Wood-laminated board, better known to us as plywood, is widely used both in finishing work and in furniture production. And one of its most unique properties is the ability to create almost any bend. This allows you to create unique aesthetic designs and use the material more efficiently.

In this article we will look at how plywood is bent in industrial and domestic conditions.

Unusual furniture made of bent plywood

Features and advantages of products made from bent plywood.

Details made from bent plywood allow you to create original interior items of a wide variety of shapes. Furniture production manufactures furniture from bent plywood using multi-layer veneer. There are more than 200 types of parts made of bent plywood, including interior items, chairs, armchairs, components: armrests for chairs and chairs, frames and parts of various configurations. Bent-laminated plywood is widely used to create decorative wooden radiator screens, folding stools, and for the production of health products, in particular exercise seats.

Thanks to their unique structure, chairs and armchairs made of bent plywood are a bright and original decor for any room, both office and home. Using bent plywood, you can create high-quality, practical furniture of unusual design at an affordable price.

Bent plywood is made from thin sheets of wood. The sheets are produced by sawless division. The sheets are firmly glued together in a given shape. The finished product is particularly durable and flexible.

Currently, a fashionable trend has become the combination of bent plywood with other materials, for example, metal. The best option is a combination of bent plywood with steel, aluminum, decorated with glass. As a construction material, bent plywood has ample opportunities for the flight of design imagination. Furniture made from this material is practical, comfortable, and special exercise seats made from bent plywood have a positive effect on human health. From bent plywood you can make original models of sofas, chairs, armchairs, beds, bedside tables, cabinets and many other office and home interior items.

Furniture production company “Formex” produces high-quality products from bent-glued plywood (multi-layer veneer - plywood

).

We offer more than 100 types of components

products for the production of executive chairs, staff chairs, chairs on a metal frame, chairs for cafes and bars, armrests for chairs and chairs. The company's production capabilities and the versatility of the forms allow us to produce an endless number of chair frames and chair parts of any configuration.

Our bent plywood products - plywood - are also used in the manufacture of decorative battery screens, folding stools, and orthopedic products.

Currently, not a single manufacturer of office furniture, staff furniture, upholstered furniture and furniture for cafes and bars can do without the use of products made from bent-glued plywood - plywood.

What is it for?

Ready-made bent-glued plywood board is intensively used to produce products of unusual shapes, which decorate any living space with their unique appearance. More needed items are:

- decorative elements of cabinets, walls, cabinets, dressing tables, drawers, shelves and low shelves;

- latoflexes (frames) for beds;

- comfortable chairs or rocking chairs;

- ordinary blanks for creative looking chairs or unique inserts for armchairs and sofas;

- elegant facades for decent cabinet structures;

- office chairs, hard chairs, cheap furniture products for schools, hospitals and hotels;

- stylized elements for dining tables and small tables.

Products made from flexible veneer are always luxurious and prestigious, and for this reason they will effortlessly give any room in your home a pleasant appearance.

Features of plywood behavior when bending

The veneer from which plywood is made is nothing more than a set of elongated fibers. They are rigid and durable, the space between them is filled with a soft binder. To give the sheets additional strength and compensate for warping in plywood layers, veneer has different fiber directions in adjacent layers. Due to this, plywood is a rigid material that is difficult to bend.

Typically, plywood with an even number of veneer layers is used for bending, that is, it does not have a predominant fiber direction. Otherwise, you should calculate the direction of bending across the minimum number of longitudinal fibers, or vice versa - along, if the part is required to have increased strength.

The thinner the plywood, the easier it is to bend. Sheets with three layers bend easily across the grain of the outer layer even when cold

When the fibers are parallel to the fold line, they do not interfere with the curvature of the plane. However, layers located transversely experience significant loads. Typically, the fibers can stretch quite strongly; the conditions necessary for this are provided by their softening due to heating or moistening.

At the same time, layers located on the inner radius of bending experience compressive loads, which are not compensated by the elasticity of the material. If the bend is steep enough, folds may form on its inner side. Sometimes the stress in this area is high enough to cause delamination—rupture of the adhesive layer or even the fibers themselves. This characteristic behavior can be compensated for by a number of technical techniques, which are the focus of this article.

Video description

Laying plywood on a screed.

Installation on plank floors

Laying plywood over plank flooring is the easiest way. The sheets are fastened with ordinary self-tapping screws. If the wooden base is strong, then it will be enough to use sheets with a thickness of 3 mm.

When the boards are very old and rotten in places, they will definitely need to be replaced with new ones. If there are any mechanical defects on the surface, it is recommended to use thicker plywood products (at least 1 cm).

Plywood is laid on a dry and flat surface of a wooden floor, without the use of adhesives and mastics, unless required by base repairs Source green-ply.ru

More information about the material

Before bending plywood with your own hands, you need to familiarize yourself with such products in more detail. The product is a wood board obtained by gluing fragments of prepared veneer. To improve the strength properties, the fibers are positioned so that they are perpendicular to each other.

As for the number of layers, it may vary. Most often, sheets consist of an odd number of veneer layers. It is easiest to work with thin slabs, but their scope of application is limited to decorative functions. To construct arches or form volumetric structures of a round type, in any case, thick sheets will be required, which are quite problematic to bend.

Shaping PVC tube

To make it easy to bend or flatten a PVC pipe, it should be heated with a gas burner, then quickly given the required shape. As an exception, in the absence of a burner, it is permissible to heat the element of the future product on the fire of a gas stove. Cutting pipes can be done with a metal file or jigsaw; parts can be fastened conveniently using cold welding (a special adhesive will be required for this purpose).

From pipe elements you can make beautiful garden chairs with your own hands, the smoothness of whose lines can be envied. As already noted, this result is achieved by heating on a gas burner and then manually shaping the element into the desired shape. You just need to remember to let the PVC pipe cool after processing.

Features of the material

Plywood is a multi-layer board-type material. To make it, veneer sheets are used, which are laid crosswise and coated with a resin-based adhesive. The strength and durability of the material is ensured by the cross arrangement of veneers. This guarantees additional resistance to mechanical damage.

However, when it becomes necessary to bend the material, its strength becomes a disadvantage. But there are effective ways to bend plywood at home without damaging the material.

Peculiarities

Bending plywood requires heat and moisture. It is also possible to use the dry method of changing the shape of wood. These methods are applicable to plywood of various thicknesses, but it must be taken into account that the thicker the material, the more time it takes to obtain the desired result. The scope of application of bent plywood is quite wide - from construction work (making the base for arches, cladding spiral staircases, etc.) to the production of bent furniture.

Return to contents

Plywood selection

Since this material is produced by gluing thin wood layers that are located in different directions, the bending resistance increases. Therefore, for work you need to take thin plywood - it has fewer layers. In factories, it is bent on special machines, using it to obtain the desired matrix shape. The material is given the necessary elasticity by pre-treating it with steam.

Plywood bending diagram.

At home, when renovating an apartment, structures that have a rounded shape are often needed (for example, when constructing an arch). You can make them yourself from bent plywood. If the technology is followed, it is possible to obtain a high-quality product, despite the use of improvised means.

Plywood is sold at construction markets and in specialized supermarkets of the same profile. You need to choose a flexible material that is available with a thickness of 3-4 mm. It is usually used to create arches in doorways. After processing, a part made of such material is secured to the frame using screws. Recently, similar Chinese-made plywood has appeared on the market, which combines an affordable price and the required quality. There are several methods that are used to create bent structures:

- steaming;

- gluing;

- cuts;

- various combinations of the above methods.

Return to contents

Workpiece fastening

To ensure the stability of the resulting plywood shape, it must be secured. This work can be done in the following ways:

- a heavy object is placed at the bend site, the ends are tied together with a rope and supports are installed under them;

- the part is secured in the template using cord, tape or rope.

In the first case, everything is clear, but you will need to constantly monitor the structure, since the plywood may move slightly away from the desired angle when cooling. In the second case, in the form of a template, you can use any design with bending angles that need to be obtained on the newly created part. Most often, a homemade template made from fiberboard is used. If an arch is being made, then the steamed wood can be directly installed in place by clamping it in the opening with screws.

Plywood bent by gluing has the greatest strength.

You can use a steel template to secure the plywood. It is bent along with the wood. This technique is used for the manufacture of large parts with complex shapes. The steel strip is attached to the plywood before immersion in the bath begins. Then it is bent together with a sheet of material. This template is removed only after the plywood has completely dried.

When used to secure a load, you must try to ensure that it is equal in width to the sheet of material. If this is not the case, then only that part that is equal to the width of the load will be bent. Such methods are applicable only for plywood with a thickness of less than 2 cm. It is also necessary to take into account the fact that different types of wood have different bending (extension) abilities. Satisfactory results are obtained when using plywood made from walnut, ash and beech. It is not recommended to use sheets of larch, oak or maple material for such work. Typically, wood can be stretched by 1.5-2.5% and compressed by 25-33%.

Necessary equipment

The required fixtures and tools largely depend on which bending method has been chosen. In some cases you need:

- A template by which a form is given. How to level plywood? For straightening, a regular board with the required rigidity is often used.

- Device for clamping a workpiece.

When choosing a moistening method, you need a bath in which the workpiece will be soaked. In case of steaming, an airtight container is required. An electric tool, such as a grinder, is used to create grooves.

Making frequent cuts along the bend

If the question is how to bend thick plywood, then an effective way is to create numerous notches in the right place. To create the cuts you will need a cutter. With its help, special stripes are made in a certain area of the wood board.

When working, do not make deep cuts. They should reach a maximum of half the thickness of the sheet. The veneer layer located on the opposite side must not be damaged. Modern boats are often made from slabs rounded using this technology.

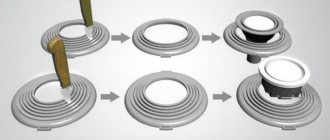

So, how to bend plywood by making cuts in it, step by step:

- Frequent incisions are made in a specific location.

- The workpiece is given the desired shape by fixing it in the required position.

- Thick veneer is glued using PVA or epoxy resin.

- After about 24 hours, the fasteners are removed.

The cuts are best placed on the inside. When gluing veneer over them, voids are formed. If the manufactured structure is used carelessly, cracks may appear.

Buy or make it yourself

There are many advantages of furniture (including stools) made by yourself. These include:

the ability to make a stool with a unique design. In furniture stores, the choice of models is limited, so you can only get a unique design that no one else has by making it yourself;

You can make truly unique stools

- saving money. When making a chair or other furniture, the material is chosen by the craftsman himself, so if plywood is used for this purpose, the finished product will be relatively inexpensive;

- gaining experience working with wood. Every day, template furniture is losing its popularity, and original designer products are gradually taking its place. Therefore, making chairs with your own hands is a unique opportunity to practice a new craft;

Design features of the stool

- ease of manufacture. For some people, the process of creating a stool from plywood may seem very complicated, but if you strictly follow the instructions and follow the recommendations, then even without special skills you can create a masterpiece in just a few hours;

- an opportunity to pleasantly surprise loved ones. Furniture made by yourself can be an excellent gift for a loved one. It is much more pleasant to receive such products, because they are made with your own hands.

Plywood stool - photo

Stools should match the style of the room

We work in cities of the Moscow region

- © 2004 – 2021 “PLYWOOD TRADE”

- Address: Moscow region, Mytishchi, Kropotkinsky proezd, vl. 1 page 7

- (Yaroslavskoe highway)

* Please note that this website (fanera-trade.ru) is for informational purposes only and under no circumstances constitutes a public offer as defined by the provisions of Article 437 of the Civil Code of the Russian Federation. For detailed information on the cost of plywood and other wood-based materials, please contact our managers by phone or E-mail. When using site materials in full or in part, a link to www.fanera-trade.ru is required. All rights reserved and protected by Russian law. We also inform you that our company does not sell plywood and other wood-based panel materials that are prohibited for trade in the Russian Federation. All our products are certified, tested and supplied with relevant documents.

Complex plywood structures

There are a large number of different plywood parts on sale that have complex shapes. The most common arches are for doorways. The soaking method is suitable for creating original designs of almost any complexity. In this case, you need to take into account:

- A template is prepared in advance.

- Fixation is carried out using special clamps. When clamping, it is necessary to eliminate the possibility of damage to the surface, since after soaking the surface becomes softer.

Despite the flexibility of plywood, not all complex shapes can be given to it. Too many transitions cause loss of strength.

Arches, portals

Various arches and generally complex-shaped openings are another typical application of bent plywood products.

Plywood arch in the opening leading to the loggia.

The main competitors of this material are drywall and plaster.

- Possibility of installation without a frame. For gypsum boards it is necessary, and assembling a frame for an arch of the correct shape sometimes turns out to be a very non-trivial task;

- Speed of installation against the background of plaster arches. Finishing the opening is possible immediately after installing the arch; if the opening is finished with plaster, you will have to pause for at least a week while the cement-sand mortar gains strength;

- Mechanical strength. It is relatively easy to damage both plaster and gypsum board, but not everyone can destroy the integrity of plywood 10–15 millimeters thick.

Method for gluing thin sheets

Before bending a thick sheet of plywood, you should consider using multiple boards. You can glue a number of fragments together, since bending them separately is much easier. However, when using low-quality glue, problems with delamination of the product may arise already at the initial stage of operation.

First, solid sheets are cut to obtain blanks of suitable sizes. All fragments are bent by hand and fixed to each other using epoxy glue. To avoid deformation changes, clamps must be used.

The final part is wiped off from the dried glue. Possible defects are removed from its surface. The last stage is sanding.

Furniture

A chair or armchair is usually a compromise between ergonomics (in other words, comfort) and practicality.

READ Plywood and chipboard - what's the difference?

Making chairs from wood and plywood | Part 1

A simple wooden or plywood seat is practically not dirty and can be easily washed if necessary. There will never be untidy stains from sauce or fat on it; Your cat probably won’t even think of sharpening its claws on a wooden seat.

The price of practicality is convenience: a horizontal flat seat and an equally flat back are quite tiring during long work or during a feast.

On the other hand, all types of soft furniture upholstery constantly suffer from all of the above troubles. Light furniture fabric darkens within just six months of active use; The presence of animals or children at home aggravates the picture.

Furniture made from bent plywood has the advantages of both solutions:

- The shape of the seat and back evenly distributes body weight over the maximum area, reducing fatigue from a static posture and without impairing blood circulation;

- At the same time, caring for such furniture remains extremely simple. It does not require re-upholstery; Removal of dirt is reduced to simple wiping using mild cleaning agents.

Let us clarify: over time, small scratches often appear on the varnish and polishing. A chair made of bent plywood can be easily polished with a felt wheel or defects can be removed by re-varnishing.

How to bend?

You can bend plywood to the desired degree to make a beautiful chair or headboard out of it using various methods. It is worth remembering that when choosing any of these methods, you cannot position the upper part of the veneer so that its fibers are across the intended bend, because this will most likely result in an unwanted break.

Using molds

This well-known technique is more often found in large production and involves the use of special expensive molds. They are first well heated by electric current or steam. Well-glued and neatly bent plywood is placed in them. It stays in the molds until the glue used dries, because it will subsequently firmly hold the bend of the material used.

At home, in order to professionally bend thin plywood sheets, you will need to use special equipment, which is not always possible, but then you can do something completely different:

- first you need to glue the slabs with ordinary wood glue;

- with your own hands you carefully bend the sheet;

- the bend is fixed at the edges with a good epoxy compound;

- All you have to do is wait until the product is completely dry.

This simplified method is very good, but the main disadvantage is the fact that in this case only thin plywood sheets can be bent. If you need to bend plywood of significant thickness, you will have to choose a different method.

To ensure that you end up with stylish and durable elements of the highest quality, you must take into account the following points:

- made parts cannot be stored in low humidity;

- Bending of steamed or heated elements in a special way must be carried out until they have cooled completely.

After the gluing procedure

If you need to bend a rather thick sheet for the headboard, you will have a hard time. First, the material must undergo special processing. This is necessary so that the plywood becomes softer - only then can you try to carefully bend it.

Special processing may include the following operations:

- in large industries, for such cases, a special industrial-type steam installation is used;

- If you need to do this process in your own home, then regular steam coming from a boiling kettle (for oversized parts) or from a household steam generator will do.

If the plywood parameters are really large, then before processing it is better to put the sheet in very hot water in order to give it the necessary elasticity. It is important here to prevent delamination of the sheet being processed.

In this case, you can use 3 methods available to any average person.

- You can leave the sheet in hot water for just 30 minutes, then carefully move it into the prepared hard workpiece. The material will have to be left there for exactly 7 days.

- You can generously moisten the workpiece with water, bend it slightly and iron it properly with a hot iron. Then wet it well again, bend it again and remove all the liquid from the surface. And you will have to do this until the very moment you get the desired shape.

- You can also heat the sheet to a certain state in a hot oven, but when choosing this method, you must be prepared for the fact that noticeable cracks may appear on the material.

Using cuts

If you need to bend an overly thick sheet of plywood as quickly as possible, then the most effective method is to create a large number of notches in a strictly defined place on the sheet. To make these cuts, you will need a cutter. The cuts should not be too deep. They can only reach half of the sheet. The veneer layer, which is located on the reverse side, must not be damaged.

Using templates

At home, this type of operation is carried out by performing a certain sequence of steps.

In the place where you need to get a bend, you should secure a small weight, and the edges of the plywood sheet (supports should be placed under them) will be tied together with a strong rope or strong tape.

The role of a template can well be played by all kinds of structures that have the desired angle of curvature and excellent strength. For example, you can use durable fiberboard sheets that are cut according to specified parameters.

When creating a part of a substantial size or a non-standard shape, it is best to choose a sheet of steel as a suitable template. Bending of the plywood sheet should be done simultaneously with the steel blank. It will be possible to separate the template from the plywood element only after the entire structure has dried thoroughly.

If your sheet of plywood has a thickness of 4 mm or 6 mm, as well as 10 mm, then it will have increased quality characteristics , since such plywood is created from tree species that grow in Asia, which means bending will be carried out with some difficulty.

Plywood is an excellent material that is great for both interior decoration of a home and for making stylish furniture. The low price and excellent qualities have turned it into a worthy rival to ordinary wood. A distinctive feature can be considered the fact that plywood has the ability to bend into all sorts of shapes, which ordinary wood cannot boast of.

For information on how to bend plywood, see below.

Video description

DIY wood putty.

Preparing plywood for puttying

It’s easy to prepare a concrete surface for puttying: clean it of debris, widen all the cracks, remove dust, apply a primer, and dry it. Proper preparation of a wood floor is much more difficult.

Sequencing:

- Soak the base well with drying oil. The liquid should be heated to 60° C, then applied with a brush or roller.

- Dry the treated surface with a hair dryer.

- Repeat the procedure several times.

To check the floor's readiness for applying putty, you need to spill a little water on it. If it begins to form drops, the treatment can be completed. It is important to pay special attention to the outer parts of the material. Otherwise, if moisture penetrates, they will become ruffled and eventually delaminate.

Advice! A water-repellent effect can also be obtained by impregnating plywood sheets with PVA glue.

Drying oil applied to plywood penetrates deeply into the structure of the material and forms a water-repellent film Source stroy-podskazka.ru

Padding

Plywood laid on the floor must be primed. Unlike impregnations aimed at preventing rotting, soil helps improve the quality of putty. After application, it significantly increases the adhesive properties of the surface. In addition, the primer prevents excessive penetration of putty compounds into the wood.

Priming must be carried out only with specialized products intended for finishing wood. Such compositions necessarily contain antiseptic components. They are applied with a roller or brush. The drying time of the surface depends on the external temperature and the level of humidity inside the room. It usually takes up to six hours to dry the treated base.

Attention! You can putty a plywood floor only after the soil has completely dried.

Before you putty the plywood, it must be cleaned of any contaminants and primed Source dekorator-s.ru

Puttying

Putty is applied to plywood panels in the same way as on a concrete base. To do this you will need the following tools: a spatula, a rule. It is important to pay special attention to the joints. The optimal thickness of the putty layer is 2-3 mm.

If any particles remain on the base after the material has dried, they must be removed with sandpaper. But such problems can be prevented by first passing the solution through a nylon or fine sieve. When the surface is completely dry, further finishing is allowed.

Applying putty to plywood is carried out according to the same principle as to concrete or brick Source stroiremdoma.ru

Bending according to templates

In the simplest case, the role of a template can be played by pieces of hard plywood shaped like a bending profile. Since most parts are bent along the same contour on both sides, the templates are made in pairs and then fastened together with spacers slightly smaller than the width of the part. Templates can also be different if it is necessary to bend a part of an irregular shape, that is, curved along two axes.

Another type of template is a frame made of beams that does not form an exact bending contour. In this case, the transverse bars are placed at the pressure points, that is, on the most protruding and concave parts of the part profile. For fastening at intermediate points, you can add an arbitrary number of jumpers to the frame.

When making the frame, you need to take into account the type of clamping devices used. Thus, plywood inserts can have holes for clamp jaws, and the frame itself can be equipped with additional stiffening ribs in the direction of pressure and tensile loads. If the part has a uniform bend along its entire length, it can be fixed without a frame, for example, tied with a rope, cable, chain with a screw tow bar, or using sling belts.

Collapsible stool

A famous designer from Amsterdam has designed a unique stool design that can be disassembled if desired. The product is easy to manufacture, transport and assemble. In addition, the finished stool looks very stylish. To work, you only need one material - plywood. Next, you just need to follow the step-by-step instructions.

Step 1. Make marks on a sheet of plywood and cut out such parts. The triangles that serve as legs can be larger, but their sizes must be the same. Once all the elements have been cut out with a jigsaw, the cut areas must be treated with sandpaper.

Design details cut out

Step 2. Connect the plywood legs together by inserting the elements into the grooves. They must create one strong structure. There is no need to use wood glue here.

Connection of stool legs

Step 3. Check the reliability of the resulting structure. If everything is done correctly and the grooves are cut to the required dimensions, then the connected lower parts of the stool should be tightly fixed.

Checking the reliability of the design

Step 4. Attach the seat and, turning the stool upside down, install the lower part of the structure. It should be made in the shape of a triangle.

The lower part of the stool is in the form of a triangle

Step 5. Screw the triangular piece using self-tapping screws. To make the task easier, make holes in the top of the product using a drill.

The part is screwed on with self-tapping screws

Step 6. This is what the finished collapsible stool should look like. Its dimensions can be adjusted to suit you, but this is done at the design stage.

Ready-made collapsible stool

Step 7: Paint the stool some color. It is advisable that this color be combined with the interior of the room. Once the paint has dried, the stool can be used for its intended purpose. If necessary, it can be easily disassembled.

Stools after painting

Some nuances

The above information makes it clear how to bend plywood in different ways. To achieve the best result, it is advisable to familiarize yourself with some subtleties:

- when soaking, it is allowed to bend the slabs only at elevated temperatures, otherwise cracks may appear;

- elements that will be given a curved shape should be stored in rooms with a stable level of humidity;

- If the purchased material is expensive, you can use the services of specialized companies.

Before bending plywood 10 mm or more, you need to decide on the method to be used. The option should be selected depending on the angle of the break. As for products of smaller thickness, they are bent only by soaking with water or steam.

Why do you need to level the floor?

Alas, many modern coatings are very capricious to the base of the floor, which is why in many repair work, leveling the floor has already become a mandatory preparatory step.

Parquet or laminate do not tolerate uneven floors well, since these coatings are joined by a lock. If a floor covering of this type is placed on an uneven floor, the lock will soon lose its strength and a crack will appear in the place of the lock, into which water and dirt will enter. The crack will grow over time and produce even greater deformation of the floor.

About choosing a method

The choice of method depends on the characteristics of the future product. They are as follows:

- The bending radius across is much smaller than along. The product can be bent or rounded at different radii; as it increases, the strength decreases.

- The part that has been bent should be stored in a dry room with low humidity. If this condition is not observed, the product may lose its shape.

- When choosing the steaming method, the shape is transferred to the workpiece before cooling. In this case, it is much more difficult to straighten the part. Alignment is associated with returning the structure to its original state. If the bending was carried out in violation of the technology, then the veneer distribution alternated incorrectly.

Even minor defects can cause the part to fail to bend; if force is applied, it may burst. Products can be bent from plywood according to a template, for which the home workbench is equipped with special clamps.

Each layer has its own approach

In a workshop, everything is, of course, simpler.

In fact, of course, the solution to the question of how to bend plywood is not calculated with precision down to the layer, but there is still a certain amount of truth in the title of the chapter. Let us explain: there are a number of difficulties when bending plywood, which are associated specifically with the structure of the material, as well as with the technological features of the bending process.

Namely:

- The thinner the plywood, the easier it is to work with. However, for the sake of objectivity, we must also take into account the fact that to construct, for example, arches, the plywood must be at least 10 mm thick, that is, you already need to bend a fairly serious puff (see also the article Do-it-yourself plywood arch - basic techniques) ;

- Initially, the veneer layers are located at different angles to each other precisely in order to increase the material’s resistance to bending;

- In workshops and special workshops, bending and the required curvature are achieved quite simply: the part is practically saturated with steam and then comes under the influence of a kind of vice, which bends it to the required radius of curvature.

All this is real, but there are two points that need to be taken into account:

- First, wood cools very quickly, this equally applies to plywood;

- Secondly, it is very difficult to achieve uniform heating of the entire part, so this type is suitable for small fragments with curves, most likely for the production of curved surfaces of furniture or other small products.

How to bend

The bend depends on the purpose of the fragment.

So, how to bend plywood without unnecessary hassle?

There are two main technologies:

- Ferry, (which has already been described);

- In the bathroom with hot water.

The second technology is much simpler; it allows you to calmly place the required fragment in a bathtub or other sufficiently large container and leave it in hot water for half an hour. The effect will be guaranteed, since the wood veneer softens under the influence of water and temperature, and the plywood part acquires the necessary elasticity.

Take a strip of plywood of the required thickness and soak it in the bathtub. Check the condition of the fragment every 5 minutes for bending; if after a certain time (within half an hour) the fragment bends normally, then this time is enough to soak the entire working fragment.

The softened part can be installed in a stationary place, attached with self-tapping screws and left until completely dry, this is if you are making a false column, a simple arch or other part that does not require additional complex structural inserts.

A few words about complex structures

Bending is a delicate matter.

Arch is different from arch, just like a curved design is different from another curved design. Often, home craftsmen resort to complex, combined solutions using overlay ornaments and other decorative elements. In this case, the entire structure is assembled into a single ensemble, and only then it is mounted and strengthened in a permanent place.

The material is soaked, bent as far as possible, then left to dry completely. Then everything is repeated again until the part acquires the intended curvature.

Attaching to templates.

There are several basic technologies for securing workpieces after soaking.

We will not repeat them all; we will focus only on the one that we consider the most acceptable for the following reasons:

- If you do not install the workpiece immediately in a stationary place, then you need an accurate, even bend and a combined solution;

- The maximum winning result can only be ensured by a pre-prepared blank or template;

- Fixing on the template is guaranteed to save you from the need to redo or correct the part.

In this case, we are talking specifically about fixing the fragment on the template until it dries completely. Making the template itself is quite simple; by the way, there are also a lot of manufacturing options.

Here is one of them:

- Take wooden slats with a length equal to the length of the part;

- Cut out several fragments from chipboard or wood (from 3 or more, depending on the length of the plywood sheet to be bent) and attach them to the slats;

- Attach the plywood layer to the finished frame with self-tapping screws and leave until completely dry.

About working with large sheets

Option with cuts.

Sometimes it becomes necessary to bend a large sheet of plywood with your own hands. This occurs when designing an arched vault of considerable length or another similar shape.

In this case, do the following:

Photo gallery

Original bent plywood parts for furniture, see a small photo gallery