What should you do if, after a certain period of proper operation, your machine or RCD in the electrical panel starts to trip when you turn on the washing machine?

Not everyone wants to immediately run to a service center, especially when the warranty has already expired. And transporting such large equipment is not an ordinary task.

In most cases, you can identify the breakdown and eliminate the cause yourself. The main thing is to know what to check and how.

Moreover, with a competent approach, it is possible to identify the cause of the shutdown even without special measuring instruments. There are several common symptoms and cases, let's look at them in order.

Damage in the wiring - the washing machine is not to blame

Where to start troubleshooting? Firstly, you don’t need to immediately climb in and disassemble the machine. Maybe it has nothing to do with it at all, but the socket, wiring or the machine itself is to blame.

How to find out? Connect a load of approximately the same power to the same outlet. For example, an electric kettle and see how the machine behaves.

If he knocks it out again, then the washing machine has nothing to do with it. You need to look for damage:

- in the socket

- in the wiring

- in a machine, RCD or panel

If nothing turns off, then most likely the machine is to blame. To make sure of this 100%, temporarily connect it from a portable outlet from another outlet that is not connected to the bathroom line.

True, several conditions must be met here:

- this should be a short-term option, just for testing

The SMA cannot be permanently connected through a carrier.

- such an extension cord must have grounding contacts

- the protection device of the other outlet must correspond to the rating of the bathroom line

- the plug must be installed in exactly the same way, that is, you need to guess the phase and zero

The fact is that if you turn the plug 180 degrees, the protection often stops triggering.

For a faulty washing machine, it turns out that there is a difference where the phase is supplied and where the zero is supplied.

Sometimes people “treat” their problems this way. Although the device cannot be turned on for a long time in this operating mode.

Only if all the above conditions are met, in the event of a malfunction of the washing machine itself, another machine or RCD will trip.

By the way, when you do not have a dedicated line to the bathroom, and there are other sockets on the same circuit breaker, before all manipulations and checks, be sure to turn off all extraneous loads.

Suddenly it turns out that the reason is not the washing machine at all, but other equipment connected in parallel.

So, if you find out that without the machine in the outlet, nothing turns off. We are looking for a leak or short circuit before it.

Turn off the machine, check that there is no voltage in the outlet and disassemble it for visual inspection.

It is very important that only waterproof sockets are used for washing machines in the bathroom. Otherwise, oxidation of the contacts and constant tripping of the RCD or automatic circuit breaker are guaranteed.

When opening a simple socket, all its contacts and the housing itself will be constantly wet. In this case, the RCD may spontaneously trip even at idle, when nothing is connected in the bathroom.

In order to somehow work with such an outlet, you will have to constantly keep the exhaust fan on in the bathroom.

Also, condensation often forms inside machines with a washing temperature of no more than 40 degrees. With this mode and when rinsing in cold water, droplets of moisture first settle on the inner walls and then reach the electrical contacts.

If there is damage in the outlet, you will definitely see it by soot and burnt contacts.

Well, if you don’t find anything suspicious here, then check the cable.

In a good way, this is done with a special device - a megohmmeter.

The ends on both sides of the cable are unscrewed and the insulation is caused.

The problem is that not even all electricians have such a measuring device at home. What can we say about ordinary consumers?

How can we manage without it? A modern home electrical panel in most apartments and private houses no longer consists of just two switching devices or plugs.

It contains at least ten switching devices, or even more.

All you need to check is to transfer the cable going to the outlet in the bathroom under the washing machine to another protective device of a similar rating.

To do this, for greater safety, turn off the common input and check that there is no voltage in the switchboard.

Next, unscrew the phase conductor from the terminal of the washing machine and transfer it to another protective device of the same rating.

Having first removed the original cable from it, which goes to another load. Turn on the input and the “new automatic” protection. Again, check everything by turning on the load in the form of a kettle in the bathroom.

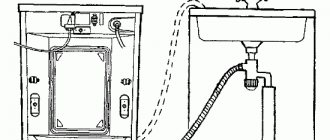

Normal power supply

Power test circuit

If your other machine is knocked out, it means there is a defect in the wiring. You will have to check the entire chain, open all junction boxes, etc.

Read more about the steps of this check in the article below.

By the way, an RCD in such cases can often trip simply due to a weakened zero in the switchboard itself. You will run around the whole room, open the wallpaper, and the reason will be right under your nose. Don't rule out this option either.

If, after switching to the new device, everything works properly, then change the original switch. Most likely, the contacts in it have burnt out and it no longer holds its rated load.

Reasons for failure of temperature sensors

The main causes of thermostat failures are:

- Frequent washes at high temperatures. Such temperature conditions affect the rapid wear of many parts of washing machines, and also negatively affect the quality of the fabrics of the washed items. Modern detergents are quite effective in removing stains even at low washing temperatures;

- Unstable voltage in the power supply network. Voltage fluctuations have a detrimental effect on any electronic components, and short circuits instantly damage them. To use a washing machine, it is best to install a separate electrical wiring line from the meter of your home.

- The wires must have a sufficient cross-section to avoid overheating of the insulation. The device must be grounded. For your own safety, you need to install an RCD (residual current device).

- How is blood washed off?

- How to wash membrane clothes

Causes of failure in the washing machine

Now let's look at the reasons when the malfunction is related to the washing machine itself.

There are many more damage options here:

- short circuit or breakdown of heating element

- defective plug or cable in the machine itself

This is most often visible even visually. It is enough to carefully examine all contacts on both sides.

You won't be able to disassemble the fork; it comes cast. But the integrity of the insulation can be traced.

- engine damage (water entered due to leaky gaskets)

- faulty line filter or control board

You should always start your search with the most common breakdown - a malfunction of the heating element. In 2/3 of cases, it is because of this that the machine and the RCD are turned off.

Again, everything can be revealed without instruments. How to do it?

Identifying the faulty element

If periodic self-draining of warm or hot water occurs (can be monitored by heating the drain hose), it is necessary to eliminate the siphon effect and correctly connect the washing unit to the drain system. The problem is successfully solved by installing a check valve in the system.

If the washing machine does not heat the water at all, you should remove the back or side covers and check the connection of the heating element terminals (TENA) with the current-carrying wires.

When washing, especially in spin modes, all elements of the washing unit are subject to vibration loads, which can lead to separation of the elements. By reconnecting the disconnected wire, you can eliminate the problem.

Washing units from Samsung, LG, Ariston, Candy, Bosch and other well-known brands have a similar structure and connection of heating elements. As a rule, a tubular heating element is used, which converts electrical energy into thermal energy by creating electrical resistance.

Checking the heating element in a washing machine without a multimeter

First of all, do not forget about safety precautions and before any work inside the machine, not only turn off the machine in the panel, but also pull out the power plug from the socket.

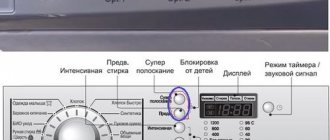

Next, remove the back or front cover (depending on the design) to get to the contacts of the heating element. The heating element will be located at the bottom.

The phase and neutral are suitable at the edges, and in the middle there is grounding.

When you don’t even have a multimeter at hand, to check the heating element, simply remove the phase and neutral conductors and insulate them.

Now plug the washing machine into the socket and turn on the machine. If the machine starts and the machine stops knocking out, then change the heating element.

It was he who caused the malfunction.

However, keep in mind that some SMAs do not work without a heating element. They have it connected in the same circuit with the water supply valve. In this case, unfortunately, there is no way to do without a tester.

Pressostat malfunction

A pressure switch is a sensor that controls the water level in a machine tank. Its function is to send a signal to the electronic control module that the required volume of water has been collected, the inlet valve can be closed and heating can begin. Failure in its operation can be caused by hair, animal hair, lint from fabrics, which can clog the pressure switch tube, which will lead to a breakdown in communication with the control module. This will cause the machine to fill with water, but it will not heat up. Therefore, if the machine does not heat the water, you should try to clean the pressure switch tube by first removing it.

Checking the heating element of a washing machine with a multimeter

If you still don’t trust all these experiments and want to be 100% sure that it is the heating element that is damaged and not something else, then your only assistant is a multimeter.

How to properly check the heating element? Again, pull out the plug from the socket, and put the tester in resistance measurement mode.

A measurement scale of up to 200 ohms will be sufficient.

Apply probes to the contacts of the heating element to check its integrity and absence of breakage. In a normal situation, its resistance should be in the range from 20 to 50 Ohms.

If the device shows infinity, then the spiral is broken.

You also need to test it for a short circuit to the body. Apply one probe to the metal part of the heating element or the central bolt where the grounding is located.

And with the others, you alternately touch the phase and neutral terminals.

Any values, even several tens of kiloOhms, indicate that the heating element is broken and must be replaced.

By the way, if there is a simple break in the heating element without shorting it to the housing, the machine will not knock out.

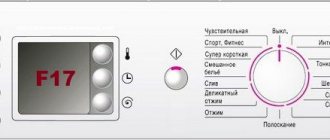

In this case, an error may appear on the display indicating that the water is not heating.

If you do not have a display with a description of the error code, then simply touch the glass on the washer door. Warm water should warm it up a little.

Diagnostics

If you notice that your SMA has stopped heating water, then you should carry out express diagnostics, which will help you find out the technical condition of those elements that may interfere with heating the water. In this case, it is necessary to carry out a visual inspection and other actions aimed at identifying the source of the problem.

- External inspection of the condition of the internal wiring - it is possible that mice have chewed it. In most cases, such defects can be noticed with the naked eye, but it happens that the defect is not visible. In this case, you should check the voltage in the wiring that goes to the heating element - in operating condition, the closed relay pair rings.

- Inspect the heating element for scale detection.

- Checking the functionality of the heating element using a special measuring device - a multimeter. To do this, you need to measure the resistance of the device, after which the heating element is heated and the resistance is measured again. If the final parameters are almost identical, then this directly indicates that the element has burned out. In good condition, the resistance is about 25–40 Ohms; if these parameters are different, it means the heating element requires replacement.

How to change the heating device?

We found the heating element and made sure that it should be replaced. First, disconnect all wires. To avoid confusion in the future, it is recommended to first record the order of their connection with a camera.

To remove the heating element, you need to unscrew the nut located in the middle part of the device. Now you need to pry the heater with a screwdriver and carefully remove it, rocking it in different directions. It is now recommended to immediately remove scale from other elements surrounding the water heater. The new heating element is carefully installed on special mounts. If you make a mistake, it will touch the tank during operation. All that remains is to connect the wires and assemble the machine to run it for testing.

Where and at what price can I buy a new one?

You can buy a new part in an online store, an LG service center or from a supplier of spare parts for equipment in your city. The easiest way to select the right part is to show it to the seller or name the marking. You can also determine the standard element from catalogs for washing machine models.

When purchasing a heater online, you need to consider the following parameters:

- seat dimensions;

- presence of a collar, seals, holes for the sensor;

- configuration of the working part of the heating element (shape, length and width);

- power.

LG washing machines are equipped with heating elements with a power of 1.1 to 3.2 kW and a length of 173-240 mm.

If a strictly similar part is not supplied, you can select a heater with similar characteristics . The permissible discrepancy in length is -1 cm, and in power - ±200 W. The new element must have the same shape as the previous one: straight or curved.

Some models of heating elements have a protective coating, which does not affect its configuration and interchangeability, but increases wear resistance and service life. The cost of the heater ranges from 400 to 1500 rubles. The best manufacturers of tubular elements for LG washing machines are IRCA and Thermowatt.

Expert advice

In order for the heating device to work as long as possible, you should provide proper care for the washing machine.

When performing repair work, be sure to disconnect the washing machine from the electrical network.

Many people recommend first removing the heater from the machine and then checking its functionality with instruments. But this is probably not necessary - the check can be easily carried out at the installation site. This will save time and avoid unnecessary work.