The installation of sealed window structures entails a deterioration in the microclimate of the room: humidity rises, a lack of oxygen and air staleness appear. Problems can be easily solved by placing a supply valve on plastic windows - the device normalizes natural ventilation and stabilizes air exchange.

We will tell you how to choose the right ventilator to ensure the supply of fresh air to rooms with plastic window frames. We describe in detail popular device models tested in practice. For independent home craftsmen, we provide detailed installation instructions.

Which supply and ventilation valve should I choose for installation on windows and is it needed?

A ventilation valve for PVC windows is needed in order to create the correct microclimate in the room, since the design of profile systems does not provide for natural air circulation. Unlike old wooden windows, which belong to the category of “breathable - blown” materials and are capable of letting air through, plastic windows, aluminum and wooden windows are completely sealed, perfectly protect the house from dirt, dust and noise from the street, but are not always equipped with special devices for fresh air supply.

Why do you need a check valve on ventilation?

During normal operation of exhaust ventilation, air moves from the room to the street. Exhaust vents are located “in dirty or damp” rooms - bathrooms, kitchens. The task of this part of the ventilation system is to remove odors and excess moisture to the street. But sometimes a situation arises when air flows through the exhaust ventilation in the opposite direction - into the premises. This moment is called thrust overturning and they try to fight this phenomenon.

A check valve for ventilation is needed for normal operation of the system.

Why do you need to fight backdraft? In the case of apartments, this is fraught with odors coming from neighbors, which is very unpleasant. If we consider private houses, portions of outside air in them reduce the temperature in winter. The second point is more dangerous and unpleasant - with reverse draft, the boiler may go out, and combustion products (and carbon monoxide too) may return to the room from the chimney. In any case, the reverse movement of air flow is an incorrect operation of the ventilation system and this phenomenon must be combated. A check valve is installed on the ventilation to block the movement of air in the wrong direction.

Supply valve - characteristics and features of the device

To dilute stale air in the room, the window design provides an air flow function. To do this, just put the sash in the correct tilted position and leave it that way. But, a problem arises with ventilation during rain, with heavy snowfall, or the most common problem of ventilation in winter is an increased supply of cold street air, and not all residents are comfortable with the discomfort from the cold. Supply ventilation valves will solve this problem. Not all of them are installed at the factory; in most cases they are mounted into the frame already when the window is in place; this is considered an additional element of the window and is installed upon request.

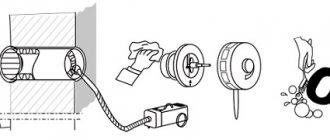

The valve consists of the following elements:

- Air intake - an outdoor unit with a visor that will prevent insects, fluff and dust from getting inside.

- The working channel is of a telescopic type - fixed inside the profile using a sleeve.

- Injectors.

- Filter.

- Adjustment element.

The last 3 elements can be attributed to the internal filling of the valve; their main task is to change the intensity of air flow.

Advice from the experts

Wall models are recommended to be laid during the construction of walls, but their installation in finished premises is also possible. It is not recommended to install window valves yourself - it is easy to break the tightness of the window frames and lose warranty service from the manufacturer. But the main thing is to choose the right type of additional ventilation you need. Poorly chosen models can clog the natural ventilation system of the premises, overturn it, or create uncomfortable conditions with additional noise from the operating fan.

How does it work and why is it needed?

The valve is designed to create so-called passive ventilation, if you can call it that. If the temperature outside is less than +5 degrees, a pressure difference will be created, due to which street air will be sucked into the room naturally, due to the fact that the main exhaust ventilation is working in the room. If the temperature outside is higher and an air flow is needed, then the room must be equipped with a forced flow of outdoor air, or turned on permanently.

For this to work correctly it is important:

- So that ventilation works inside the room.

- The entrance door to the apartment was sealed.

- The doors in the rooms, on the contrary, were not airtight for air passage.

- Or there were passages in the walls to allow air to escape from the room towards the exhaust ducts

- It is necessary that there is a free exchange of air masses - there are gaps from the room

Window valves in appearance resemble a gap created in the frame of a window with shutters.

Clients often come to me asking how necessary it is to install this type of device. I never tire of saying that installing a supply valve on a plastic window allows you to create a comfortable, healthy microclimate in the room and remove stale air unnoticed by household members. Since there is no ventilation effect in any translucent window structures, they should be equipped with valves. Without them, it will simply be impossible to remove carbon dioxide from the room, which has accumulated in rooms where someone is constantly present, and with the help of valves it is possible to reduce the level of humidity, and, consequently, the growth of mold and mildew on slopes. The worst consequences of constant oxygen starvation for a person are deterioration in well-being and decreased performance.

After all, you don’t have to use air supply devices; it’s enough to ventilate regularly?

Yes, of course it’s possible, and many people do it, I’ll tell you about the disadvantages:

- A constantly open “window” is noisy and cold, especially in the cold season.

- You are guaranteed drafts, since the air masses are not controlled in any way.

- This option is ideal if you like to ventilate the room as quickly as possible, open the window slightly and maximum street air enters the room.

The conclusion suggests itself.

By installation method

Ventilation valves are divided into supply, exhaust and supply and exhaust. There are 2 main types of supply valves: window and wall. Wall devices are a heat- and sound-insulated cylinder mounted in the wall.

On the outside of the cylinder there is a grill with a mosquito net and a control valve inside. The air flow control method is manual or automatic, depending on the model. Automatic devices operate by responding to changes in pollution, humidity, and air pressure.

Wall ventilation valves are most often installed in the kitchen, especially if there is no exhaust system above the stove where food is prepared. Periodically opening the windows will not save the apartment from the dominance of kitchen odors, especially if the ventilation system is malfunctioning. Constantly open windows are also not a solution, because cold air flows into the house, and all the noise from the street is heard much more clearly. Special filters are built into wall devices to clean the incoming air. The maximum power of such devices is 60–72 cubic meters. m/hour.

Wall models of supply valves have the following disadvantages:

- installation complexity;

- the need for frequent cleaning of installed filters;

- possibility of freezing in severe frosts;

- high price.

Often, wall valves are installed above the heating system - this provides additional heating of the incoming air flow.

Wall valve devices come in the following varieties:

- throttle valves consist of a metal pipe of round or square cross-section and a damper with the ability to control its movement;

- poppet valves can be installed both in the walls and on the ceiling of the room;

- a three-way valve is designed to regulate the temperature of passing air;

- The solenoid valve differs in that the opening and closing of the damper is carried out by an electric drive.

Window ventilation valves are, in simple terms, slits in a sealed window with dampers. They are distinguished by their simplicity of design and automatic operation 24 hours a day. The power of such a device is small - only 3–7 cubic meters. m/hour. Window supply valves can be built into frames made of almost any material - wood, aluminum, plastic. Location: top of windows. For adequate operation of the device, the following conditions must be met:

- natural exhaust should be in the room where the window valve is installed;

- the outside air temperature should not be more than +5 degrees;

- the door from the entrance must close tightly;

- free air circulation between the rooms of the apartment.

The main advantages of window supply valves are the following:

- invisibility;

- ease of installation;

- sound insulation;

- the flow of incoming air is directed upward;

- affordability.

Important! Automatic valves are equipped with a device that responds to the level of humidity in the room.

The disadvantages of window models are the following:

- work only with a good exhaust system;

- low productivity;

- no filters;

- letting in cold outside air in winter;

- risk of device freezing.

Window valves are divided into 3 types.

- Slotted. Air is supplied through a gap, the dimensions of which are as follows: width - from 14 to 17 cm, height - from 1.2 to 1.6 cm. From the outside, this hole is covered with an inlet block. It protects the valve from insects, dirt, debris and precipitation. Inside the room, the gap is covered with a control block. Slot devices are mounted in the highest part of the frames or in a horizontal profile separating parts of the frames. The advantages of this type are good throughput and ease of installation.

- Folded. They are used when plastic frames are already installed. They are cheap and easy to install. Fresh air is supplied through small narrow holes in the vestibule. Advantages: ease of installation and preservation of sound insulation. The disadvantage is the small amount of air passed through the slots, which is why rebated valves are not suitable for large rooms.

- Invoices. The largest amount of air passes through such valves, but they must be provided before installing window frames; they cannot be installed on already installed plastic or aluminum windows.

Window devices usually have several modes of operation. The adjustment can be carried out either manually or automated. For manual adjustment, some models have a cord, like a blind, while others have a manual adjuster. Automatic valve adjustment is always more expensive, but it's worth it. For this purpose, the valve is equipped with humidity and/or air pressure sensors inside and outside the room.

The exhaust ventilation valve is designed to remove exhaust air to the street.

Among other things, it protects the premises from the penetration of insects, fluff and litter.

It has a simpler structure when compared with the supply valve, namely:

- the stationary part (grid) prevents mechanical damage to the moving part;

- movable flap that opens only in one direction;

- flange for attachment to the ventilation duct.

The exhaust valve requires careful installation to prevent damage to the damper and the entry of construction debris. Otherwise the device will not work properly. Therefore, after installation, be sure to check the operation of the device. Changeover valves are mounted strictly vertically, duplicating the main exhaust system. Hermetic ventilation valves are essentially a shut-off device installed in exhaust ducts. It blocks the air flow.

There are also types of valves such as check valves. In a situation where so-called reverse draft appears in apartments, that is, odors from neighbors’ apartments come to you, it is appropriate to install a check valve.

It is usually mounted in a ventilation duct. It can function both in a natural ventilation system and artificial injection/exhaust. There are devices with a round or square cross-section.

Check valves are divided into several types.

- Membrane household. Used in conjunction with exhaust fans with low power electric drive. The lightweight flexible flap opens with air flow. When the vector of air movement changes to the opposite, the damper is pressed and the passage is closed.

- Petal. The damper is rigid and attached to the axle. The valve is opened and closed by turning it.

- Butterfly. There are 2 dampers mounted on springs in the valve pipe. The opening of the channel occurs under the action of air flow, and closing by a spring mechanism. The kit requires a fan of sufficient performance.

- Gravitational. The damper flaps swing open under the pressure of a stream of air and close under their own weight.

The exhaust system and check valve must be installed together. The choice of check valve type depends on the operating mode of the ventilation hood. If you plan to use this system regularly, the type of valve is not important. If the exhaust system operates irregularly, the damper must be as light as possible so that the natural air flow can open it slightly. “Butterflies” are installed in industrial buildings; the power of household fans is not enough to open their doors.

There are only two suitable positions for installing gravity valves - vertical and horizontal. Their design does not provide for tightness. Other types of check valves can function in any location. The damper is kept closed by force - under the action of a spring mechanism or a system of counterweights. The device must be carefully configured - an incorrectly adjusted system requires more fan power, and as a result, additional energy costs. And the noise level will increase.

Disadvantages and advantages

The advantages of valves include:

- Continuous flow of outside air and constant indoor air circulation.

- No drafts, which is especially important in a children’s room where a child always lives.

- Creating the right microclimate in a room is important for a person.

- No condensation, reducing the likelihood of developing fungus and mold.

- Preservation of the noise and heat insulation properties of the structure.

- A simple option to use, the main thing is to control the humidity.

- Adjustable, you can let in more or less air.

Flaws:

- If you choose a mechanical valve, it will have to be adjusted manually at height.

- There is a possibility of freezing in winter if there is no traction and humidity indoors.

- If you do not install a filter, lint and dust may enter the room.

As for adjusting the amount of air entering the room, it depends on many factors: the number of people in the room, the weather outside, the temperature in the room, and the rate of air outflow through the ventilation.

Methods of ventilation of plastic windows

Metal-plastic windows are the most in demand at the moment, and many of their owners have faced the problem of controlled ventilation. Let's consider common options for ventilation of rooms glazed with PVC structures.

Micro-ventilation

Another name for this ventilation method is slot ventilation . Essentially, this is opening the window in such a way that a gap of several millimeters is formed between the sealing elements of the sash and the frame. Externally, both from the outside of the room and from the inside, the window looks completely closed, which minimizes attempts of unauthorized entry through it.

Turn the handle at an angle of 45 degrees and pull it towards you

The micro-ventilation function will only work in units equipped with the appropriate fittings. Its operating principle is quite simple: to open the sash in this mode, you need to place the handle at an angle of 45˚ between the folding and turning positions.

Roto fittings for micro ventilation

This method of ventilation is more in demand in the cold season, when the use of conventional options will lead to excessive cooling of the room. This is especially true in children's rooms and rooms with a high probability of drafts.

Step opening

Unlike the previous method, the adjustment options in which are limited to one position, stepped ventilation provides wider possibilities for room ventilation. The ventilation gap is adjusted in accordance with external and internal climatic conditions in several positions (from 3 to 5).

As in the case of micro-ventilation, a stepped mode is available if there are special fittings in the unit.

There are two options:

- It is more aesthetically pleasing when the step mechanism is located on the inside of the sash (under the rebate) and is not externally noticeable to others. Adjustment of the gap in such cases is carried out using the opening handle and will correspond to the degree of its tilt (3-5 positions between the folding and rotating positions);

- Less attractive in appearance, but much more affordable in terms of installation and cost - comb.

The comb can be bought at a hardware store.

It consists of two elements - a strip with special recesses (attached to the frame) and a counter protrusion on the sash, which engages with the recesses of the strip.

All of the methods described above require the direct participation of people in the room, which is not always convenient. The ventilation process can be partially automated using special window modules and built-in devices.

Installation of three-stage micro-ventilation fittings on a plastic window:

Choosing the right valve

When deciding to buy a supply valve in Moscow, consider several parameters at once:

- The material of manufacture can be plastic or aluminum. It is worth choosing it based on the appearance of the window, for example, for PVC structures a plastic option will look organic, and for aluminum ones - aluminum painted in the color of the frames, although it is ideal for PVC and wooden windows.

- Type of installation - it can be mortise into the frame, or overhead on top of the window frame, while such an overhead reduces the height of the window frame. There is also a valve that is installed in a double-glazed window; a new one is needed; the old one will not be suitable.

- Type of adjustment - the manual version is much cheaper and more familiar, but the automatic one is simpler and more convenient to use. The cheapest ones come without adjustment at all, therefore, in strong winds they may not function and will blow heavily.

- Size – there are models that are simply invisible, while others stand out. Choose the one that suits you in your opinion.

- The presence of sound insulation will reduce the level of unwanted noise in the room.

It is believed that seam and slot models will be easy to install yourself.

know more

You have questions?

Write!

I'm in touch right now!

Finally, about the importance of a full influx

In a “thermos” house with tightly sealed windows and entrance doors, the following happens:

- indoor air is humid and heavy;

- residents feel stuffy; windows are often opened for ventilation;

- unpleasant odors are slowly removed from the kitchen and bathroom;

- Gas-using equipment - household stoves, ovens, instantaneous water heaters - does not work well due to lack of oxygen.

Note. An insufficient amount of inflow provokes automatic shutdown of gas boilers - the draft or flame ionization sensor is triggered. Difficulty ignition is also observed - the electrodes “spark” for a long time, and when ignited, a strong bang is heard in the chamber.

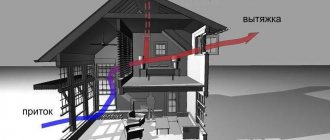

A supply valve in the outer wall solves all of the above problems. When fresh air enters the house, the hood functions properly. The ventilation elements are distributed as follows: exhaust ducts are located in more contaminated rooms (kitchen, toilet), and inflow valves are located in living rooms.

More about types

There are these types of valves:

- Seam - has a small capacity, is not good enough in terms of noise insulation of the room. To ensure optimal air flow, it is better to install 2 products per window. The undeniable advantages of this model include its affordable price, simple installation of such a valve, the installation of which does not require the dismantling of double-glazed windows and drilling of window frames.

- Mortise - when holes are milled in a window product to the street and a cover is installed from the streets, and inside the mechanism itself with a filter to control the inflow, this is the best option, for sufficient air flow, you can put one on a window with a width of no more than 1500mm

- Slot cover - with dimensions from 60mm in height and width over the entire length of the frame. This is made in the form of a solid block, and is installed when installing the window, included in the design of the window opening and the window configuration. It has decent throughput. The excellent thermal and sound insulation properties of the window will be preserved, the throughput is 4 times greater than that of rebated windows, in this option I recommend the VILPE RENSON INVISIVENT valve; it will ideally solve the problem.

- Slotted mortise valve - this valve is installed in the area of the double-glazed window itself, while the old double-glazed window is removed and a shortened version is installed in its place so that the valve fits in the sash area. Ideally, such a valve should be stopped in production so that the double-glazed window can be manufactured in advance, and in this case there will be no additional costs. The ideal valve in this case I recommend VILPE RENSON AR 75

As for the type of control, it can be:

- Manual – often present in cheap models, it provides for mechanical adjustment of the valve to the desired operating mode using a part located on the body. The adjustment does not take into account the microclimate in the room.

- Automatic - in this case, the adjustment is performed by a mechanism built into the device, which connects to the smart home. Everything is controlled using a sensor inside the room - which will determine the level of humidity in the room and accordingly control the intensity of the incoming air flow.

On budget valve options, the regulators are equipped with handles to indicate whether the valve is open or closed, and the valve shutter indicates the position of which indicates the direction of the air:

Possible difficulties and errors

The most difficulties that lead to installation errors occur when installing a ventilation valve using the perforation method.

Since this method requires making through slot holes in the PVC window frame.

Most often, mistakes are made when choosing a ventilation valve, when a low-power device that is not capable of creating the required circulation rate is installed over a large area of the room.

The most common mistakes that performers make when installing a ventilation valve on a PVC window frame:

- the work was not carried out carefully, without a previously prepared template;

- the seams on the frame have not been sealed;

- a new seal has not been installed;

- The automatic operation of the valve has not been adjusted.

What to consider when choosing?

When deciding to purchase a ventilation valve, consider:

- Not all valves can be installed on an existing window, this needs to be diagnosed from a photograph or a paid visit by a technologist can be arranged; in Moscow it costs 2000 rubles, which are then taken into account in the cost of work and materials

- The capacity of the supply valve is a kind of device performance. It is affected by flow area and pressure. Numerical indicators do not always reflect real performance, since they may not take pressure into account at all. It is believed that a device with a throughput capacity of 20-35 cubic meters per hour at 10 Pa will become the norm.

- Sound insulation properties - it is believed that for comfortable use of windows, this figure should not be less than 30-35 dB. Some manufacturers offer windows with the highest noise-proof properties, then the valves must meet these parameters.

- The operating internal temperature and humidity conditions are an important parameter that will prevent the valve from icing up indoors in winter. To avoid this, a thermal break is created, that is, air must flow from the radiator to the valve area.

- Type and ease of adjustment - if it is important for you to control the level of incoming air, choose an option with an adjustment function.

To prevent unwanted dust and dirt, as well as insects, from entering the room, manufacturers equip some models with filters.

Advantages and opportunities

The main advantage of ventilation valves is the automatic adjustment of air supply and exhaust. Currently, valves equipped with special humidity sensors can be found on sale.

Their peculiarity is that they provide the required amount of fresh air depending on the humidity level.

Equipping plastic windows with ventilation valves significantly reduces the likelihood of condensation forming on the glass unit, reduces the level of penetrating noise to 46 dB, and also creates all the conditions for the formation of recovery - heating the incoming cold air with the outgoing warm air.

When installing such miniature devices, the area of visible glazing, and therefore the amount of light passing through the glass, does not decrease.

Let's compare ventilation options

- A mortise climate control valve for a window will be relatively inexpensive and extremely easy to use and install. Their operation is silent, but they are not able to maintain the original sound insulation parameters of the structure. For maintenance, regular cleaning is sufficient - once every 6 months. Do not wash them with chemicals.

- The valve on the window from above will work properly, but its peculiarity is that you need to install it on the window during installation and design it in advance so that the window is made to the appropriate size, and it has good sound insulation, and is high in cost.

- Wall inlet valve - this option requires installation using a special tool that makes a hole in the wall. In some options, filters are installed that clean the incoming air. Inexpensive and difficult to install.

- A breather is a powerful electrical device that includes a climate control, air supply and air purification system. The throughput is decent - up to 150 cubic meters per hour, and the noise level is very low - 19 dB. Some models may have an air heating function. This option cannot be installed by yourself; a specialist with experience must work here. The cost is high.

- A recuperator is an electric unit, which has in its design a fan for air inflow and outflow from the room, with heating and filtration. Decent productivity of more than 120 cubic meters/hour. and this option requires careful consideration of the possibility of installing equipment. The cost is high for the equipment itself and the work performed.

If you live far away from a highway or an industrial zone, and there are no more than 2 people in the room, you can opt for a classic valve, but if you are near a noisy road, then you need to think about more serious equipment.

Features of air duct installation

Before installing the valve, it is necessary to determine its location. The best place for this purpose is considered to be near the heating radiator on a load-bearing wall.

Supply device structure: 1 - external casing; 2 - fan; 3 - filter; 4 — insulated casing; 5 - adjustable body; 6 — decorative panel with a switch; 7 - ceramic element

- Step 1. Drilling a hole to install the air exchanger. The diameter of the hole should be slightly larger than the valve tube. This will allow you to correctly position the device and securely fix it in the wall.

- Step 2. Outside on the wall in the area where the device is placed, it is necessary to provide protection from rain. If it is not possible to do this (the valve outlet will be located in a place inaccessible for work), the hole must be made with a slight slope towards the street. This will prevent raindrops from entering the device.

- Step 3. Install the supply valve into the wall and fix it with construction foam.

To install the device you will need to drill into the wall.

Subtleties you need to know

In addition to the above-mentioned model SVK V-75 M, the remaining wall supply ventilation valves can be mounted in any location on the outer wall. However, the following areas are the most successful :

- Under the windowsill, next to the radiator.

- At the level of 2/3 of the height of the window opening (for an ordinary apartment - at a height of about 1.8-2 meters from the floor).

In the first case, the air entering inside is immediately heated by the battery. In the second, it enters the upper part of the room, where it mixes with warm air. Both options are good because this arrangement allows you to hide the wall valve behind the curtains.

The only requirement that should be taken into account in the second case: there must be at least 30 centimeters from the location of the supply valve in the wall to the window slope. Otherwise, this area may freeze in winter.

Installation in the kitchen with a hood

When installing a forced-air hood in the kitchen, many people want to maintain natural ventilation. To do this, you will need to install a tee at the entrance to the ventilation duct. Connect a hood with a check valve to one of its inputs, and install only a check valve in the second. As you can see, the system is not too complicated, but it works.

Why should there also be a check valve on the hood? Because if it is not there, the reverse flow of air may pass through the hood. Yes, this will not happen every time, but with a strong flow it will.

When installing this unit, try to ensure that the check valve for ventilation is located as high as possible under the ceiling

As a result, the warmest and most humid part of the air will be removed, which is very important for the kitchen.

How to install a window valve yourself?

In order to install a valve, you first need to purchase it, and you can install the simplest one, the one that is installed without milling or disassembling the window structure, such a valve can be purchased at any store, and its price starts from 750 rubles

So, you will need a stepladder, a knife (preferably a stationery knife), a screwdriver or a screwdriver. You will need to remove part of the seal at the bottom of the opening sash, 100mm high, to allow air to flow through it into the sash area. And also cut out at the top under the valve itself and then follow the instructions. Devices are often equipped with valves, seals, fasteners - everything necessary for proper installation.

Let's get started:

- The elastic must be cut to the shape of the valve on both sides.

- Install the valve in place of the seal cutout

- Secure the valve using self-tapping screws.

- And the valve is ready for use

Using a thinner seal allows you to create natural air circulation, and regulate the flow intensity with a special handle. If there is a lot of blowing from the valve, then you can correct the situation in this way: in the area of the cutout of the seal, insert it back, but of a smaller size, and thus the inflow will be less.

Instructions for construction without perforation

This option is the simplest, can be performed by a home craftsman with any level of technical training , and does not require much time or the use of complex tools.

Such valves can be purchased in retail chains with and without adjustment of the volume of circulating air. In turn, adjustable valves can be either mechanical or electrical with automatic control.

Automatic systems have built-in temperature sensors with thermo- and hydroregulation, which ensure that the room does not become overcooled, and in addition, internal relative humidity is monitored.

Important. The volume of air circulation is regulated thanks to a damper that opens/closes depending on the size of the electrical signal coming from the primary sensors.

Necessary equipment

The main set of necessary consumables is included with the ventilation valve.

It includes:

- self-tapping screws;

- the valve itself measures approximately 35 cm;

- 1 piece of seal 35 cm and two 16 cm;

- 3 plugs for securing the device.

In order to secure this device, you will need a sharp knife, an electric screwdriver, a screwdriver, a ruler and sealant.

Step-by-step algorithm

Before you begin the process of installing the valve, determine the location on the valve for the valve. Experts recommend installing it in the center of the sash, and if it is narrow, then slightly offset so as not to interfere with the operation of the window fittings.

Algorithm for installing a ventilation valve without perforation:

At designated points, marked according to a pre-prepared template, cuts are made with a knife and the seal is removed from the groove.- To install the valve, fasteners are installed in the open groove - in the middle and 2 at the edges.

- To prevent the valve from moving, double-sided tape is glued to its body, on one side of which the protective film is removed.

- The valve side with tape is glued in the required place.

- Next, using self-tapping screws, attach the valve to the window sash.

- Screwing self-tapping screws into pre-assembled dowels through the valve mounting holes.

- Install a new seal between the fasteners of two short pieces that are supplied in the kit.

- Another seal, the longest of the set, is installed exactly opposite the supplied valve. It is narrower in size, therefore it provides a technological gap between the sash and the PVC frame, which facilitates the flow of outside air into the room.

At this point, the installation process is completed and they begin to adjust the required level of air flow using the damper. As a rule, its position on the far right corresponds to the maximum volume of air flow, and the position on the far left corresponds to the minimum. More precise recommendations for setting the ventilation valve are specified in the manufacturer's instructions.

Note! If the installation of one or two ventilation valves on PVC windows does not bring the desired result and does not provide the necessary indoor air characteristics, the apartment owner needs to take care of changing the existing ventilation system to a more efficient supply or recuperative one.

How to install if you need to do milling?

In some cases, installation requires milling. The valve should be located at the top of the frame, the sash must be dismantled, first removing it from its hinges. It is better to do this work in the warm season, cutting the hole carefully with a power tool, eliminating the possibility of damage to the seal. You will need 10 and 5 mm drills, silicone-based sealant, a jigsaw, and a template that will allow you to correctly mark the installation location.

- Mark the place.

- Drill a hole at the same level, connecting with a jigsaw in one plane. The resulting chambers should be filled with silicone sealant.

- Also seal the outer strip, attach it to the sash and connect it with self-tapping screws.

- Install the inner part.

- Check the strength of the fasteners.

- Install the canopy, securing it with self-tapping screws, and seal the joints with sealant.

- Place the sash in its original place and set the operating mode.

If problems arise after installation, it is likely that the ventilation system will need to be improved. The valve cannot solve the problem if there is a problem with ventilation, it will only help freshen the air and make the microclimate comfortable, provided that everything works perfectly.

It is better to entrust such work to professionals, the valve is not expensive, but a damaged window may cost rework and replacement with a new one, it is better not to risk it.

To get detailed advice on air flow, installation of valves, and working ventilation, you just need to leave your phone number in the callback request form on the website, or contact me in a way convenient for you: through social networks, WhatsApp, by phone number or by writing to [ email protected]

Average prices for the service

The final price for installation of a valve on a PVC window depends on the cost of the product, its functionality, air performance and design of the window unit, as well as the level of automation and installation method - with or without perforation.

Note. The price includes not only installation of the valve, but also checking the operation of the ventilation ducts and preventing the operation of the fittings.

Average prices for installation of ventilation valves depending on the brand, cost of the kit and productivity in m 3 / hour:

- Air-box Standard, 0.58 m 3 /hour of air, product price - 600 rubles, installation - 800 rubles;

- EMM, air flow 5-35 m 3 /h, automatic, kit price - 4,900 rubles, installation - 1,800 rubles;

- Aquvent HY supply air, 8-42 m 3 /h, automatic, kit price - 3,800 rubles, installation - 2,000 rubles.

- MACO seam up to 5 m 3 /hour, product price - 480 rubles, installation - 900 rubles.

- Acoustic canopy A-EMM with protection against insects, product price - 850 rubles, installation 600 rubles.

- OKFIL window filter with replaceable filter, set price - 2000 rubles, installation 1000 rubles.

- Valve ENA 2 air capacity 5-35 m 3 /h, automatic, kit price - 5700 rubles, installation - 2200 rubles.

How to do it yourself?

Inlet valves are presented on the market in a wide range, and each consumer has the opportunity to choose the most suitable model based on the criterion of price-quality ratio. If it is not possible to purchase a factory-made product, you can make the valve yourself, according to step-by-step instructions :

- The pivoting window sash opens to provide access to the internal space between the profile and the frame.

- Along the perimeter of the fixed frame on the bottom side, a strip of polymer elastic seal with a length of 10 to 50 mm is cut out.

- The same piece of rubber product is removed from the side of the sash, but already in the upper part of the window.

- Street air enters through the resulting gap into the internal space between the frame and the sash, heats up after passing through the zero mark and rises upward, where it safely enters the room.

- To ensure purification of the supply air, you will need a piece of plastic lining, the dimensions of which are 10 - 20 mm larger than the gap formed.

- In a hollow design, the lining compartments are filled with synthetic porous material, for example, foam rubber.

- A piece of lining is fixed to the frame at the location of the gap. Before entering the room, the air is filtered through the foam structure.

The disadvantage of such products is the lack of a quality certificate, as well as the risk of freezing or damage to the sound insulation of the window unit. If there are signs of discomfort during operation, the owner of the premises will not be able to make a claim.

Varieties

If we take the shape of the drainage holes as a criterion, two types should be distinguished:

- flat;

- round.

Professional craftsmen claim that flat cavities are more reliable and correct. They are installed in high-quality windows by conscientious manufacturers. The plugs for them, accordingly, are also different in shape.

If there is an impost in the window, then in this case drainage cavities are a necessity. They will look like holes drilled with a drill at the bottom of the mullion.

Drainage holes in plastic windows according to GOST

According to GOST 30674-99, drainage holes should be located in the deepest places of the folds, and the distance between them should be at least 60 cm. At the bottom of the profile there are two openings with a diameter of 5x10 mm, and at the top - also two, if the profile has a length of up to 1 m ., and if more than 1 m, 3 cavities are placed. That is, the number of holes depends on the dimensions of the metal-plastic structure.

The window frame must contain at least two “holes” of round and semicircular shape. If the structure is large, many holes are made. GOST regulates not only the quantity, but also the location of drainage cavities. This information should also be contained in the individual window system's "recycler folders".

Possible problems and solutions

When choosing, installing and adjusting supply valves, beginners often face a lot of problems :

- The purchased valve does not provide proper air exchange. Before purchasing a product, you need to calculate the required supply ventilation performance and select a device with optimal characteristics. If such indicators are not provided by one valve, it is recommended to buy several pieces.

- After installation, the air temperature in the room drops sharply - there was an error in selecting the valve, or the device requires manual adjustment by adjusting the position of the blocking damper.

- Dust settles on windowsills, furniture and other surfaces - when installing equipment on a window facing a busy street, it is recommended to pay special attention to installing the filter.

- The efficiency of the inflow drops sharply - during long-term operation, the product requires maintenance, cleaning it from dust and grease deposits.

When choosing the right product and carrying out its correct adjustment, the owner of the premises will feel an improvement in the microclimate already in the first hours after the start of operation.