Heating devices are an essential element of any water heating system. They are usually the most expensive part. A good opportunity to save money would be to use homemade radiators. They are made from smooth round steel pipes or from profile pipes. The latter option is somewhat more expensive, but allows you to reduce the depth of the device and get a more aesthetic appearance.

The use of a profile pipe for the manufacture of heating registers has a number of features. When starting to work with your own hands or deciding to buy a “homemade” product, you need to carefully weigh the pros and cons. Studying the basic rules by which heating registers are made from a profile pipe will help you avoid mistakes when working independently and will make it possible to make a competent choice of the necessary parameters.

Features of homemade radiators made of metal pipes: types and characteristics

Experienced craftsmen know that the use of profiled and round pipes made of carbon steel for the manufacture of heating devices has its own specifics. Therefore, studying the basic rules for assembling homemade heating registers will help in the future to get rid of errors and make an informed choice of parameters.

Design of a homemade heating battery

The design of such devices is a system that consists of horizontal or vertical pipelines interconnected by jumpers. Smooth pipes with a round cross-section are used for the production of heating radiators much more often than analogues with a rectangular or square profile. However, combined designs are also possible.

Without a doubt, registers made of carbon steel are considered the most convenient to use. The option made of galvanized or stainless steel looks much better in terms of characteristics. But, firstly, it is expensive, and secondly, only experienced specialists can work with such material.

Homemade heating devices are suitable for both single-pipe and two-pipe systems. They can be wall and floor mounted. The simplest example of execution is a heated towel rail in bathrooms. Handicraft registers are divided into two main types:

- Sectional.

- Serpentine.

Section registers

They are a pipe structure, where elements of a larger caliber are parallel and capped at the ends, and tubes of a smaller cross-section serve as connecting elements. For strength, additional jumpers can be used.

The coolant in such a battery always moves from the top tank, then through the connecting pipes it passes to the bottom row, and so on. This scheme practically eliminates the situation when the radiators are hot and the house is cold.

Judging by practical application, sectional registers cope with their tasks quite well. However, there was a fly in the ointment here. During operation of the device, it will not be possible to get rid of high hydraulic resistance; the reason for this is the difference in the diameters of the pipes and jumpers.

Serpentine registers

Such batteries look like an S-shaped structure assembled from components welded in series. The main advantage of this solution is that the diameter of the pipes is the same, which means that the hydraulic resistance is quite low. For the same reason, the coil is effective, since heat exchange is carried out over the entire surface of the homemade radiator.

A register bent from solid pipe is much more reliable in terms of operation than a welded one. But, unfortunately, it is almost impossible to carefully bend a steel pipe with a diameter of 70-100 mm at home - ideally, you need a pipe bender, and in extreme cases, a gas torch. This is where register prefabricated structures come to the rescue.

The heating system with S-shaped radiators, assembled only from metal pipes, is particularly reliable and durable; moreover, it is not so difficult to carry it out step by step. Compared to sectional batteries, there are significantly fewer welds, which means there are fewer potential sources of leakage.

Characteristics of homemade heating devices

Registers of this type can withstand pressure up to 10 kgf/m² and are able to work with any coolant: water, oil, antifreeze and steam. The permissible cross-section of pipes used in sections must be in the range of 32-219 mm.

Answers from experts

Tori:

plastic pipes and aluminum radiators.

LegendaSporta:

polypropylene.

mu.rza:

we bought polypropylene ones. each has its pros and cons. Read this, a very informative article about pipes

Vladislav Ushkalov:

Igor Shkurny:

Polypropylene... have less trouble with it... unless of course you have a soldering iron!!!!

Lizard:

I bought a house with completely defrosted metal pipes and cast iron radiators. I chose, consulted, changed to polypropylene and aluminum batteries. I bought one cast iron. and what? It was she who cracked in the very cold (there was no heating, and there was antifreeze in the pipes, but it did not help). I also changed it to aluminum. Further, in the well next to the house there is water supply for five houses, each has its own valve, the pipes are all iron. They rusted like hell. When it burst again, I raised a fuss, collected money from the people, and the local master replaced the filling of the well with polypropylene again. Now we are all calm. So polypropylene is perhaps more reliable. Some people claim that pipes made of polyethylene (very dense) are even more reliable and are not afraid of frost at all, but I don’t know.

Floors:

Iron pipes are 3-5 times cheaper and much more reliable than propylene and plastic. The disadvantage is corrosion of the metal from the inside, which cannot be gotten rid of in any way, but if the water is not drained from the system, then after cutting a 20-year-old pipe, it is as good as new inside (I myself have cut old heating pipes more than once - there is almost zero corrosion inside. And heating devices are more aesthetically pleasing than aluminum and bimetal. USSR cast iron is no longer in fashion, and the material consumption is appalling)))

Sergey Rudin:

Look here: agrosad m /catalog/tverdotoplivnie_kotli_1

Solo:

In a private house AOGV. ) There seem to be no other options.

Andrey:

rephrase the question. A radiator heating system is one thing, but pipes and radiators are a completely separate issue.

Alexander Bonn:

Gas boiler, steel radiators, welded pipe. Energy consumption: 10 sq. m = 1 kW. For a private house, warm floors (1st floor) and radiators are combined. But there must be an emergency heating system (electric or solid fuel).

Alasseia:

question about heating a spherical house in a vacuum, no information about the source of energy supply, no information about the house itself, what would I recommend - a project for heating your bungalow completed by a specialist

F F:

Boilers, boiler equipment. Heating 2 x storey house. : // forum .domostroy /#gazosnabjenie-vodoprovod-otoplenie-konditsionirovanie Gas wall-mounted boiler Heating, plumbing, sewerage for a house or cottage. Heating 2 x storey house.

Which radiators or pipes are better? - it is necessary to rely on the volume of coolant for the correct operation of the boiler! example - 70 sq. wooden house, - they wanted a fan system with aluminum. heating radiators, after calculating the amount of coolant, we chose a register system of pipes.

For a brick house, combine heated floors (1st floor) and radiators, a fan distribution system, and metal-plastic in a screed. Alexander Bonn +++

alexm66:

The question is very general: which is better, a foreign car or a VAZ - for which there is money and opportunity. I think the main criterion is the reliability of the equipment, and a competent installer will be able to make a workable system out of it, but an illiterate one will ruin any “luxury” equipment.

Basic heating register calculation

If the level of heat transfer of a purchased battery can be found out from its passport, then in the case of homemade heaters you have to calculate everything yourself. Otherwise, it will not be possible to heat the room effectively and evenly.

Calculating the required radiator power to heat a room

For calculations, they use formulas that may be simple, but require certain mathematical skills. Another option is online calculators, of which there are now more than enough on the Internet. Strictly speaking, the topic is quite extensive and deserves a separate article, so we will use simple calculation methods. In any case, this issue should be given close attention, otherwise your family will complain that the radiators do not heat well and the room is cold.

A simplified method for calculating the required thermal energy is to calculate the heating area and then multiply by 100. Why is this so? Because for comfortable living per square meter you need 100 W of heat. To be more precise in the calculations, let’s take into account the number of window openings and walls:

- A room with one window and one external wall – 100 W per 1 m² of area.

- A room with one window and two external walls - 120 W per 1 m².

- A room with two windows and two external walls - 130 W per 1 m².

Important! The calculations are suitable for rooms with ceilings of no more than 3 meters, when the house is located in a moderate climate in the middle zone. If the building is located in the northern regions, then the result must be multiplied by a factor of 1.2-2.0, and if in southern latitudes - by 0.7-0.8.

Simple calculation of the thermal power of a radiator made of steel pipes

Knowing what to strive for, all that remains is to choose the design of the heating device that would satisfy your needs. How to do this?

There is an elementary solution - use a table. It already calculates the heat transfer rates of rolled pipes. The values take into account the temperature regime, in which the supply temperature of the coolant is +90℃, and the return temperature is +20℃.

So, the table below allows you to find out the thermal power of one linear meter of register pipe per square meter of heated area.

| External section of the pipe, mm | Heated room area, m² |

| 25 | 0,5 |

| 32 | 0,57 |

| 42 | 0,69 |

| 57 | 0,94 |

| 76 | 1,19 |

| 89 | 1,37 |

| 108 | 1,66 |

| 133 | 2,0 |

| 159 | 2,43 |

Important! Keep in mind that calculations based on square footage alone are fairly rough estimates. It is advisable to use special formulas that use the temperature conditions of the system and the linear parameters of the radiator.

What other quantities do you need to know?

So, we have decided on the option - all that remains is to draw up a drawing. At this stage, such a parameter as the distance from section to section – h – is often forgotten.

When assembling a coil-type radiator from steel pipes, this value is determined by the dimensions of the bends used. Here it is worth paying attention to the value of F - this is the so-called outlet height. Without a doubt, the intersection distance here will be expressed by the formula:

h = 2F-D

If you decide to assemble a simple sectional radiator, then the gap between the pipes can be set independently, but with one condition:

H = D+50 mm

The same principle applies when working with rolled profiles, only instead of the diameter the height of the square or rectangular profile is used. Of course, the design features of the device are taken into account.

Main selection criteria

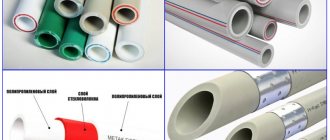

Any specialist has a whole arsenal of tools that help him make the right choice. Each type of pipe has both positive and negative characteristics. Therefore, taking them into account, it is not difficult to find the optimal solution. Much also depends on knowing what heating systems exist and what engineering conditions must be met

Here is a list of basic initial data that must be taken into account when choosing heating pipes:

- Availability of forced or gravity heating system

- Laying method - internal or external

- Complex or simple system configuration.

- System pressure power

- Maximum water temperature

Below is a list of existing options. It will help you decide correctly which pipes to choose.

Making sectional heating batteries from metal pipes using a homemade method

Tools

To make a register yourself, let’s prepare the necessary tools:

- Welding machine, electrodes and protective mask.

- Grinder, electric drill, abrasive wheel and metal drills.

- Hammer, gas wrench, building level, tape measure.

- Vise, clamps, brush with metal bristles.

In addition to a protective mask for welding, it is worth taking a special suit, gloves and strong boots or boots.

Necessary materials

For example, let's take the manufacturing process of the radiator shown in the drawing. It consists of 4 sections one meter long. Material – 108 mm steel pipe. In addition to all of the above, at a minimum, you need two ball valves. They are placed at the input and output of the device; in addition, you can connect a tap to the upper section of the battery to bleed air from the system.

| № Positions | Detail | Part parameters | Quantity |

| 1 | Steel pipe | Ø 108 mm (DN 100) | 4 |

| 2 | Impassable jumper | Ø 48x3.5 mm (DN 40) | 3 |

| 3 | Passage jumper | Ø 48x3.5 mm (DN 40) | 3 |

| 4 | Male thread fitting | G1/2″ (DN 15) | 2 |

| 5 | Elliptical end cap | Ø 108 mm (DN 100) | 8 |

Important! Think about register installation options in advance. These can be powerful stands or brackets. In any case, the finished battery will have quite a lot of weight, and this is not counting the mass of the coolant.

Assembly technology

- The first stage is marking and cutting pipe blanks. Their inner surface must be cleaned of rust and burrs so that nothing interferes with the circulation of the coolant.

- The next step is preparing the stubs. If necessary, they should also be cleaned of rye. Holes are drilled in two for mounting fittings.

- Insert and weld fittings into the holes, weld plugs onto the ends of the pipes.

- Using the drawing dimensions, mark the places where the jumpers are attached. On pipes Ø 108 mm, where there will be passage channels, drill holes according to the diameter of the jumpers. Be careful when marking!

- Weld passage jumpers onto the horizontal sections where the holes were drilled; where there are no holes - impassable. A tandem of jumpers will unite the sections and form the correct direction of coolant movement.

- Clean all welds. Check the device for leaks: close the lower radiator fitting and fill it with water through the upper one. If even a minimal leak appears, the water is drained and the defect area is additionally boiled.

- After checking, the surface of the sectional heating radiator made of metal pipes must be painted with heat-resistant paint. This treatment will protect against corrosion and add aesthetics to the product.

Practical heating registers: what to choose for your home and apartment

On the market, everyone can choose heating registers for installation in an apartment or private house. On sale there are designs made of metal horizontally located pipes connected to each other by special jumpers, due to which water moves through the heating device. Modern registers have higher heat output than traditional Soviet batteries. The most popular aluminum registers have the best technical characteristics. Homemade batteries are used in small apartments or rooms, ensuring proper heating of the available space.

Subtleties of installing homemade registers

Actually, the procedure is not much different from installing factory heating devices. The only difference here is the weight and dimensions of the structure. However, keep in mind a few simple rules:

- The distance between the battery and the wall should be at least 25 mm, and the same to the floor. From top to window sill - at least 50 mm.

- When assembling threaded connections for sealing, use paronite gaskets, FUM tape or tow with sealant.

- The slope of the underwater pipes in relation to the register should be 5-10 mm per meter in the direction of the coolant movement. When the line length is less than 500 mm, it is not necessary to make a slope.

- The installation part of the work should be carried out before the onset of the heating season - this way you can do a test run of the heating system, check its tightness and design power.

Briefly about the cost where to buy

The price of metal structures is indicated either per meter or per ton. Be sure to pay attention to this point. The cost of metal channels varies over a very wide range. The price depends on the quality of the material, production technology, wall thickness and other properties of the product.

Structures made of black steel are the cheapest. Next comes galvanization, which costs a little more. Stainless steel is the most expensive. However, as you have already learned, pipes made from it are the most reliable. Corrugated stainless steel channels are the most expensive.

The easiest way to order the products in question is from companies specializing in the sale of rolled metal products. It is advisable to deal with structural manufacturers or their official dealers. This will allow you to purchase the products you need at an affordable price.

In some cases, it makes sense to buy used pipes. The main thing is that they are in good condition. When purchasing, be sure to ask for a certificate of conformity. This will allow you to avoid purchasing inferior products.

Additional design features

Some experts advise welding supports or brackets.

This is not very good, because it makes the structure more massive and not universal. Without welded supports and brackets, it can either be hung on the wall or installed on stands fixed to the floor. In some cases, the owner who dismantled the old sectional batteries. using a radiator key and made a device, he could have made a mistake in calculating the optimal dimensions of a homemade radiator. As a result, the design is not able to heat the air in the room to the required temperature. One way out is to make an additional heater. However, you can improve what has already been made.

To enhance heat transfer, vertical metal plates can be welded. They will also heat up and give off heat. Thanks to them, convection will improve.

These plates can be cut from a metal sheet with a thickness of 1.0-2.0 mm. Their features should be as follows:

- Height - greater than the height of the battery.

- Width - 10-15 cm.

- The presence of 3 cut out squares or rectangles on one side. The dimensions must correspond to the dimensions of the profile pipe.

Such plates are applied to the battery and welded. As for their quantity, the more the better, because the greater the heat transfer becomes.

Selecting a heating battery based on the area of the apartment How hot the heating batteries should be Making a solar battery Heating meters for batteries

Which metal is better

To begin with, we note that structures of this kind can be intended both for heat transfer, performing the function of radiators, and for heat intake, when a tubular register is mounted directly in the combustion chamber of a boiler or furnace.

Plus, in some models, instead of a coolant liquid, heated gas is used, for example, a radiator chimney pipe.

- Steel pipes for heating radiators are deservedly considered leaders in this market sector. Of course, the heat transfer of steel is not as high as that of aluminum or copper; it is susceptible to corrosion and requires regular maintenance. But these shortcomings are more than compensated for by the affordable price, as well as a wide range of types and sizes. In addition, it is much easier to weld ordinary ferrous metal than non-ferrous metal.

- Stainless steel is used extremely rarely for such structures. Apart from the fact that its cost, to put it mildly, is far from budget, argon welding is used for soldering stainless steel, and not every professional welder can work with it.

Important: in this case there is simply no point in using galvanized iron. Thin zinc coating simply burns out during the welding process.

As a result, the already weak weld is further affected by corrosion.

The use of copper tubular registers is justified only in the case of copper wiring throughout the house. The heat transfer of copper is four times higher than that of ferrous metals, so here we can talk about heating with pipes without radiators, or rather with a minimum number of radiators. But, firstly, the price of copper is incredibly high, and secondly, this metal is very demanding in terms of operating conditions.

Copper heating wiring.

- Copper systems require a finely purified coolant that does not have solid abrasive inclusions.

- In such systems, fittings must be copper or compatible metals such as bronze, nickel, chrome or brass. Moreover, it is strictly forbidden to combine aluminum with copper.

- Copper pipelines necessarily require high-quality grounding, as there is a danger of electrochemical corrosion.

- Copper is a soft material, so the system needs additional protection; naturally, casings and shields also cost money.

The cast iron radiator heating pipes shown in the photo are still used in industrial buildings and technical rooms. But the weight of such a design is much higher than that of a household cast-iron battery. Considering the unesthetic appearance and rather low efficiency, they are not popular.

Tubular cast iron batteries.

Tip: cast iron tubular registers are ideally suited for installation in the combustion chamber. Optimal heat capacity, low price and unpretentiousness in terms of coolant make them leaders in this area.

Advantages of using heat-resistant finned tubes

Heat-resistant finned products obtained as a result of the use of new technologies have a number of advantages that have led to their widespread use. They differ:

- high manufacturing technology. The use of resistance welding does not require a large amount of energy, special consumables, or complex equipment;

- increased intensity of convective heat transfer. In the space of the intercostal channels, turbulization of the flow of the working medium occurs, and all sections of the fins work equally well;

- excellent thermal contact between the load-bearing structural element and the ribs. The use of resistance welding made it possible to achieve almost ideal thermal contact;

- lower thermal resistance of heat transfer. Since the thickness of the condensate film has decreased, the level of condensation of vapors of the process fluid flowing through the pipeline has decreased. This is due to the presence of a heat-resistant coating.

Finned tubes for heat exchangers

- They are made from all kinds of materials using several methods.

- Each method has its own significance.

- They have different technical and target features.

The most common group is considered to be spiral fins, where their production is completely automated. In this case, a rib made of an iron strip is welded to the outer wall. In this case, the connection comes out uninterrupted and runs in a spiral around the entire pipe.

After production, the finished pipe does not require further processing.

Modern technologies and the method of frequency welding make it possible to achieve a truly reliable welding seam, as a result of which the rib is perfectly firmly fixed.

There are two types of pipes - bimetallic and monometallic.

Properties of finned tubes:

- The heat transfer rate increases, sticking to 50%.

- The production resource of equipment equipped with pipes increases significantly.

- The authority of heat exchangers is greatly reduced, and their costs are reduced.

- They are ready to withstand heavy work due to the welded rib.

- The finned pipe tolerates changes in temperature, pressure and other rapid changes without the cost of initial data.

Due to the highest technical performance, pipes are widely used in such important areas as gas processing, oil refining, and including the nuclear industry. Machine-building factories and the chemical industry also often need this product.

- Heat-resistant products

- Technical properties of spiral strip fins

- Application

Material of manufacture

If you make a selection depending on the material of manufacture, then the registers can be classified into the following categories:

- Steel;

- Aluminum;

- Cast iron.

Which heating registers are best to choose? Steel registers became the most common. Their connection to the heating system is carried out by threading or welding. Such devices have good heat transfer and reasonable cost.

Aluminum registers are much lighter than steel registers. In addition, they are resistant to corrosion, are made without connecting seams and have good heat dissipation. The main disadvantage of such devices is their very high price.

Registers made of cast iron are connected to the heating system using a flange connection. They are quite easy to install and inexpensive. The disadvantages of cast iron products include low inertia, which significantly reduces the heating time of the registers.

Results and conclusions.

- I managed to increase the air temperature in the room by as much as 6ºC, and in extreme fan operation mode even by 9ºC, which confirmed the assumption that it is possible to increase the heat transfer of a central heating battery, even at such a low coolant temperature.

- When using a regular household fan without a speed controller, the room becomes too noisy. However, if you use the heat accumulated in the room, then, for example, you can turn off the fan in the bedroom at night, and, on the contrary, turn it on in the dining room. Then you can use the fan at full power.

- If you are in that part of the room where the movement of air generated by the fan is most noticeable, then a false sensation of a decrease in temperature is created.

- Those who are afraid that the fan will wind up a lot can calculate the monthly energy consumption.

35(Watt) * 24(hours) * 30(days) ≈ 25(kW*hour)

Caulking of cast iron pipes

Since external sewer networks are made mainly of cast iron, it is impossible to do without caulking and caulking. Caulking is carried out when assembling a system that includes cast iron pipes to seal the gaps that arise at the site where the transition to another cast iron pipe is made. It is produced using:

- Resin sealant and cement mortar.

- A slightly moistened mixture of cement and asbestos fiber.

- Gray fills.

Important! When caulking, the pipes are carefully tapped with a hammer so that the bell moves freely.

If the bell could not be freed, it means that sulfur filling was used. They carefully burn it out, making sure to wear a respirator. Having freed the bell, it is thoroughly cleaned. A sealing ring coated with a special lubricant is inserted into the socket, and a new part is inserted into it.

How to make fins with your own hands?

You can create fins on pipes yourself only on small parts of products and only on small-sized workpieces. There are several options for solving the problem. You can achieve the desired result by:

- applying deep threads using turning equipment;

- winding copper wire;

- notches and tension;

- welding;

- notches and welding.

If it is not possible to use a factory finned tube, you must use one of the methods listed above. The required method must be selected in accordance with the technical characteristics of the workpiece and its future purpose. Each task requires careful calculation. Therefore, the issue of applying ribs to pipe equipment must be treated with extreme caution.

Application

- They are intended for use both in domestic conditions and in various areas of the construction industry.

- The fins promote effective heat loss and heat removal in heat exchangers, for freezing gases and liquids with air, for heating the building.

- Both in industry and in domestic conditions, this type has found the most extensive use.

- They are unique in their heat transfer properties, manufacturability and performance qualities of the heat transfer surface, which has no analogues in the world.

Used in the following areas:

- Heat exchangers of all types and purposes must have pipes of the provided category in their own system.

- Air conditioning equipment. Here they are used for condensers and in huge cooling plants.

- In the engineering industry. For freezing equipment, turbine compressors, oil coolers, and also for interstitial refrigerators.

- At nuclear power plants. Steam air heaters, gas coolers, drying towers, intermediate refrigerators are equipped with these pipes.

- It is no longer news that the petrochemical, chemical, and oil refining industries also need their production. Air-cooled gas coolers, gas heaters and condensers require the production of this type of pipe.

Product design

The differences between different types of products lie in the shape of the petals and the finning ratio. Industrial production of the group of pipes under consideration can be based on different technologies. It all depends on the purpose of the products.

Let's look at the most common way to create finned copper products. First, a groove in the form of a snake is applied over the entire area of the pipe. This operation is performed on turning equipment using a special cutter.

Then strips of copper are placed in the created grooves under tension. They are pressed inside. Most often, such equipment has an additional heating function. This allows the operation to be performed more accurately and efficiently.

Finned copper tubes come in several varieties. The most popular type are products made entirely of copper. Such products perfectly transmit temperature. It can be used for both cooling and heating.

Another product option is bimetallic products. They are made from copper and steel. The first metal is a layer occupying about fifteen percent of the wall thickness. It can be located both on the outside and on the inside. In some cases, a layer of copper is placed on both sides. It all depends on the purpose of the product.

The advantage of bimetallic pipes is their low cost. You can buy these products relatively inexpensively. The price of a pipe made entirely of copper will be much more expensive. Bimetallic products in some cases are the optimal means for creating a high-quality heat exchanger. These products are widely used in heating systems.