A gas sauna stove is a convenient and economical heating option. For Russian users, this method is somewhat unusual, since it does not apply to traditional options for arranging a bathhouse.

However, the use of gas furnaces allows for quick and economical heating, the ability to use different types of fuel (natural or liquefied gas), and the absence of the danger of carbon monoxide poisoning. At the same time, gas furnaces have their own specifics, which do not allow frivolous or inattentive attitude. The issue is serious and requires careful consideration.

4.5/5 — (2 votes)

Specifics and features

A traditional wood-burning stove in a bathhouse has two important drawbacks: it takes a long time to heat up and can become a source of deadly carbon monoxide.

A gas oven is a modern and efficient alternative to traditional ovens. It is much more convenient to use, costs less and has previously known performance qualities. This distinguishes gas stoves from traditional wood stoves, each of which has its own characteristics.

In addition to rapid convective heating of air, a gas furnace can heat water. In this case, two modes are possible - flow and heating in a storage boiler connected to the burner. Both options give quick, high-quality results, and are often used in pairs.

The heating itself is always carried out in flow mode, but in one case the water immediately goes to the point of analysis, and in the other it enters the container, from where it is supplied again to heat and maintain the set temperature.

The operation of gas furnaces is characterized by uniformity and stability. However, the specific design and design features of the burners may have their own subtleties. In addition, there are furnaces that are completely autonomous and require connection to the power supply network (for the operation of auxiliary control systems).

Therefore, for the correct selection and safe operation of the furnace, it is necessary to understand its structure and operating principle. Otherwise, failures or emergency situations with unpredictable consequences are possible.

Heater location

Usually the bathhouse is heated using one heat source. For a house next to which a unique bath complex is built (with a dressing room, steam room, swimming pool, relaxation room, room for playing billiards), a generally accepted heating system is required.

If heating is designed for a classic bath, then the stove is positioned so that it can be used to warm up each room. A tank of water is allocated a place near the washing room.

The ideal is a “through” arrangement of the furnace. The firebox door can be opened while in the dressing room. The stove itself will be located in the steam room, and the water tank will be located in the wash room.

It is important that each of the combustible elements of the furnace structure is protected from fire-resistant material. To comply with this, you can build a heater from brick, but it will have large dimensions and take up a lot of space.

A practical option is to build a stove, the design of which includes a tank and an open heater. The firebox for heating water is equipped with a register, which will prevent premature boiling of water, during which the unheated bath is filled with damp steam. Heating a bathhouse in this way requires observing an important nuance - the bottom edge of the tank should be 50 cm above the register.

Advantages and disadvantages

Statistics show that gas models are the best-sellers among all types of sauna stoves.

This success is due to the many advantages of gas furnaces:

- rapid heating of rooms and water;

- fuel costs are lower than alternative models;

- gas consumption is much lower than the amount of solid fuel or electricity required to heat the same premises;

- there is no need to monitor the combustion process and constantly add fuel - simply, the combustion mode is adjusted, and the process proceeds automatically;

- the steam room (and the room in general) is clean, there is no soot or ash;

- the ability to quickly and accurately adjust the temperature;

- light weight, no need to build your own independent foundation

- the presence of heat-protected chimneys, passage units through the ceiling and roof;

- ease of operation. There is no need to constantly remove ash and clean the ash pan;

- small size, the stove does not take up useful space from the main room of the bathhouse;

- a large number of models of different capacities with a wide range of functionality.

Disadvantages of gas furnaces:

- the need to obtain permits for the operation of gas equipment and carefully follow the operating rules;

- accidents are possible caused by violations of operating rules or the use of low-quality devices;

- After turning off the stove, the temperature in the bathhouse drops quite sharply.

Despite some shortcomings, the demand for gas sauna stoves is steadily increasing. The undeniable advantages of such equipment make gas furnaces the most popular and preferred among all possible options.

Gas procedure, practical advice

The preparatory stage is the purchase of pipes, consumables and gas equipment. To gasify a bath according to the rules, you need to check the project and the received technical conditions.

The documents contain a calculation of the length of the pipes, an indication of their diameter, as well as the name and brand of permitted equipment. Experienced users advise purchasing pipes and consumables with a 30 percent reserve.

Stage No. 1 - installation of an external gas pipeline

Since it is recommended to install an external gas pipeline above ground, reliable supports will be required to secure the pipes. They must raise the gas pipeline above the ground by at least two meters.

The following requirements apply to supports:

- the distance between the supports is determined by the project;

- the strength of the structure should be calculated based on the gas pipeline’s own weight and the weight of possible ice with a coefficient of 1.2;

- the fastening part must correspond to the design dimensions of the pipe.

If the project specifies the installation of a gas pipeline with a slope, you can install metal spacers between the soles of the supports and embedded structures. The installation of such gaskets between the pipe and the support is prohibited.

The rules for placing supports also apply to the distance between them and the welds on gas pipes. This distance cannot be less than 5 cm

To protect against the effects of wet precipitation, the outer pipeline is painted with bright yellow oil paints. This is done by employees of the gas company that took over the installation.

But after they leave, many summer residents repaint the pipes in other colors that match the main palette of the site. This is prohibited.

Stage No. 2 - laying pipes inside

The internal gas pipeline must also consist of metal pipes. In places where they pass through the walls, it is necessary to drill holes and install embedded iron sleeves in them. Laying pipes through walls is permitted only through such sleeves.

When gasifying wooden buildings, this is extremely important, since any wood shrinks over time. And this is fraught with damage to the unprotected gas pipeline.

Holes for the gas pipeline are prohibited from being made between logs or beams, at their junction. They must be located inside solid wood

Fastening must be carried out using the products specified in the project. It is better to purchase fasteners in specialized stores, since regular retail outlets often offer analogues that do not meet the requirements.

To implement turning moments, it is important to use an induction pipe bender - a device that allows you to change the angle by 90 degrees. The manual bending method with heating is not suitable in this case, as it can damage the structure of the metal.

At the points where gas equipment is connected, the end of the pipe is threaded. Filters are attached to this thread and shut-off valves are installed. During the final pressure testing, a specialist must check the tightness of these connections and the integrity of the welds.

Before performing welding work, you should make sure that you have a fire extinguisher, cover the wooden walls of the bathhouse and nearby buildings with asbestos or metal sheets

It is important to ensure that the gas pipes inside the bathhouse do not intersect with the electrical wire. The minimum distance between them is 10 cm. If water supply or sewerage is installed in the bathhouse, then it is necessary to maintain a distance of 2 cm between them and the gas pipeline branch.

Stage No. 3 - installation of the chimney

We have already discussed the rules for installing a gas stove. Therefore, the next step is the organization of the chimney. Gas companies also have special requirements for it.

During installation, it is recommended to ensure:

- lack of pipe joints in the ceilings - it is necessary to install the chimney so that the connections are located above or below the ceiling;

- the location of the pipes relative to the flammable elements of the building - the distance between them should not be less than 1 meter.

Above a flat roof, the chimney can protrude 1.2 meters or more. Above a roof with slopes, the minimum elevation value is 0.5 meters.

How it works

A gas sauna stove operates on the general principle of gas devices - gas is supplied to the burner. When burned, it releases a large amount of thermal energy, heating the air in the room and water for hygiene procedures.

The main element of the furnace is the gas burner. For sauna stoves, it is specially made and has an elongated shape to accommodate the device in a remote firebox.

The use of conventional stoves in a bathhouse is undesirable - it is easy to get burned on the body or complicate ignition in stoves of a conventional design.

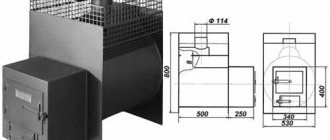

The gas burner is located in the combustion chamber. A copper coil is placed inside it to heat the water. In addition, there may be a heat exchanger for flow heating. A chimney is connected to the combustion chamber, which is then connected to a sandwich pipe and a passage through the ceiling (as a rule, they are purchased separately).

All nodes are located in a common housing. A grate or mesh for the heater is installed in its upper part. The weight of a gas stove (without additional components and heater) is relatively small - approximately 50-70 kg (although variations are possible). For installation, it is enough to provide a strong fireproof (ideally, heat-insulated) platform.

Requirements

To talk about the pros and cons of a heating system, you must first determine what requirements it must satisfy.

And this:

- Safety.

- Economical.

- Ease of use.

- Warm-up speed.

Knowing the requirements listed above, you can see how gas sauna stoves meet these points.

Criterias of choice

Choosing a gas furnace is a responsible task that requires preliminary calculations and knowledge of design features.

The selection criteria are usually:

furnace power

It is necessary to first calculate the required power, taking into account the volume of the room, correction factors for decoration, windows, number of rooms (compartments), etc. The power is selected based on the volume (on sale it is usually indicated for which rooms a particular model is suitable);

burner type

Manufacturers claim that the best option is a supercharged design. However, it has a lot of features that complicate operation. In particular, high-quality grounding and a voltage stabilizer are required. Therefore, atmospheric burners are more often chosen - they are unpretentious and only need stable draft;

water heating method

Double heating is preferable (in a container and in a flow-through method), but here they are guided by their own needs and considerations;

fuel type

Most designs can operate on both natural and liquefied gas. However, most burners require reconfiguration from one type to another, change of burner nozzles and other procedures. They can only be performed by specialists from the service center.

Expert opinion

Lovkachev Boris Petrovich

Bath master who knows everything about steaming

Taking these criteria into account and comparing them with the characteristics of commercially available gas furnaces, the optimal option is selected. An important factor is also the price of the stove, which many users consider the main selection criterion. Here any recommendations are useless - they are guided by their own financial capabilities.

Gas-wood boiler

For those who cannot imagine visiting a steam room without the unique smell of burning wood and want to save on the operation of the bathhouse, a gas-wood stove may be the ideal solution.

Such a heating device is a modern universal design that allows the use of various types of fuel: natural and liquefied gas, coal and wood. This is possible due to the fact that such stoves have removable elements necessary for working on solid fuel and gas.

Devices designed for gas combustion consist of burners, filters and various valves. At the same time, to operate a solid fuel stove you need a fuel receiver. Such heating devices are not new on the modern market. They were used back in Soviet times. A striking example of this is the OGV (heating gas water heating) boiler.

The equipment necessary for gas combustion is installed in the ash pan of the furnace. If it is dismantled, the boiler will function properly using solid fuel.

Gas-wood stoves are very popular not only due to their versatility. Their cost is at an acceptable level, which is an important factor for bathhouse owners.

Best models

There are a large number of gas-fuelled sauna stoves on sale.

Most of them are domestically produced, and this is no coincidence - imported designs do not work well in our conditions. They need a stable supply of electricity, since almost all designs are supercharged. In addition, spare parts and replacement units for such furnaces are too expensive, which sharply reduces user interest.

Domestic furnaces are designed taking into account technical conditions and operating features. They are relatively cheap and unpretentious, have stable parameters, are durable and reliable. Therefore, user interest is focused specifically on domestic equipment.

Let's study the rating of the most popular models of gas stoves for baths:

Kutkin G-4.0

Oven with a power of 40 kW, weighing 85 kg (without stones). Capable of heating a heater weighing 120 kg. Designed for rooms with a volume of 40-75 m3.

- Pros - economical fuel consumption, the presence of 4 operating modes, the ability to adjust air convection without over-drying, heating the heater from 5 sides.

- Disadvantages - narrow range of burner settings, possibility of overheating of the stove (the housing material is not designed for long-term operation at maximum conditions), no steam generator.

Troika No. 06-GT80

Special design with a closed heater. This allows for maximum heating without loss of thermal energy. The furnace power is 80 kW, designed for use in a room with a volume of 40-70 m3.

- The advantages of the stove are high power and the ability to remain heated for a long time, no danger of getting burns from the hot body, no overheating and no drying out of the air.

- Disadvantages - heavy weight, requiring the manufacture of your own foundation, mandatory brick lining, large oven size.

Ermak Uralochka 30

Modular oven with a power of 30 kW, designed to operate in rooms with a volume of 24-30 m3. The 4mm thick body ensures durable and stable performance. The maximum weight of the heater is 110 kg (recommended - 70 kg).

- Pros : energy independence, intense air heating, ability to obtain dry and wet steam.

- Disadvantages - the resource of the water tank is relatively small, the weight of the stove is too large.

Teplodar Sahara-16

An efficient oven with a power of only 26 kW. At the same time, it is capable of heating a steam room with a volume of 8-16 m3 in 30 minutes to a temperature of 110 °C. The design is well thought out, the operation of the furnace in all modes is stable and trouble-free.

- The advantages of the stove are a multi-mode type of operation, the presence of wood power in parallel with a gas burner, the possibility of remote control, and compactness.

- Disadvantages - lack of a steam generator; the furnace lining wears out before the structure itself.

Izistim Yalta 35

A high-quality stove capable of long-term conservation of thermal energy even after shutdown. Capable of heating a bathhouse with a volume of 30-40 m3 in 1 hour 50 minutes (in winter, 30 minutes faster in summer). Power - 40 kW.

- The advantages of the stove are its durability, large heater, and a built-in steam generator.

- Disadvantages : heavy weight, limited fuel burning time to 10 hours.

Only the most popular models according to online stores are considered. The range of gas stoves is much wider; there are many alternative offers. When choosing a suitable stove, you should first consider its characteristics.

It is not advisable to be guided by popularity or position in the ranking - often such indicators do not correlate well with the true qualities of the equipment.

Construction of a gas stove

Gas is an explosive fuel. If you plan to use gas, then the stove must be equipped with an automatic system that will shut off the fuel supply in the event of no flame.

When the house is connected to a central gas main, natural gas can serve as fuel for the heater. If the heating is individual, propane or butane will do.

Gas heating in the bathhouse at any time of the year is carried out in accordance with fire safety rules established for hazardous fuels.

Questions and answers

The selection and operation of a gas stove for a bath requires experience and skills in operating such equipment. At first, a lot of questions arise, and most of them are the same. It is easier to answer them immediately to eliminate the risk of errors.

Which gas stove burner should you prefer during the selection process?

There are many options here. First of all, you should not be guided by the name of the manufacturer - you need to pay attention to the design of the device and consider how it is installed. The burner flame should not touch the metal of the body or firebox - this will cause rapid burnout and failure of the stove. The best option would be a micro-flare burner, the efficiency of which is in no way inferior to conventional models, but there is practically no danger of burning through the walls of the furnace.

What is more convenient, atmospheric or closed (pressurized) burner design?

Atmospheric structures can be used if the volume of the room exceeds 12 m3. In addition, they are highly dependent on external conditions, require stable draft and are often capricious due to drafts. However, if normal conditions are created for them, the furnace operates stably and does not require electricity. Closed burners require power supply (ventilation, control, control of the combustion process). At the same time, they have much less danger of self-extinguishing.

How to choose the furnace power?

The power of a gas furnace must be calculated. This is a difficult procedure, requiring calculation of the volume of premises, adjustments for the size and number of windows, finishing materials, etc. Independent calculation is difficult, but you can use an online calculator (there are many of them on the Internet, you can use several resources to clarify the results). You can do it simpler and calculate the furnace power based on the ratio of 1 kW per 1 m3. However, this method will give too approximate (and possibly erroneous) results.

What is the fuel consumption of a gas furnace?

This parameter is individual for each model. Average indicators here provide too little useful information, since gas consumption depends not only on the size or configuration of the premises. Here it is necessary to take into account the combustion mode, water heating losses and other specific features. However, for orientation, we can proceed from average values - a 10 kW furnace in average mode consumes 0.85 m3 of liquefied gas or 1 m3 of natural gas per hour of operation.

What is better, to choose an imported or domestic gas stove?

Imported stoves are expensive. In addition, they are too dependent on the quality and pressure of the fuel, the stability of the power supply, grounding and other technical details. Therefore, it is more profitable and correct to purchase an unpretentious and inexpensive gas stove of domestic production.

How often should furnace maintenance be done?

This depends on the load, device parameters, its design and operating conditions. The frequency of maintenance is indicated in the device passport. It is not recommended to ignore the manufacturers' instructions. If exact data is not available, prophylaxis should be carried out once a year. To do this, you should call a technician from the service center or a gas service technician.

Algorithm for constructing a metal furnace

The foundation for the stove should be made of non-combustible material. Fireclay brick, sheet metal or concrete are suitable. To make the base aesthetically pleasing, it can be tiled. The firebox door is directed to the opposite corner. The floors are made of fireproof material. If wood is used, it is covered with a metal sheet 60 cm wide.

To create a classic interior design in a bathhouse, a metal stove can be lined with brick. In addition to being beautiful, this move will prevent burns. To properly build a chimney and determine at what distance from the walls the heater should be placed, be sure to study the instructions.

Gasification methods

There are several ways to provide a sauna with gas:

- Lay a pipe from the house to the bathhouse in the ground, while the gas line can be either metal or polypropylene;

- Perform air installation of the main; this is the most common and most expensive gasification option. Laying a pipe usually takes ¼ of the entire estimate for laying gas;

- Install a ramp with three cylinders in a separate room of the bathhouse or even outdoors in an equipped box;

- Equip a gas holder gas supply for your home and bathhouse.

The latter case can be considered the most convenient, but the cost of such gasification will exceed the cost of laying gas from a centralized supply pipe. If the house already has gas, no one will interfere with gasifying the bathhouse using a gas holder. A huge advantage of a gas holder is the quick completion of work. That is, the contractor company will complete the project, approve the gas tank, install the tank underground and connect the gas equipment of the bathhouse in literally three to four days. She will also fill the gas into a 3-5 thousand liter tank. This is enough for several years of using the bathhouse.

How to cover a pipe on the roof of a bathhouse

Based on experience in operating metal chimneys, we can say that the main problem always remains ensuring seals at the joints and at points of contact with the roofing. Metal expands when heated, so any hard type of seal will fail over time.

Additional thermal insulation with a cord reduces the thermal load on the foam

In the lock, at the junction of the two sections, the elastic band can be reinforced with red heat-resistant sealant. It is actively used for repairing hot areas of mufflers and exhaust systems. But only the joints of the upper sections can be sealed; the rest of the chimney, especially at the outlet of the stove, is sealed with asbestos cord.

Is it possible to use polyurethane foam in a bath?

It’s another matter if you need to fix the pipe body in an opening or passage through a wall or pier. For relatively cold sandwich pipes, if the surface temperature does not exceed 120°C, polyurethane foam is suitable for the bath, but with preliminary coating of the surface with a heat-resistant mixture of liquid glass and asbestos.

For hotter chimneys, with temperatures up to 250 ° C, you can use the same scheme, but with the obligatory additional winding of the pipe with a basalt or asbestos fiber cord. The remaining space is filled with heat-resistant foam for chimneys. You can use “Soudal Soudafoam FR” or “Ognez”, “MAKROFLEX FR77”, any material with a zero flammability class according to EN 13501-1B.

If heated for a long time, even fire-resistant foam can ignite

You cannot directly apply polyurethane foam to the chimney. The best and most heat-resistant polyurethane foam seal lasts a maximum of 360 minutes. heating Then the process of oxidation and destruction begins. Therefore, we must wrap the chimney with fiberglass, mica or cord and only then blow it with foam.

To seal the chimney on the roof of the bathhouse, you can use superheated liquid glass. The pipe must also first be wrapped in one layer of fiberglass, but the material must first be washed to remove lubricants. Add ¼ part of water with liquid soap and asbestos fiber to liquid glass.

We wrap the wooden roof structures in foil, fill the space around the chimney with a thick mixture and heat it with a hand-held gas burner. When heated, the glass boils, turning into a kind of mineral foam. The surface must be coated with protective paint or sealed with a metal apron.