Stoves and fireplaces have different designs. All home fires have a firebox, where organic raw materials are burned, and a chimney. Depressurization of any area is dangerous due to the possibility of carbon monoxide entering the room.

Carbon monoxide is often the cause of poisoning in residents because it is odorless and colorless. It is impossible to feel an increase in gas concentration. The integrity of the stove and chimney should be carefully checked; control traction in the system.

If cracks appear in the pipe or where it meets the roof, sparks and a heated flow of gases can enter them. This poses a risk of fire.

In addition to all the risks, due to depressurization, the efficiency of furnaces is significantly reduced. Part of the energy released during combustion evaporates uncontrollably into space.

Some modern chimneys are made from ceramic or metal fragments. Sandwich structures for removing smoke from stoves are gaining popularity.

When installing chimneys, it is necessary to ensure a monolithic connection of all components, preventing the leakage of hot fuel combustion products. You can gain confidence in the safety of using stoves and fireplaces only by correctly using fireproof sealant during initial installation and repair.

Removing joints in brickwork

An unsealed seam is often hidden behind the facade of any built house. The reason for this is the poor quality work of the builders. After all, when laying bricks, cement mortar should be applied to the entire surface of the masonry, and not in pieces, as unscrupulous workers do.

The plaster may partially fly off over time, and an empty seam will appear. It looks just terrible. The void between the seams in the masonry can eventually lead to the destruction of the latter. Brick laying should be treated well at the initial stage of construction to avoid such problems, but often sealing seams is not uncommon.

If the damaged wall is minimally destroyed and there are few such seams, then this can be easily and quickly eliminated. To do this, you need to have a screwdriver or chisel on hand.

The seam is cleaned of old mortar using a brush or screwdriver.

Using these tools, you need to carefully remove the remains of the old mortar from the seams of the brickwork and under no circumstances push it back; absolutely nothing should remain in the seams. Then you need to moisten the brick with water, because dry material absorbs a lot of liquid from the solution. After these steps, you can safely begin filling the joints in the brick walls with fresh cement mortar. It should be mixed dryer so that there is as little water as possible, this is done to avoid cement leakage.

The first step is to cover the vertical seam, and then the horizontal one. The seams must be sealed until they are completely filled. The finished solution should adhere well both inside and outside the masonry. For the inside of the joints, the cement mortar may be wetter than for the outside.

Practical advice

Knowledge of the nuances and experience of professionals will help you avoid mistakes and improve quality:

- Be sure to sift the sand. There should be no large fractions in the grout mixture.

- A fresh batch should sit. Let the solution sit for at least 20 minutes.

- When filling the seam, try not to get the solution on the surface of the masonry.

- When laying on the front side, leave gaps to decorate the seam.

- A concave seam can be made by filling the vertical and horizontal at the same time.

- It is better to remove the remaining solution immediately.

- Correct any unevenness/mistakes immediately while the solution is damp; this will not be possible after it has hardened.

- It is better to work on a cloudy, dry day.

- You can make the jointing yourself from an old knife or any metal object.

Start filling the seams from the vertical gaps

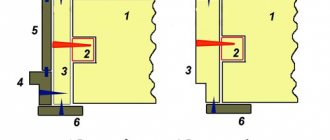

What to do if there are cracks around the casting

Due to the large difference in the magnitude of the temperature expansion of metal and brick, cracks often form at the junction. To avoid them, during installation, recesses are made in the brick, which allow the metal to expand when heated without destroying the masonry (the recesses are 3-5 mm larger than the casting shelf). To soften the impact, the casting is wrapped in thermal insulation material. Previously, they used asbestos cord or cardboard, but now they often use mineral wool cardboard cut into strips or a special sealing cord (asbestos is harmful). When choosing cardboard, pay attention that it must withstand temperatures of 800°C and above.

If cracks do appear, they are repaired as described above - using a solution with the addition of fireclay. But if the damage is such that the door wobbles, as do the bricks above it, if the design allows, it is better to disassemble and reattach everything, tighten the fastening wire and re-wrap the casting with heat-insulating material.

Available Blends

For grouting, ready-made products consisting of epoxy resin or a cement base are used. Cement-based mixtures are more in demand, are easy to use, can be easily cleaned from the surface, and have an affordable price. Manufacturers place instructions on the packaging with clear proportions for diluting the mixture. Usually this is water, but there are more advanced building materials that are mixed with latex.

Long lasting grout

The classic composition includes the following components:

- Dyes.

- High-quality types of cement.

- Quartz sand.

- Universal additives to speed up drying.

- Plasticizers.

The color range of cement grouts is varied.

Decorative grout

Epoxy products are used in places with increased mechanical loads, in conditions where exposure to aggressive environments is possible. In terms of durability, epoxy mixtures are significantly superior to cement ones.

Application of a construction mixer

How to properly caulk a stove

The experience of repairing furnaces has a long history. Each area has its own characteristics of work. The tools you will need are a trowel and a grater (a grater, as a rule). Some people finish trimming the plaster directly with their hands. In general, the main stages of work are the same:

- First, the surface of the stove must be thoroughly cleaned and swept;

- then it is advisable to heat it; existing cracks can be sprinkled with water to moisten;

- after which a thin layer of putty should be applied. The main thing is not to overdo it;

- after the smeared layer has dried, if necessary, large cracks can be strengthened with reinforcement with a special mesh;

- then the surface is covered with plaster. It is advisable to do this in two stages, each time applying a layer up to 5 mm thick.

If the stove is covered with decorative finishing, then the coating is removed before covering the cracks. If necessary, the doors are reinforced with wire. Special adhesive compositions are prepared in small portions, since they can harden strongly.

Ultimately, by spending a little money, you can get rid of defects on the stove surface. The result will please the appearance and ensure safety for the home owners.

Jointing technology during construction

In this case, the seams are processed immediately after laying several brick lines. The starting point for work is the beginning of hardening of the composition. The composition itself must retain its plasticity.

It is important to follow the following sequence:

- When laying this material, the entire composition that protrudes outwards is cut off flush with the laid masonry. Such pruning significantly increases the rate of jointing. An example of this is shown in the figure below:

Pruning

- The wall surface is thoroughly cleaned. The working tool is a stiff fleecy brush.

- Sewing vertical seams. The tool moves from top to bottom and is pressed into the masonry. Air is removed from the composition by pressure. The density and strength of the composition develops. First of all, short seams are unstitched vertically.

- To make the seams horizontally even, a wooden strip is attached to their underside. You should lean on it and guide it along the masonry line. Uniform pressure here will create a pleasant aesthetic finish.

- Filling seams vertically. Then - horizontally. Movement on the working surface: from top to bottom.

- When the composition has completely set, the elements of the jointing mixture are removed from the wall. A broom or brush is used here.

Methods of applying grout

The following methods can be distinguished for applying grout material to the seams between tiles:

Semi-dry method

When applying grout using this method, the mixture is diluted with a small amount of water. The result is a consistency that resembles wet sand. Using a special jointer, the mixture must be placed in the seam.

The advantages of this application method:

- low cost of the product;

- There are no substances among the components that provide plasticity.

Disadvantages of this grout:

- a seam that is less than 5 mm cannot be sealed;

- the color palette is limited only to gray and beige;

- the installer must have experience in sealing seams using this method, otherwise the design will be of poor quality or unaesthetic.

Using a construction gun

The grout is diluted with water and poured into a special construction tool - a gun. All seams are coated with a thin tip, and excess product is removed. To fill the joint more tightly, you can process the line by pressing the grout in with your finger or some other tool.

- simplicity and ease of application of the composition;

- You can choose the desired grout color.

- high price of the composition;

- you need a special tool;

- Among the components are plasticizers.

Applying the composition over the entire cladding area

The creamy mixture is applied over the entire surface of the tile, then cleaned off with a rubber spatula, leaving the mixture in the joints. The grout for the oven joints is removed from the tiles using a damp sponge.

- long-term operation;

- You can use any type of tile.

- high price;

- small palette of colors.

What types of efflorescence impregnations are there?

Water-repellent impregnation consists of water, a binder and mineral pigments. Products are divided into different types depending on the properties and type of surface for which they are intended, among them:

- One-component acrylic. Designed to seal bricks, protect against efflorescence and precipitation. They have a high drying rate.

- Silicone two-component water-based. Prevents the proliferation of fungi and other microorganisms. Colorless, can be coated with paint. Suitable for treating walls made of silicate material.

- Varnish. Made on the basis of a special varnish that gives the surface a glossy shine.

- Water-repellent water repellents. They have high insulating and antimicrobial properties. They process red and sand-lime bricks.

Solution

Bricks are usually held together with cement-sand mortar. You can make it yourself, but experienced builders strongly recommend purchasing ready-made compounds in which all proportions are carefully observed and special additives are present that increase adhesion, frost resistance, etc. Consistency is also very important. Too liquid a mass will flow into the voids of the brick, and this is not only inconvenient, but also uneconomical. Thick ones are very difficult to evenly distribute and level.

You can determine the mobility of the solution by lowering the so-called standard cone onto it and observing how deeply it sinks (on average from 7 to 14 cm). For hollow bricks, you need a mixture with a mobility of no more than 7-8 cm of cone draft, and for solid bricks - about 12-14 cm.

Required tools and materials

Before you start jointing the brickwork, you should prepare the following tools and materials:

- brushes - with hard bristles and wire;

- hammer;

- a stitching tool, which can be used as a finished factory product or home-made devices;

- a flat wooden strip with a length of at least 1 m;

- roller or soft brush to wet the surface.

If you plan to restore an old wall, you will additionally need:

- a hammer drill, a wooden wedge or a narrow chisel with the width of the working part slightly less than the thickness of the seam;

- a special mixer designed for mixing the solution;

- container for preparing cement-sand mixture;

- trowel or trowel.

In addition, you will need cement, sand, lime and water in the required quantities.

Facade repair

If there are few defective areas, then they are not difficult to repair with fresh cement mortar. Repairs begin with preparation: using improvised means (screwdriver, chisel, etc.) you should remove all remnants of the dried mortar. Under no circumstances push the chipped pieces deeper. The brick wall is moistened with water so that it does not absorb it from the applied mortar. After this, you can begin to carefully fill the space between the bricks with cement mortar.

The consistency of the solution should be thick so that it does not leak. To do this, add water carefully during the cooking process, controlling the resulting mass. The first step is to seal the vertical seams, and then the horizontal ones. They are sealed as tightly and flush as possible. In all areas there should be good adhesion to the existing masonry.

The solution that is located at the outer surface should contain less water than the one that fills the seam in the depths of the masonry.

Unstitch the seam in the same way as other sections of the wall so that there are no visible differences. For this purpose, not only a trowel, but also cuttings of a hose will do. When the repair comes to an end, excess mortar and other inclusions are removed from the brick wall. After drying, the influx of cement mortar is mechanically removed.

Safety precautions

You should not grout in hot weather, because the mortar mixture dries out much faster. Craftsmen recommend waiting out rainy weather so that the solution does not absorb a lot of moisture.

Carrying out such work requires the use of protective equipment - helmet, goggles, gloves, overalls and a respirator. Before working on scaffolding, you should study the safety requirements for high-rise repairs.

It is prohibited to hang yourself on a wall or lean on freshly laid brickwork, work on random supports, or leave tools unattended.

What requires more attention: a stove in the country, a wood-burning stove in the countryside, or a sauna stove?

Furnaces in which coal and brown coal are burned .

A few years after construction, repairs are required for bathhouse and country stoves. Heating appliances in which tin bread, loaves and pizza are baked .

Italian Pompeii ovens are built in many countries. Pizza baked in such facilities has a special taste and smell. This oven is usually built outdoors. Food is cooked under a brick vault, under the influence of fire and the heat of heated bricks. There are two types of Pompeii ovens - Neapolitan (with a low arch, intended mainly for baking pizza) and Tuscan (with a high arch, which allows you to put a pot or pan inside and cook not only pizza, baked meat and fish, but also soups).

Average cost of work in the Russian Federation

The price for repairing defects is influenced by the complexity of the work, the area of preliminary cleaning of debris, as well as the technology used by the craftsmen.

For example, in Moscow they will charge from 500 rubles per square for surface preparation , and from 350 rubles for the jointing itself. In total, for a complete renovation you will have to pay from 850 rubles for 1 square of brickwork.

If you are interested in the issue of repair and restoration of brickwork, take a look at this section.

Calculation of the amount of primer

Quantitative calculation of the primer composition is a material indicator as part of the costs of finishing work. There are no uniform reference standards, since when determining consumption it is necessary to take into account the condition of the surface, the number of layers of application of the composition, and the type of finishing material.

The average figures per 1 square meter in one layer are indicated by the manufacturer and they are approximately as follows:

- acrylic primer – 130 -150 g/m2;

- water-dispersed soil – 100 g/m2;

- deep penetration soils – 180 g/m2.

When calculating, it would be correct to increase the total amount of composition by 10%. This is explained by the fact that there may be corners and protrusions on the surface that have to be primed with a slight excess of material.

So, when calculating the amount of soil, you need to: measure the surface area, multiply this figure by the average consumption, then multiply by the number of layers and add 10% of the resulting value. This will determine the total amount of primer.

Coating features

The principle of working with varnishes is similar to painting. First of all, you need to prepare the surface to be treated. The walls must be cleaned of dirt and dust, cracks filled with putty, growths cut down, and recesses filled with plaster or putty. If the facade was previously painted, the paint should be completely removed.

Leveled walls must be sanded with coarse sandpaper and then washed. A household detergent will work for this. After drying, a re-inspection is carried out. Identified deficiencies are eliminated. A dry, clean surface is primed. It is advisable to use primer and varnish from the same manufacturer.

Application is carried out in several ways: brush, roller or spray. In the latter case, the mixture (if it is not in an aerosol can) must be mixed with a solvent to reduce the density. If this is not done, the spray gun will not cope with heavy varnish.

Varnishing begins from one of the upper corners, gradually moving down. On large areas it is convenient to work with a 20 mm long pile roller. Small elements are treated with a brush with natural hard bristles. Adjacent strokes should be applied with an overlap of several millimeters. The varnish is applied in two layers or more. Each subsequent layer is applied after the previous one has completely dried (absorbed).

Caring for the varnish coating consists of treating it with a mild detergent twice a year.

See below for more details.