During the construction of a country house, its owner is faced with the question of choosing a floor. Both concrete and wooden structures have advantages. Both of them have features that need to be taken into account. Therefore, do not worry when choosing a base. First you need to consider the type of room, how often and for what purposes it is used. Even the area of the rooms is important. But the last thing you should look at is the price, because the cheapness of building materials often leads to problems in the future.

Comparing all these parameters, let's consider the features of wooden and concrete floors.

Pros and cons of concrete floors

As a rule, such bases are preferred due to their strength and durability. Concrete screeds are quickly installed and are moisture resistant. In addition, concrete is completely uninteresting to rodents and insects. This material is fire resistant.

Healthy! Concrete floors, unlike their wooden counterparts, can reduce the thickness of the floor. Usually a 5 cm concrete screed is sufficient.

If we talk about the price of the issue, then, of course, a concrete screed will cost less. You will need to buy cement, sand and preferably reinforcing mesh. On average, 1 m2 will cost 230-250 rubles.

But a concrete floor is much heavier than a wooden one. This means that it will heavily load the supporting structure of the house. This option is rarely used for the second floor, and even more so for an old wooden dacha. In addition, if you prepare the concrete mixture incorrectly and do not take into account the installation technology, then such a floor can easily crack. For example, the mixture should be poured evenly. If there is much more of it in one place, then the composition will set differently, in one area it will already harden, and in another it will only begin to gain the required strength. Therefore, it is important to use special beacons to monitor the level of the concrete composition.

Another significant drawback is that the floor cannot be used for quite a long time after pouring. The composition gains strength in 28-30 days, so the room cannot be used for a month.

You also need to understand that concrete is much cooler than wood. Therefore, in living rooms on the ground floor it is necessary to lay flooring (for example, laminate). But even if the room is warm, the concrete looks very unsightly. Wood can be treated or varnished and this will be quite enough.

The coating will also be needed to increase the noise and heat insulation of the room. The tree also benefits in this sense.

Healthy! The problem with thermal insulation can be easily solved by adding expanded clay to the concrete mixture during its preparation.

Communications (heating, water supply, etc.) are laid in the floor. If you fill them with concrete, then if a pipe breaks or if it simply needs to be replaced, you will have to destroy the entire floor. If a wooden base is laid, then it will be enough to remove a couple of boards, carry out the work and then lay the same boards back.

Waterproofing

The waterproofing layer is created in two stages:

- Gluing a damper tape 10-20 mm thick and 2-3 times wider than the screed. Scotch tape is used for fastening.

- Laying polyethylene with an overlap of 10 cm and overlapping the walls by 20 cm. If during the work the film is torn or punctured, it should be carefully patched and taped.

It is better to avoid a large number of joints and damage, since the tightness of the entire structure depends on the quality of waterproofing.

Return to contents

When should you pour a concrete floor?

A similar base is suitable for industrial premises, garages and rooms where supplies are stored. Concrete is used if the building is expected to experience strong mechanical loads. But this does not mean that it is not used for houses, just as it is used.

For example, a concrete floor is rational on the first floor of a two- or three-story house with a massive structure. It is also the only correct solution when it comes to the basement. No matter how you treat the wood, if it is in constant contact with wet soil, it will still begin to rot.

Installation of beacons

The beacons are mounds of concrete for the screed, which are formed along the entire perimeter of the future floor at a distance of 15 cm from each other, provided that the 120 cm rule is used. The distance from the wall should be 25-30 cm. A metal profile is laid on the formed beacons. It should be recessed along the marks corresponding to the leveling layer. Installation must be carried out within the first hour after mixing the solution. Otherwise it will be difficult to work with.

Return to contents

Wooden floors

Such floors have a huge number of advantages. For example, wood is certainly much more environmentally friendly than concrete. If you choose high-quality materials, you don’t need to think about spending on additional flooring.

In addition, the tree has other advantages:

- Retains heat much better.

- Does not create increased load on the supporting structures of the house.

- If one of the boards is cracked or damaged, it can be easily replaced with a new one without replacing the entire structure.

- If you are tired of the shade of the floor, then the wood can be repainted without any problems. It will not lose its aesthetic appearance.

Healthy! If you need to wait almost a month after pouring concrete, then a wooden floor can be used immediately after installation.

But there are also disadvantages. For example, if the house does not have a basement floor, then you will have to make a double floor. First, the so-called subfloor is laid (for this you can use boards of no better quality), then comes the insulation and finishing layer (you need to use the best materials for it).

Healthy! If a concrete screed costs about 230 rubles per “square”, then a tree will cost at least 1,000 rubles. Moreover, there is always a risk that you bought low-quality material. In addition, to lay such a floor you need to have at least minimal carpenter skills or you will have to hire a craftsman.

You will also have to take care of impregnating the wood with specialized compounds that will increase fire and moisture resistance. But even this may not save you from insects and rodents, which will gradually destroy the structure. Thus, wood has a shorter service life than concrete.

Healthy! Over time, the wooden floor begins to creak. This is annoying, especially when you go to drink water at night and wake up everyone in the household.

It is also worth paying attention to such disadvantages as:

- Wooden floor is higher than concrete. During the installation process you will have to use logs. These additional structures make the installation process more labor-intensive and expensive.

- The tree is prone to drying out. The boards may crack.

- Wood should not be used for rooms with high humidity. The material will quickly begin to rot.

Therefore, when installing a floor, you need to take into account not only the characteristics of the building material, but also the type of room.

Reinforcement

The two most popular methods of reinforcement are metal mesh and fiberglass:

- The technology for arranging the reinforcing mesh is carried out using an unconventional method. A layer of concrete without beacons is immediately poured. A break of 1 month is taken for hardening. Then the mesh is laid, beacons are installed and the second layer is poured. This technology avoids unwanted punctures of the waterproofing film.

- Fiber reinforcement differs from the above method. The strengthening material is added directly to the concrete solution at the stage of its preparation. The peculiarity of fiber fiber: its molecules are located in a chaotic order, therefore, when interacting with the molecules of the cement mixture, the material is strengthened in all directions. The use of fiberglass significantly reduces the overall weight of the concrete covering, therefore reducing the pressure on the wooden flooring.

Return to contents

Which base is best for different rooms?

Every house has an entrance hall. This is the place where a large amount of dirt and dust accumulates from shoes (especially in winter). Therefore, even if you prefer wood, you will have to consider a floor covering with high moisture resistance. Usually tiles are laid in this room. But then the weight of the wooden floor will increase, and the whole point of using natural material will be lost. Therefore, in the hallway, the best option would be to pour concrete and lay tiles on it.

Something is constantly being prepared in the kitchen. The room is filled with steam, and grease ends up on the floor. If you lay a wooden floor, you must cover it with varnish or another compound that forms an easy-to-clean protective film.

But in living rooms it is better to install eco-friendly wooden floors. They retain heat well, so at night you won’t have to deal with a surprise in the form of an icy floor that you accidentally stand on while you’re looking for slippers.

The bathroom is always damp. In rooms of this type, fungus and mold often begin to grow, so the bathroom and toilet are often treated with rather aggressive chemicals. A tree is not able to “survive” such an amount of chemicals without serious protective treatment. Therefore, for bathrooms it is better to equip a concrete screed, on which tiles can again be laid.

Comparative analysis

Of course, a wooden floor is more environmentally friendly, its price is often lower than concrete, it is warm and reliable, but short-lived. And there is a possibility that your descendants, having decided to change their gender, will remember you “with a not evil, quiet word.”

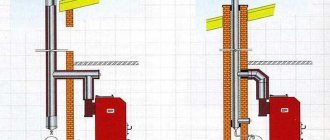

In our opinion, it is more reasonable to make a combined version of the covering, in other words, the base is poured from reliable, durable concrete, and then you make a slab flooring on the joists. If necessary, you can tear it down and install an economical heated water floor or other covering to suit your taste in its place.

Installation of slab flooring.

Lags

The basis for the wooden flooring are logs - thick beams laid on posts. Most often they are made of wood, but there are also plastic and reinforced concrete logs. At the same time, it is wooden ones that are considered the most practical, since they are inexpensive, easy to install, and with proper treatment can last for decades.

The main advantages of wooden logs include:

- Environmental friendliness of the material.

- Good level of heat and noise insulation.

- Fairly simple installation of wood flooring.

- Uniform load distribution.

- Possibility of installing a ventilated underground.

- Excellent performance properties of the material.

- Availability and ease of repair.

As a rule, joists are made from inexpensive wood that is common in the region. For example, logs made of pine and birch, spruce and larch have proven themselves well. Second- and third-grade wood with a moisture content of less than 20 percent can be used as joists.

Note:

the logs must have the correct shape (smooth edges). At increased loads, the height of the bar should be approximately twice as high as its thickness.

Joists laid on blocks and waterproofing

What is a screed

You can level the floor base using one of the following methods: screed or wooden joists. The screed happens:

- Wet.

- Dry.

These are different technological processes. Wet technology involves the production of cement mortar using water . The finished mixture is poured onto the work surface, then leveled. Advantages of this coating:

- They hide communications, a pipeline crossing the floor.

- Distributes thermal insulation loads.

- Adjust slopes.

In addition, the basis is obtained:

- Neat.

- Smooth.

- Durable.

The developer will have to take into account:

- Prepare the base with careful leveling.

- Working moments with installing beacons, mixing the solution in the required portions of each component.

- The adjacent surfaces of the house will receive their share of moisture from the cement screed.

- You have to wait until the coating is completely dry; usually the solution hardens for a month.

- For a specific period, movement in this area is excluded, which creates inconvenience and disorder in other rooms from construction dust.

- Finishing in the room stops until the solution has completely hardened.

- After the mixture hardens, an undesirable result may result from uneven settlements; you will have to use materials with self-leveling properties.

- The complexity of the technological process, which is carried out according to certain rules, calculations of area and quantity of materials with the selection of tools.

For dry screed, finely dispersed expanded clay . This bulk material is evenly distributed and leveled as a rule over the floor surface of the room. The finishing coating can be immediately laid on such a base. But no master can give a guarantee that during operation deformation will not begin to appear in areas of greatest load.