Other names are telepressostat and pressostat. After some time, the K contacts open and the KU contacts close. In this case, independent adjustment of the actuator will be relevant. However, sometimes situations arise in which it is necessary to adjust the device yourself: Adjustment after partial or complete repair. Start the motor - compressor from the refrigerator without a relay

When the slider moves to the right, Rv immediately opens, but this does not affect the operation of the engine, since contactors L1, L2 receive power through the economic resistor Re1 and block contact L2.

The use of single-phase switches for three-phase loads is unacceptable, since one of the phases remains permanently connected to the winding. Automated control schemes In Fig.

Detailed description of the pressure switch for a compressor video Connection diagram Pressure switches for compressors can be for different load connection diagrams.

In emergency situations, when the pressure level is higher than the permissible norm, and the telepressostat does not work, the safety unit comes into operation and vents the air. Thermal relay.

Check the atmospheric pressure. In accordance with the rating of the power supply line, the appropriate model of the relay unit is selected. Electric motor connection diagram FUBAG Compressor

Application area of air compressors

Air compressors are widely used in many areas of human activity. These devices are indispensable when carrying out installation, carpentry, construction and repair work. Aircraft are also successfully used in everyday life. For example, a household unit can be used for inflation of tires, painting, airbrushing, etc. As a rule, this is a compressor with an electric motor operating from a 220 V network. For professional use, a rotary oil unit, which has an increased service life and does not require frequent maintenance, is better suited.

Air compressors are also in high demand in the industrial sector, in industries that require the use of compressed air.

There are devices with a high degree of air purification. They are used in “clean” industries, for example, in the chemical, pharmaceutical and food industries, as well as in the electronics industry.

In addition, air compressors have found application in the oil and gas industries, in the mining industry, in coal and stone mining.

Let's first consider how a three-phase motor is connected to a 380V network.

Three-phase motors come with either three terminals - for connection to a star only - or with six connections, with the ability to select a circuit - star or delta. The classic scheme can be seen in the figure. Here in the picture on the left there is a star connection. The photo on the right shows how it looks on a real engine frame.

It can be seen that for this it is necessary to install special jumpers on the required pins. These jumpers come with the motor. In the case where there are only 3 terminals, the star connection is already made inside the motor housing. In this case, it is simply impossible to change the winding connection diagram.

Some say that they did this to prevent workers from stealing units from home for their own needs. Be that as it may, such engine options can be successfully used for garage purposes, but their power will be noticeably lower than those connected by a triangle.

How an air compressor works and works

The design of the air compression unit is determined by the type of construction. Compressors are piston, rotary and membrane. The most widely used are piston air units, in which air is compressed in a cylinder due to the reciprocating movements of the piston inside it.

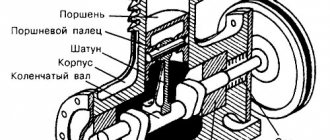

Device diagram

The design of an air piston compressor is quite simple. Its main element is the compressor head. Its design is similar to the cylinder of an internal combustion engine (ICE). Below is a diagram of the piston unit, which clearly shows the structure of the latter.

The compressor unit includes the following elements.

- Cylinder. This is the volume in which air is compressed.

- Piston. By reciprocating movements it sucks air into the cylinder or compresses it.

- Piston rings. Installed on the piston and designed to increase compression.

- Connecting rod. Connects the piston to the crankshaft, transmitting reciprocating movements to it.

- Crankshaft. Thanks to its design, it allows the connecting rod to move up and down.

- Inlet and discharge valves. Designed for inlet and outlet of air from the cylinder. But compressor valves are different from internal combustion engine valves. They are made in the form of plates pressed by a spring. The opening of the valves is not forced, as in an internal combustion engine, but due to the pressure difference in the cylinder.

To reduce the friction force between the piston rings and the cylinder, oil is supplied to the compressor head. But in this case, the air leaving the compressor contains lubricant impurities. To eliminate them, a separator is installed on the piston apparatus, in which the mixture is separated into oil and air.

If special purity of compressed air is required, for example, in medicine or electronics production, then the design of the piston unit does not imply the use of oil. In such devices, the piston rings are made of polymers, and graphite lubricant is used to reduce the friction force.

Piston units may have 2 or more cylinders arranged in a V-shape. Due to this, the productivity of the equipment increases.

The crankshaft is driven by an electric motor via a belt or direct drive. With a belt drive, the design of the device includes 2 pulleys, one of which is installed on the motor shaft, and the second on the shaft of the piston block. The second pulley is equipped with blades for cooling the unit. In the case of direct drive, the shafts of the motor and the piston unit are connected directly and are on the same axis.

Also, the design of a piston compressor includes another very important element - a receiver, which is a metal container. It is designed to eliminate pulsations of air leaving the piston block and works as a storage tank.

Thanks to the receiver, you can maintain the pressure at the same level and distribute air evenly. For safety, an emergency relief valve is installed on the receiver, which is triggered when the pressure in the tank rises to critical values.

In order for the compressor to operate in automatic mode, a pressure switch (pressostat) is installed on it. When the pressure in the receiver reaches the required values, the relay opens the contact and the engine stops. And vice versa, when the pressure in the receiver decreases to the set lower limit, the pressure switch closes the contacts and the unit resumes operation.

Operating principle

The operating principle of a piston compressor can be described as follows.

- When the engine starts, the crankshaft begins to rotate, transmitting reciprocating movements through the connecting rod to the piston.

- The piston, moving downwards, creates a vacuum in the cylinder, under the influence of which the intake valve opens. Due to the difference in air pressure, it begins to be sucked into the cylinder. But before entering the compression chamber, the air passes through a cleaning filter.

- Next, the piston begins to move upward. In this case, both valves are in a closed state. At the moment of compression, the pressure in the cylinder begins to increase, and when it reaches a certain level, the exhaust valve opens.

- After opening the exhaust valve, compressed air is directed to the receiver.

- When a certain pressure is reached in the receiver, the pressure switch is activated and air compression is suspended.

- When the pressure in the receiver drops to the set values, the pressure switch starts the engine again.

Types of pressure switch devices

There are only two variations in the design of the automatic compressor unit. The determination is made based on their operating principle.

In the first version, the mechanism turns off the electric motor when the established limits of the air mass pressure level in the pneumatic network are exceeded. These devices are called normally open.

Schematic structure of a membrane pressure switch: 1 – pressure converter; 2 and 3 – contacts; 4 – piston; 5 – spring; 6 – membrane; 7 – threaded connection

Another model with the opposite principle - turns on the engine if a drop in pressure is detected below the permissible level. Devices of this type are called normally closed.

Common faults and their solutions

Let's look at the main malfunctions in the operation of an air compressor that you can fix yourself.

The unit engine does not start

First of all, if the engine of the unit fails, you should make sure that there is voltage in the network. It is also a good idea to check the power cable for damage. Next, fuses are checked, which may blow out during a power surge. If any faulty cables or fuses are found, they should be replaced.

The pressure switch also affects engine starting. If it is incorrectly configured, the unit stops turning on. To check the operation of the relay, you need to bleed the air from the receiver and turn on the device again. If the engine starts, carry out the correct (according to the instructions) adjustment of the pressure switch.

In some cases, the engine may not start due to the thermal relay tripping. This usually happens if the unit operates intensively, almost non-stop. In order for the equipment to start working again, you need to give it some time to cool down.

The engine hums but does not start

The humming of the engine without rotating its rotor may be due to low voltage in the network, due to which it does not have enough power to start. In this case, the problem can be solved by installing a voltage stabilizer.

Advice! If the network “sags” due to the operation of any machine, for example, a welding machine, then it should be turned off while using the compressor.

Also, the engine is unable to crank the crankshaft if the pressure in the receiver is too high, and pumping resistance occurs. If this is the case, then you need to bleed the air from the receiver a little, and then adjust or replace the pressure switch. Increased pressure in the receiver can also occur if the relief valve is faulty. It must be removed and cleaned, and if damaged, replaced.

The air coming out has water particles

If the air leaving the receiver contains moisture, then it will not be possible to paint any surface efficiently. Water particles may be present in compressed air in the following cases.

- There is high humidity in the room where the unit operates. It is necessary to provide the room with good ventilation or install a dehumidifier on the compressor (see figure below).

- Water has accumulated in the receiver. It is necessary to regularly drain the water from the receiver through the drain valve.

- The water separator is faulty. The problem is solved by replacing this element.

Decrease in unit performance

The performance of the device may decrease if the piston rings burn out or wear out. As a result, the compression level decreases and the device cannot operate in standard mode. If this fact is confirmed when disassembling the cylinder, then the worn rings should be replaced.

Valve plates can also cause a drop in performance if they are broken or stuck. Faulty plates should be replaced, and clogged ones should be washed. But the most common reason that causes a loss of unit power is a clogged air filter, which should be washed regularly.

Compressor head overheating

The piston head may overheat if the oil is not changed in a timely manner or if a lubricant is used that does not correspond to what is specified in the passport. In both cases, the oil should be replaced with a special compressor oil with a viscosity, the value of which is indicated in the passport for the unit.

Also, overheating of the piston head can be caused by over-tightening the connecting rod bolts, which causes poor oil flow to the bearings. The malfunction is eliminated by loosening the connecting rod bolts.

Unit overheating

Normally, the unit may overheat when operating in intensive mode or at elevated ambient temperatures in the room. If, under standard operating mode and normal room temperature, the unit still overheats, then a clogged air filter may be the culprit. It should be removed and washed, and then dried well.

Advice! This procedure is recommended to be carried out regularly. If the unit is used intensively, the filter should be washed daily.

Knock in the cylinder

Caused by breakage or wear of the piston rings due to carbon deposits. It usually appears if you use low-quality oil.

Also, knocking in the cylinder can be caused by wear of the connecting rod head bushing or piston pin. To fix the problem, these parts should be replaced with new ones. If the cylinder and piston are worn out, air compressor repair involves boring the cylinder and replacing the piston.

Knock in the crankcase

The appearance of a knock in the crankcase during operation of the unit is caused by the following breakdowns.

- The connecting rod bolts are loose. It is necessary to tighten the bolts with the required force.

- The crankshaft bearings have failed. Bearings need to be replaced.

- The connecting rod journals of the crankshaft and connecting rod bearings are worn out. Elimination of these faults involves processing the connecting rod journals to repair size. The liners are also replaced with similar repair-sized parts.

Reduced pressure in the system when the power is turned off

The problem most often occurs due to leaks in one or several elements of the system . First of all, it is worth checking the outlet valve with the piston valve, and also inspect the entire line where the pressure is injected and maintained.

You can adopt an old proven method: lubricate problem areas with soapy water. An air leak will immediately make itself known by the appearance of bubbles. Any cracks that appear are sealed with any sealing material: preferably with a jelly-like consistency to prevent peeling.

The outlet valve is checked in the same way. If the solution bubbles when fixed in the off state, the part must be replaced. In this case, special attention must be paid to sealing: when installing a new faucet, it is imperative to wrap plumbing tape around the threads.

Important! Before carrying out repair work on the air line, it is necessary to bleed all the air in the system. Otherwise, you can not only get serious burns, but also damage the hoses with valves.

Sometimes, to normalize the pressure, it is enough to clean all moving elements - taps and valves from accumulated dirt.

Periodic activation of thermal protection sensors

The obvious reason for this effect is a very high room temperature or operation of the device in direct sunlight. If the climatic conditions are all right, then the problem may be due to insufficient voltage in the network.

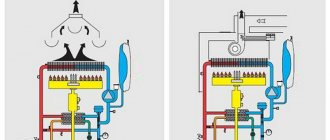

Air cooled compressor

A multimeter will help to identify faults of this kind. When the ringing indicators are significantly lower than the standards established by the equipment manufacturer (indicated in the instructions for the device), then we supplement the circuit with a voltage stabilizer.

The engines in classic compressors are air cooled. If the room is poorly ventilated, the device will quickly heat up, and as a result, the thermal protection sensors will work. In this case, it is necessary to move the equipment to a place with sufficient ventilation. It would also be a good idea to check the air filter: clean it of accumulated dirt or replace it altogether.

Unstable engine operation

The problem may occur due to too intense air output or a malfunction of the pressure control sensor. If the power consumed by construction equipment does not correspond to the performance of the compressor, then a significant difference will always affect the operation of the engine.

Therefore, it is imperative to take into account the characteristics of a pneumatic tool, namely, the volume of air consumed per unit of time, and correlate them with the capabilities of the unit. The air flow for the equipment should not exceed 70% of the compressor output.

Pressure switch for compressor

If the technical characteristics of both devices comply with the standards, then the problem is with the pressure switch. The sensor can be repaired, but it is more practical to replace it: fortunately, it is inexpensive and is sold in almost every specialized store.

Increased air flow

First of all, you need to check the air filter: clean or replace if necessary. The next reason is a gas leak in the system. We check every centimeter of the highway, and especially the joints and connections. The latter are treated with sealing material and fum tape.

Some users, after cleaning the receiver from condensate, forget to fix the outlet valve. Sometimes, as a result of increased pressure, it goes down a couple of millimeters on its own: we pull it all the way and check the pressure in the system.

DIY pressure switch

With known skills, as well as the presence of a working thermostat from a decommissioned refrigerator, a pressure switch can be made independently. True, it will not have any special practical capabilities, since the ability to maintain upper pressure is limited by the strength of the rubber bellows.

Thermal relays of the KTS 011 type are most convenient for conversion into a compressor pressure switch, since they have a strictly reverse sequence of operation: when the temperature in the refrigeration chamber increases, the relay turns on, and when it decreases, it turns off.

The essence and sequence of work is as follows. After opening the cover, the location of the desired group of contacts is established, for which it is enough to ring the circuit. First, the connection between the thermal relay and the compressor is finalized. To do this, the outlet pipe, together with the control pressure gauge, is connected to the unloading valve, and the contact groups are connected to the terminals of the electric motor circuit. An adjusting screw will be found under the thermostat cover. When the compressor is turned on (the receiver should be filled to no more than 10...15% of its nominal volume), the screw is rotated sequentially, monitoring the result using the pressure gauge. To set the lower position (which determines the minimum air pressure), you will have to gradually move the face button rod. To do this, the cover is installed in place, and the adjustment is actually made blindly, since there is nowhere to connect the second pressure gauge.

For safety reasons, the pressure adjustment range using such a thermal relay cannot be more than 1...6 atm, however, using devices with a more durable bellows, you can increase the upper range to 8...10 atm, which in most cases is quite sufficient.

After checking the functionality of the relay, the capillary tube is cut off and the refrigerant contained there is released. The end of the tube is soldered into the unloading valve.

Next, work is carried out to connect a homemade pressure switch to the compressor control circuit: using a nut, the relay is attached to the control board, a thread is made on the rod, and a lock nut is screwed on, by rotating which you can adjust the limits of air pressure change.

Considering that the contact group of any thermal relay from a refrigerator is designed for fairly high currents, in this way it is possible to switch circuits of significant power, including secondary compressor motor control circuits.

Source

Compressor Maintenance

Periodic maintenance and following simple rules, which are indicated in the operating instructions for the device, will significantly increase the service life of the equipment. At the time of purchasing a compressor, you must make sure that you have a passport, a warranty card and a factory inventory of components. Otherwise, the service center may refuse service.

The general recommendations of equipment manufacturers and service center specialists sound like this.

- When starting the unit for the first time, we must check the oil using a dipstick. Select lubricant (technical composition) taking into account the operating instructions. After starting, let the engine run idle for 10-15 minutes.

- The oil is changed to a new one after 500 hours of operation (we keep a record book). After draining the waste, the container is cleared of accumulated dirt.

- Before using the tool, it is necessary to lower the pressure to normal if it is too high.

- The air filter should be cleaned at least once a week. Many manufacturers recommend changing it every quarter, especially when the equipment is actively used.

- At the end of each working day, it is necessary to drain the accumulated water from the receiver.

- At the end of the work, the air is bled off and the equipment is completely de-energized.

- When the compressor is idle for a long time, the platform and moving parts of the air valve must be lubricated.

- Keep the device clean. The entry of dirt into the system is fraught not only with a loss of pressure, but also with failure of the main components of the compressor.

Particular attention should be paid to equipment grounding for all non-current-carrying metal components. In a good half of cases, manufacturers output the corresponding conductor to the plug. All that remains is to ground the outlet itself where the device will be connected.

What can be redone

Low-power 380 Volt electric motors are suitable for conversion: up to 3 kW. Theoretically, powerful motors are also reconnected. But this will additionally entail the installation of a separate circuit breaker in the electrical panel and special wiring. And this work becomes meaningless if it suddenly turns out that the input cable cannot carry such a load.

Read also: Btb10 800bw how to check with a tester

Even if your network carries high loads, and you managed to convert a 3 kW motor from 380 to 220 Volts, you will be upset the first time you put it into operation. The launch will be difficult. You will decide that the work was in vain. Therefore, if you redo it, then it will be low-power models.

Let's summarize.

Sometimes it becomes necessary to change the direction of rotation of the electric motor. This option is also available for 380V motors used in a single-phase network. To do this, you need to make sure that the end of the capacitor connected to a separate winding remains unbroken, and the other can be transferred from one winding, where the “zero” is connected, to the other, where the “phase” is connected.

This operation can be performed by a two-position switch, the central contact of which is connected to the output from the capacitor, and to the two outer terminals from “phase” and “zero”.

More details can be seen in the figure.

There are three-phase electric motors for 220V. Each winding of them is designed for 127V and when connected to a single-phase network in a delta circuit, the motor will simply burn out. To prevent this from happening, such a motor should be connected to a single-phase network only according to the “star” circuit.

Technical specifications

The technical parameters of the control device are designed to visualize the maximum and minimum gas pressure, as well as the flow rate of the working medium. The highest value at the inlet/outlet for a liquefied medium is 250 atm, for liquefied fuel - 25 atm. At the output, the indicator varies between 1−16 atm. In the design, the 220 V electric gas pressure regulator contains a sensitive mechanism that can compare the signal from the set pointer with the current value and converts the command pulse into mechanical work to move the movable plate to the neutral position. If the switching force is exceeded, the sensing element, or pilot, transmits a command to switch off to the sensors.

The pilot regulator can be astatic, static, isodromic.

Astatic

During operation, an astatic type relay experiences two types of load: active (acting) and passive (reacting). It is recommended to connect the device with a sensitive membrane to the equipment for sampling gas from the central pipeline. A device of this type adjusts the pressure of the system medium according to specified parameters, regardless of the degree of workload on the control element.

How to select capacitors for a three-phase motor using it in a 220V network.

The first thing you need to know is that the capacitors must be non-polar, that is, not electrolytic. It is best to use containers of the brand ― MBGO. They were successfully used in the USSR and in our time. They perfectly withstand voltage, current surges and the damaging effects of the environment.

They also have mounting eyes that help you easily place them at any point on the device’s body. Unfortunately, getting them now is problematic, but there are many other modern capacitors that are no worse than the first ones. The main thing is that, as mentioned above, their operating voltage is not less than 400V.

Calculation of capacitors. Working capacitor capacity.

In order not to resort to long formulas and torture your brain, there is a simple way to calculate a capacitor for a 380V motor. For every 100 W (0.1 kW) 7 µF is taken. For example, if the motor is 1 kW, then we calculate it like this: 7 * 10 = 70 µF. It is extremely difficult to find such a capacity in one jar, and it is also expensive. Therefore, most often the containers are connected in parallel, gaining the required capacity.

Starting capacitor capacity.

This value is taken at the rate of 2-3 times greater than the capacity of the working capacitor. It should be taken into account that this capacity is taken in total with the working capacity, that is, for a 1 kW motor, the working capacity is equal to 70 μF, multiply it by 2 or 3, and get the required value. This is 70-140 µF of additional capacitance - starting. At the moment of switching on, it is connected to the working one and the total is 140-210 µF.

Features of the selection of capacitors.

Capacitors, both working and starting, can be selected using the method from smallest to largest. Having thus selected the average capacity, you can gradually add and monitor the operating mode of the engine so that it does not overheat and has enough power on the shaft. Also, the starting capacitor is selected by adding until it starts smoothly without delays.

In addition to the above type of capacitor - MBGO, you can use the type - MBGCh, MBGP, KGB and the like.

Safety precautions

Although a drill press is easy to connect and use, working with it can be dangerous without proper safety precautions. Among them it is worth highlighting the following:

- Perform any repair or cleaning work only with the engine power off;

- use protective clothing and glasses to protect yourself from flying chips, dust, drops of cutting fluid, and parts of the drill that break;

- hide long hair under a hat, avoid working with gloves - if they get wrapped around rotating elements, they can lead to serious injuries;

- Before starting work, carefully check all moving parts of the machine for defects and damage. If they are detected, it is prohibited to use the device.

To find out more about how to connect a drilling machine, contact Metaltool and they will answer your questions in detail.

Source

Using a magnetic starter

The good thing about using a 380 electric motor connection diagram is that it can be started remotely. The advantage of a starter over a switch (or other device) is that the starter can be placed in a cabinet, and the controls can be placed in the work area; the voltage and currents are minimal, therefore, the wires are suitable for a smaller cross-section.

In addition, connection using a starter ensures safety in the event that the voltage “disappears,” since this opens the power contacts, and when the voltage appears again, the starter will not supply it to the equipment without pressing the start button.

Connection diagram for a 380V electric asynchronous motor starter:

At contacts 1,2,3 and start button 1 (open), voltage is present at the initial moment. Then it is supplied through the closed contacts of this button (when you press “Start”) to the contacts of the coil starter K2, closing it. The coil creates a magnetic field, the core is attracted, the contacts of the starter close, driving the motor.

At the same time, the NO contact closes, from which the phase is supplied to the coil through the “Stop” button. It turns out that when the “Start” button is released, the coil circuit remains closed, as do the power contacts.

By pressing “Stop”, the circuit is broken, returning the power contacts to open. The voltage disappears from the conductors and NO supplying the engine.

Video: Connecting an asynchronous motor. Determination of engine type.

If you have a three-phase electric motor, you know it doesn't come cheap. Therefore, if you need to use a single-phase motor, the thought of buying new equipment will only come to you when you do not know how to make an electric motor at home. We will tell you how to convert an electric motor from 380 to 220 Volts with your own hands.

Connection diagram for a 3-phase motor in a 220V network connected by a star.

As you can see, the 220V voltage is distributed over two series-connected windings, where each is designed for such a voltage. Therefore, the power is lost almost twice, but such an engine can be used in many low-power devices.

The maximum power of a 380V motor in a 220V network can only be achieved using a delta connection. In addition to minimal power losses, the engine speed also remains unchanged. Here, each winding is used for its own operating voltage, hence the power. The connection diagram for such an electric motor is shown in Figure 1.

Fig. 2 shows a terminal with a 6-pin terminal for delta connection. The three resulting outputs are supplied with: phase, zero and one terminal of the capacitor. The direction of rotation of the electric motor depends on where the second terminal of the capacitor is connected - phase or zero.

In the photo: an electric motor with only working capacitors and no capacitors for starting.