Often, choosing heating for a private home confuses people. Dazzling advertising promises reliability, cheapness and comfort at the same time. In most cases, painfully familiar and outdated heating systems are served under this sauce: gas, diesel, electric. Nothing new except the wrapper! But the future has already arrived and all this has a worthy alternative.

Technological Electrolux inverter convectors, produced by one of the leaders in this field, serve as the basis for creating an inexpensive and, most importantly, highly efficient heating system. The inverter system has a number of undeniable advantages compared to heating with an electric boiler with water radiators.

Inverter heating system based on Electrolux convectors with digital INVERTER control unit and WiFi module

Advantages and disadvantages

Let's start with the advantages, and there is a lot to list here.

Cost-effectiveness is the most important advantage. When the temperature reaches a certain or specified limit, the device switches to a mode with lower power consumption

It will remain quite comfortable in a heated place. There is no need to use the device frequently, and it does not waste much electricity. When compared with analogues, the level of operation and efficiency of this device is higher than that of other home heating units.

Practicality is first and foremost convenience. Even in low temperature conditions in a heated room, the heater will continue to operate at lower power. Environmental friendliness along with safety. No fuel combustion occurs.

During operation, the noise emitted is minimal, which ensures special comfort. High efficiency.

After the advantages, we can also mention the disadvantages.

- High price. For so many benefits you need to pay a lot of money.

- Weak resistance to network fluctuations. In case of any decline, you will need to adjust the temperature and the device itself again.

- Expensive repairs. Since these units themselves are expensive, it is also not easy to find the necessary good quality parts for them. This can take a lot of time and money. Repair work may take several weeks and will not be cheap.

- Inability to start the compressor at temperatures below -10 and above +42 degrees.

Distinctive feature

The inverter heating system consists of convectors connected by a single control. A convector is an electric heater whose operating principle is based on convection, that is, heating and mixing hot and cold air masses.

When heating with electricity, all electrical energy is converted into heat. Therefore, every extra degree means additional energy costs. Extra degrees occur when the operation of the device is controlled by a conventional thermostat. Such a convector first overheats the air by several degrees above the set value, wasting more energy, then turns off, giving time for the temperature to drop by several degrees. A new heating cycle follows, and so on. In such cycles, excess electricity is wasted and the electronics of the device wear out faster.

Control unit with digital INVERTER technology

A convector with an inverter control unit and a highly sensitive temperature sensor does not have this drawback. To maintain the set temperature, the heating element of the inverter convector does not need to be constantly turned on, using maximum power, and then turned off to cool. The inverter control unit smoothly reduces the power of the heating element as the current temperature approaches the set one and then works to accurately maintain the temperature with a constant minimum electricity consumption.

If we compare inverter heating with a boiler, then the system based on an electric boiler and radiators is much more inert, it reacts more slowly to changes in internal temperature and therefore consumes more electricity than is necessary to maintain a comfortable temperature.

Analysis of the arguments "for" and "against"

Let's start with the cons. In addition to the material consumption, which affects the cost of the project, there is the need to install a manifold cabinet, which will require additional space.

This is where the disadvantages of the beam system end, and a series of advantages begin:

- simple design and installation, the system uses pipes of the same diameter;

- with hidden installation there are no connections in the walls and floor;

- high installation speed due to the minimum number of connections;

- expansion of functionality due to the installation of shut-off valves, sensors, air vents and thermal heads to automate the operation of the heating system;

- temperature control in each individual room using mechanical elements or automation;

- the ability to cut off any radiator without stopping the heating process;

- uniform heating of all rooms.

The external control panel allows you to program the heating operation, including automatic adjustment depending on the weather conditions outside. Thanks to the installed sensors, all residents can set any parameters that are comfortable for them while in a specific room.

The radiant system is materially expensive in terms of implementation, but is ahead of all other options in flexibility of settings and ensuring the efficiency of all heating

Thus, the radial wiring diagram makes it possible to achieve high controllability of the heating system and achieve optimal coolant flow.

Microclimate in the house

A heating system based on inverter convectors makes it easy to control the home microclimate. Often it makes no sense to maintain the same temperature in all rooms. It makes more sense to divide the house into separate zones. For example, in the bathroom it can be 25 degrees, in the living room and bedroom 22˚C, and in utility rooms 18˚C is enough. This effect can be achieved in several ways.

- Through a special HOMMYN mobile application and additional WiFi modules installed in the control unit. The application allows you to combine devices into zones, set the temperature and operating mode of the devices for each zone at once.

- Using Electrolux smart thermostats. A thermostat with a built-in temperature sensor controls the convectors combined into a common zone. Thermostats allow you to maintain the set temperature as accurately as possible and quickly respond to its changes; increase energy efficiency and minimize energy costs. In this case, you can control the heating system both through the application and directly from the thermostat. Smart thermostats stably control convectors even in the absence of an external Internet connection.

- Special remote control for centralized climate control HOMMYN. This device controls the operation of all convectors and thermostats of the system, continuously calculates the energy consumption required to consistently maintain a comfortable temperature. In addition, the central console increases energy efficiency and reduces energy consumption. And the remote control also makes it possible to flexibly configure the heating operation according to the calendar, and ensures stable communication with system devices even in the absence of an Internet connection. Situations often arise when there is not enough electrical power allocated to the house. In this case, the remote control can limit the power consumed by heating and configure cascade switching on/off of convectors. This will prevent them from operating simultaneously and will not create a peak load on the power grid that exceeds the permissible load.

- Commercial facilities and large homes are best managed by a specialized system based on the HOMMYN Professional controller. The controller supports power limitation and distribution technology and can be integrated into a building automation system (MODBUS protocol).

Distribution of convectors by zones

Principle of operation

Inverter heaters operate on a very simple principle, which is to convert direct current into alternating current, thereby changing the frequency and voltage. The operation of an inverter is very similar to that of an air conditioner. The main structural element is a pump, consisting of internal and external blocks. The internal one contains a heat exchanger in which freon accumulates under the influence of high pressure. Its temperature can reach up to 80°C.

Freon is a liquid substance circulating through a heat exchanger

The accumulated substance is then sent to the external unit, where the pressure is much lower. It is at this point that freon is converted from a liquid state to a gaseous state. As a result, a large amount of heat is released.

The inverter can control the heating process automatically. This means that if the set room temperature is reached, the system does not turn off, but simply switches to a lower power level. Thanks to this ability, the room always maintains the optimal temperature. The main feature of such heaters is minimal energy consumption, and the fact that they do not need to be constantly turned on and off.

Simple and accessible information about the types of voltage converters

The type of inverter is the main criterion when choosing, which you need to decide on first. Each type has certain properties, operating algorithm and characteristics.

Off-line

Off-line inverters are also called backup inverters; they have the simplest design and operating algorithm:

- At normal voltage in the electrical network, the inverter is inactive, and the boiler operates in normal mode, exclusively from the electrical network.

- As soon as the voltage in the electrical network drops below a critical level (usually 175-190 V) or disappears altogether, the inverter instantly switches the power to the boiler to the battery connected to the converter. The switching occurs imperceptibly, in modern models it takes 4-8 ms, which is enough for the uninterrupted operation of the boiler unit.

- As soon as the voltage in the electrical network is restored, the inverter switches power to the main network and goes into standby mode.

We recommend: Antifreeze for heating: selection and features of antifreeze liquid warm home

Also, most devices are designed for overvoltage, usually they operate at values above 260-300 V. Off-line inverters are the simplest and most inexpensive, their prices start from 4 thousand. rub.

However, it is better not to use them if the power supply voltage fluctuates too often or constantly. With such instability, the converter switches from the main power source to the backup one too often, which leads to very rapid wear of the batteries.

Line-interactive

Line-interactive voltage converters are the most optimal and universal for a modern heating boiler. In addition to the converter and switching relay, as in Off-line devices, linear-interactive models use a voltage stabilizer.

In standard mode, the boiler still consumes electricity from the main network, but the voltage is equalized by a built-in stabilizer; some more technologically advanced models are equipped with additional filters that smooth out noise, eliminate interference in the network, etc. With this type of operation, the battery is used less frequently and the energy efficiency (efficiency) is much higher.

Linear-interactive models often have a built-in battery that can ensure the boiler operates for 20-120 minutes, while it is also possible to connect external additional batteries that can extend autonomy to several days.

A Line-interactive inverter will always be sufficient for any gas, solid fuel or low-power electric boiler. However, such equipment also has disadvantages - poor smoothing of the sinusoid during interference, disruption of its uniformity during deep drawdowns or drops (switching time of 4-6 ms does not protect overly sensitive modules).

On-line

The most technologically advanced and expensive double conversion inverters. A simplified operating algorithm looks like this:

- At the input, the inverter converts the alternating voltage of the electrical network into a constant voltage of 12 V.

- At the output, the inverter converts 12 V to 220 V with a perfectly pure sine wave with a frequency of 50 Hz.

The batteries in such a device act as a buffer capacity necessary to equalize the current parameters. The advantage of the technology is that the boiler does not contact the electrical network directly and, at any current parameters in the network, receives an ideal, pure sine wave produced by the inverter. However, due to double conversion, the efficiency of such equipment is lower, up to 90%.

Advantages of using polypropylene in heating systems

There are many such advantages:

- Easy installation. As already mentioned, even one person with a soldering iron can handle it, while installing steel pipes will require a welder.

- Heating with plastic pipes will cost you several times less.

- This material is not subject to corrosion, so it can last up to fifty years.

- Its use has a positive effect on the heat transfer of the system.

- Such pipes do not “overgrow”, that is, salts are not deposited on their inner surface.

- Finally, polypropylene, although flexible, is also very strong, so it can be used under high pressure or temperature.

Video on pipe selection

https://youtube.com/watch?v=fKf2kG7gHvw

All this contributes to the fact that heating systems using polypropylene pipes are becoming more common today.

What pipes should be used for heating systems?

When choosing polypropylene pipes, you need to compare the operating features of your future heating with the conditions under which this or that material can be used. For heating systems, it is advisable to use the following types of pipes:

- PN25.

- PN20.

The fact is that they perfectly tolerate a coolant temperature of ninety degrees, and for some time (albeit limited) they can withstand an unexpected jump to one hundred degrees. Such pipes should be used under conditions where the pressure does not exceed 25 and 20 atmospheres, respectively. But if you choose between these options, then, of course, for heating systems it is better to choose a PN25 reinforced pipe.

Benefit and safety

It is worth highlighting the high reliability, durability and unpretentiousness of the inverter system. Convectors have a high class of dust and moisture protection, which makes it possible to use the equipment in damp rooms. Inverter convectors have passed all the necessary tests and have a fire safety certificate from the Ministry of Emergency Situations.

An analysis of the Electrolux inverter system showed that its use, including installation, is more profitable and cheaper than the operation of electric boilers. An important factor is flexibility - individual modules can easily form a system that will be adapted to a specific living space; if necessary, the house can be divided into zones and controlled, including using power limiting technology.

Heating system made of polypropylene pipes

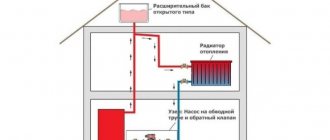

The technical characteristics of the object and the amount of allocated funds affect the heating installation scheme. In apartments in multi-storey buildings it is connected to the Central Heating Network, and in private houses - with an individual boiler. Regardless of the type of object, the system can have one of three designs.

Single-pipe

The system is characterized by simple installation and quantity of materials. It uses one pipe for supply and return, which reduces the number of fittings and fasteners.

It represents one closed circuit with alternating vertical or horizontal placement of radiators. The second type is used specifically in private homes.

As the coolant passes through each radiator, its temperature decreases. Therefore, a single-pipe circuit is not able to heat the entire object evenly. There is also the difficulty of temperature control, since the heat loss factor is not taken into account.

If the radiators are not connected through valves, then when one battery is repaired, the heat supply is stopped throughout the entire facility. When installing such a network in a private house, an expansion tank is connected. It allows you to compensate for changes in pressure in the system.

A single-pipe circuit allows the installation of radiators with temperature controllers and thermostatic valves that allow for the correction of heat loss. Ball valves, valves and bypasses are also installed for repairing individual sections of the thermal circuit.

Two-pipe

The system consists of two circuits. One of them is for serving, and the second is for returning. Therefore, a larger number of pipes, shut-off valves, fittings, and consumables are installed. This increases installation time and budget.

The advantages of a 2-pipe network include:

- Uniform heat distribution throughout the entire facility.

- Minimal pressure loss.

- Possibility of installing a low power pump. Therefore, coolant circulation can occur by gravity.

- Repairing an individual radiator is possible without shutting down the entire system.

A 2-pipe system uses a passing or dead-end coolant flow pattern. In the first case, it is allowed to install batteries with the same heat output or radiators with different power, but with thermostatic valves.

The associated circuit is used if the thermal circuit is long. The dead-end option is used for short highways. When installing a 2-pipe network, it is necessary to install radiators with Mayevsky taps. Elements allow air to be released.

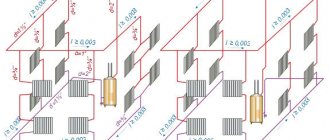

Collector

This system uses a comb. It is a collector and is installed on the supply and return. This is a two-pipe heating circuit. A separate pipe is installed both to supply coolant to each radiator and to return cooled water.

The system may consist of many circuits, the number of which depends on the number of batteries.

When installing a collector heat circuit, an expansion tank is installed. It holds at least 10% of the total volume of coolant used.

During installation, a manifold cabinet is also used. They try to place it at an equal distance from all batteries.

Each circuit in the manifold system is a separate hydraulic system. It has its own shut-off valves. This allows you to turn off any of the circuits without stopping the entire system.

Collector

Advantages of the collector network:

- It is possible to regulate the heating temperature of any heating device without damaging the remaining batteries.

- High efficiency of the system due to the direct supply of coolant to each radiator.

- It is possible to use pipes with a smaller cross-section and a less powerful boiler due to the high efficiency of the system. Therefore, the costs of purchasing equipment, materials and operating the network are reduced.

- Simple design process, without complex calculations.

- Possibility of installing heated floors. This allows you to create a more aesthetically pleasing interior, since there is no need to install traditional batteries.

To install a collector system, a large number of pipes, fittings and shut-off valves will be required. You will also need to purchase combs, a circulation pump, an expansion tank and a cabinet for manifolds.

A large number of elements increases the complexity of the installation process. The installation of batteries is carried out together with Mayevsky taps to prevent airing of each circuit.

Inverter for heating boiler - features and types

If an electric or gas boiler is used for a closed heating system in a private home, then in the event of a power outage, heating of the premises will naturally be stopped. To avoid such an unpleasant phenomenon, a special device was invented - an inverter for a heating boiler, which converts the constant voltage of the battery into a sinusoidal voltage of 220 volts with a frequency of 50 Hz.

Features of inverters for gas and electric boilers

The inverter is part of an uninterruptible power supply (UPS) for volatile systems. IBNs duplicate the power supply, which significantly increases the reliability of heating equipment. Such emergency power supply devices turn on instantly when the voltage level drops or completely disappears.

The following types of uninterruptible power supplies are used in heating systems of private houses:

- backup IBNs, which are turned on only when the 220 V network voltage disappears or decreases below a certain threshold;

- line-interactive devices contain a voltage stabilizer for reliable and safe operation of the boiler’s electronic equipment;

- Double conversion systems operate continuously online.

When choosing an IBN, you need to take into account that the inverter for a gas boiler must provide power sufficient for the normal functioning of all electricity consumers - a circulation pump, an automation unit. In practice, this power usually does not exceed 300 W, taking into account the required margin.

For electric boilers of any type, when choosing an IBN, the power consumed by the boiler must be added to the power used by the automation unit and circulation pumps.

Inverter electric heating boilers

If we strictly approach the term - inverter heating boiler, then this name corresponds to a device whose power is supplied through a double conversion inverter. The 220 volt network voltage is rectified and supplied to an inverter, which converts DC voltage into high frequency voltage in the range of 15 - 40 kHz to power the inductor (winding) of an electric induction boiler.

There are two types of induction boilers:

- induction heating boilers SAV;

- induction vortex boilers VIN.

Boilers SAV

SAV electric boilers are connected directly to the electrical network, single-phase or three-phase depending on the power and connection diagram. If cascade connections are used to increase power, then each device is connected to a separate phase.

Boilers VIN

Vortex induction boilers of the VIN type were developed as inverter heating boilers with high-frequency voltage supply to the inductor.

The use of high frequency made it possible to reduce the dimensions of the boiler, the number of turns of the inductor winding and reduce its weight.

Many manufacturers offer VIN vortex boilers, which for some reason require a power supply of 220 v 50 Hz, that is, such a boiler for heating a house turns out to be a modernized SAV-type boiler. It cannot be called an inverter vortex device of the VIN type, because the very principle - the use of high-frequency voltage - has been lost. There is a huge confusion on the Internet regarding the use of terms and concepts. It even goes as far as outright deception. For example, an induction electric boiler A006 is offered. Let's look at its technical data:

- total power of heating elements – 6 kW;

- step power adjustment – 3/6.

These parameters alone clearly determine whether the boiler belongs to heating element heaters.

Despite the fact that induction equipment is one of the most economical, safe and reliable, its widespread adoption is hampered by the price of electricity. The use of IBN, which includes inverters for heating, in conditions of an unstable network is completely justified, because increase the reliability of the circuit and ensure uninterrupted operation. The term inverter heating can only be applied to vortex induction boilers of the VIN type, the inductor of which operates from the high-frequency voltage generated by the inverter.

spetsotoplenie.ru

Installation

Installing an induction boiler yourself will not cause much trouble. You just need to follow a few rules:

- do not forget about the mandatory installation of an expansion tank and, in most cases, a circulation pump in the system;

- the power supply network and wiring must correspond to the power of the device; automatic protective equipment will not be superfluous;

- the boiler should be placed at a certain distance relative to the nearest objects;

- The device must be grounded.

Methods for installing inventory heaters

The absence of the need to equip a separate room for an induction boiler, its ease of maintenance, safety, noiselessness and other numerous advantages give this device an undeniable advantage over other devices of similar purpose.

Equipping it with something like an electronic programmer will also allow you to remotely control the heat in your home, which may be a pleasant addition for owners of periodically visited country houses.

Why should you buy an electric boiler?

There are many options for heating your home.

The choice depends on the availability of a particular resource and conditions of use. So the gas main may be located away from a private building. In this case, you will not be able to connect gas equipment. Heat generators operating on solid or liquid fuels require special conditions. To store raw materials you need to allocate a specific place. In addition, constant monitoring of the operation of the unit is required. In this regard, the 220 electric boiler is more practical and easier to maintain. Its installation is quite simple, the device works stably and does not take up much space. Of course, the cost of electricity is constantly rising. But this does not reduce the popularity of units of this type. Moreover, today there are energy-saving models.

Many owners of suburban areas prefer boilers powered by electricity.

Some models of these units can provide the room not only with heat, but also with hot water. In city apartments, electric boilers are sometimes also installed. It should be noted that an electric sauna boiler can also be successfully used. There are devices that can be controlled remotely. This way you can turn on the boiler while still on the road, so that upon arrival the bathhouse will already be sufficiently warmed up. Therefore, in many cases, electric heaters are an excellent alternative to other types of heat generators.

Beam wiring diagram

Pipelines are usually placed in a cement screed on the subfloor. One end is connected to the corresponding collector, the second is brought out from the floor under the corresponding radiator. The finished floor is laid on top of the screed. When installing a radiant heating system in an apartment building, a vertical line is installed in the channel. Each floor has its own pair of collectors. In some cases, if the pump pressure is sufficient and there are few consumers on the top floor, they are connected directly to the collectors of the first floor.

Diagram of a radiant heating system

To effectively deal with traffic jams, air valves are placed on the manifold and at the end of each beam.

Preparatory work

During preparation for installation, the following work is performed:

- establish the location of radiators and other heat consumers (warm floors, heated towel rails, etc.);

- perform a thermal calculation of each room, taking into account its area, ceiling height, number and area of windows and doors;

- select a radiator model taking into account the results of thermal calculations, type of coolant, pressure in the system, calculate the height and number of sections;

- make a routing of forward and return pipelines from the collector to the radiators, taking into account the location of doorways, building structures and other elements.

There are two types of tracing:

- rectangular-perpendicular, pipes are laid parallel to the walls;

- free, the pipes are laid along the shortest route between the door and the radiator.

The first type has a beautiful, aesthetic appearance, but requires a noticeably higher pipe flow. All this beauty will be covered with a finished floor and floor covering. Therefore, owners often choose free tracing.

To trace pipes, it is convenient to use free computer programs; they will help you perform the tracing, allow you to accurately determine the length of the pipes and draw up a statement for the purchase of fittings.

System installation

Laying a radiant system on a subfloor will require a number of measures aimed at reducing transport heat losses and preventing freezing if water was chosen as the coolant.

Between the rough and finished floors, a distance should be provided that is sufficient for thermal insulation.

If the subfloor is a concrete floor (or foundation slab), then a layer of heat-insulating material will need to be laid on it.

For beam tracing, metal-plastic or polyethylene pipes with sufficient flexibility are used. For radiators with a thermal power of up to 1500 watts, 16 mm pipes are used; for more powerful ones, the diameter is increased to 20 mm.

They are laid in corrugated sleeves, which provide additional thermal insulation and the necessary space for thermal deformations. After a meter and a half, the sleeve is secured with ties or clamps to the subfloor to prevent it from moving during the cement screed.

Next, a layer of heat-insulating material at least 5 cm thick is installed, made of dense basalt wool, penoplex or expanded polystyrene. This layer also needs to be fixed to the subfloor using disc dowels. Now you can pour the screed. If the wiring is done on the second floor or higher, it is not necessary to install thermal insulation.

It is important to remember that there should be no joints left under the poured floor. If there are few consumers on the second, attic floor, and the pressure created by the circulation pump is sufficient, then a scheme with one pair of collectors is often used

Pipes from collectors on the first floor extend pipes to consumers on the second floor. The pipes are collected into a bundle and carried through a vertical channel to the second floor, where they are bent at right angles and led to the consumer locations

If there are few consumers on the second, attic floor, and the pressure created by the circulation pump is sufficient, then a circuit with one pair of collectors is often used. Pipes from collectors on the first floor extend pipes to consumers on the second floor. The pipes are collected into a bundle and carried through a vertical channel to the second floor, where they are bent at right angles and lead to the consumer locations.

It is important to remember that when bending, you must observe the minimum bend radius for a given tube diameter. You can view it on the manufacturer’s website, but for bending it is better to use a manual pipe bender

At the exit point of the vertical channel, sufficient space must be provided to accommodate the rounded section.

Professional installation of an inverter for a gas boiler or for a home

The last factor influencing the reliable, safe, long-term and efficient use of inverters for gas boilers or for the whole house is the competent installation of the devices by experienced specialists who use professional equipment.

To assess the condition of the wiring, measure the starting power of household electrical appliances, correctly break the line and connect the cables coming from the electrical panel to the input and output of the inverter for a country house, and also perform a test run, contact CyberPower specialists. We will provide free consultations and install the UPS for the boiler at the proper level.

Purpose of uninterruptible power supplies

Residents of the private sector have repeatedly faced the problem of power outages. To avoid such troubles as breakdown of household appliances, interruption of heating or water supply, it is necessary to take care of a backup power source. The wide range of CyberPower products will pleasantly surprise you with their variety and functionality.

A properly selected inverter can provide your home with electricity for the required period. The most important criterion when choosing an uninterruptible power supply is its power. To determine it, it is necessary to sum up the power of the main appliances in the house.

UPS for boilers from professionals

Holiday villages often suffer from power outages, so for comfortable life it is important to have backup batteries. Clients of our company order inverters for necessary household appliances, such as boilers, boilers, refrigerators, TVs

Clients of our company order inverters for necessary household appliances, such as boilers, boilers, refrigerators, TVs

.

Boilers for autonomous heating, electric or gas, are highly sensitive to voltage changes. During the cold season, they turn off on their own due to increased electricity consumption. This negatively affects their effectiveness.

In order not to buy an uninterruptible power supply for the whole house, you can install a backup power source specifically for the gas boiler

. the price of which is significantly lower than an inverter for conventional household appliances.

For long-term use, you need to purchase a set of additional batteries.

High-quality installation of equipment

We advise clients on all issues of interest.

This ensures maximum safe and reliable operation.

An inverter is a source of uninterruptible power supply in any home; it will provide comfort and peace at any time of the year in any weather.

How to use the device correctly

Unlike an oil heater or central heating, inverter heaters automatically reduce their power when the room has reached a set temperature, which will save money for customers. To achieve the maximum shelf life of the device, there are several rules that will extend its service:

- the distance from the device to the nearest object or surface should not be less than 40 centimeters;

- It is not recommended to leave it on overnight;

- do not place wet clothes on it;

- Do not install the device near a window.

Heating electric boilers for 220 V

What to consider when choosing a heating boiler:

- type of structure;

- boiler price;

- stability of electrical networks and the ability to obtain the necessary power.

If paying for used kilowatts is not scary, and the electrical networks are stable and allow you to get the necessary power, and in the place where you live there is no central heating and gas, and there are also problems with installing a solid fuel device, then 220V electric boilers will help solve this problem.

Select a 220V electric boiler according to the required power for heating a room of a certain area. The calculation formula is as follows. For 10 m2 you need 1 kW of power from a 220V electric boiler with a ceiling height of up to three meters.

Varieties

Let's go through the varieties to better understand what these heaters can be.

By type of fastening

These units can be floor-mounted, wall-mounted or baseboard-mounted.

Floor-standing ones are distinguished by the presence of wheels, which allows you to transport the unit from one room to another. This suggests that floor-standing options are mobile. For example, when heating one room, you can then warm up another. And given the low power consumption, this device has even more advantages.

By type of heating element

Presented in 3 types:

- electric;

- gas;

- energy saving.

Electric ones operate from the mains. Such devices are popular among those who purchase them for an apartment.

Gas models operate using gas. The main function is to maintain heat in small areas or even in some unheated rooms. The advantage is that with low fuel costs, the device effectively heats the entire room.

Energy saving is suitable for those people who do not have a particularly powerful electrical system. Considering the increased efficiency (compared to other equipment of this type), this feature makes this type of equipment even more preferable. If you look at statistical calculations, you can see that the total amount of electricity saved is up to 60%. Very serious numbers, especially with high efficiency.

Also, the elements themselves can be of different types.

A heating element in the form of a tape or needle. The loops are located on the sides of the plate, and these loops are frangible. Due to the fact that the design does not include fins, the air heats up rather slowly. Nowadays it is rare to find such equipment, since it has not been produced for a long time.

A heating element (tubular electric heater) can also heat. The tube consists of ribs. The greater their number, the more heat the room will receive. The heating element can heat up to a high temperature, so the efficiency of this device is higher than that of a tape or needle.

Prices: summary table

| Model | View | Available nominal powers, W | Input voltage range, V | price, rub. |

| CyberPower SMP550EI | Off-line | 200, 300, 375 | Advanced: 100-280 Normal: 190-260 | 6 200-7 900 |

| Exmork NB-Y300W LCD DC12V | Line-interactive | 300, 600, 800, 1000 | 140-280 | 6 100-6 500 |

| POWERMAN ONLINE 1000 | On-Line | 900, 1800, 2700 | 115-295 | 12 900-15 500 |

| SibKontakt IS2-12-300 | Off-line | 300 | 220-300 | 3 900-5 000 |

Advantages of an inverter over a current generator when used in heating systems

There are plenty of advantages of the inverter both from the technical side and from the standpoint of routine maintenance and maintenance at home.

System startup, ready for work

- The generator is most often started manually. To do this, the owner needs to jump out in frosty weather into a special room with a generator placed there. Filling fuel (gasoline), switching switches and the starting procedure itself are not for older people, and children are generally prohibited from being allowed close to gasoline and the electrical panel. In addition, the generator will almost never start the first time while it is cold.

- The inverter will automatically start the battery power system within 10 milliseconds without anyone noticing.

No exhaust gases

- The exhaust gases of the generator must be removed from the premises using high gas exhaust pipes, which spoil the entire surrounding landscape with their appearance.

- Inverters do not emit exhaust gases.

Total costs over the operating period are much lower

If we add up the costs of purchasing an inverter or generator, as well as their maintenance, then the conditional “estimate” for the generator will additionally include the mandatory costs of building a special warm room with noise protection and a gas removal system, constant costs for liquid fuel, equipment with special switches, an electrical panel , grounding and protection against stray currents, costs for periodic equipment maintenance.

For a 12-year service life of gel batteries as part of an inverter, the total costs, including the cost of the inverter, will be much lower than those for a generator. More recently, inverter heating boilers have become available not only to industrial enterprises, but also to household consumers.

The operating principle underlying its work was discovered by M. Faraday in the 19th century and is known as electromagnetic induction. Therefore, such a boiler is also called an induction boiler.

The device has several (a pair of main and an external protective) cylindrical contours nested inside each other like nesting dolls:

- Internal, in which the coolant heats up as it flows;

- electric, through which a high-frequency current passes, providing contactless heating of the coolant;

- External, performing the function of a heat/electrical insulator.

The inverter provides the required power characteristics of the electrical circuit. Some models of such devices, usually of low power, have the additional ability to operate on batteries.

Autonomous power supplies

Often, for an electric heating system to operate normally, it must periodically switch to an alternative power source, and batteries in this case will be much more convenient than generators. The explanation for this reason is obvious: generators are very dependent on the availability of fuel, which must be purchased, delivered, stored and refueled.

Batteries make it possible to eliminate human actions, since all switching in this case will be carried out automatically. In addition, batteries are much better from an environmental and economic point of view, despite their high cost.

Conclusion

Inverter heating is an excellent solution for heating your home. The cost of purchasing and installing such a design is usually quite high, but in the long run these costs are offset by the good performance of such a system.

How does inverter heating work?

When organizing home heating by any means, it is necessary to insulate the premises as much as possible. Proper thermal insulation of building envelopes is the main condition for the energy efficiency of any heating and ventilation system. It is also necessary to protect the metal elements of the equipment from corrosion if the boiler design involves heating the coolant from heating elements: in this case, the liquid should not get on the thermoelements. But a more modern inverter boiler does not have the design flaws that heating element boilers have.

An induction boiler, as its name suggests, works using the principle of electromagnetic induction. Modern boiler models have built-in batteries, and the boiler can operate fully in conditions of unstable power supply. Houses connected to sections of the network where outages, breakdowns and voltage fluctuations are frequent can be heated with induction boilers, and the operation of these boilers is quite convenient.

Main elements of induction boilers:

- Heat exchange circuit in which the coolant is heated

- Inductor coil, or inverter. It can work both from the mains and from batteries. The alternating magnetic field causes heating of the heat exchanger and coolant, which is then sent to the circulation system

A little more about the design of an induction boiler:

The case has several layers - inside there is a core with a double wall, then electrical and thermal insulation, then the outer layer of the case. Industrial boilers had a cylindrical core winding, but domestic inverter boilers are designed with a toroidal copper winding. Two thick-walled (wall thickness from 1 cm) ferromagnetic pipes connected by welding form an inductor, and the magnetic core, or core, is an outer pipe of a larger diameter, having a toroidal winding of copper wire. The inner pipe is a heating element for the coolant fluid.

Boiler operation: the coolant can be either water or antifreeze. The liquid passes into the boiler through an inlet pipe welded through the heating pipe and magnetic circuit. The internal area of the heat exchange pipe is large enough, so more than 95% of the thermal energy generated by the boiler is transferred to the coolant. The inertia is significantly less than when heated by heating elements, therefore the heating time is shorter. The work is based on the use of electromagnetic induction - an alternating high-frequency magnetic field generates an induction current. In turn, the induction current heats the material of the core pipe, since eddy currents arise in the ferromagnet. Scale is not deposited on the pipe surfaces, since high-frequency vibrations of the walls prevent this. External thermal and electrical insulation creates protection against current leakage and minimizes heat loss.

The complete set of inverter boilers includes: an inverter converter based on semiconductors, through which the boiler receives power (alternating current) and a control unit with automatic switches; the boiler body has a built-in temperature sensor for an electronic thermostat.

The coolant in the inverter boiler is heated from a steel magnetic core-pipe. High voltage currents generate an electromagnetic field, and the ferromagnetic core is quickly heated by Foucault currents (or eddy currents). The boiler operation cycle can be described in a little more detail as follows: connecting the power supply - the primary toroidal winding is powered by high voltage current - the core pipe is heated, from the outside inwards, as a result of the action of the electromagnetic field, “pressing” eddy currents into the outer surfaces of the pipe - from The heated core receives heat from the circulating coolant - transport of the heated coolant to the heating radiators. The operating temperature of the inverter boiler core pipe is 75 degrees, and it only takes about 6-8 minutes to heat up to operating temperature.

DIY inverter boiler installation

When installing electrical equipment yourself, you need to have some knowledge and skills, but their list is usually small. When all materials and tools are ready, you can begin installing the heating system. Given the possibility of a sudden power outage, it is necessary to take measures to protect the equipment from damage.

An excellent solution to this problem would be to purchase inverter heating batteries, the cost of which is quite high, but in the future they can significantly save on heating the building.

Installing inverter batteries makes it possible to minimize the possible risk of problems occurring during a power outage: the automation will switch the equipment to backup power mode in 10 milliseconds, which will keep the operating temperature at the same level. When the electricity turns on, the reverse procedure will be carried out and the boiler will operate normally. Thus, inverter heating of the house allows minimizing system control.

Peculiarities

After you have calculated the required power, you must select the type of electrical connection. It can be single-phase or three-phase. In order to heat a small country house, 10-12 kW of power is enough. A single-phase electrical network is suitable for such a house. And three-phase is suitable for inverter boilers that have a power of more than 6 kW. Such heating boilers can be connected to a network with a voltage of 220 or 380 V. Such devices can be used without installing an additional circuit.

Industrial-type boilers are usually used to heat industrial buildings and premises. They are large in size, have a volumetric heat exchanger and a complex current conversion system. Household inverter boilers are used to heat private houses. Since they are small in size and low in cost.

Advantages

The inverter boiler has the following advantages:

- Ability to work with any type of coolant. That is, it does not matter whether water or antifreeze circulates through the heating system. For comparison, it’s worth remembering electrode electric boilers. They can only work with water or a liquid that is electrically conductive such as water. Antifreeze cannot be used in them.

- The heating inertia is low. This means that the water or other liquid heats up quickly. The nice thing is that you can speed up heating by using a centrifugal pump.

- Long service life. The first elements that can fail are electrical. At the same time, the coil, automation or inverters for the boiler work for a very long time. It is worth adding that this plus is also the result of the fact that the heating element (induction coil) does not come into contact with the coolant, because the coil is isolated from the liquid. Over time, the walls of the water tank may become dirty , but this only occurs if the procedure for filtering water before filling it into the heating system is neglected.

- The possibility of depressurization of the case is almost zero. Therefore, there is no point in worrying about possible leaks.

- High fire safety. Solid fuel and gas boilers are very far behind in this regard.

- Quite a weak noise.

- The efficiency is almost 100%.

- Small sizes. They are significantly smaller than gas or solid fuel units. True, inverter boilers have more characteristics than similar electric boilers.

- This cauldron is easy to make with your own hands.

List of popular models and manufacturers

There are many domestic and foreign companies, firms and organizations operating in the electrical engineering market segment. Some of them produce products under license, others develop their own technologies and offer customers unique, innovative and competitive products at a very reasonable price.

Device

Inverter Energy PN-500 is an inexpensive, practical device that provides uninterrupted power supply for modern low-power boilers. Manufactured at the production facilities of ETK Energia, one of the leaders in the domestic electrical market.

ETK Energia inverters fully comply with all GOST standards and requirements for household electrical equipment. The environmental safety and quality of products are confirmed by international certification certificates issued to the company.

Connecting one basic battery to the device ensures full autonomous operation of the fuel boiler for 6-7 hours. If you connect a second battery, the operating time will double.

The unit produces a pure sine wave at the output, which helps preserve the expensive electronic “filling” of modern heating boilers. When the operation of the central electrical system returns to normal, the inverter automatically switches to voltage stabilization mode and protects the boiler from sudden power surges.

Device "Elim-Ukraine"

has been operating in the electrical equipment market for more than 10 years and is respected by customers.

Devices produced under this brand have a switching power supply, eye-pleasing LED display and demonstrate an extremely high level of efficiency (up to 98%). Produces a pure sine wave signal without distortion or surge levels.

Inverters are also convenient because they work correctly with both gel and car batteries

Equipped with protection against overheating, general overload and deep battery discharge. One of the expansion options allows you to connect an additional battery of any capacity to the equipment to maintain autonomous operation of the heating system even in the absence of voltage in the central main networks for a day or more.

Unit Rucelf UPI-400-12-EL

The Rucelf UPI-400-12-EL device belongs to the category of linear-interactive energy sources. It has a built-in stabilizer, which, even if there is a minimum mains voltage, equalizes the current flow without using the battery. This makes it possible to economically use the battery life without overloading and extending their service life.

Important advantages of Rucelf UPI are completely silent operation and efficient provision of devices with the necessary power supply during a power outage

Reasonable cost is another characteristic feature of the products of the Russian company Rucelf.

Thanks to this, customers can create a full-fledged autonomous infrastructure to recharge heating systems during emergency power outages or power surges.

Complete set of inverter energy sources

In the modern market of household related equipment, inverters are presented in several versions. Some brands produce extremely simple units that work only as voltage converters.

The rechargeable battery is not initially included in the package of such modules, but its connection is allowed by the design, and the user can purchase this element separately in the future.

You need to purchase inverter equipment only from the regional official representative office of the manufacturer. There, in addition to the product, the buyer will be given a warranty card for service and, in case of problems identified in the first working days, the product will be replaced with a working one

Some types of inverters have a built-in battery of a certain, usually small capacity, but increasing its volume using external additional batteries is not possible.

Devices of this type keep the heating equipment operating for a short time and mostly serve to enable the owner to correctly disconnect the system from the power supply in an emergency.

A basic battery is built into universal units. Expanding the capacity of the device is carried out by adding external batteries. In this way, the operating time of the device is increased from several hours to several days.

How to Improve Heating Efficiency

Inverter equipment will work much more efficiently if the following design solutions are implemented in the system:

Inverter heating boiler

- High-quality thermal insulation of premises is useful for any heating organization, and for an inverter it is a prerequisite for performance.

- Metal pipes cannot be used in the heating circuit; plastic pipes are the best option.

- The use of a circulation pump will speed up the movement of the coolant, which significantly reduces electricity consumption.

- Installation of temperature sensors and regulators that ensure a decrease in power as the temperature increases.

The simultaneous use of equipment operating using different principles, as well as inverter heating and alternative types of energy, is also becoming popular.

This allows not only to ensure continuous heating even when traditional energy sources are turned off, but also allows you to significantly reduce operating costs by using each device depending on the situation.