Why do you need to insulate heating pipes?

Typically, cottage owners insulate only those heating pipelines that are located outside the home. There, heat losses are most likely and large-scale. It’s not for nothing that all city heating mains are so carefully insulated. You also need to choose the heating pipes themselves very carefully.

Energy workers have already learned to count their money. However, the pipes of the heating system in the basement or boiler room should also be insulated. Heating such non-residential premises in a house is a waste of money.

There are five good reasons to cover heating pipes with a heat insulator:

- Protection of coolant from freezing.

- Prevents condensation.

- Reduced heat loss.

- Extending the “life” of boiler equipment and pipelines.

- Possibility of laying external sections of the heating system in the ground above its freezing point.

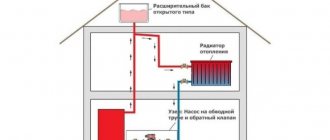

Pipes are insulated in the basement, attic, boiler room and outdoor areas. It is not worth installing insulation on risers inside the house in living rooms. If you do this, the heat will still enter the room, but through the radiator. There is no point in such actions. Money will be spent on a heat insulator, but it will be of no use.

When the coolant moves through insulated pipelines, it does not waste thermal energy. All the heat goes to heating the necessary rooms. At the same time, the boiler and pumping equipment in the boiler room do not have to operate at maximum settings in order to maintain a comfortable temperature in the rooms.

Another couple of disadvantages of heating pipes without insulation are condensation and freezing. In operating mode, when a coolant circulates through the system, most often heated water, there are no problems with its freezing inside and condensation outside. But during accidents on the heating network, the pipelines begin to “get wet” and then freeze.

Thermal insulation material in such a situation provides several additional hours, during which the coolant cools down, but not so quickly.

In general, insulation of heat supply pipes is carried out:

- when laying heating system communications outdoors;

- on sections of pipelines located in unheated basements and attics;

- when installing heating mains and branches from them onto risers in the basements of apartment buildings.

Insulated pipes provide warm batteries while reducing energy costs. Here it is better to spend money on thermal insulation materials rather than pay huge heating bills. It is always more effective to insulate than to spend money on fuel for a stove or boiler.

Insulation with polyurethane foam

Recently, more and more people have begun to pay attention to modern heat insulators. And one of the most popular and effective is polyurethane foam (PPU). This type of material is excellent for pipes and is, in fact, the outer shell for a water pipe (“pipe within a pipe”).

Polyurethane foam significantly reduces heat loss.

This type of design not only minimizes thermal energy loss, but also gives the pipes a high level of strength.

Positive characteristics of polyurethane foam:

- the material does not contain any compounds hazardous to humans;

- high level of resistance to climate impacts;

- increased mechanical strength;

- neutral to electricity and biological influences.

Polyurethane foam insulation materials will not rot or be destroyed by chemical exposure. The only obvious drawback of the material is its high cost. In fact, only this can be considered a reason to refuse thermal insulation from polyurethane foam in the basement of a private house.

Ready-made polyurethane foam shells.

It should be noted that insulating pipes with polyurethane foam is not so easy to do with your own hands, so it is better to hire specialists for this work. In the basement of a private house, the use of polyurethane foam often does not look like a very profitable option: the cost of a single installation (for example, for one or two pipes) will be quite high, so there is no urgent need for it.

A few words about current insulation methods

Insulated heating pipes are used if the route runs outside a construction site or through outbuildings, attics, basements and other non-residential premises. There is no need to insulate pipes in a living room, since the pipeline releases heat into the environment and acts as a heating radiator.

The photo shows a polyurethane foam shell with a reflective foil surface

At the moment, there are many varieties of thermal insulation materials and methods of their use. Pipelines, depending on their configuration and location, are insulated with expanded polystyrene, foamed polyethylene, foam rubber, mineral wool, foil insulation, etc.

Current methods of pipeline insulation are distinguished by such characteristics as the thermal conductivity of the finished result, the temperature range at which long-term operation of the insulation is possible and, of course, price.

Unfortunately, not all methods of insulating pipelines can be done with your own hands. Therefore, in my review I will talk about those technologies that I myself have encountered and the results of which I was pleased with.

So what will we look at in this article?

- Application of liquid insulating compounds;

- Application of polyurethane foam;

- Application of mineral wool;

- Application of insulating shell.

Application of coating liquid insulation on heating mains

Heating main covered with coating insulation based on perlite

The easiest way to insulate heating pipes in the basement, attic and outbuildings is done using liquid coatings such as “ARMOR CLASSIC” (ultra-thin thermal insulation).

The product is intended for application to polymer and metal surfaces at an ambient temperature of at least +7°C. Storage of the material is allowed only at positive temperatures. Operation of the material is allowed in a temperature range from +200°C to –60°C.

According to the manufacturer, the service life of the insulation is at least 15 years.

Standard five-liter packaging of “ARMOR CLASSIC”

Instructions for insulating pipelines are given in the following diagram.

Coating insulation application technology

Let's consider the main stages of working with liquid insulation in more detail:

- We prepare the surface, namely, we remove crumbling rust, dust and dirt from the material, and then wipe it with a rag soaked in thinner;

- While the surface is drying, prepare the material - open the jar and mix the contents;

Liquid insulation is used with the consistency of thick sour cream, so diluting the product with water to thin it is not recommended.

- We apply liquid thermal insulation with a regular brush over the entire surface in 2-3 layers, with a break for each previous layer to dry.

The applied layer does not look particularly neat, but it copes with the task perfectly.

Explanations for installation work:

- Despite the fact that the product is not toxic, we use protective gloves and goggles when working with it;

- We work in good lighting so that when covering the working surface there are no unpainted areas left;

- We do not paint fittings and moving areas of shut-off valves, since when liquid thermal insulation dries, it forms a dense crust, which will subsequently be difficult to remove.

How to thermally insulate a route using polyurethane foam

In one of the previous articles, I talked about how polyurethane foam is sprayed. PPU is a universal material that can be applied to various surfaces, including heating pipes.

The method I want to talk about next is one of the options for using rigid foam.

To complete the planned work you will need:

- installation for spraying polyurethane foam;

- components for producing foam;

- roofing felt and soft aluminum wire;

- plywood for cutting stiffeners.

Conclusion

As you can see, independent insulation of ventilation pipes, both in the attic and in any other room, is not something exorbitant. And if desired, a good owner will be able to cope with this task. The photos and videos in this article show options for installing such insulation. If you have anything to add or have any questions, write in the comments, I will try to help.

In a private house, the attic can be very warm and used as an additional room. But most often it is used as a storage room. The pipelines that run across its area make it difficult to change its purpose. If you decorate them correctly and sew them up with boxes, you will be able to make this room more cozy and comfortable.

Heating pipe insulation technology

The choice of pipe thermal insulation and the method of its installation are influenced by the location of the pipeline.

Insulation of heating pipes on the street

External thermal insulation of pipes is the most difficult method of insulation, since in the open air it is not only the pipes that need protection, but also the insulation itself. For outdoor installation, non-hygroscopic materials or other materials are used, but reliably protected from moisture by a film or casing.

In addition, it is advisable to use the densest and thickest insulation outdoors. Another requirement is the use of a material that is resistant to ultraviolet radiation, bad weather and mechanical damage.

Insulation of heating pipes in an unheated room

Basement, cold attic, boiler room - a feature of such rooms is the absence of heating radiators. But since the pipes are filled with coolant and are located in an environment with minimal humidity, there are no special requirements for either the thermal insulation material or its thickness.

Thermal insulation of heating pipes in an unheated (cold) room

Insulation of heating pipes underground

The specificity of installing heating pipes underground is that they must be laid below the freezing level of the soil, which is a depth of one and a half to two meters. If you do not adhere to this requirement, the coolant will cool greatly while it passes through the heating main located in the ground. In order to reduce heat loss, you need to take care of high-quality insulation of the underground pipeline.

Experts say that the optimal solution in this case would be to use a cable pipe heating system. But due to the high cost, users prefer enhanced thermal insulation of heating pipes.

Good insulation of underground heating pipes requires the following requirements:

- insulation of insulation from moisture in the soil;

- eliminating the possibility of deformation of the insulation, because in this case, its properties are reduced. This is especially true for soft thermal insulation materials;

According to reviews, the optimal solution is thermal insulation of heating pipes using polyurethane foam shells.

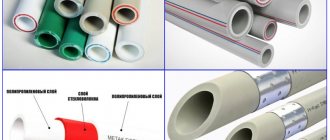

Note. Users recommend using a combined insulation system for pipes that are laid above the ground freezing level, namely: a combination of cotton wool and a hard polyurethane foam shell with a protective fiberglass coating. Ideally, even at the installation stage, use factory-made multilayer pipes in polyurethane foam insulation.

Technical characteristics of polystyrene foam

Two half-cylinders of polystyrene foam are placed on the pipe from above and below. There is a groove at the cut points, which ensures the absence of gaps and reliable joining of the parts to each other. The insulated pipe is wrapped with metal wire, tape or secured with clamps. The casing reliably protects the line from cooling and physical damage. Despite the water-repellent properties of the material, it must be protected from moisture. For this purpose, waterproofing is provided.

Compared to mineral wool, expanded polystyrene is a cheaper and easier to use insulator. It is preferably used when installing heating systems in private homes and basements, since the material is easy to install even for a non-professional

It is quite easy to insulate risers with your own hands - it is important to choose the correct diameter of the casing, secure it to the main line, and treat it with waterproofing. If the area is damaged, the coating is removed and replaced with a new one.

The disadvantage of using polystyrene foam as pipe insulation is the inability to handle bends and turns of the heating system with a casing made of this material.

The main characteristics of expanded polystyrene are given in Table 1.

| The name of indicators | PSB-S-15U | PSB-S-15 | PSB-S-25 | PSB-S-35 | PSB-S-50 |

| Density, kg/m3 | to 10 | up to 15 | 15,1-25 | 25,1-35 | 35,1-50 |

| Compressive strength at 10% linear deformation MPa, not less | 0,05 | 0,06 | 0,08 | 0,16 | 0,20 |

| Bending strength, not less | 0,08 | 0,12 | 0,17 | 0,36 | 0,35 |

| Thermal conductivity in dry condition at 25 °C, W (m K) | 0,043 | 0,042 | 0,039 | 0,037 | 0,036 |

| Water absorption in 24 hours, % by volume, no more | 3,0 | 2,0 | 2,0 | 2,0 | 2,0 |

| Humidity, % no more | 2,4 | 2,4 | 2,4 | 2,4 | 2,4 |

How to insulate heating pipes

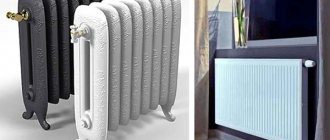

What material is used to insulate heating pipes in order to achieve a high protective effect and minimal heat loss: mineral wool is popular because of its low cost, high heat retention coefficient and ease of installation anywhere and on any surface. Mineral insulation for heating pipes is produced in several versions:

- Basalt wool is made from rocks containing the mineral basalt. The main quality of these thermal insulation materials is high fire safety (NG group - non-combustible material). It begins to melt (but not burn) only at a temperature of at least 650 0 C. In this case, toxins are not released into the atmosphere. The disadvantage of insulation with any material of mineral origin, produced in the form of cotton wool, is its tendency to quickly become moistened, even with moisture from the atmospheric air, and this leads to a violation of the thermal insulation parameters. In order to properly and efficiently wrap an outdoor heating pipe with cotton wool, a waterproofing layer is first applied to the pipes. Waterproofing prevents contact between heat-insulating materials and moisture (including condensation on the air overpass), since mineral wool is a porous material, and water penetrates quickly into air pores. Considering that moisture is an excellent conductor of heat, we get the maximum possible heat loss if we do not apply a layer of waterproofing. The simplest waterproofing material is roofing felt; it is secured by wrapping it around a pipe and securing it with soft steel wire. Also, any waterproof materials can be used as waterproofing layers, including liquid hardening solutions - bitumen, mastics, sealants, tar, heat-insulating paint for pipes. The main thing is that the protective surface has high resistance to mechanical loads. It is recommended to use heat paint in combination with some other insulation;

- Fiberglass insulation consists primarily of quartz sand, not necessarily refined. Glass wool is used for insulation of pipes not only outside, but also for thermal insulation of buildings in indoor areas - in ceilings, in the space between walls, in the underground. As a fire-fighting material, glass wool has proven itself to be excellent (sand does not burn), and is successfully used in heating lines with coolant temperatures up to 200 0 C;

- Conventional construction foam is the last of the insulation materials that can be recommended for external insulation of heating mains. The material is flammable; it will not be possible to lay it tightly around the pipes - you will have to build a special foam box. In addition, polystyrene foam is brittle and brittle.

Features of using mineral wool as insulation

Mineral wool is perhaps the most famous, oldest and reliable material of all types of insulation. Along with high-quality thermal insulation, it ensures the safety and durability of pipelines. The material does not burn, is inert to acids, alkalis, and other chemical compounds. The cost of mineral wool is significantly lower than most modern insulators, which plays an important role for large volumes of construction.

Types of mineral wool for insulation:

- glass - obtained from molten glass;

- stone - obtained from the melt of volcanic rocks;

- slag - a product of processing slag from a blast furnace.

Like most porous materials, mineral wool is hygroscopic and readily absorbs moisture from the environment. A material saturated with water sharply loses its thermal insulation properties and contributes to metal corrosion. Therefore, when insulating pipelines, external waterproofing must be provided. Usually these are sheets of roofing felt or aluminum foil of increased strength.

The need to use waterproofing dramatically increases the overall cost of installing a heating system. Therefore, today mineral wool is used for insulation of heating pipes in rare cases when it is not possible to use cheaper analogues.

The process of insulating attic ventilation

The most common material for thermal insulation of ventilation pipes is foamed polyethylene. It follows the shape of the pipe, completely enveloping and insulating it.

To properly perform thermal insulation, you should prepare the material of the required size. Then, cutting the shell, install it around the pipe. Using polyurethane foam or special tape, glue the joints and seams. This type of insulation is absolutely safe for the human body. The material is environmentally friendly and does not emit toxic substances.

Thermal insulation is the main type of protection for pipeline ventilation and heating systems. It reliably protects materials from exposure to harsh climatic conditions, significant heat loss and mechanical damage, preserving their performance for a long time. In addition, many modern materials are environmentally friendly and cost-effective.

Recommendations from experts

When choosing a suitable material for thermal insulation of a ventilation system, consider:

- The thermal conductivity coefficient should be as low as possible.

- Moisture resistance. The loss of insulating properties due to moisture absorption can nullify all the advantages of the material, including the low price.

- Difficult to install. The cost of specialist services depends on the danger of the material and the characteristics of its fastening. Insulating with cheap insulation can end up costing more than the highest quality insulation. If the work is supposed to be done independently, then the investment of time and effort is important.

- Fire safety class. This indicator can be decisive when choosing between two insulation materials with similar characteristics, if we are talking about a room with a high risk of fire.

According to experts, the best option for insulating vent pipes is foamed polyethylene. Foam rubber surpasses it in all characteristics and has no disadvantages.

Insulation of ventilation ducts.

Insulation underground

When laying heating pipes underground, it is important to take into account the following nuances:

- communications should be buried below the soil freezing level, and this indicator is absolutely individual, depending on the region;

- The ingress of moisture onto the insulation must be prevented;

- There should be no deformation of the insulation under the influence of the weight and pressure of the earth.

Laying heating pipes underground is quite an expensive pleasure, since in this process it is important not only to use high-quality materials, but also to be especially careful.

The most effective and common option for thermal insulation is the use of finishing material in combination with rigid casings. There are only two options here:

- pipes wrapped in insulation and placed in plastic sewer pipes (any heat insulator can be used, preferably mineral wool, polystyrene foam or foam materials;

- factory multilayer pipes.

Classification

Cardiomyopathies are divided into primary (idiopathic) without an established cause and secondary with a known etiology.

Primary cardiomyopathies

- genetic: hypertrophic cardiomyopathy;

- arrhythmogenic right ventricular cardiomyopathy;

- non-compact myocardium of the left ventricle;

- Lenegre's disease;

- ion channelopathies.

- mixed: dilated cardiomyopathy;

- primary restrictive cardiomyopathy;

- acquired: inflammatory cardiomyopathy;

- stress-induced cardiomyopathy (tako-tsubo syndrome);

- postpartum cardiomyopathy.

Secondary cardiomyopathies

The group of secondary cardiomyopathies is extensive and includes myocardial lesions in various diseases and pathological conditions. Among secondary cardiomyopathies, the most common are alcoholic cardiomyopathy, thyrotoxic cardiomyopathy, diabetic cardiomyopathy, autoimmune cardiomyopathy, etc.

The need and advantages of chimney pipe insulation

Condensation does not form in an insulated chimney, so the materials last longer

When building their own mansion, many owners of land plots underestimate the role and importance of communications for the removal of gases released during the combustion of fuel. By leaving a pipe exposed to the environment, they risk the loss of real estate and their own lives.

An insulated chimney pipe is a necessity based on the following factors:

- The pipe gets very cold in the winter cold. Heating it takes a large amount of energy, which entails a decrease in coolant temperature and increased fuel consumption.

- The difference between the internal and external temperatures of the pipe walls leads to the formation of condensation. When mixed with smoke, it forms a caustic substance that will corrode even stainless steel.

- Solid particles of combustion products settle on the moisture formed in the channel, which leads to the appearance of solid deposits. The draft deteriorates, the risk of complete blockage of the pipe and smoke in the room where the boiler is installed increases.

- The dew point is low because the gases leaving the furnace cool quickly. An insulated chimney does not have a dew point as such, because its temperature is the same throughout, and the internal walls do not come into contact with cold air.

- Brick channels are the most vulnerable. Moisture is absorbed into the brick, and when it freezes, it ruptures the material, causing slow but steady destruction of the entire structure.

If you insulate the chimney immediately after construction, the performance of the stove will increase and the safety of the inhabitants of the house will increase.

Asbestos-cement chimney - proper thermal insulation

The structure is insulated using a frame method. Before carrying out major work, the pipe is thoroughly cleaned. Further actions:

- Galvanized sheets are used to make the protective casing. The blanks are marked with the expectation that there will be a distance of 6 cm or more between the inner and outer walls. In height, the standard galvanized width is 1 meter.

- Install protection starting from the bottom. Each segment is densely filled with mineral wool. The sections are connected with bolts.

- The upper part is covered with cement mortar so that the insulation does not get wet. The layer is formed with a slight outward slope so that water does not stagnate.

Insulation without sheathing is used as a temporary measure.

It can often be observed that the insulation of an asbestos-cement chimney is carried out by a simple wrapping of mineral wool, which is fixed with ties. A similar option is allowed in the attic, and in relation to any material. Outside, such a structure will not last long: it gets wet and suffers from the wind.

Foamed polymer materials

In addition to polyurethane, other synthetic substances are also used to create reliable thermal insulation.

These include:

- Foamed rubber

. It has a number of advantages: elastic, temperature-resistant, fire-resistant. Good resistance to high temperatures and open fire allows this material to be used in cases where the insulation is constantly exposed to open fire or sparks. - Foamed polyethylene

. This material is well suited for internal insulation of premises. Foamed polyethylene is produced in the form of tubes with special cuts that facilitate the installation of insulation. A large assortment allows you to choose a heat insulator of the required shape and size. Polyethylene reacts quite calmly to cement and other building materials, which makes it possible to use it in any construction work. - Styrofoam

. Its characteristics are similar to polyethylene foam, but it has greater rigidity. It is manufactured in the form of pipe elements equipped with grooves for fastening. Polystyrene foam is very durable: its service life can be several decades. - Foam glass

. It is far from the most common material, despite its good performance. It is moisture resistant, has low thermal conductivity, and is very dense. It retains its shape during prolonged physical exposure. Well protects against a variety of rodents.

What do angiography indicators mean?

The amount of radiation that will penetrate the veins and other brain tissue is determined by their density. It is expressed in various color shades. The bone in the image will be white, and the cerebrospinal fluid will practically not appear on the resulting images. Other brain substances have different colors and densities. Using them, doctors evaluate the internal structure. The doctor will provide a detailed transcript of the received images.