | 3558 | 3772 | 4079 | 4637 | |

| PuralFarm | 3177 | 3280 | 3379 | 3578 | 3773 | 3987 | 4294 | 4852 | |

| granite farm | 3177 | 3280 | 3379 | 3578 | 3773 | 3987 | 4294 | 4852 | |

| Food Safe | 3352 | 3455 | 3554 | 3753 | 3948 | 4162 | 4469 | 5027 | |

| AISI 430 | |||||||||

| Ral | 2272 | 2375 | 2474 | 2673 | 2868 | 3082 | 3389 | 3947 | |

| Zn | 2252 | 2355 | 2454 | 2653 | 2848 | 3062 | 3369 | 3927 | |

| Aisi 304 | 3552 | 3655 | 3754 | 3953 | 4148 | 4362 | 4669 | 5227 | |

| AISI 430 | 3072 | 3175 | 3274 | 3473 | 3668 | 3882 | 4189 | 4747 | |

| PVDF | 2482 | 2585 | 2684 | 2883 | 3078 | 3292 | 3599 | 4157 | |

| PuralFarm | 2697 | 2800 | 2899 | 3098 | 3293 | 3507 | 3814 | 4372 | |

| granite farm | 2697 | 2800 | 2899 | 3098 | 3293 | 3507 | 3814 | 4372 | |

| Food Safe | 2872 | 2975 | 3074 | 3273 | 3468 | 3682 | 3989 | 4547 | |

| PVDF | |||||||||

| Ral | 1682 | 1785 | 1884 | 2083 | 2278 | 2492 | 2799 | 3357 | |

| Zn | 1662 | 1765 | 1864 | 2063 | 2258 | 2472 | 2779 | 3337 | |

| Aisi 304 | 2962 | 3065 | 3164 | 3363 | 3558 | 3772 | 4079 | 4637 | |

| AISI 430 | 2482 | 2585 | 2684 | 2883 | 3078 | 3292 | 3599 | 4157 | |

| PVDF | 1892 | 1995 | 2094 | 2293 | 2488 | 2702 | 3009 | 3567 | |

| PuralFarm | 2107 | 2210 | 2309 | 2508 | 2703 | 2917 | 3224 | 3782 | |

| granite farm | 2107 | 2210 | 2309 | 2508 | 2703 | 2917 | 3224 | 3782 | |

| Food Safe | 2282 | 2385 | 2484 | 2683 | 2878 | 3092 | 3399 | 3957 | |

| PuralFarm | |||||||||

| Ral | 1897 | 2000 | 2099 | 2298 | 2493 | 2707 | 3014 | 3572 | |

| Zn | 1877 | 1980 | 2079 | 2278 | 2473 | 2687 | 2994 | 3552 | |

| Aisi 304 | 3177 | 3280 | 3379 | 3578 | 3773 | 3987 | 4294 | 4852 | |

| AISI 430 | 2697 | 2800 | 2899 | 3098 | 3293 | 3507 | 3814 | 4372 | |

| PVDF | 2107 | 2210 | 2309 | 2508 | 2703 | 2917 | 3224 | 3782 | |

| PuralFarm | 2322 | 2425 | 2524 | 2723 | 2918 | 3132 | 3439 | 3997 | |

| granite farm | 2322 | 2425 | 2524 | 2723 | 2918 | 3132 | 3439 | 3997 | |

| Food Safe | 2497 | 2600 | 2699 | 2898 | 3093 | 3307 | 3614 | 4172 | |

| granite farm | |||||||||

| granite farm | 2322 | 2425 | 2524 | 2723 | 2918 | 3132 | 3439 | 3997 | |

| Food Safe | |||||||||

| Food Safe | 2672 | 2775 | 2874 | 3073 | 3268 | 3482 | 3789 | 4347 | |

1.7.2 Cost of PIR roofing sandwich panels, rubles. per square meter, depending on the thickness and type of polymer coating of the metal

| Coating material | Panel thickness (without hump), mm | ||||||

| Side A | Side B | 40 | 60 | 80 | 100 | 120 | 150 |

| Fire resistance limit | RE 15 | RE 30 | |||||

| Ral | |||||||

| Ral | 1656 | 1874 | 2056 | 2251 | 2445 | 2767 | |

| Zn | 1636 | 1854 | 2036 | 2231 | 2425 | 2747 | |

| Aisi 304 | 3151 | 3369 | 3551 | 3746 | 3940 | 4262 | |

| AISI 430 | 2590 | 2808 | 2990 | 3185 | 3379 | 3701 | |

| PVDF | 1901 | 2119 | 2301 | 2496 | 2690 | 3012 | |

| PuralFarm | 2152 | 2370 | 2552 | 2747 | 2941 | 3263 | |

| granite farm | 2152 | 2370 | 2552 | 2747 | 2941 | 3263 | |

| Food Safe | 2357 | 2575 | 2757 | 2952 | 3146 | 3468 | |

| Zn | |||||||

| Ral | 1636 | 1854 | 2036 | 2231 | 2425 | 2747 | |

| Zn | 1616 | 1834 | 2016 | 2211 | 2405 | 2727 | |

| Aisi 304 | 3131 | 3349 | 3531 | 3726 | 3920 | 4242 | |

| AISI 430 | 2570 | 2788 | 2970 | 3165 | 3359 | 3681 | |

| PVDF | 1881 | 2099 | 2281 | 2476 | 2670 | 2992 | |

| PuralFarm | 2132 | 2350 | 2532 | 2727 | 2921 | 3243 | |

| granite farm | 2132 | 2350 | 2532 | 2727 | 2921 | 3243 | |

| Food Safe | 2337 | 2555 | 2737 | 2932 | 3126 | 3448 | |

| Aisi 304 | |||||||

| Ral | 3151 | 3369 | 3551 | 3746 | 3940 | 4262 | |

| Zn | 3131 | 3349 | 3531 | 3726 | 3920 | 4242 | |

| Aisi 304 | 4646 | 4864 | 5046 | 5241 | 5435 | 5757 | |

| AISI 430 | 4086 | 4304 | 4486 | 4681 | 4875 | 5197 | |

| PVDF | 3396 | 3614 | 3796 | 3991 | 4185 | 4507 | |

| PuralFarm | 3648 | 3866 | 4048 | 4243 | 4437 | 4759 | |

| granite farm | 3648 | 3866 | 4048 | 4243 | 4437 | 4759 | |

| Food Safe | 3852 | 4070 | 4252 | 4447 | 4641 | 4963 | |

| AISI 430 | |||||||

| Ral | 2590 | 2808 | 2990 | 3185 | 3379 | 3701 | |

| Zn | 2570 | 2788 | 2970 | 3165 | 3359 | 3681 | |

| Aisi 304 | 4086 | 4304 | 4486 | 4681 | 4875 | 5197 | |

| AISI 430 | 3525 | 3743 | 3925 | 4120 | 4314 | 4636 | |

| PVDF | 2836 | 3054 | 3236 | 3431 | 3625 | 3947 | |

| PuralFarm | 3087 | 3305 | 3487 | 3682 | 3876 | 4198 | |

| granite farm | 3087 | 3305 | 3487 | 3682 | 3876 | 4198 | |

| Food Safe | 3291 | 3509 | 3691 | 3886 | 4080 | 4402 | |

| PVDF | |||||||

| Ral | 1901 | 2119 | 2301 | 2496 | 2690 | 3012 | |

| Zn | 1881 | 2099 | 2281 | 2476 | 2670 | 2992 | |

| Aisi 304 | 3396 | 3614 | 3796 | 3991 | 4185 | 4507 | |

| AISI 430 | 2836 | 3054 | 3236 | 3431 | 3625 | 3947 | |

| PVDF | 2146 | 2364 | 2546 | 2741 | 2935 | 3257 | |

| PuralFarm | 2398 | 2616 | 2798 | 2993 | 3187 | 3509 | |

| granite farm | 2398 | 2616 | 2798 | 2993 | 3187 | 3509 | |

| Food Safe | 2602 | 2820 | 3002 | 3197 | 3391 | 3713 | |

| PuralFarm | |||||||

| Ral | 2152 | 2370 | 2552 | 2747 | 2941 | 3263 | |

| Zn | 2132 | 2350 | 2532 | 2727 | 2921 | 3243 | |

| Aisi 304 | 3648 | 3866 | 4048 | 4243 | 4437 | 4759 | |

| AISI 430 | 3087 | 3305 | 3487 | 3682 | 3876 | 4198 | |

| PVDF | 2398 | 2616 | 2798 | 2993 | 3187 | 3509 | |

| PuralFarm | 2649 | 2867 | 3049 | 3244 | 3438 | 3760 | |

| granite farm | 2649 | 2867 | 3049 | 3244 | 3438 | 3760 | |

| Food Safe | 2853 | 3071 | 3253 | 3448 | 3642 | 3964 | |

| granite farm | |||||||

| granite farm | 2649 | 2867 | 3049 | 3244 | 3438 | 3760 | |

| Food Safe | |||||||

| Food Safe | 3058 | 3276 | 3458 | 3653 | 3847 | 4169 | |

What are PIR boards and where are they used?

Thanks to the very high adhesion of polyisocyanurate, it became possible to use various lining materials in the manufacture of slabs. This allows them to be used in various construction fields and to select the optimal type of insulation according to the characteristics and needs. Any of the following materials is also a limiter for further increasing the volume of foam and has a thickness of 50 to 100 microns, that is, from 0.05 to 0.1 mm.

- PIR boards with kraft paper lining. This type is most often used for internal insulation of buildings, for example, for lining the ceiling. In turn, the slabs serve as a reliable basis for further high-quality finishing and have a high level of adhesion;

- Insulation with a fiberglass is successfully used for both interior and exterior decoration of buildings. For example, for finishing plastering using a “wet facade” type system;

- Plates with a fiberglass lining and bitumen impregnation are used when it is necessary to weld waterproofing materials directly onto the surface of the insulation. Most often, this method is used for high-quality insulation of flat roofs;

- PIR boards lined with several layers of aluminum foil, or in other words - aluminum laminate. They are used for various insulation systems, even for thermal insulation of foundations and loaded floors directly on the ground;

- Fire resistant slabs made of graphite, which is capable of protecting polyisocyanurate from exposure to open fire for a long time, are used, for example, to insulate military vehicles. When a projectile hits, the flame from the explosion not only does not spread into the cabin, but the combustion process itself is not supported.

Some manufacturers can produce PIR boards with a lining of other materials that are required by a specific customer. In addition, PIR boards ideally suited for:

- Insulation of balconies or loggias. Unlike other insulating materials, slabs can have a minimum thickness, which will save precious centimeters of usable space. In addition, the installation of the slabs does not require the preliminary organization of a wooden frame, and the insulation layer will be uniform. For such purposes, slabs covered with fiberglass or aluminum laminate are best suited;

- For organizing air ducts for ventilation, air heating or air conditioning systems based on plates coated with aluminum foil. Such structures weigh 5-8 times less than steel ones. The installation process is much simpler than the construction of steel structures. And in some cases, when there are restrictions on the load on supporting structures, such a solution is the only possible one. At the same time, PIR boards are fireproof - they do not support or spread flames and do not create dangerous molten drops. And the connection with steel elements is made using standard flange connections;

- For cladding baths and saunas. Due to the moisture resistance of the material, its environmental friendliness even when heated to high temperatures and low thermal conductivity, this is one of the ideal insulators;

- For insulation of not only flat, but also pitched roofs. PIR boards can be laid directly on top of wooden rafters to create a seamless coating without cold bridges. While the same mineral wool can only be laid between the rafters. In this case, heat leakage occurs through uncovered wooden logs, which few people think about.

Sandwich panels made of polyurethane foam (PPU, PUR)

PUR sandwich panels are a three-layer building material with polyurethane foam insulation. It is distinguished by its high thermal insulation characteristics and has a density in the range of 42…45 kg/m3.

2.1 Technical characteristics of PUR sandwich panels

| Indicator name | Meaning | |||||||||||

| Filler type | PPU (PUR) polyurethane foam | |||||||||||

| Average density, kg/m3 | 42 | |||||||||||

| Weight, kg/m2 with metal thickness 0.5 mm | wall | 9,5 | 11,6 | 12,4 | 13,2 | 14,5 | 16,6 | |||||

| roofing | 9,8 | 11,5 | 12,3 | 13,1 | 14,4 | |||||||

| Metal thickness, mm | 0,50-0,70 | |||||||||||

| Metal surface, mm | profiled or smooth | |||||||||||

| Standard version | RAL 9003 or Zn (galvanized sheet) | |||||||||||

| Thermal conductivity coefficient, W/m K | 0,022 | |||||||||||

| Thermal resistance coefficient | Wall | 1,9 | 3,81 | 4,76 | 5,71 | 7,14 | 9,52 | |||||

| Roofing | 2,0 | 3,9 | 4,86 | 5,81 | 7,24 | |||||||

| Sound insulation, dB | 35 | |||||||||||

2.2 Scope of application of PUR panels

Sandwich panels with PUR insulation are most often used in construction:

- Car washes;

- Food or any other “clean” production premises;

- Swimming pools, sports grounds;

- Warehouses, hangars;

- Storage facilities for hazardous substances;

- Industrial workshops;

2.3 Prices for PUR sandwich panels

2.3.1 Cost of wall sandwich panels PPU (PUR)

| Coating material | Panel thickness, mm / Joint type (tongue and groove) | |||||||||||

| single | double | triple | ||||||||||

| Side A | Side B | 40 | 50 | 60 | 80 | 100 | 120 | 140 | 150 | 160 | 180 | 200 |

| Fire resistance limit | EI 15 | |||||||||||

| Ral | ||||||||||||

| Ral | 1421 | 1505 | 1569 | 1769 | 1943 | 2126 | 2381 | 2432 | 2608 | 2820 | 2947 | |

| Zn | 1401 | 1485 | 1576 | 1749 | 1923 | 2106 | 2361 | 2412 | 2588 | 2800 | 2927 | |

| Aisi 304 | 2701 | 2785 | 2876 | 3049 | 3223 | 3406 | 3661 | 3712 | 3888 | 4100 | 4227 | |

| AISI 430 | 2221 | 2305 | 2396 | 2569 | 2743 | 2926 | 3181 | 3232 | 3408 | 3620 | 3747 | |

| PVDF | 1631 | 1715 | 1806 | 1979 | 2153 | 2336 | 2591 | 2642 | 2818 | 3030 | 3157 | |

| PuralFarm | 1846 | 1930 | 2021 | 2194 | 2368 | 2551 | 2806 | 2857 | 3033 | 3245 | 3372 | |

| granite farm | 1846 | 1930 | 2021 | 2194 | 2368 | 2551 | 2806 | 2857 | 3033 | 3245 | 3372 | |

| Food Safe | 2021 | 2105 | 2196 | 2369 | 2543 | 2726 | 2981 | 3032 | 3208 | 3420 | 3547 | |

| Zn | ||||||||||||

| Ral | 1401 | 1475 | 1576 | 1749 | 1923 | 2106 | 2361 | 2412 | 2588 | 2800 | 2927 | |

| Zn | 1381 | 1465 | 1556 | 1729 | 1903 | 2086 | 2341 | 2392 | 2568 | 2780 | 2907 | |

| Aisi 304 | 3981 | 4065 | 4156 | 4329 | 4503 | 4686 | 4941 | 4992 | 5168 | 5380 | 5507 | |

| AISI 430 | 3501 | 3585 | 3676 | 3849 | 4026 | 4206 | 4461 | 4512 | 4688 | 4900 | 5027 | |

| PVDF | 2911 | 2995 | 3086 | 3259 | 3433 | 3616 | 3871 | 3922 | 4098 | 4310 | 4437 | |

| PuralFarm | 3126 | 3210 | 3301 | 3474 | 3648 | 3831 | 4086 | 4137 | 4313 | 4525 | 4652 | |

| granite farm | 1826 | 1910 | 2001 | 2174 | 2348 | 2531 | 2786 | 2837 | 3013 | 3225 | 3352 | |

| Food Safe | 2001 | 2085 | 2176 | 2349 | 2523 | 2706 | 2961 | 3012 | 3188 | 3400 | 3527 | |

| Aisi 304 | ||||||||||||

| Ral | 2701 | 2785 | 2876 | 3049 | 3223 | 3406 | 3661 | 3712 | 3888 | 4100 | 4227 | |

| Zn | 2681 | 2765 | 2856 | 3029 | 3203 | 3386 | 3641 | 3692 | 3868 | 4080 | 4207 | |

| Aisi 304 | 3981 | 4065 | 4156 | 4329 | 4503 | 4686 | 4941 | 4992 | 5168 | 5380 | 5507 | |

| AISI 430 | 2201 | 2285 | 2376 | 2549 | 2723 | 2906 | 3161 | 3212 | 3388 | 3600 | 3727 | |

| PVDF | 1611 | 1695 | 1786 | 1959 | 2133 | 2316 | 2571 | 2622 | 2798 | 3010 | 3137 | |

| PuralFarm | 1826 | 1910 | 2001 | 2174 | 2348 | 2531 | 2786 | 2837 | 3013 | 3225 | 3352 | |

| granite farm | 1826 | 1910 | 2001 | 2174 | 2348 | 2531 | 2786 | 2837 | 3013 | 3225 | 3352 | |

| Food Safe | 2001 | 2085 | 2176 | 2349 | 2523 | 2706 | 2961 | 3012 | 3188 | 3400 | 3527 | |

| AISI 430 | ||||||||||||

| Ral | 2221 | 2305 | 2369 | 2569 | 2743 | 2926 | 3181 | 3232 | 3408 | 3620 | 3747 | |

| Zn | 2201 | 2285 | 2376 | 2549 | 2723 | 2906 | 3161 | 3212 | 3388 | 3600 | 3727 | |

| Aisi 304 | 3501 | 3585 | 3676 | 3849 | 4023 | 4206 | 4461 | 4512 | 4688 | 4900 | 5027 | |

| AISI 430 | 3021 | 3105 | 3196 | 3369 | 3543 | 3726 | 3981 | 4032 | 4208 | 4420 | 4547 | |

| PVDF | 2431 | 2515 | 2606 | 2779 | 2953 | 3136 | 3391 | 3442 | 3618 | 3830 | 3957 | |

| PuralFarm | 2646 | 2730 | 2821 | 2994 | 3168 | 3351 | 3606 | 3657 | 3833 | 4045 | 4172 | |

| granite farm | 2690 | 2792 | 2891 | 3089 | 3283 | 3496 | 3742 | 3801 | 3978 | 4207 | 4357 | |

| Food Safe | 2821 | 2905 | 2996 | 3169 | 3343 | 3526 | 3781 | 3832 | 4008 | 4220 | 4347 | |

| PVDF | ||||||||||||

| Ral | 1631 | 1715 | 1806 | 1979 | 2153 | 2336 | 2591 | 2642 | 2818 | 3030 | 3157 | |

| Zn | 1611 | 1695 | 1786 | 1959 | 2133 | 2316 | 2571 | 2622 | 2798 | 3010 | 3137 | |

| Aisi 304 | 2911 | 2995 | 3086 | 3259 | 3433 | 3616 | 381 | 3922 | 4098 | 4310 | 4437 | |

| AISI 430 | 2431 | 2515 | 2606 | 2779 | 2953 | 3136 | 3391 | 3442 | 3618 | 3830 | 3957 | |

| PVDF | 1841 | 1925 | 2016 | 2189 | 2363 | 2546 | 2801 | 2852 | 3028 | 3240 | 3367 | |

| PuralFarm | 2056 | 2140 | 2231 | 2404 | 2578 | 2761 | 3016 | 3067 | 3243 | 3455 | 3582 | |

| granite farm | 2056 | 2140 | 2231 | 2404 | 2578 | 2761 | 3016 | 3067 | 3243 | 3455 | 3582 | |

| Food Safe | 2231 | 2315 | 2406 | 2579 | 2753 | 2936 | 3191 | 3242 | 3418 | 3630 | 3757 | |

| PuralFarm | ||||||||||||

| Ral | 1846 | 1930 | 2021 | 2194 | 2368 | 2551 | 2806 | 2857 | 3033 | 3245 | 3372 | |

| Zn | 1826 | 1910 | 2001 | 2174 | 2348 | 2531 | 2786 | 2837 | 3013 | 3225 | 3352 | |

| Aisi 304 | 3126 | 3210 | 3301 | 3474 | 3648 | 3831 | 4086 | 4137 | 4313 | 4525 | 4652 | |

| AISI 430 | 2646 | 2730 | 2821 | 2994 | 3168 | 3351 | 3606 | 3657 | 3833 | 4045 | 4172 | |

| PVDF | 2056 | 2140 | 2231 | 2404 | 2578 | 2761 | 3016 | 3067 | 3243 | 3455 | 3582 | |

| PuralFarm | 2271 | 2355 | 2446 | 2619 | 2793 | 2976 | 3231 | 3282 | 3458 | 3670 | 3797 | |

| granite farm | 2271 | 2355 | 2446 | 2619 | 2793 | 2976 | 3231 | 3282 | 3458 | 3670 | 3797 | |

| Food Safe | 2446 | 2530 | 2621 | 2794 | 2968 | 3151 | 3406 | 3457 | 3633 | 3845 | 3972 | |

| granite farm | ||||||||||||

| granite farm | 2271 | 2355 | 2446 | 2619 | 2793 | 2976 | 3231 | 3282 | 3458 | 3670 | 3797 | |

| Food Safe | ||||||||||||

| Food Safe | 2621 | 2705 | 2796 | 2969 | 3143 | 3326 | 3581 | 3632 | 3808 | 4020 | 4147 | |

| Paper | ||||||||||||

| Paper | 642 | 793 | 906 | 1118 | 1387 | 1656 | 1926 | 2060 | 2196 | 2466 | 2736 | |

| Film | ||||||||||||

| Film | 689 | 840 | 953 | 1165 | 1434 | 1703 | 1972 | 2107 | 2242 | 2512 | 2783 | |

| Foil | ||||||||||||

| Foil | 774 | 925 | 1037 | 1249 | 1518 | 1788 | 2057 | 2192 | 2327 | 2597 | 2867 | |

2.3.2 Cost of roofing sandwich panels PPU (PUR)

| Coating material | Panel thickness (without hump), mm | ||||||

| Side A | Side B | 40 | 60 | 80 | 100 | 120 | 150 |

| Fire resistance limit | RE 15 | ||||||

| Ral | |||||||

| Ral | 1 562 | 1 758 | 1 923 | 2 097 | 2 271 | 2 560 | |

| Zn | 1 542 | 1 738 | 1 903 | 2 077 | 2 251 | 2 540 | |

| Aisi 304 | 3 057 | 3 253 | 3 418 | 3 592 | 3 766 | 4 055 | |

| AISI 430 | 2 496 | 2 692 | 2 857 | 3 031 | 3 205 | 3 494 | |

| PVDF | 1 808 | 2 004 | 2 169 | 2 343 | 2 517 | 2 806 | |

| PuralFarm | 2 058 | 2 254 | 2 419 | 2 593 | 2 767 | 3 056 | |

| granite farm | 2 058 | 2 254 | 2 419 | 2 593 | 2 767 | 3 056 | |

| Food Safe | 2 263 | 2 459 | 2 624 | 2 798 | 2 972 | 3 261 | |

| Zn | |||||||

| Ral | 1 542 | 1 738 | 1 903 | 2 077 | 2 251 | 2 540 | |

| Zn | 1 522 | 1 718 | 1 883 | 2 057 | 2 231 | 2 520 | |

| Aisi 304 | 3 037 | 3 233 | 3 398 | 3 572 | 3 746 | 4 035 | |

| AISI 430 | 2 477 | 2 673 | 2 838 | 3 012 | 3 186 | 3 475 | |

| PVDF | 1 788 | 1 984 | 2 149 | 2 323 | 2 497 | 2 786 | |

| PuralFarm | 2 038 | 2 234 | 2 399 | 2 573 | 2 747 | 3 036 | |

| granite farm | 2 038 | 2 234 | 2 399 | 2 573 | 2 747 | 3 036 | |

| Food Safe | 2 243 | 2 439 | 2 604 | 2 778 | 2 952 | 3 241 | |

| Aisi 304 | |||||||

| Ral | 3 057 | 3 253 | 3 418 | 3 592 | 3 766 | 4 055 | |

| Zn | 3 037 | 3 233 | 3 398 | 3 572 | 3 746 | 4 035 | |

| Aisi 304 | 4 552 | 4 748 | 4 913 | 5 087 | 5 261 | 5 550 | |

| AISI 430 | 3 992 | 4 188 | 4 353 | 4 527 | 4 701 | 4 990 | |

| PVDF | 3 302 | 3 498 | 3 663 | 3 837 | 4 011 | 4 300 | |

| PuralFarm | 3 554 | 3 750 | 3 915 | 4 089 | 4 263 | 4 552 | |

| granite farm | 3 554 | 3 750 | 3 915 | 4 089 | 4 263 | 4 552 | |

| Food Safe | 3 759 | 3 955 | 4 120 | 4 294 | 4 468 | 4 757 | |

| AISI 430 | |||||||

| Ral | 2 496 | 2 692 | 2 857 | 3 031 | 3 205 | 3 494 | |

| Zn | 2 477 | 2 673 | 2 838 | 3 012 | 3 186 | 3 475 | |

| Aisi 304 | 3 992 | 4 188 | 4 353 | 4 527 | 4 701 | 4 990 | |

| AISI 430 | 3 431 | 3 627 | 3 792 | 3 966 | 4 140 | 4 429 | |

| PVDF | 2 742 | 2 938 | 3 103 | 3 277 | 3 451 | 3 740 | |

| PuralFarm | 2 742 | 2 938 | 3 103 | 3 277 | 3 451 | 3 740 | |

| granite farm | 2 993 | 3 189 | 3 354 | 3 528 | 3 702 | 3 991 | |

| Food Safe | 3 197 | 3 393 | 3 558 | 3 732 | 3 906 | 4 195 | |

| PVDF | |||||||

| Ral | 1 808 | 2 004 | 2 169 | 2 343 | 2 517 | 2 806 | |

| Zn | 1 788 | 1 984 | 2 149 | 2 323 | 2 497 | 2 786 | |

| Aisi 304 | 3 302 | 3 498 | 3 663 | 3 837 | 4 011 | 4 300 | |

| AISI 430 | 2 742 | 2 938 | 3 103 | 3 277 | 3 451 | 3 740 | |

| PVDF | 2 052 | 2 248 | 2 413 | 2 587 | 2 761 | 3 050 | |

| PuralFarm | 2 304 | 2 500 | 2 665 | 2 839 | 3 013 | 3 302 | |

| granite farm | 2 304 | 2 500 | 2 665 | 2 839 | 3 013 | 3 302 | |

| Food Safe | 2 509 | 2 705 | 2 870 | 3 044 | 3 218 | 3 507 | |

| PuralFarm | |||||||

| Ral | 2 058 | 2 254 | 2 419 | 2 593 | 2 767 | 3 056 | |

| Zn | 2 038 | 2 234 | 2 399 | 2 573 | 2 747 | 3 036 | |

| Aisi 304 | 3 554 | 3 750 | 3 915 | 4 089 | 4 263 | 4 552 | |

| AISI 430 | 2 993 | 3 189 | 3 354 | 3 528 | 3 702 | 3 991 | |

| PVDF | 2 304 | 2 500 | 2 665 | 2 839 | 3 013 | 3 302 | |

| PuralFarm | 2 555 | 2 751 | 2 916 | 3 090 | 3 264 | 3 553 | |

| granite farm | 2 555 | 2 751 | 2 916 | 3 090 | 3 264 | 3 553 | |

| Food Safe | 2 759 | 2 955 | 3 120 | 3 294 | 3 468 | 3 757 | |

| granite farm | |||||||

| granite farm | 2 555 | 2 751 | 2 916 | 3 090 | 3 264 | 3 553 | |

| Food Safe | |||||||

| Food Safe | 2 964 | 3 160 | 3 325 | 3 499 | 3 673 | 3 962 | |

Interlocking connection of PIR/PUR wall panels

Wall panels with PIR/PUR insulation are equipped with a tongue-and-groove locking connection with a unique design. It can be single, double or triple, it all depends on the thickness of the material.

The main advantages of this connection are:

- Eliminating the possibility of the formation of so-called “cold bridges”.

- Excellent hydro, heat and sound insulation of junction areas.

- Reducing the consumption of polyurethane foam during installation.

Requirements for materials for entrance doors

The most important requirement for any material used not only as insulation, but also for door upholstery is safety for humans. The operational requirements that fillers for entrance doors must meet include the following:

- heat and sound permeability;

- low temperature resistance;

- moisture resistance;

- durability.

It is believed that the best door filler should meet all these criteria. But the installation location of the door block also matters. So, if you need soundproofed entrance doors for installation in a heated entrance, then the level of thermal insulation is not important. And vice versa, if you plan to install the structure from the street side, then low thermal conductivity is preferable to other qualities.

Familiarization with the features and advantages of materials will allow you to decide which door filler is best for specific operating conditions.

Types of materials and their features

The insulating qualities of door blocks are affected not only by the internal filling of the leaf, but also by the external upholstery:

- leatherette is a common material, characterized by practicality and wear resistance at low cost;

- felt - used as a “lining” in combination with other finishes to improve thermal insulation;

- genuine leather is a durable but expensive material, therefore it is used only in luxury products.

Currently used door insulation is divided into three price segments: budget, medium and premium. Their cost is correlated with performance, so in each category we can name the best insulation for the front door.

Budget options for filling materials for doors

- Honeycomb corrugated cardboard is a simple cellular filler for doors that provides a minimal degree of heat and sound insulation.

- Sintepon is a fibrous material with low heat transfer, due to which it is used as insulation, but does not absorb sound well.

- Foam rubber is a leader in the budget segment, combining optimal insulating qualities at low cost.

Average price category

- Izolon is a rolled self-adhesive insulation for doors, which is usually used in combination with other materials.

- Molded foam or expanded polystyrene - in doors it is used to provide heat/sound insulation, provided that the structure is used indoors.

- Foamed propylene plates are a material that has the best characteristics in its class, is durable and easy to install.

Premium segment of fillers

- Rigid polyurethane foam is a porous plastic with low thermal and sound conductivity, widely used in construction.

- Mineral wool (“ISOVER”, “URSA”) is a modern environmentally friendly filler with high sound-absorbing and heat-insulating properties.

Both of these materials have outstanding characteristics and it is all the more difficult to determine which door filler is better: polyurethane foam or mineral wool. However, the thermal conductivity of the second of them is still lower, and if you need an insulated street entrance door, choose a design filled with mineral wool.

Disadvantages of materials

When assessing which insulation for the front door is better, remember that materials have their own weaknesses. In particular, the best heat and sound insulator - mineral wool - needs an internal frame, since it tends to shrink.

The production of a door with polyurethane foam filling is technologically more complex, which is why the price of such structures is higher. In addition, doors with polyurethane foam, as with other synthetic materials, are dangerous in case of fire.

Reviews of foam rubber, padding polyester and foam filling indicate that such outdoor metal doors often suffer from condensation on the inside of the door leaf.

PIR/PUR sandwich panel coating

In the production of sandwich panels with PIR//PUR insulation, galvanized cold-rolled steel with the following coating options is used as cladding:

- without cover;

- pural;

- plastisol;

- polyvinylidene fluoride (PVDF);

- polyester paint (any shade according to the RAL catalogue).

With this product look

Address

Russia, Perm, Sibirskaya st., 69

Operating mode

from 10:00 to 19:00

- home

- Metal doors

- doors private house

- Eco-veneer doors

- Interior doors

- Door handles

- Doors Argus

- Doors to the bathroom and toilet

- Doors to the office

- Enamel painted doors

- Wooden doors

- Sliding compartment doors

- About personal data

- Doors wholesale

- Reviews, video reviews about the store

- Doors on Guyva

- Doors Zakamsk

- Delivery

- Door catalog

- Communication with the administration

- Entrance

- Registration

Fill out the form and our specialists will contact you shortly.

Packaging of PIR/PUR sandwich panels

To protect against precipitation and mechanical damage during transportation, the panels are covered with a special polyethylene film, which can be easily removed after installation. The coating thickness is 50 microns.

During transportation, the “sandwiches” are laid out on pallets, stacked on foam pads and covered with stretch film. One pallet can contain from 5 to 28 wall panels and from 6 to 18 roofing panels, depending on the thickness.

The cost of packaging is included in the cost of the product.

Advantages

Thickness - 30-50 mm. This saves space during internal insulation.

Fireproof. Upon contact with fire, the outer layer chars, forming a carbon matrix. It prevents the spread of flame.

Thermal conductivity - 0.22 W/m°K. The minimum indicator among materials of this class. Thermal insulation properties are further improved by a foil layer, which reflects and does not transmit heat.

Economical. The overall cost of the work is reduced - the installation of a vapor barrier is not required due to the foil layer.

Made from rigid polyurethane , an environmentally friendly material. Does not give off any foreign odor, does not emit harmful substances at any temperature.

Does not get wet, does not absorb moisture, does not rot. Fungus, mold, etc. do not form in the thermal insulation layer and on its surface.

Service life - 50 years , during which the material retains its properties.

Easy installation due to the high compressive strength of the material. The risk of accidental damage is minimal.

Expanded polystyrene, rub. per m².

The insulation density is 25 kg/m³ with metal cladding with a thickness of 0.5 .

| Thickness | 50/60 | 80 | 100 | 120 | 150 | 200 |

| Wall up to 500m² | 2380 | 2450 | 2530 | 2600 | 2720 | 2920 |

| Wall from 500m² | 2360 | 2430 | 2510 | 2580 | 2700 | 2900 |

| Roofing up to 500m² | 2535 | 2605 | 2685 | 2785 | 2885 | 2980 |

| Roofing from 500m² | 2515 | 2585 | 2665 | 2765 | 2865 | 2960 |

Please note that sandwich panels with a thickness of 50 and 60 mm do not differ in price.

Installation procedure

Preparing the base. The surface of the wall, floor or ceiling is cleared of debris and leveled. The cracks are sealed. The surface of the base must not have any defects. It needs to be leveled as much as possible. The absence of irregularities is checked with a 2 m long rack; depressions larger than 5 mm are removed.

Fastening thermal insulation. Use temporary fasteners to install the slabs. Place them with offset end joints (staggered). After removing the temporary fasteners, the remaining holes are filled with construction foam and sealed with tape. Next, the slabs are attached to the wall through wooden slats using self-tapping screws or dowels. The step between fasteners is no more than 40 cm.

Vapor-proof layer. The insulation has a multi-layer structure, the top layer is formed by foil and is vapor-proof. To create a sealed vapor barrier layer, the joints of the slabs formed during installation are additionally sealed with aluminum tape. This provides protection from getting wet, humidified by steam, and condensation.

Finishing. The previously fixed slats are used as sheathing. The lining is attached to it with metal finishing nails or clamps (it is recommended to use hardwood).

Mineral wool [MV], rub. per m².

The insulation density is 110 kg/m³ with metal cladding 0.5 .

| Thickness | 50/60 | 80 | 100 | 120 | 150 | 200 |

| Wall up to 150m² | 2540 | 2695 | 2790 | 2910 | 2990 | 3400 |

| Wall 150-500m² | 2520 | 2675 | 2770 | 2890 | 2970 | 3380 |

| Wall from 500m² | 2500 | 2655 | 2750 | 2870 | 2950 | 3360 |

| Roofing up to 150m² | 2695 | 2855 | 2945 | 3075 | 3245 | 3525 |

| Roof 150-500m² | 2675 | 2835 | 2925 | 3055 | 3225 | 3505 |

| Roof from 500m² | 2655 | 2815 | 2905 | 3035 | 3205 | 3485 |

Minimum order volume 30 m2 for each item + 20% extra charge Volume from 30 to 100 m2 extra charge 20% production time from 15 working days.

PIR insulation - popular products

| Name | Weight | Thickness | Size | Weight m2 | Price from | Read more.. |

| Thermal insulating PIR plate TechnoNIKOL LogicPir Bath (1200x600x50 mm) | 50 | 1200x600 mm | 963 | More details | ||

| Thermal insulating PIR plate TechnoNIKOL LogicPir Balcony (1200x600x20 mm) | 20 | 1200x600 mm | 546 13 | More details | ||

| Thermal insulation LOGICPIR plate TechnoNIKOL PROF F/F G1 L-edge (2385x1185x30 mm) | 30 | 2385x1185 mm | 26 018 98 | More details | ||

| Thermal insulating PIR board TechnoNIKOL LogicPir Floors (1200x600x20 mm) | 20 | 546 13 | More details | |||

| Thermal insulating PIR plate TechnoNIKOL LogicPir (1200x600x20 mm) | 20 | 546 13 | More details | |||

| Thermal insulating LOGICPIR plate TechnoNIKOL PROF SKhM/SKhM G2 L-edge (2385x1185x30 mm) | 30 | 2385x1185 mm | 28 462 | More details | ||

| Thermal insulating PIR board PirroGroup PirroThermo (1200x600x30 mm) | 30 | 1200x600 mm | On request | More details | ||

| Thermal insulating PIR board PirroGroup PirroWall (1200x600x30 mm) | 30 | 1200x600 mm | On request | More details | ||

| Thermal insulating PIR board TechnoNIKOL LogicPir Walls L (1185x585x30 mm) | 30 | 346 95 | More details | |||

| Thermal insulating PIR plate TechnoNIKOL LogicPir L (1185x585x30 mm) | 30 | On request | More details |

Polyisocyanurate foam [PIR], rub. per m².

| Thickness | 40 | 50 | 60 | 80 | 100 | 120 | 150 | 200 |

| Wall up to 500m² | 2780 | 2900 | 3030 | 3305 | 3570 | 3870 | 4360 | 5190 |

| Wall from 500m² | 2740 | 2860 | 3000 | 3265 | 3550 | 3850 | 4420 | 5150 |

| Roofing up to 500m² | 3100 | 3240 | 3390 | 3620 | 3880 | 4180 | 4670 | — |

| Roofing from 500m² | 2060 | 3200 | 3350 | 3580 | 3840 | 4140 | 4630 | — |

Installation of sandwich panels from 500 rub. sq.m. To receive a commercial offer, call us at +7(495)118-36-14 or write to us by email

Rational approach: choosing an option

Case one: a balcony as an independent room for occasional use. It is quite easy to heat such a room to an acceptable temperature by leaving the balcony door open - the air from the room will quickly fill its small volume; or use a “warm floor” heating system on the balcony.

Insulation of such a balcony can be carried out using any of two fundamentally different technologies for installing insulation: in a frame or in a continuous layer.

The technology of installation in a frame involves the preliminary assembly of a frame, usually from wooden blocks, into the cells of which insulation is then inserted.

The continuous layer installation technology involves attaching the heat-insulating material directly to the surface to be insulated, while the insulation forms a continuous, unbroken layer without cold bridges. This solution is only possible with slab thermal insulation that has sufficient rigidity and strength.

Case two: the balcony becomes part of the living space.

Insulation of such a balcony should be carried out only using a continuous layer installation technology. It is necessary to provide for the placement of an additional heat source, for example, a heated floor system, because the power of the main heating device is not designed for the increased volume of the room and the increased area of external surfaces - the floor and ceiling of the balcony. Even if your neighbors above and below already have insulated balconies, your floor and ceiling need thermal insulation, since the ends of the balcony slabs face the street.

As a result of insulation of balcony walls, floors and ceilings, the temperature in the room should not decrease. To find out the thickness of the thermal insulation layer required to insulate your balcony or loggia, you should use online calculators posted on the websites of insulating material manufacturers, or request advice from a specialist.

Read also

- Production of sandwich panels - details about the service.

- What are the dimensions of sandwich panels - plan the size of your building.

- What you will need for installation of sandwich panels - select self-tapping screws for installation.

- How to bring sandwich panels correctly - details on the rules for transporting sandwich panels.

- Current prices for sandwich panels - + price list in PDF.

Designing a doorway without a door

- Peculiarities

- Kinds

- Dimensions

- In various rooms

- How to apply correctly?

- Materials

- Options in the interior

The design of an opening without a door involves several features. Not all materials are suitable for this type of finishing, and the selected options will have to be handled quite carefully. Some structures can be created with your own hands, but the construction of others is best left to a professional.