Five thousand years ago, minters from Egypt discovered a new type of joining metals using the soldering method. The essence of the method is to create a connection between different metals by filling the seams with solder, which is a molten material with a melting point lower than that of the parts of the product being connected. Unlike steel, it is more expedient to connect copper parts by soldering rather than welding. This is especially important if you have to work with thin-walled copper pipes, which are widely used in heating, plumbing, gas and refrigeration systems. Even a beginner can handle this kind of work.

Features of copper pipes

The chemical composition used in the production of copper pipes consists of 99% copper, but minor impurities of tin, iron, antimony, and lead are allowed.

Copper pipes are hard (not annealed) and soft (annealed). During manufacturing, through machining, the copper material loses its natural ductility.

This property can be restored by annealing the metal, that is, heating it to 600-700 degrees and then cooling it under natural conditions. As a result of such actions, the copper pipe receives some technological advantages over solid copper. Of course, a soft pipe loses in strength, but it is much superior in ductility, which increases the value of its elongation at break by 40-60%. This means that the soft pipe can be easily bent without fear of breaking. Due to the plastic deformation of copper, such pipes can prevent the water supply from rupturing if it accidentally freezes.

Copper pipes have the following advantages:

- durability of operation;

- strength;

- ability to be easily processed;

- are not afraid of ultraviolet radiation;

- withstands the highest possible temperatures;

- operate safely under high pressure;

- have bactericidal properties;

- do not corrode;

- have high thermal conductivity and a smooth surface.

Of course, the higher cost of copper compared to other modern materials can be attributed to its disadvantages, but soldering technology allows you to save on fittings.

Rules for installing freon pipes of multi-zone systems:

For the installation of the cooling circuit coming from the freon installation, only copper pipes specially designed for refrigeration units are used.

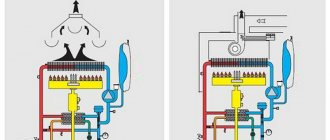

During installation, you need to ensure that the pipes are located in a vertical or horizontal position. There are two exceptions to the rule:

- the suction pipeline that returns oil to the compressor must be sloped towards the compressor;

- the discharge pipeline must be sloped towards the condenser.

It is important to note that if the compressor is installed below the level of the evaporator, an oil lifting loop should be mounted at the outlet of the evaporator and the vertical part of the suction pipe should be raised above the level of the evaporator. Such measures help prevent coolant from draining and oil from entering the compressor from the evaporator. For the system to work properly, the above sequence must be repeated every seven and a half meters.

Soldering methods for copper parts

Permanent connection of pipes at industrial facilities, as well as copper soldering at home, is carried out using two methods:

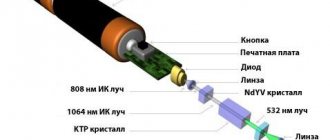

- High-temperature method - used on pipelines operated at high temperatures and under heavy load. Solder melting by this method occurs at a temperature of 600-900℃.

- Low temperature method - used for domestic systems. When using soft solder, the heating of the soldering area reaches 450℃, and for hard solder - more than 450℃.

Messages 13

1 Topic by Kp_glagolevo 2013-09-08 17:08:28

- Kp_glagolevo

- New member

- Inactive

- Registered: 2013-09-08

- Messages: 2

Topic: How to use nitrogen gas to solder copper pipes for air conditioners

They are installing a VRV system for me, they are soldering a lot of connections, I heard that you need to solder the tubes with nitrogen, or in nitrogen. Only the guys who do the soldering don’t use nitrogen in any form, they don’t have any nitrogen at all, at least not at the workplace. I inquired about this, they explained to me that nitrogen would be brought in later for pressure testing and cleaning the tubes from internal carbon deposits.

It seemed to me that my questions somewhat discouraged the workers; they answered somehow awkwardly. I want to figure out how nitrogen gas is actually supposed to be used for soldering copper tubes for air conditioners, during or after soldering, etc.

I would be grateful if you could briefly describe the process in a language accessible to the common man.

2 Reply from ITR 2013-09-08 22:45:41

- engineers

- Administrator

- Inactive

- From: Moscow

- Registered: 2013-03-20

- Messages: 127

Re: How to use nitrogen gas for soldering copper pipes for air conditioners

Soldering in a nitrogen environment is necessary to maintain high-quality installation; moreover, soldering VRV systems without nitrogen is completely unacceptable. Copper pipes for air conditioning, unlike water pipes, are soldered with so-called “hard” solder, which allows them to withstand the high pressure created by the compressor. Hard soldering occurs at high temperatures, the copper heats up to a red-burgundy glow, the processes occurring in copper at high temperatures destroy it.

The same scale that forms outside and inside the pipe is nothing more than burnt copper. As a result, the pipe walls become thinner. Nitrogen prevents copper from burning out from inside the pipe, and copper burnout from the outside is compensated by a thin layer of solder.

3 Reply from Ventspetsnaz 2013-09-08 22:46:48

- Ventspetsnaz

- Participant

- Inactive

- From: Leningrad

- Registered: 2013-03-30

- Messages: 201

Re: How to use nitrogen gas for soldering copper pipes for air conditioners

Soldering routes without nitrogen is, at a minimum, not professional.....

4 Reply from Kp_glagolevo 2013-09-08 23:02:33

- Kp_glagolevo

- New member

- Inactive

- Registered: 2013-09-08

- Messages: 2

Re: How to use nitrogen gas for soldering copper pipes for air conditioners

What about water pipes that are also soldered with nitrogen?

5 Reply from ITR 2013-09-08 23:29:16

- engineers

- Administrator

- Inactive

- From: Moscow

- Registered: 2013-03-20

- Messages: 127

Re: How to use nitrogen gas for soldering copper pipes for air conditioners

No, water pipes and copper pipes are not soldered with nitrogen, since they are soldered with soft solder and do not require high temperatures. Copper does not heat up to the point of glowing and therefore does not burn out.

6 Reply from lis0911 2014-06-27 21:19:16

- lis0911

- New member

- Inactive

- Registered: 2014-06-27

- Messages: 2

Re: How to use nitrogen gas for soldering copper pipes for air conditioners

I have the same problem. Can anyone tell me - when the system is soldered without nitrogen, what can be done to minimize the negative consequences? Maybe install additional filters to collect scale?

7 Reply from Ventspetsnaz 2014-06-28 20:15:28

- Ventspetsnaz

- Participant

- Inactive

- From: Leningrad

- Registered: 2013-03-30

- Messages: 201

Re: How to use nitrogen gas for soldering copper pipes for air conditioners

All equipment in the semi-industrial line is equipped with filters. But these filters are small in capacity, in terms of the fact that they are designed for small amounts of various debris (chips, scale, dust and even moisture). If we allow a VRV system consisting of 5-10 indoor units to be soldered without nitrogen, then of course the filter will become completely clogged and the system will easily go into error due to freon pressure. In this case, the filter must be cut off and a new one soldered in.

Read also: GOST service life of a building

8 Reply from ITR 2014-06-28 20:21:11

- engineers

- Administrator

- Inactive

- From: Moscow

- Registered: 2013-03-20

- Messages: 127

Re: How to use nitrogen gas for soldering copper pipes for air conditioners

In this case, the filter must be cut off and a new one soldered in.

This may have to be done more than once because the scale does not fall off all at once, but gradually, about 50% at once, and the rest within a month of active use.

9 Reply from Ventspetsnaz 2014-06-28 23:55:03

- Ventspetsnaz

- Participant

- Inactive

- From: Leningrad

- Registered: 2013-03-30

- Messages: 201

Re: How to use nitrogen gas for soldering copper pipes for air conditioners

It is, of course, possible to collect scale. Now, it’s just not clear what happened to the copper pipe, how much the pipe wall burned through. If this is not a problem for conventional split systems, then for VRV it can be fatal. The VRV compressor creates pressure in the system, up to 30-40 atmospheres, and if the wall of the copper tube is greatly weakened, then depressurization of the freon circuit may occur, followed by a refrigerant leak.

10 Reply from Shatokhin Valera 2014-06-29 10:36:02

- Shatokhin Valera

- Moderator

- Inactive

- From: Dolgoprudny

- Registered: 2013-03-27

- Messages: 148

Re: How to use nitrogen gas for soldering copper pipes for air conditioners

In order for defects of poor-quality soldering of the freon circuit to appear, it is necessary to pressurize the system with a pressure exceeding the working pressure at least two to three times. Typically, for VRV systems, pressure testing is done at a pressure of 150 atmospheres.

11 Reply from Maxsim_D 2014-06-29 11:04:11

- Maxsim_D

- Participant

- Inactive

- From: Krasnodar

- Registered: 2013-03-30

- Messages: 85

Re: How to use nitrogen gas for soldering copper pipes for air conditioners

I don’t understand what installers are thinking about when they solder lines without nitrogen, what are they hoping for? Maybe to Russian?

12 Reply from ITR 2014-06-29 18:55:08

- engineers

- Administrator

- Inactive

- From: Moscow

- Registered: 2013-03-20

- Messages: 127

Re: How to use nitrogen gas for soldering copper pipes for air conditioners

Share with the forum members how it happened that they soldered the line without nitrogen?

13 Reply from Shatokhin Valera 2014-07-02 11:31:11

- Shatokhin Valera

- Moderator

- Inactive

- From: Dolgoprudny

- Registered: 2013-03-27

- Messages: 148

Re: How to use nitrogen gas for soldering copper pipes for air conditioners

Share with the forum members how it happened that they soldered the line without nitrogen?

I can answer this question. These installers don't charge much. And no, because they are altruists, but they simply put little work into their work, and then they can get it inexpensively. But why the installers do not carry out all the necessary work and technologies is a question. It’s one thing if they were sincerely mistaken and didn’t know that nitrogen, fluxes, etc. were needed. It’s another thing if installers deliberately abandoned processes that complicate installation in order to offer a lower price for their services, and at the same time not lose money.

Tools and accessories

Of course, to solder copper pipes with your own hands as standard, you can use many elements that are easy to find in your own household supplies. In extreme cases, you will have to purchase special devices to perform the soldering process. So, to carry out high-quality installation of copper products you may need:

- A manual pipe cutter that will allow you to get a strictly perpendicular pipe cut.

- A chamfering device is used to remove various burrs and round off the cut area.

- A pipe expander will help in many situations to do without the use of fittings. For soldering, you need to increase the diameter of one end of the pipe in order to insert another workpiece there.

- Brushes and pipe cleaners will help clean the pipe soldering area from oxide.

- To increase the safety of work, you need to install a fire reflector (reflector) on the burner nozzle, which will help protect flammable materials located near the work site. This will prevent heat loss and ensure uniform heating of the pipe.

- A gas torch is the main tool for soldering copper pipes. There are several types of burners - from high-performance models to household devices.

Welding process

The soldering technology consists of a number of successive stages:

- First, the pipe should be cut with a pipe cutter.

- The edge of the pipe is processed with a chamfer.

- Then the appropriate fitting is selected or the edge of the second pipe is expanded using a pipe expander.

- The parts are connected and the presence of gaps is checked.

- A small amount of flux is applied to the surface at the soldering site. If you are going to solder using a high-temperature method using self-fluxing solder, then you do not need to use flux.

- Using a copper pipe soldering torch, the joint is evenly heated to a temperature at which the solder will melt.

- Solder is applied to the gap. The solder should melt precisely from the heated pipe, and not from the open flame of the burner.

- The remaining flux is removed with a damp cloth or washed with water.

It is worth noting that heating a copper pipe and melting the flux is a process that occurs in a short time - 5 minutes. It is very important not to overheat the burner and not overheat the pipe.

Copper Connection Materials

The entire technological process of soldering copper tubes with a gas torch can be carried out using flux and copper solder, as well as with or without the use of fittings.

Flux and solder paste

Flux for soldering copper pipes is of great importance for the formation of a high-quality connecting seam. It can be low temperature with activity up to 450 ℃, and high temperature - more than 450 ℃.

The use of flux is necessary in the following cases:

- high-quality cleaning of the surface of the connected pipes from oxides;

- protecting the connection site from oxygen contained in the air;

- increasing the adhesion of solder to the metal surface;

- improving the process of solder spreading.

Today there are the following types of fluxes:

- activated;

- acidic;

- non-acidic;

- anti-corrosion.

Solder paste is a thick mass consisting of flux, small particles of solder and special additives. This composition is often used in industrial enterprises when soldering radio components on printed circuit boards. The paste form is very convenient for applying to small parts.

Types of solders

The connection of copper and its alloys can be made by both low-temperature and high-temperature soldering. There are many soft and hard materials that can provide ideal fastening of metal parts.

The use of solders with a low melting point makes it possible to solder parts under conditions that have little effect on the strength of copper, but at the same time the connecting seam has worse mechanical parameters. Solders for high-temperature joints increase the strength of the joint between metals, but require certain skills to prevent burning of copper.

Features of soldering with flux

When connecting copper pipes using flux, soldering can be done at temperatures up to 450⁰. During low-temperature soldering, the base metal is not deformed, the seam is smooth and uniform, since the flux wets the surface well and penetrates the capillaries. Thanks to it, the solder is distributed evenly, and there are no pores or slag inclusions in the seam.

During the soldering process of high-temperature joints, the flux spreads over the seam and closes it from contact with air, preventing oxidation.

The flux should be selected according to the solder. It should melt before the solder itself and provide a good connection at the capillary level.

Copper pipe soldering technology

The entire technological process of connecting parts made of copper material can be divided into preparatory operations and the actual stage of creating a strong joint.

Basic connection operations using a torch:

- It is most convenient to cut a pipe using a pipe cutter. To do this, the tool is installed on the workpiece so that the cutting roller coincides with the cutting line. Next, the screw is clamped and a cut is made by rotating it around the axis of the pipe. After every two revolutions, the rotation of the screw presses the cutter towards the pipe. You can cut metal with an ordinary hand hacksaw, but it is very difficult to achieve a perpendicular cut.

- After cutting, you need to remove the outer and inner edges. The outer chamfer is removed to facilitate assembly, but the inner chamfer may resist the flow of water or gas. There are special devices for carrying out this type of operation. Sometimes they are built directly into the pipe cutter, and sometimes they act as a separate device.

- The next step is to clean the mating parts of the part from oxides. The outer surface can be easily cleaned with fine abrasive paper or a special device with a hole framed by a steel brush. To clean the inner edge, brushes, mesh or sandpaper are used, screwed onto any pin of the appropriate diameter. After cleaning the surface to a shine, you need to remove any remaining abrasive, which significantly reduces the quality of soldering.

- After cleaning, it is necessary to apply flux to the surface. The paste-like composition is applied with a brush to the outer part of the inserted pipe. After this, the parts are immediately connected to avoid debris.

- During assembly, the mating parts must be rotated relative to each other in order to achieve complete distribution of the flux over the surface. Then excess flux is removed with a cotton rag, and the parts are fixed in a position convenient for soldering.

- Before you start heating the pipes, you must remove all plastic and rubber parts that may be damaged during soldering. The burner flame should be normal - without a lack or excess of oxygen. A balanced flame has a bright blue color. Excess oxygen in the flame oxidizes the metal surface, as indicated by black oxide deposits. It is necessary to heat the joint evenly, moving the flame from different sides of the product. When the solder begins to melt, the soldering temperature has reached the optimal value. After completely filling the connecting seams with molten solder, you need to move the burner flame away from the joint and allow the soldering area to cool naturally.

What is solder?

Solder is a pure metal or thermoplastic alloy made from several components. Designed to connect copper parts into a common integrated network.

When exposed to high temperatures, the solder melts, spreads across the processing area and seals the surface. After final cooling, a strong, even seam without errors is formed on the pipe material

The technology of joining two fragments, carried out according to this principle, is called soldering.

Among the main advantages of the technique it is worth highlighting:

- connection without deformation;

- preservation of the original shape of the processed parts;

- absence of any internal tension;

- excellent strength and high level of tightness of the created seam;

- resistance of the bonded area to different temperature conditions, including intense heating;

- simple separation of seam sections in case of need to change the system format.

Soldering is carried out with special equipment - a soldering iron, a gas torch or a blowtorch. Immediately before work, the area is thoroughly cleaned of surface defects and technical oils, and only then work begins.

The process of connecting pipe fragments is easy and quick, but requires mandatory compliance with basic safety rules. To avoid problems and injuries, you should wear thick work gloves on your hands, cover your face and eyes with special goggles or a mask, and protect your clothes with a thick apron. This will protect the technician from potential accidents.

For soldering at home, a soldering iron is most often used. A torch or lamp is used where the power capabilities of a soldering iron are not enough or where it is necessary to connect parts of great thickness and impressive mass.

Unacceptable errors

The reason for poor-quality joining of two parts is most often haste, so you must not forget to check the edges of the product for the absence of foreign small objects that may form after cutting.

When applying flux, it is important to try not to miss even the slightest area of the surface, because any defect can cause poor contact.

If any area of the surface is weakly heated, this will lead to weak fusion of the two metals. Overheating can lead to combustion of the flux and the formation of scale or oxide at the soldering site, which affects its reliability.

Moderately corrosive compounds

Fluxes made from rosin to which alcohol is added with any of the following substances are characterized by low corrosive activity:

- acetic acid,

- zinc chloride,

- orthophosphoric acid.

When soldering, a copper flux made from a solution of rosin in alcohol with the addition of zinc and ammonium chlorides works well. It is effective to use a mixture of glycerin and a solution of zinc, ammonium, and sodium chlorides.

A high-quality connection during soldering is ensured by a flux made from a solution of glycerin in water, to which hydrazine hydrochloride is added. You can successfully use a mixture of alcohol and phosphoric acid solution.

Fluxes containing rosin are used at temperatures up to 300 °C. Other compositions can be heated to 350 °C.

Safety precautions

Since soldering work is carried out using high heat, it is necessary to strictly perform all operations wearing protective gloves.

The presence of dangerous chemical fumes can lead to damage to the respiratory system, so work should be carried out in a well-ventilated area and wearing a protective mask.

Soldering pipes made of copper material is not particularly difficult. A video tutorial that can be viewed on many Internet sites will tell you in more detail about soldering copper wires.

Originally posted 2018-03-28 15:01:27.

Mistakes made when soldering

The most common mistakes:

- The solder weakly heats the joint , as a result of which the part does not fuse with the solder. With a small load, the soldering area is destroyed.

- Overheating of the soldering area leads to the fact that the flux burns out and scale and oxide form on the surface, which affects the reliability of soldering.

Only an experienced craftsman who is constantly engaged in this type of work can determine the correct operating temperature at which high-quality soldering of connections occurs.