Porcelain stoneware is one of the hardest materials used for various coatings (floors, walls, kitchen tables, etc.). During the installation process, there is a need to cut porcelain tiles. For large volumes, the recommendation is clear - a professional tool. At home, you can get by with one of the following methods, or a combination of them (especially if you take into account the little tricks):

- angle grinder (grinder);

- manual tile cutter.

Shaped cutting of porcelain tiles

Hole saw

If you need to cut porcelain stoneware into straight lines, then the choice is quite wide, but with curved cuts it is a little more difficult.

The scope of use of a hole saw equipped with a carbide tip also extends to porcelain stoneware. It is also used to create rounded holes in hard materials such as cement tiles and stone. A hole saw can cut any quality of porcelain tile: soft or hard, but cutting tiles with a glazed surface is slow. Advantages: the most effective option for obtaining round holes, working with various building materials. That is, if necessary and for performing specific work with porcelain stoneware, a hole saw will be useful.

Disadvantages: in some cases, processing takes a long time, and porcelain stoneware is subject to strong thermal influences.

Wire cutters

Of all the cutting devices, this is the simplest. It is sometimes very difficult to do without nippers when laying porcelain tiles in residential premises. Most often, nippers are used for cutting porcelain stoneware with irregular shapes.

Advantages: relatively cheap option, the ability to cut various materials to produce cutouts with a variety of shapes.

Disadvantages: bitten edges leave uneven surfaces, which later have to be sanded.

Ballerina

This tool specializes in rounded holes in porcelain tiles. The main advantage of the ballerina is that the characteristics of the planned hole can be different, since the parameters of the incisors are adjusted manually. But the ballerina cut usually comes out uneven and curved, so it is not often used when processing tiles, although special attachments for porcelain tiles are also sold on the market. In addition, centering the device is quite difficult, which can cause damage to both the ballerina and the tile.

Little tricks

These two methods do not exhaust all methods. With their help, you can get an acceptable result for any cuts at home. Round holes in the material are made with ordinary tools without any special nuances: drills with carbide coating, ballerina drills, crowns. The only difference is that due to the hardness of the material, the cutting tool will fail faster.

To solve the problem of laying tiles, you can use an integrated approach:

- The easiest way to cut tiles is with a manual tile cutter. It is recommended to cut the bulk of the tiles with it;

- Tiles with cut edges, covered with skirting boards or overlays. In this case, it will be enough to use a manual tile cutter or grinder (in limited cases);

- There are few tiles with an exact fit. Adjust by sanding;

- Lay all intact tiles. Depending on the available tools, adjust the tiles that are covered with baseboards and trims. The remaining elements should be accurately measured and marked on the tile. Either rent a professional tile cutter, or take it to the nearest construction company that has such equipment and cut it.

Advice! If you need repairmen, there is a very convenient service for selecting them. Just send in the form below a detailed description of the work that needs to be performed and you will receive proposals with prices from construction teams and companies by email. You can see reviews about each of them and photographs with examples of work. It's FREE and there's no obligation. Good advertising Most read

Video: How to Cut Porcelain Tile with a Glass Cutter

A shredder is a potentially dangerous tool, so don't ignore safety rules. Safety equipment should be considered. The kit includes:

- Wear a respirator because cutting creates a lot of dust.

- Safety glasses to prevent splinters from entering your eyes.

- Workwear.

- Headphones or headphones that protect your hearing from loud noise.

It is not recommended to neglect protective equipment, even if you plan to cut several plates.

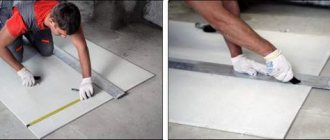

Correctly cutting porcelain tiles using a grinder is quite simple if you follow the instructions:

- We are preparing a place to work. Place a backing sheet on a flat surface to protect the base. You can choose foam, foam, etc.

- Place the piece face up on the base and trace the cutout area on it. To reduce the number of chips, place a strip of adhesive tape on it and run the cutting line along it.

- We place the metal corner on top of the tile along the cut path and secure it with clamps. This will allow you to cut accurately. This should be done when cutting thick products.

- We start the grinding machine. We immediately cut out the part, directing it away from us. To get a smooth edge, cut the piece so that the marking line remains on the product. This will be removed during sanding and the tile will remain the specified size.

- Remove the adhesive tape and sand the end of the part if necessary.

If a thin or perfectly straight cut is not required, you can simplify your job. The chopper does not cut, it only cuts. Then the fragment comes off with a sharp, strong movement.

It is very convenient to use a grinding machine to cut porcelain stoneware. First of all, because it is the most affordable of all the devices that can be used. They can make cuts of various shapes, including any curved ones

However, the coffee grinder is traumatic; you need to work very carefully. It is very dusty and noisy

READ How to Make a Screwdriver Directly from the Network

Some tips about forgotten technologies

Are you going to lay the tiles yourself? Please note that this process is very labor intensive and will require some experience from the contractor. Beginners should be given some practical advice: if you are using a grinder to cut tiles without a tile cutter, then do not make sudden movements, because the diamond-shaped circle will damage the part that should remain clean.

Also follow safety precautions and always use personal protective equipment against dust for the respiratory system and eyes. The fragments can damage the cornea, and the dust can clog the airways.

Forming holes

It is advisable to form small-diameter holes using drills with a Pobedit tip. This approach is relevant for diameters up to 12 mm with tiles. A drill or hammer drill is selected/adjusted to a power of 800 W. The chuck must be centered to avoid hitting the tile. If the surface is smooth, then 4-5 pieces of masking (paper) tape are glued onto it to prevent the drill from slipping.

Standard holes with a diameter of up to 50 mm are drilled with crowns with pobedit cutting edges. It is better if they are equipped with a centering drill. It will not allow the cylinder to move away from the intended lines. The cutting begins at low speeds until a starting groove is formed with a depth of 3 mm. Then the speed can be increased.

Drilling with a crownSource recn.ru

Non-standard holes in size (55, 68, 71 mm) are made with a ballerina. This is a Device with a centering drill, on which the cutter is attached by means of a rod. The distance between the elements is adjusted; the clamp is a clamping screw. The latter is considered the weakest point of the equipment, but insufficient tightening of the structure leads to disruption of the correct drilling process.

Drilling with a ballerinaSource remontpro.pro

It is often necessary to design inlet openings for sewer or ventilation pipes with a diameter of over 100 mm. Here they resort to a grinder with a diamond blade. It is less common to cut with the side edges of the disc without a protective casing. More often, individual notches are made, the tiles are broken with nippers or pliers, and the edges are sharpened with a file or disk. The third option is an electric jigsaw.

Glass cutter - a cheap and practical tool

A glass cutter is a traditional hand-held glass cutting tool that can be used to cut thin ceramic tiles. It is cheap and accessible to everyone - it costs 150–200 rubles. A glass cutter is a device with a pencil-shaped handle, at the end of which a rotating roller is attached. The sharp roller is made of a hard material that can cut through hard surfaces.

Glass cutter.

There are several types of glass cutters on sale, differing in design features:

- Roller. This is the traditional, simplest type of glass cutter. Its cutting roller is made of high-strength tungsten-cobalt alloy. A roller glass cutter is capable of cutting glass, porcelain, and tiles up to 10 mm thick.

- Diamond. In it, the metal roller is replaced with natural or artificial diamond. This solution gives a more accurate cut and is suitable for working with thin tiles up to 6 mm.

- Oil. It differs from a simple roller in the presence of lubricant, which reduces friction and increases the service life of the device. This is a professional tool that is more expensive than roller models, lasts longer, and cuts material 12 mm thick.

Glass cutters are the simplest tools that are suitable for straight cuts of thin wall tiles. It is not used for working with floor ceramics, porcelain stoneware, cutting along a curve or at an angle of 45. For large volumes of work, you need to get another tool.

Let's take a step-by-step look at how to cut tiles with a glass cutter:

Step 1. Marking.

The cutting line is marked on the surface of the tile with a regular pencil or marker.

Step 2. Fixation.

To fix the tile, hold it with your left hand, placing a ruler or a straight strip on the cutting line as a stop so that the roller does not slip off the smooth tile surface.

Step 3. Cut.

When working, the glass cutter is held like a pen in the right hand. The cut is made in one movement, pressing the cutting roller quite tightly to the surface. During the cut, a characteristic sound should be heard indicating that the top layer of the tile has been cut. After making the cut, a bead is placed under the tile with the intended fault line and pressed along the opposite edges. The tile breaks at the point of the cut.

Step 4. Revision.

The seam is neat, but not perfect. To process the edges, use abrasive materials, such as sandpaper.

Briefly about the main thing

To cut tiles at home, use tools with carbide cutters, rollers or replaceable discs.

Porcelain tiles are practically not cut with a glass cutter. They resort to a manual tile cutter.

With replaceable diamond wheels, it is permissible to use a grinder, a circular saw, or an electric tile cutter.

Artistic cutting can be done with a hand jigsaw with diamond wire or a more advanced water jet machine.

Holes in the form of a circle are formed with drills, crowns or a ballerina. For large diameters, use a grinder or jigsaw.

Features of the material

The raw materials, consisting of clay, kaolin, quartz sand, feldspar and mineral additives, are pressed under high pressure and then sintered at high temperatures. The resulting material has virtually no pores and has a hardness equal to that of corundum (7 – 8 on the Mohs scale). It is inferior in hardness to only a few materials, such as diamond, sapphire, ruby, etc. At the same time, thin tiles (3 mm and thinner) are quite fragile.

Note! Cutting material of such hardness will not work with hand glass cutters, stone blades or jigsaws. They can only be used as an auxiliary tool.

Let's look at two ways to cut tiles at home. The methods have limitations, which will be discussed below, as well as ways to circumvent these limitations. They can achieve acceptable results, but it is better to cut porcelain tiles using professional equipment. Only it will give a guaranteed result in an acceptable time with a relatively large amount of work.

Power tools for cutting porcelain tiles

Power tools in the form of:

- electric tile cutter;

- Bulgarians;

- jigsaw;

- circular saw;

- drills with ballerina;

- waterjet installation.

Electric tile cutter

Diamond coating on the electric tile cutter disc allows you to cut porcelain tiles of different thicknesses and lengths. There are different models of such tools: in some, a disk moves along the tile, in others, a table moves with the help of a motor.

The advantage of this tool is that it uses so-called “wet cutting discs”, that is, water is used to reduce the formation of dust while cutting tiles. In some models, a container of water is installed under the disk, into which the disk itself is partially immersed. For others, the disc is wetted with running water.

IMPORTANT! When working with wet cutters, you need to monitor the degree of contamination of the disk, clean it in time and change the water, otherwise the quality of the cut may significantly decrease

Bulgarian

You can also cut porcelain stoneware at home with a grinder. To do this, you need to purchase a diamond-coated disc with a thickness of 2 mm and an edge width greater than the thickness of the porcelain stoneware.

REMEMBER! When working with an angle grinder, you should install the disc with the correct side and be sure to protect your eyes with glasses, since many chips are formed during processing. Cutting should be done in one step, otherwise the cut will be uneven. You also need to leave a margin of a few millimeters for sanding the edge.

Jigsaw

This tool is suitable for cutting porcelain tiles with a small thickness. To do this, you need to take a diamond-coated thread.

A circular saw

Refers to professional equipment and is used for large-scale processing of ceramic tiles. During the cutting process, tiles must be fed manually, which increases the risk of injury.

This saw is not always suitable for cutting porcelain stoneware at home. Before making a choice, you need to weigh how useful it will be in the future; it may be easier to get by with improvised tools, for example, a grinder.

Drill

No matter how strange it may sound, an electric drill is often used to cut porcelain stoneware. Using a “crown” or “ballerina” attachment, you can make a round hole of the required diameter in the tile.

The crowns have a given diameter, and the ballerina works like a compass, so it is used to make a large hole.

Waterjet unit

This tool is used in industrial enterprises. Tile cutting is carried out with a mixture of water and solid crumbs, the thickness of the jet is tenths of a millimeter.

In conclusion, we can say that there are many tools suitable for cutting porcelain tiles. Which one is preferred depends on the volume of the tile and the frequency of its processing.

If this is a one-time cutting for finishing small rooms, then it is better to use electrical appliances already available at home, such as an angle grinder or electric saw. If you plan to continue processing ceramic tiles in the future, then it makes sense to purchase special equipment.

Professional waterjet equipment

It is hardly possible to cut porcelain tiles at home using a waterjet machine, since this is high-tech, bulky, and most importantly, extremely expensive equipment. Nevertheless, you should pay attention to it, since sometimes it is necessary to cut unimaginably complex figures from ceramic stone, and no other devices can cope with this task. Moreover, the quality of the resulting material will definitely amaze you, because the cut edges are almost the same as with factory pressing.

The operating principle of such a machine is quite simple, despite the complexity of the design itself. A stream of water mixed with tiny abrasive particles under enormous pressure is supplied through a special narrow nozzle. It is this water that cuts even the most durable, hard and viscous materials, even metals. Therefore, cutting porcelain tiles on such a machine will be very easy.

Since not everyone will be able to purchase such equipment for their home, you can find out, for example, where you can cut porcelain tiles in your city by simply making a request to any search engine. For a small fee, you can get perfectly cut tiles, exactly according to your measurements or patterns, so it’s worth considering this, least labor-intensive option.

Cutting ceramic granite with a jigsaw and circular saw - features

A jigsaw with diamond wire makes it possible to perform complex shaped processing of products that interest us. It is rarely used by home craftsmen, as it requires certain skills in using such a tool. However, there is nothing difficult in its use. You only need:

carefully monitor the movement of the wire (first mark the contours of the cutout you need on the tile); constantly blow off dust from the surface of the workpiece (in this case, the cutting thread will follow a clean line and cut the material efficiently); Moisten the porcelain tiles a little with water; pay special attention to processing the edges of products where there is a high risk of chipping.

Processing the edges of the product from chipping Direct cutting of a large number of tiles can be done with a circular saw - a unit with a gear-type disk, which many home craftsmen have. You need to mount a disk (diamond) on such an installation, with which you can carry out dry cutting.

The principle of using the “circular” is as follows:

- mark the cutting line;

- press the ceramic granite product to the work surface with both hands;

- move the tile forward onto the rotating disk.

Using a circular saw requires maximum care. The tiles have to be moved manually, which can lead to serious injury to your fingers. Be extremely careful when working with this tool!

- www.ivd.ru

- septik.guru

- remoskop.ru

Safety rules for cutting

Safety rules when working with cutting tools are as simple as possible; compliance with them is mandatory, since your health and even life depend on it. When using non-electric tools, the main set of protective equipment is gloves and goggles. Gloves will help avoid cuts from the sharp edges of the material, and glasses will prevent splinters and dust from getting into your eyes.

When working with an electric tool, grinder or tile cutter, special attention is paid to safety precautions:

- It is strictly forbidden to change or clean the cutting disc if the machine or grinder is plugged into an outlet. The equipment must be completely de-energized.

- It is forbidden to bury the cutting disc more than one-third into porcelain tiles when cutting with a grinder. When working with a tile cutter, it is allowed to deepen the circle no more than halfway.

- The grinder must have a protective casing and the tile is cut away from you.

- Use special clothing made of thick material and do not leave exposed areas of the body. When the cutting wheel heats up, the spray particles can bounce off and leave burns on the body.

- It is important to use gloves made of thick fabric. Experience shows that knitted gloves are not suitable and can cause injury. Often, if the tool is not handled correctly, the disc or locknut will catch the threads of the glove and can twist them.

- Clothing should not have hanging straps or fasteners, and if you have long hair, it should be hidden in a headdress.

Since electric tools create noise and often a large amount of dust, glasses, headphones and a respirator should be mandatory protective equipment.

You may be interested in learning about pressure hatches under tiles or convectors built into the floor.

For which tiles is the glass cutter not suitable?

The use of a glass cutter is justified only for glazed varieties of tiles, the surface of which resembles glass in structure and appearance. Restrictions also apply to the thickness of the tile product - its maximum values should not exceed 5 mm.

It is impossible to process mirror tiles with a glass cutter. Its dimensions and laying pattern are selected in such a way that solid elements are used.

Gypsum tiles are not recommended for processing - their rough coating will be difficult to cut, crumble and delaminate. Porcelain tiles with a high wear resistance class (two or higher) would not be the best option. These are durable and rigid types of materials such as porcelain tiles and floor tiles.

What types of tools are there for cutting tiles, what is their difference?

All tools for cutting tilers can be divided into: manual tools (glass cutter, tile cutter, nippers) and power tools (electric tile cutter, angle grinder, jigsaw).

The choice of each tool depends on several factors:

- Scope of work performed. To cut one or two tiles, a glass cutter or grinder is enough; to finish an entire apartment or house, you need a tile cutter.

- The type and quality of the cut to be made. Straight and curved cuts are made with different tools; for drilling round holes, you may need diamond core bits and a drill. To cut thin wall tiles and thicker, more durable porcelain floor tiles, you need to use different equipment.

- Execution speeds. The larger the area on which the tiles are laid, the more advanced the tool for processing it must be.

- The amount of money that the master is willing to pay for the tool. Professional manual and electric tile cutters are expensive, but you can get by with more affordable tools.

Professional tilers usually have a full set of cutting tools to solve any task. To lay tiles yourself, the home owner does not have to purchase expensive professional equipment; you can do the work with inexpensive equipment or rent power tools from a hardware store.

How to properly cut tiles with a manual tile cutter

This procedure can be performed without any problems, just follow the manufacturer’s instructions.

Sequence of operations:

- mark the cutting line. This can be done with a felt-tip pen or pencil, marker - depending on the surface of the product. For models with a laser pointer, this item can be skipped;

- The tile is fixed on the platform so that the cutting line and the wheel align as accurately as possible. If you need to make a cut diagonally or at an angle, it is convenient to use a model with a square and corner markings. If you use a simple device, without supporting corner sides, simply turn the tile into the desired position;

- by moving the carriage, an even cut is made to the end of the tile;

- lower the lever, thereby pressing on the tile on both sides of the cut. The ceramic splits along the cut line.

If the leverage is not enough, you can lay the tile on the floor, placing a narrow bar under the cut line, and simultaneously press (step on your feet, place heavy objects) on both sides of the cut.

Important: increasing the distance from the cutting line to the load application points, of course, increases the leverage and reduces the impact force. But at the same time, this increases the risk of the panel breaking not due to a cut, but arbitrarily.. As always, there are certain nuances:

As always, there are certain nuances:

- the cut is made once, it is not worth running the cutter several times in one place - the break will be uneven, with jagged edges;

- the force applied to cut the glaze must be strictly measured, as well as the force on the lever to break the panel. It is better to practice on waste or unnecessary trimmings before performing important work;

- play of the cutter (wheel) and its incomplete mobility (jamming, jerky movement) are unacceptable, the device must be adjusted and lubricated before starting work;

- Before cutting, you should check the cleanliness of the platform (presence of debris, splinters, large dust) and its stability.

Porcelain tiles should be cut according to the same principles, making allowances for the greater strength of the material. It may take more force to cut and break the panel.

In addition, a short video about exactly how a standard manual tile cutter works.

Method of using a tile cutter

To make an even, correct cut of ceramic tiles with a special tile cutter, follow these steps:

- place the tiles in a tile cutter. The previously made marking line must coincide with a special mark on the tool;

— lower the handle onto the tile and move it with equal pressure and uniform speed in the direction away from you. The roller should cut through the icing to the same depth. One roller wiring is enough.

Warning! Performing several passes will not improve the result of the work, but, on the contrary, may worsen it. Due to microscopic discrepancies in the cutting on the glaze, the break turns out to be of poor quality!

— using special paws located near the roller, we break the cut tile into pieces. To do this, you need to press the lever sharply and firmly.

All models of tile cutters have a special metal tubercle on the platform. It has soft linings along the edges to prevent damage to the tile parts after a break. When the paws press on the edges of the tile, internal tension is created along the cut line and, with precise and correct placement, an even split into two parts occurs.

High-quality modifications of the tile cutter without any problems allow you to cut even 10 mm tiles at any angle - 40 or 30 degrees - it doesn’t matter. The tool will cope perfectly with any task.

Porcelain stoneware cutting technologies

Let's look at the technologies for cutting porcelain stoneware using the most popular tools.

Manual tile cutter

Despite its simplicity, a manual tile cutter provides a fairly high quality of work. The tool consists of a support platform, two guides, thanks to which the cut is perfectly smooth, a lever with a cutting roller and clamps for breaking the tiles.

The manual tile cutter is suitable for tiles with a thickness of 8 mm, 1 cm, etc. (up to 12 millimeters). Please note that the thicker the tile, the larger the cutting roller should be in diameter. Ideally, these two values should coincide.

Preparing the tile cutter for work

Before starting work, you need to make sure that the cutting roller is not dull and its size corresponds to the thickness of the selected tile. If necessary, the roller is replaced.

The ease of movement of the tile cutter along the guide rods is determined. If the cutting element passes tightly or, on the contrary, dangles, it is worth checking the bearings and cleaning the guides.

Cutting porcelain stoneware

The cutting technology on a manual tile cutter is quite simple.

- After taking measurements, make appropriate marks on the tile with a pencil or marker;

- the tiles are laid on the tile cutter platform, the cutting line is aligned with the cutting roller;

- so that the tile does not move during cutting, it must be fixed by hand;

- the roller is installed on the edge of the tile and, gently pressing the lever, it is drawn along the entire cut line;

The smoother you move the roller, the better the finished cut will be.

- after the cut is made on the tile, it is secured to the platform with fixing tabs so that the cut line is between them;

- They begin to press on the part of the tile protruding beyond the platform with their hand until the tile breaks.

When cutting with a manual tile cutter, the edges of the tiles are quite smooth, but the appearance of small chips and unevenness is possible. In this case, the deformed edge must be sanded.

Video: how to cut porcelain tiles with a manual tile cutter

We offer you a master class on cutting porcelain tiles with a manual tile cutter.

Bulgarian

A grinder can cut a wide variety of materials, porcelain stoneware is no exception.

Preparing for work

To cut porcelain stoneware, a special “diamond blade” must be installed on the grinder. When installing the disk, check that it is securely fastened, and be sure to wear safety glasses and gloves.

Working with an angle grinder

The technology for cutting porcelain stoneware differs little from cutting other materials.

Markings are applied to the tile with a pencil along which the cut will be made;

Using a grinder you can make shaped cuts and even holes

- The tiles are cut along the marked line with a grinder. To reduce the number of chips, try to cut the tiles “in one go”;

- Since when cutting porcelain stoneware with a grinder, small chips and cracks may remain on the edges and front side of the tile, the end of the tile after cutting is cleaned with sandpaper or a grinding disc.

Video: how to cut porcelain tiles with a grinder

Electric tile cutter

If the two previous methods are considered within the framework of “dry” cutting, then the next technology refers to “wet”. In other words, during the process, water is supplied to the tile cutter, which protects the cutting element from overheating. This ensures an almost perfectly even and smooth cut.

Electric tile cutters come in two types: with a movable and a fixed disk. In the first case, the cutting module moves along the tile along special guides, in the second, the tile is fed onto the disk using a platform or simply by hand.

In addition to the platform and cutting module, most electric tile cutters are equipped with a container of water into which part of the cutting disc is immersed. This helps protect the disk from overheating and also significantly reduces the amount of dust during operation.

Preparing for work

Before starting work, you should check the reliability of the disk fastening and the presence of water in a special container.

If the tile cutter has already been used, then the cutting disc must be cleaned and the water changed, since porcelain stoneware chips that have fallen into it interfere with the cooling process.

Tile cutting

A professional tool allows you to cut porcelain tiles almost perfectly

The cutting technology itself with an electric tile cutter is very simple: a pre-designated cutting line is aligned with the cutting disk and a special lever moves it along the tile or feeds it onto the disk.

Since the cut edges on an electric tile cutter are almost perfectly smooth, no additional processing is required.

Jigsaw

A jigsaw is an indispensable tool if you need to cut tiles along a curved line, and the required bends are quite sharp. However, using a jigsaw to cut into porcelain tiles is very difficult; this method is only suitable for ceramic tiles. Naturally, not just an ordinary saw for fibreboard is used, but a special diamond jigsaw file of good quality, since the tiles have increased strength. A circular saw is more suitable for cutting porcelain tiles.

Before making an internal cut with a jigsaw, you need to drill a hole whose diameter will be slightly larger than the width of the diamond file. You need to drill it, stepping back from the cutting line inward a few millimeters more than the radius of the drill so as to give a margin for possible chips during drilling.

Angle grinder (grinder) - multifunctional tool

Cutting tiles with a manual or electric tile cutter requires the purchase of these tools, which is not always justified in the case of household work. In addition, after tiling work, you will no longer be able to use these tools anywhere.

For a home craftsman, a good solution may be to use an angle grinder (grinder). But working with this tool has its own specifics.

First, you need to decide on the size of the angle grinder itself. The best option for cutting tiles would be a grinder with a 125 mm disc. It is convenient to hold and manipulate.

Angle grinder with 125 mm disc

It is better not to use grinders with a disc diameter of 230 mm for such work. The tool is very bulky, which makes manipulation difficult and significantly degrades the quality of the cut. It is permissible to use an angle grinder with a disc diameter of 180 and 150 mm, but only if cutting thick tiles or porcelain stoneware.

A grinder can cut all types of ceramic tiles - wall, floor and even porcelain tiles. Without any problems, you can make straight cuts, at an angle and some curved ones.

To simplify the work, you can consider purchasing a special attachment for an angle grinder - “Slider”.

Angle grinder with Slider attachment.

Let's take a step-by-step look at how to cut ceramic tiles with a grinder without chipping:

To cut ceramic wall or floor tiles, you must use a solid diamond blade for dry cutting.

Disc for cutting ceramic tiles.

The tiles are fixed in a stationary state using clamps.

Step 3. Cut.

The incision is made towards you, the disc is positioned perpendicular to the surface. Sometimes the grinder moves back and forth to reduce the heating temperature. To prevent chips from forming on the front surface, the angle grinder must be tilted slightly to the side. If the cutting angle is less than 90, then chips will not form.

Step 4. Revision.

Abrasive processing of edges when operating an angle grinder is necessary. If you used an abrasive disc with a special “Slider” attachment, you will have to sand the edge less, since the number of chips is minimized. Grinding the edge is done with the same grinder used for cutting, or with emery cloth attached to a block.

How to cut porcelain tiles with a grinder:

Next, we’ll look at how to cut porcelain tiles at home. To cut porcelain stoneware, it is necessary to choose solid diamond-coated wheels designed for wet operation.

When choosing a wheel, pay attention to the maximum permissible rotation speed, it must correspond to the rotation speed of the angle grinder

Disc for cutting porcelain tiles.

Cutting porcelain tiles must be carried out with a constant supply of a small amount of water. Otherwise, the coating on the disk will not last long and it will quickly cease to perform its functions. Therefore, before work, you need to prepare a plastic bottle of water by first piercing a hole in the bottle cap.

Step 3. Res.

By moving towards you, you need to apply a thin groove on the surface of the porcelain stoneware. Then the cut line must be moistened with water and again make a shallow cut, moving towards you. These operations must be repeated until the tiles are completely cut.

Step 4. Revision.

At the bottom of the cut, the tile may have roughness. To refine it, you need to turn it over to the reverse side, clamp it with a clamp and use an angle grinder and a diamond disk to slightly grind the edge.

Can a tile cutter handle porcelain tiles?

Most often, this task is faced by a master who works on the road, but deals with this business professionally. In this case, you need to take into account only a few nuances, and you can safely get down to business. Most likely, he already has everything or almost everything he needs.

If the volume of cutting required is not too large, and the thickness of the porcelain tiles is not large, the relevant question is, can a tile cutter cut porcelain tiles? The answer is yes, you can get by with a familiar tool.

For straight cuts, a manual tile cutter may be suitable. The main thing is that it is of good quality. However, for thicker porcelain tiles or embossed ones, you can’t do without power tools.

In addition, the increased strength of the material makes it difficult to cut porcelain stoneware correctly and so that the tile does not burst. It will also not be possible to cut a narrow piece of porcelain tile 3–5 cm wide with a tile cutter.

In addition, tiles are available in large sizes. It may simply not fit into the tile cutter. Or the surface of the tile has texture unevenness. In such cases, the question arises, what is the best way to cut porcelain tiles?

The relevance of the classic tile cutting tool

For cutting ceramic products, mechanical or electrical devices are chosen - it depends on the desired quality of the cut, the scale of the work and the characteristics of the material being processed. So, for home repairs, three options are considered: cutting the tiles with a glass cutter, a manual tile cutter, or a grinder.

Cutting tiles with a glass cutterSource globus-baumarkt.de

Glass cutter

The glass cutter consists of a rod, at one end of which a monolithic or hollow handle for oil is fixed, at the other - a cutting element: faceted diamond, pobedite cutter, carbide roller. The permissible thickness of the glass to be cut is 10, 8 and 7 mm, respectively. Often, the supporting steel platform has rectangular grooves for breaking off the blade.

Working with a glass cutter will be effective only if a deep furrow is formed in one pass. This is possible if the surface of the tile is smooth, which is not often found with artificial stone. As a result, such a tool is difficult. It is possible to cut porcelain tiles in a straight line, but not in a curved line.

Manual tile cutter

This tool is essentially an improved modification of the glass cutter. There is also a cutting element - a carbide roller. Only to increase the force is a lever mechanism that moves along tubular runners. To break the tiles, there is a small protrusion on the stand, and in the area of the cutter there is a lifting sole at a slight angle to the central axis.

Cutting tiles with a manual tile cutterSource bosch-do-it.de

Tile cutters are available in a wide range. The determining criteria for choosing a tool are:

- physical parameters of the tile;

- travel of the lever mechanism (dry, lubricated, on bearings);

- backlash of the cutter, or rather its absence.

They also consider the quality of the materials from which the device is assembled. For professionals, the functionality of the device is important. In addition to straight cuts, additional options allow you to cut holes.

Cutting porcelain stoneware with a tile cutter follows the same principle as with a glass cutter. A marking is applied and the tiles are placed on the stand according to it. A roller is placed along the line, which, under the pressure of a lever, is rolled over the entire canvas. Finally, the pressing sole is lowered onto the furrow edge farthest from the master. Under pressure, the tiles split.

Smooth fracture of ceramic sheetSource sense-life.com

It is worth noting here that cheap appliances work well with wall tiles, but are more difficult with porcelain tiles. Especially when the surface is not smooth or it is necessary to cut off strips 15-20 mm wide. There may not be enough pressure to fracture or form a groove. In order to reduce prices, low-quality materials are used for production, so they quickly fail. This forces us to consider instruments that are no lower than the middle segment in terms of cost.

Angle grinder

A grinder with a replaceable cutting element in the form of a disk is considered a universal tool for cutting and processing various types of materials. The choice of device for working with porcelain stoneware is determined by its speed. Here, high power will have a positive effect only on the cutting speed, but not on the quality and accuracy of the resulting edge.

Discs on stone or concrete will break up the edge. Therefore, the cutting wheel is considered only with diamond coating. On trading platforms, such equipment is presented in two versions:

Solid for “wet” cutting. Here, cutting is carried out with periodic wetting of the disk with water or a special composition in order to cool it. The main advantage of such a circle is that porcelain stoneware can be cut without chipping (depending on the nature of the porcelain stoneware: thickness, texture, quality).

Solid diamond bladeSource beamtools.ru

Segmented diamond bladeSource allegroimg.com

Porcelain tiles are usually cut with a manual grinder. For it, equipment with a thickness of up to 2 mm is relevant. To obtain a better result, consider discs with a cutting edge wider than the height of the tile being processed. It is also recommended to check the play of the nozzle before each cutting, which should be minimal.

Work begins by applying markings to the front side. The canvas must be placed on a flat, solid base and secured. Before cutting porcelain tiles in order to minimize the number of chips, first form a starting groove up to 3 mm in the direction away from you. When the cutting requirements are low, it is enough to make a cut to a depth of half the height of the tile and break it.

Cutting ceramics with a grinderSource protifofas.ru

Highly specialized devices

Of course, the cutting methods that we discussed above are suitable for those who are not able to shell out a good amount of money to buy a porcelain tile cutting machine. However, for professional tilers, saving time on cutting porcelain tiles is important, so the machine will be very useful. Although only straight cuts are possible on the machine, most cuts are straight. In addition, a good machine will allow you to cut porcelain tiles at different angles.

In addition to the large permissible cutting thickness, the machine has a number of other advantages. Firstly, it will be possible to use wet cutting of porcelain stoneware. This method reduces the likelihood of both overheating of the cutting disc and the appearance of chips on porcelain stoneware. Secondly, your hands are freed from the load of the weight of the power tool. The machine has a platform on which the electric motor and cutting edge are rigidly fixed. Thirdly, the machine has devices for linear translational movement: either a tile or a motor with a cutting tool. This avoids unevenness and significantly improves the quality of the cut. All that remains is to control the feed speed along the guides while the cut is being made. But the main advantage is the absence of dust when cutting tiles, which is especially important when renovating an apartment.

Tile cutting machine options

Depending on how often and how much a craftsman has to work with tiles, he may want to think about what type and size of porcelain tile cutting machine he will need. For example, if work is carried out in a cramped room or not often, then a machine with a motor located below the workbench would be more suitable. Such machines are smaller, lighter and much cheaper compared to machines with an overhead engine (for example, the Praktika 1860 model has an average cost of 6,000 rubles). But this option has a greater limitation on the depth of cut. Not every model is equipped with guides for straight feeding of tiles and devices for fastening tiles, which requires some skills from the master. Also, cutting at an angle of 45 degrees is not provided in many models.

Wider possibilities and comfort when cutting porcelain stoneware are provided by machines with the engine located above the work table. For a craftsman who specializes in working with tiles, this option will definitely be preferable. Although these machines will have large dimensions, they will provide safer and more comfortable working conditions, a much greater cutting depth (up to 100 - 135 millimeters), some models allow cutting not only at an angle of 45 degrees, but also at intermediate values. Naturally, this type of machine will have more powerful motors and larger diameter diamond cutting wheels. Some of these machines will be stationary, that is, they will have very large dimensions and weight.

Depending on the manufacturer, equipment, size and capabilities, machines with overhead motors have a wide range of prices. Here you can read a detailed review of tile cutters.

How to cut porcelain tiles

Nice thermal panel theme! Quickly warm and reliable! There are also thermal panels made of ceramic concrete that made the office simply cool.

I built a house from aerated concrete and am going to cover the outside with thermal panels. Who has already installed them? How are the results? Or it may be easier and cheaper to make a wet facade, although it is not.

Thanks for the detailed instructions! I have an old washing machine lying around at my dacha. It will be necessary to use the motor from it to create an emery machine. Unity

This style reminded me very much of the film The Great Gatsby, in which the interiors of houses and apartments in the 1930s were decorated very luxuriously and pompously. Of course, this was a prerogative.

Hand jigsaw with diamond-coated file

A hand jigsaw is convenient for making curved cuts, but to work with durable ceramics you need a diamond-coated file. This tool can be used to process both wall and floor ceramics.

Hand jigsaw with tile file.

Let's take a step-by-step look at how to cut tiles with a hand jigsaw:

Step 1. Marking.

Done with a marker on the surface.

Step 2. Fixation.

When working with a manual jigsaw, you can hold the tile product with your hand.

Step 3. Cut.

Part of the whole is sawed off in the standard way. You can pre-stick paper tape over the cut area - there will be less chipping and dust.

Step 4. Revision.

Final sanding of the edges after cutting is necessary.

Cutting with a grinder

An angle grinder (grinder) is a universal tool for cutting and processing a variety of materials. Due to its versatility, it is not classified as a special tool. In the household, you can solve many issues with the help of an angle grinder.

In order to cut porcelain stoneware, almost any grinder is suitable. There is no need for high power. It is even preferable to use a small, lightweight tool. RPM is more important than power. A powerful tool will cut the tiles faster, but speed can have a negative impact here - it will turn out less neatly.

The main issue is the selection of the cutting wheel

It is the choice of circle that you should pay special attention to. And we are not talking about the fit size (it goes without saying)

Selecting a cutting blade

The material is cut only with diamond blades. Diamond blades are produced in two types: solid and segmented. For best results, it is recommended to try different cutting wheels to make cuts. For cutting porcelain stoneware, there are features when using both solid and segmented discs:

- Solid ones are positioned by manufacturers mainly for “wet” cutting. Those. for cutting with cooling with water or special liquids. And they are not used for cutting without cooling, as they can quickly fail. However, when the task is to obtain a cut with as few chips as possible, a solid disk may be better suited. This is situational and largely depends on the specific material (quality, thickness, relief, etc.) that is being processed;

Solid cutting disc.

- Segmental ones are more suitable for “dry” cutting. Those. acceptable for use with grinders. It is believed that the voids between the segments help cool the cutting tool. However, it is not recommended to work without a break for more than one and a half to two minutes. The same comments about the cleanliness of the cut are relevant.

Segment cutting disc.

In addition to the type, the discs differ in a whole set of parameters: the density of diamond coating, the height of the cutting edge, the thickness of the disc, etc. It is better to follow the recommendations of the disk manufacturers. The disks themselves usually indicate for what purposes they are used.

For cutting with a manual grinder, discs with a thickness of less than 2.0 mm are not acceptable. The height of the cutting edge should be greater than the thickness of the tile (affects the cleanliness of the cut).

Technology

- Mark the tiles. The best way to do this is to use a construction marker.

- Place the tiles on a flat surface. In some cases, it will be more convenient to secure the tiles to the surface with clamps or secure them in a workbench.

- To obtain an even cut, you can additionally strengthen the metal strip with clamps along the cutting line. Then you will have to cut along it.

- Cutting is carried out from the front side, since the output produces the largest number of chips. You can make double cuts. First, make a small furrow on the front side, and make the main cut on the back side. This method will minimize damage to the front surface.

- If there are no strict requirements for the cut, then you don’t have to cut it all the way. After making the cuts, break the slab with your hands.

- It is recommended to lead the instrument starting from yourself.

- Additional sanding of the cut if necessary.

General recommendations

When using an angle grinder, be sure to use protective equipment:

- a suit covering legs and arms;

- safety glasses (preferably a mask);

- protective gloves or mittens;

- a respirator (for a significant amount of work is required).

Advantages of using an angle grinder:

- The ability to cut an element of almost any shape. Curly cutting requires good tool skills;

- Possibility of trimming tiles already laid in place;

- Tool availability.

Flaws:

- injury hazard;

- it is very difficult to obtain geometrically accurate sections;

- greater difficulty in obtaining a clean cut without chips;

- low speed;

- a lot of dust and noise.

With a grinder you won't be able to get the perfect cut the first time. To obtain precise cuts without chipping, cut with a distance of 2-5 mm from the line. Then it is brought to the required dimensions by grinding. This is a rather labor-intensive operation and takes a lot of time, so it is recommended to carry out it only with elements that will be in a visible place.

Or they use a trick, as in the video below:

The best methods for cutting porcelain tiles at home

Many home craftsmen believe that since porcelain stoneware resembles ordinary ceramic tiles in appearance and production method, then cutting it will not be any more difficult, but this is a misconception. In fact, you can, of course, try to cut porcelain tiles using, for example, a glass cutter, but you will hardly be able to achieve results. But methods for cutting porcelain tiles still exist and they can be used at home, so let’s figure it out together.

Universal grinder: simple solutions

Almost every craftsman has such a multifunctional power tool as an angle grinder, because with it you can perform a wide variety of tasks. It is quite possible to cut porcelain tiles with a grinder, the main thing is to approach the issue correctly, purchase all the necessary components, and also follow the process technology exactly. First of all, be sure to select a diamond-coated disc; for example, those with special materials like “ceramics”, “concrete” and the like are excellent.

Don’t forget about safety precautions, because cutting with a grinder is always accompanied by noise and a huge amount of dust. It is worth acquiring a special suit in which the sleeves are fastened, gloves, a respirator, as well as construction glasses, preferably yellow. It is worth considering that when cutting porcelain stoneware with this tool, chips will certainly form, so the cut surface will have to be finished with a file, but it is better to purchase a special grinding disc-turtle.

- Draw a line on the tile along which the cut should be made and lay the porcelain tile on a strong, flat surface. All work is carried out exclusively on the front side, since the other side will show the maximum number of defects and chips.

- If you have an assistant, you can put him at the ready with a vacuum cleaner in his hands, this will help get rid of excess debris, and it will be easier to work when the cut is clean and clearly visible.

- Secure the tile with a clamp or press it firmly to the surface.

- Move the grinder disc along a line from the far edge towards you, smoothly moving forward, trying to avoid jerking.

It is important to make cuts on porcelain tiles in one motion, so the amount of scrap and chips will be minimal. If necessary, torn and uneven edges must be sanded and smoothed in any way, from sandpaper, which will take a lot of time, to a diamond grinding wheel.

Circular saw and jigsaw

If we talk about available tools, then often the farm has a tool such as a circular saw, especially if we are talking about those who have their own household plot. Using a circular saw, as it is affectionately called by people, you can saw off porcelain tiles along the required line. However, the toothed disk of the tool will have to be replaced with a diamond-coated one. Act as if you are about to saw wood and take care of your fingers, then everything will definitely work out as it should.

The second option is a jigsaw, for which you will have to buy special components in the form of a diamond thread. With such a cutting edge, you can get shaped cuts, not just straight ones. Simply draw the desired shape, and then carefully saw through the porcelain tiles, moving forward slowly and smoothly. Breaks and jerks should never be allowed, otherwise you can not only damage the tile, but also get injured if the thread breaks, which is unacceptable.

Mechanical tile cutter: difficult, but possible

Among the common tools that can often be found in the “arsenal” of home craftsmen are manual mechanical tile cutters. This useful and convenient tool can also be used for cutting ceramic granite tiles. Here it is important to choose the right tile cutter, since porcelain tiles usually differ from tiles in thickness and size. It is worth paying attention to the overall size, thickness of the cutting element and the bed itself, the length and power of the handle, smoothness of operation and other parameters. There is already an article on how to choose a tile cutter on our website.

- Draw a line along which you want to make a cut, and then install the tile so that the tool rollers rest exactly on it.

- With a simple movement of the lever, away from you, make a cut on the porcelain tile.

- Sharply lower the lever, thereby breaking the tile along the required cut.

It is worth conducting a few experiments before cutting porcelain tiles cleanly with a tile cutter. Different materials may have different densities and thicknesses, so it is worth taking material from the same batch for testing.

Electric tile cutter: process automation

The easiest way to cut porcelain stoneware at home is to use electrical equipment specifically designed for this purpose. Electric tile cutters can be compact, simple or cantilever. The first two types have a lower cost, but the last one is easiest to work with, since it will allow you to make even beautiful shaped cuts, which you can hardly do with any other tool at home. It is better to take such a tool with a wet type of cutting, this will eliminate excess dust and fragments flying in different directions.

- Innovative tile cutters are equipped with automatic water supply, which greatly simplifies the work and cools the blade. However, it is worth remembering that the water must be changed regularly so that abrasive particles do not spoil the sprayed circle.

- Choose those models that have water in the pan and the disk is constantly immersed in it.

- If the design involves a water pump, then you should pay attention to such a model, since then you will not have to monitor the level and cleanliness of the liquid.

Simply place the tile in the holder provided for it and run the cutting edge along its surface, or feed the tile as it is cut onto a fixed disc, depending on the design. There is nothing complicated here, so anyone who is more or less familiar with such a tool can cope with the task.

Ceramic tile nippers

Nippers are a specific tool with short cutting blades, designed not for cutting, but for breaking off (biting) fragile material. They are needed as an auxiliary tool for processing the edges after cutting the tiles with a grinder or tile cutter.

Nippers for ceramic tiles come in two types: classic pliers and improved ones - with a roller cutting element.

Regular tile nippers.

Nippers with a roller cutting element.

In the latter case, the roller element performs the functions of a glass cutter; after running it along the surface, the tile breaks at the cutting site.

Nippers come in different sizes - you can buy several to break off small and large pieces. This tool is indispensable if you need to trim narrow edges about 0.5 cm wide.

Let's take a step-by-step look at how to work with ceramic tile nippers:

Step 1. Marking.

Traditional markings are made on the surface of the tile with a marker, sometimes without it.

Step 2. Fixation.

The element being processed is located on a horizontal plane or simply held firmly in the hand. If the nippers have a roller element, then when working, it is better to apply the tile being processed to the stop, and draw the line along a ruler.

Step 3: Biting.

Break off small pieces of tile; biting off large pieces may damage the tile.

Step 4. Revision.

Since the nippers do not perform cutting operations, but break off the material, the edges then remain uneven, with chips that need to be removed. After work, careful sanding of the edges is necessary.

The choice of tool and method of cutting tiles depends on its strength, working conditions, and the skill of the craftsman. The best way to cut tiles is up to each master to decide for himself. Knowledge about tools and the features of working with them will allow you to choose cutting devices consciously.

Useful tips

There are various models of attachments for grinders on sale, some of which provide connection of the vacuum cleaner pipe to the protective casing of the tool. At first glance, the thing is quite convenient, but it is better not to use such devices, since the hose greatly interferes with the work and often only worsens the quality of the seam.

In addition, when cutting porcelain stoneware, be sure to hold the body of the grinder with both hands, while the left hand should rest on the stand or guide rail, and the right hand should directly move the tool. This method not only provides partial relief for your hands, but also allows you to more accurately align the position of the cutting disc in the vertical plane.

Regardless of which disc or method you use to cut porcelain stoneware, after completion of the work the edge must be rubbed down with hand or belt sanding. In this case, you only need to slightly level the lower edge of the porcelain stoneware and under no circumstances touch the upper front edge with the abrasive, otherwise chips will appear and the quality of the seam will noticeably deteriorate.