Natural wood floors are rightfully considered the most environmentally friendly. But many now refuse such coverage due to the fact that this material is supposedly outdated and uninteresting. But a plank floor can easily outperform any floor covering, especially in terms of comfort. It is warm, reliable, is not a source of harmful substances and can be very beautiful if made according to all the rules.

Plank floor

About the advantages of plank flooring

Wood is one of the oldest building materials. Previously, everything possible was made from it - houses, fences, furniture were built, and interior decoration was done mainly with natural wood. At the same time, such material is now considered one of the most expensive and indicates the significant status of a person. Even despite the fact that a lot of synthetic materials have appeared on sale, characterized by ease of installation and beauty, wood does not lose its position.

Plank floors are still popular

Natural wood floors continue to be one of the most popular and in demand. This is due to the undeniable advantages of this material:

- beautiful appearance - no one can argue with this factor, because wood has its own unique natural pattern, which can only be replicated by laminate or linoleum, which are much inferior to natural wood in terms of environmental friendliness;

- wood fits easily into any interior style. Even high-tech and other similar styles can be played up quite well using plank flooring, and what can we say about eco-style, one of the most popular among designers;

Eco-style interior

- durability – the average lifespan of a typical wooden floor is about 50 years. During this time, the coating may darken and begin to creak, but the creak is easy to eliminate and the floor will still serve the apartment owner well;

- environmental friendliness is an undeniable advantage of plank flooring. The material created by nature itself is not a source of harmful substances; it can easily be installed even in the apartment where a person suffering from allergies or upper respiratory tract diseases lives;

- ease of maintenance - wooden floors are easy to clean and wash;

- strength and non-slip coating - plank floors, even just washed, will not allow the apartment owner to slip and fall. They are also not subject to temporary deformation under pressure from furniture legs and are able to withstand very heavy loads without collapsing;

- tactilely pleasant material - walking on the plank floor is very pleasant: your feet do not feel cold.

It's nice to walk on this floor

But it’s also worth talking about the disadvantages of plank floors, of which, fortunately, there are very few. Disadvantages of using plank wood floors:

- Such floors are not cheap , however, like all environmentally friendly materials;

- complex installation , which involves laying joists and adjusting boards, often discourages many from installing such a floor;

- wooden floors are able to absorb odors - both pleasant and unpleasant;

- Laying wooden floors alone is quite difficult - you need to attract help;

- cracks appear some time after use urgently requires additional floor repairs;

Gaps in the wooden floor

- Over time, wooden floors can begin to creak.;

- The appearance of seasonal deformation has also been noted in plank floors - they react sharply to changes in temperature and air humidity levels and can begin to creak because of this.

Despite a fairly large number of disadvantages, plank floors are still a very good floor covering, and with proper installation it is possible to cope with most of the disadvantages of use.

Installation of plank floors

Features of the arrangement

Material selection

Before you begin installing plank floors, you need to select a material for them.

Experts recommend using coniferous wood for these purposes, such as:

- pine;

- spruce;

- larch;

- fir.

In the photo - pine boards

These wood species have the following qualities:

- attractive appearance with a pronounced texture;

- good strength and wear resistance;

- less susceptible to moisture due to the presence of a large amount of resin in the structure;

- affordable price, especially for spruce and pine.

Note! Only dry lumber can be used as flooring. Otherwise, gaps will form between the boards, and the surface of the flooring will deform and crack.

Of course, you can use other species, such as walnut or oak, however, their cost is much higher.

Forgivable floor

Types of construction

Depending on the type of structure, boardwalks are divided into the following types:

- Style plank floors are the simplest flooring option, which is formed by long boards mounted on floor beams or joists. This type of floor has recently been more often used as a subfloor;

- typesetting - consist of short boards, which are usually laid in a checkerboard pattern. Most often, the installation of stacked floors is carried out on slats. It should be noted that this type of flooring looks more attractive, so it is often used as a finishing coating.

Stacked boardwalk

Thus, the choice depends on the purpose of the plank floor. If a finishing coating will be laid over it, then it is better to lay long boards. If you decide to use plank flooring as a finishing surface, you can implement the second option.

Basic Rules

Before you begin installing a plank floor with your own hands, you need to familiarize yourself with the following rules:

- It is advisable to begin arrangement after other work has been completed - windows and doors have been installed, ceilings and walls have been finished;

- humidity in the room during installation should not exceed 60 percent;

- Before laying, boards and joists must be treated with protective impregnation and fire retardant. This will make the structure resistant to moisture, rot, insect damage and fire. Thus, impregnation is necessary so that the plank floors do not have to be repaired soon after installation;

- When laying boards, there should be a gap of at least 1 cm between the wall and the floor.

Advice! It is best to lay the floor after the end of the heating season, since in the summer the wood picks up moisture, and therefore, in the winter, gaps may appear between the boards.

Installation stages

So, the installation of plank floors consists of the following stages:

| Stages of work | Execution nuances |

| Preparing the rough foundation | This stage is performed if the plank floor is installed on the ground. The following can be used as a rough base:

At this stage, it is extremely important to ensure waterproofing between the base and the ground, as well as between the base and wooden joists. |

| Installation of logs | This stage is one of the most critical. Installation instructions for logs look like this:

The logs should be located horizontally at the same level. To adjust the position of the beams, you can place planks under them or use special adjustable legs;

|

| Laying boards | Installation of boards is carried out in the following order:

This completes the installation process. |

Installation of plank floors

Advice! The space between the boardwalk and the wall can be filled with felt, which will improve the sound insulation of the floor.

Upon completion of installation, the floor requires finishing. Most often, plank floors are painted with non-aqueous compounds, for example, alkyd, polyurethane or oil paint.

The floor can also be varnished or treated with decorative protective impregnation. This finishing option allows you to preserve the natural attractiveness of the wood.

Surface treatment with varnish

Advice! A house with unpainted plank floors can be decorated in a country, Provence or other rustic style.

Here, in fact, is all the basic information regarding the construction of floorboards.

Installation of plank floors

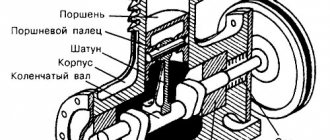

The design of a wooden floor made from planks is quite simple and includes only a few basic elements. These are wooden logs and the boardwalk itself. Also, when installing the floor, additional materials can be used - heat and waterproofing, which are laid directly under the boards.

Beam construction

Construction of a rough plank floor

The logs are long bars (usually those made of solid wood are used, or the use of glued bars is allowed).

On a note! Previously, logs were made from large hewn logs, but now this option is unacceptable due to the high price.

The logs themselves are laid on the ceiling, which can either be made of timber of a larger cross-section or be a concrete slab. Also, logs can be installed on bricks if the base for the floor is soil. In the private sector, the base can be a metal floor.

Monolithic concrete floor

The creation of a plank floor is completed by laying or applying a finishing coating. This can be varnish, paint, and if the floors are laid as a sub-base, then a number of other types of floor coverings.

Advice! If plank floors are made of high-quality and beautifully colored wood, then it is better to cover them with transparent varnish, preserving the natural shade, and leave them as the final floor covering.

Beautiful plank floor

Decoration

The floorboards in the house should be in harmony with the interior, so it is rarely left without a finishing coating, which also protects the wood from damage, discoloration, moisture and dirt. To do this, use various tinting compounds that do not hide the texture of the wood, or covering paints.

Tinting allows you to imitate any type of wood. You can change the tone using stains, impregnations, oils, wax, varnish.

Paints provide even more scope for designers. You just need to discard stereotypes and forget that a wooden floor can only be brown.

- White, light gray, beige and other light shades of the floor make the interior light, airy, and clean.

- Black color fits many modern styles, but you need to keep in mind that dust on it is much more noticeable than on a light-colored coating.

- Bright floor shades look great with light walls in minimalist interiors.

You can also paint the floorboards in different colors, create simple patterns on the floor using masking tape or patterns using a stencil.

Non-standard floor design Source systemautepleniya.com

In short, there are many options for decorating plank flooring. During the next repair, you can cycle it and change the decor.

Types of boards and their choice

Floor boards are usually made of larch or pine - these are the most affordable, but at the same time high-quality and reliable types of wood. Sometimes there are floors made of ash, oak, maple, and alder.

On a note! Boards made from aspen or alder are considered the most environmentally friendly and are recommended for use by home owners who care about their health.

Plank floor in a private house

If the final finishing layer is varnish, then the choice should be made in favor of light wood species with a pronounced, beautiful pattern. Oak boards, as well as walnut or mahogany, will look best as a floor. Among the listed options, oak wood is the cheapest.

Table. Floor boards depending on the wood used.

| Board type | Description and characteristics |

| Pine or spruce | The Brinell strength index for spruce is 1.5, and for pine – 1.6, which indicates some softness of the board. The moisture resistance of coniferous wood is low; these materials are also most susceptible to insects and parasites; they deteriorate faster than other boards. For such floors, it is necessary to treat the boards with antiparasitic compounds. The main advantage of spruce/pine boards is their low cost, since the average cost of the material is only 520 rubles/sq. m. |

| Berezovaya | Strength on the Brinell scale is 2.5. The texture of birch is very beautiful and pleasant, and if it is additionally tinted, the floor will turn out very beautiful. Price per 1 sq.m. is approximately 660 rubles. |

| Larch | Such a board does not tend to absorb moisture, and therefore can be used where the humidity level is quite high, that is, even in a sauna or bathhouse. Larch almost does not rot, and its Brinell strength is 3.1 - it is not even necessary to varnish the material. The color of this wood is very beautiful and noble. Cost of 1 sq. m. boards can vary from 600 to 1620 rubles. |

| Ash and oak boards | The Brinell strength is 4 and 3.7 - the material is very durable. Resistance to humidity is moderate, but lower than that of larch. Such floors look very noble and rich. The cost of this material is high - from 1800 to 4400 rubles / sq. m. |

| Exotic breeds (wenge, kempas, merabou) | The strength of these rocks is maximum – 4-5 points on the Brinell scale. The materials are moisture resistant and almost resistant to parasites. The floors are unique and very beautiful. Such boards are expensive - up to 6,000 rubles / sq. m. |

Prices for construction floor boards

floor boards

Brinell wood hardness chart

Pine wood floor

Floor boards come in several types, the main ones are:

- regular board with straight ridge;

- tongue and groove;

- and a quarter.

Grooved floorboard

When choosing a material, the thickness of the boards is often determined by the distance between the logs, and vice versa - the distance between the logs may depend on how thick the boards are used.

Table. The ratio of the distance between the logs and the thickness of the boards.

| Board thickness, mm | Distance between lags, cm |

| 20 | 30 |

| 24 | 40 |

| 30 | 50 |

| 35 | 60 |

| 40 | 70 |

To create the finishing floor covering, it is recommended to use boards with a tongue-and-groove connection type. The most commonly used material is 28 mm thick - this is the most common board size. If the floors will experience significant loads, it is recommended to use boards with a thickness of at least 36 mm. On average, the width of this building material varies from 68 to 138 mm.

Floor board

What should the floorboard be like?

Most often, planed pine boards are used for floors. They have good strength, resistance to rotting, an affordable price, and can be easily processed and decorated using paints and varnishes. The board can be:

- regular edged;

- tongue and groove;

- and a quarter.

Floorboards with a quarter Source garantwood.ru

The most popular option is tongue-and-groove boards equipped with a groove and a tongue on the opposite long end edges. Sometimes tongues are also present at short ends for joining boards along the length. This profile provides the highest quality coating without cracks and with minimal risk of deformation.

Thickness

Before laying a wooden floor, a base is prepared for it in the form of a frame made of logs. The thickness of the floorboards is selected taking into account the distance between the joists: the larger it is, the thicker the boards should be.

Table for determining the thickness of boards Source stroimzanovo.ru

It is important! Do not forget that after leveling and sanding the flooring, its thickness may decrease by several millimeters.

Variety

The higher the grade of products, the fewer knots, chips, scratches, resin bags and other defects they have. The best and highest quality, and therefore more expensive, is the “Extra” variety.

See also: Catalog of companies that specialize in doors, windows and related work

Humidity

Floorboards can be sold raw, immediately after leaving the sawmill. It can warp and become deformed during the drying process, especially if stored improperly.

It is better to buy natural or chamber-dried lumber. The latter have a humidity of 8-10%, they can be used immediately without fear that the flooring will dry out. Boards with a moisture content of 12-20% must be dried in a dry room, stacked using spacers. In utility rooms, on terraces, and verandas, floors can be laid from planks of natural moisture.

Storage conditions

It is advisable to select floor boards personally, inspecting each one for defects and distortions and of the same thickness. It is important to pay attention to the conditions in which they are stored. The storage location should be dry, ventilated, and the boards should not be in bulk, but in stacks.

Lumber storage warehouse Source tildacdn.com

Plank floor installation options

Plank floors can be installed in different ways. Basically, three methods are used - installation of a wooden floor on regular joists or on adjustable ones, as well as installation using compression.

Basics of installing floors on regular joists

In this case, installation begins with laying wooden blocks with dimensions usually 5x5 or 4x6 cm on the concrete floor. The logs must be laid so that they are on the same level - for this it is most convenient to use a construction laser level. Also often a soundproofing pad is placed under the bars. The elements are fastened using anchors.

Installation of wooden floors using joists

The lags are installed from the walls oriented perpendicular to the windows, and then the boards are laid perpendicular to the lags. When laying the boards, their second row is mounted with a slight offset relative to the first (checkerboard order). Then the floors will look better and more interesting. A small gap of about 1 mm is allowed between adjacent boards. The boards are attached to the joists using self-tapping screws or regular nails. In this case, the latter are driven at an angle of 45 degrees into the end of the board.

Important! When installing boards near the walls, it is necessary to leave a small gap - about 1 cm. This is necessary to ensure that the floors do not deform during expansion when exposed to moisture or temperature.

Basics of installing plank floors on adjustable joists

This method of installing plank floors is used if the base of the floor is uneven, with large differences in height, which complicates the installation of any floor covering. It is the arrangement of adjustable joists in this case that allows you to speed up the installation process and place some communications under the boards. In this case, the load on the floors, in contrast to the case when a concrete floor screed is installed, is minimal, and the thermal insulation properties of the floors increase significantly.

Adjustable joists

To create such floors, you will have to drill holes in the joists at intervals of about 40 cm, and screw special metal posts into them. The logs themselves are laid in increments of about 50 cm, leveled and secured with dowels passing through the racks. Before laying the boards, excess posts are cut off.

Prices for adjustable floor joists

adjustable joists

Basics of floor installation using compression

Clamps are special devices that allow you to connect boards together. These can be construction staples, wedge clamps, movable brackets and compression clamps. Also, for this method you will have to make wooden wedges with sides inclined at about 15-20 degrees. The wedges will be used as workers and spacers.

Clamps for holding floor boards together

Clamps for holding together floor boards: a - construction clamp, b - clamp-bracket, c - wedge clamp with a movable clamp; 1 - wedge, 2 - bracket, 3 - lag, 4 - wedge compression, 5 - spur, 6 - movable stop

The order of work is as follows: the first board is fixed, and another 10-15 pieces are placed next to it. When installing the last board, two clamps are installed so that wedges fit between them and the boards. The latter are driven in with a hammer so that all the boards fit together tightly, without gaps. After this they are secured with nails. The remaining gap near the wall will be hidden by the baseboard.

Attention! It is recommended to place the ends of the boards strictly on the joists.

Flooring rules

The process of installing wooden flooring consists of several stages.

Preparing the base

The board must be ventilated, so it is not laid on a solid base, but on joists or beams. They must also be dry and thick enough to support the load.

The following are used as support beams:

- thick boards placed on edge;

- bars;

- debarked round timber with the top side beveled into a plane.

The cross-section of the logs depends on the installation method - on a solid concrete base or on support posts. And also on the length of the span between them. Exact numbers can be found in SNiPs and reference literature.

Before laying the logs on brick or concrete columns, they are covered with a double layer of roofing material for waterproofing. You can place cuttings of boards under the logs to level them horizontally. Both joists and linings are impregnated with antiseptic before installing plank floors.

Selection of material and preparation of the base

The key to a beautiful and high-quality floor is the use of good material. Floor boards should not have various defects - for example, knots, cracks, etc. Also, if the floor will be varnished and will serve as a finishing coating, it is important to pay attention to the beauty of the wood texture.

The boards are varnished

To install the floor, in addition to the boards, you may need the following tools and materials:

- bars for logs;

- insulation;

- waterproofing material;

- fasteners - nails or screws;

- jigsaw with wood blades;

- hammer;

- baseboard;

- finishing coating;

- drill;

- building level (preference should be given to the longest option);

- protective composition for wood.

Preparing tools

The nuances of installing a plank floor

It is not enough to know the technology of arranging floorboards in an apartment. It is also recommended to listen to the advice of experienced craftsmen and know the nuances of carrying out such work.

- The best time of year to install plank flooring is the end of the heating season.

- In summer, work is carried out only in dry sunny weather, so that the tree does not absorb excess moisture.

- The optimal air humidity in the room where work is being carried out is no more than 60%.

- The best air temperature for work should not be less than +8 degrees. By the way, according to SNiP, plank floors should be used at this level.

In the photo - pine boards

- Before installation, wood must be treated with anti-parasite, mold and rot products. If this is not done, the service life of the flooring will be reduced by several decades. The greatest damage to wood is caused by colonies of putrefactive fungi, which destroy this material in record time. The floor affected by these parasites changes its sunny yellow tint to greenish and acquires an unpleasant odor. However, antiseptics are applied only to the inner surface of finishing boards and joists - the front side is rarely treated.

- The nails that secure the boards to the joists must be 3 times the width of the board.

- For floor installation, it is important to use only dried wood (no more than 12% humidity). Otherwise, the floors may become deformed after installation and cracks will appear.

- Ventilation must be present under plank floors - it will provide ventilation and reduce the risk of mold or mildew.

- If the work on installing a plank floor is carried out by a novice craftsman, then they should start from a small room, where it will be faster and easier to correct mistakes.

- During the process, it is important to ensure that the floor slope is 0 degrees.

- In long narrow corridors, logs are laid across the direction of movement in the room, and boards, on the contrary, along.

Wooden floor in the bathhouse

SNiP 3.04.01-87. Insulating and finishing coatings. Downloadable file (click the link to open the PDF in a new window).

SNiP 3.04.01-87

Video description

How to install logs for a wooden floor, watch the video:

Preparing the boards

Even kiln-dried lumber needs acclimatization to the conditions in which it will be used. Therefore, it is advisable to bring the floorboard into the house in advance and let it lie for several days. But this can only be done after all wet work has been completed - installing screeds, plastering walls, so that the wood does not absorb moisture evaporating from the solutions.

Then the boards are sorted, putting the deformed ones aside and choosing the smoothest and cleanest ones. Products that are not of the best quality can be used for wooden flooring in less significant rooms or for laying along walls where they will be hidden by furniture.

For reference! If the boards are of different widths, then narrow floorboards will deform less when drying.

After sorting, the lumber is treated with an antiseptic and left to dry. It is enough to carry out such processing only for the back side and ends, since the finished flooring will be subjected to sanding and protective and decorative finishing.

Antiseptic treatment of lumber Source myosu.ru

DIY plank floor

Let's consider the process of creating a floor from boards in the case where soil acts as the base.

Step 1. The first step is to dismantle the old flooring, if any. In this case, the old boards and joists are completely removed.

Removing the old floor

Step 2. If the room is located on the ground floor of a private house, then the sand cushion is also removed to a depth of approximately 30 cm.

Removing the sand cushion

Step 3. Then the metal frames for future column piles are installed. This will allow the beams to be raised if the groundwater is located close to the surface. To do this, depressions are created in the ground, into which metal bases are then dug. All columns are installed at the same level.

Ready holes

Metal frames for piles

Step 4. Rectangular shapes are made from plastic lining and placed on metal bases. Next they are filled with liquid concrete. After drying, the mold is removed from the lining.

The form is placed on the base

Form after pouring concrete

Ready pile column

Advice! It is recommended to add lime to the concrete solution - it will act as a kind of antiseptic for pathogens and mold.

Step 5. Small plates are cut from 6 mm thick metal and installed on the top of the concrete columns. Beams will be attached to the plates. A hole 14 mm wide is made in the middle of each plate.

Installing a metal plate

Another photo of the process

Step 6. A layer of polyethylene film is laid on the ground for waterproofing. You can secure the film to the columns using regular tape.

Laying polyethylene film

Step 7. The metal plates are coated with paint, which will protect them from moisture.

Painted metal plate

Step 8. Using metal cone washers and a powerful bolt and nut, wooden logs (100x60 mm) are fastened. Before this, a layer of thermal insulation material is laid on the concrete column.

Fasteners

How the joists are attached

Important! Beams are treated with antiseptic materials and drying oil before installation.

Step 9. The required number of lags is set in the same way.

Logs are installed

Step 10. A layer of heat-insulating material is laid between the beams, and a layer of vapor barrier material is attached on top of them. The latter is attached with a slight slack.

Attaching the vapor barrier

Step 11. To lay the decking, you will use a board with joint grooves, which will allow you to connect the boards without gaps. Depending on the size of the room, the boards are sawn in such a way that after laying the flooring there is a gap of 1 cm on all sides between them and the walls.

This is how the boards will be connected

Boards are marked

Step 12. The boards are treated with a brush with a special primer for wood. It is especially important to apply a thick layer of product to the inside and ends of each board.

The boards need to be treated with primer

Application of primer

Step 13. The first board is laid along the wall. Don't forget to leave gaps along the walls!

Laying the first board

Step 14. The first 10 boards are laid. Part of the flooring just ends near the edge of the vapor barrier. Here the rest of the vapor barrier is laid. The joints are connected using double-sided and foil tape. The first allows you to connect two layers of fabric together, the second will protect the joint from above. The overlap of two sheets of material is about 10-15 cm.

The process of laying boards

Laying a vapor barrier

Step 15. A small block is laid along the end of the last laid board. With hammer blows, the boards are pressed closer together. This will get rid of possible gaps between the boards. The board is punched along its entire length.

The boards are hammered

Step 16. Using a screwdriver, screw the screws into the corner of the board at an angle of 45 degrees where the joists pass.

The self-tapping screw is screwed in at an angle

Step 17. The ends of the boards are also fastened with self-tapping screws.

Fixed ends of the boards

Step 18. Before laying the boards continues, wood chips and chips that appeared in the places where the screws were screwed in are carefully removed.

All this needs to be removed

Step 19. After all the boards have been laid, they are sanded. This is necessary to reduce the gloss. It is recommended to wear safety glasses and a respirator when sanding, as the work is very dusty. After sanding, the floor surface is thoroughly cleaned of dust.

Sanding boards

Step 20. The final stage is applying varnish to the surface of the boards. The varnish is applied with a brush along each board in two layers, the second is applied approximately two hours after applying the first. The floors can also be painted.

Applying varnish

Video - Wood flooring

Video - Installation of wooden floors along joists

Laying the floor on adjustable joists

When the rough base is too uneven, that is, the differences in height are significant, and there is no time for leveling or it is impossible to do this, then we lay the floorboards along adjustable joists.

To do this, we assemble the necessary structure:

- After installing the logs, we drill holes in them in increments of 400-500 mm;

- We screw special stand-up bolts into them;

- We place the logs on the rough base at a distance of up to 600 mm from each other;

- We level it and also firmly fix it with dowels.

- We lay boards on top.