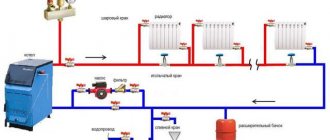

When installing heating systems in private houses, heat exchange radiators with water supply through a pipeline located in the floor under the screed are often used. This arrangement of pipes allows you to efficiently and aesthetically supply the coolant to the heat exchange devices through the lower connection of the radiator.

The connection is made from below using steel or aluminum panel radiators that have outlets at the bottom with external threads at a standard distance from each other. The radiator is connected to pipe outlets in the wall or floor using angled or straight N-shaped adapters with an American screw connector on the outlet pipe (they are also popularly called “binoculars” because of their similar appearance).

Rice. 1 Connection nodes for heating radiators - varieties

Advantages and disadvantages of the lower trim of the heating battery

First, let's look at the pros and cons of bottom connections for heating radiators. This option involves laying the supply and return pipelines not only in the screed. Installation of pipes can be carried out in the wall or even in an open way, but only near the floor directly below the device. In any case, heating lines become less noticeable.

Connecting a steel radiator with a bottom connection also has other advantages. One of the advantages is the possibility of using a coolant direction adapter. Another advantage is the presence of a thermostat in heating devices that manufacturers produce specifically for the bottom connection. Therefore, it does not need to be selected and purchased separately. This allows you to save time and even money. After all, the kit costs less than each device separately.

Coolant direction adapter installed on pipes Source homemasters.ru

The lower connection to the heating radiator also has disadvantages. One of them is the need to use air vents on all heating devices. Other disadvantages include less uniform heating of the object, the need to install a circulation pump in the thermal circuit and its constant use.

In addition, the supply and return are not connected from below to the radiators if a gravity heating system is installed in the house. An exception is gravitational heating, which has an accelerating circuit. Thanks to its presence, a height difference is formed, because it involves the rise of the main line to the ceiling, and then its descent to the floor.

Additional functions of Rifar radiators

Modern heating devices have serious requirements: they must not only heat the room efficiently, but also perform a number of other functions. For example, have an original design or take into account the nuances of the room.

There are situations when you need to choose a special radiator that will have a unique design. For example, if the room has a bay window, walls with a radius, a narrow window sill, a wide window, and so on. Here the design parameters of the radiator must be taken into account so that it not only “fits” into the interior, but also ensures high-quality heat transfer. Modern production is technologically flexible, so the optimal model can be found for each case.

The standard color in which Rifar batteries are produced is white. If desired, the user can select the desired shade based on the RAL catalog. Products with non-standard connections provide a temperature control system.

Types of batteries for bottom connection to the piping system

The greatest heat transfer is provided by diagonal piping. If you use this option, then the water will become evenly distributed in the battery and intense convection will occur.

Diagonal piping of a room heater Source odstroy.ru

The lower connection of the heating radiator to the two-pipe system should also ensure diagonal movement of water in the device. In other words, in heating equipment it must move from the upper edge of the device to the opposite corner of its lower part. However, not every manufactured device is created with an internal structure that allows the heat carrier to move in a diagonal direction.

Steel panel heating devices are popular. This is the most common equipment in which the design provides for diagonal movement of the coolant. Sectional heaters with a bottom connection to the pipes are also often installed. Their first two sections have a special internal design that provides the necessary direction of water movement.

Each type of battery under consideration is equipped with two pipes at the bottom. After installing the equipment, they are always directed towards the floor. Each of the devices has a supply pipe connected to an internal channel, which allows water to immediately rise to the top of the device.

Dimensions and flow diagram of the coolant in a sectional heater with a bottom connection Source zehnder.su

Another option is to equip standard sectional batteries with special fittings. It allows you to change the configuration of the channels through which the coolant circulates. Therefore, it becomes possible to connect heating radiators with bottom supply in a two-pipe system.

The equipment is also tied from below on both sides. This option involves connecting the supply pipeline to the heater through a valve, which is installed instead of the fitting. Its end part overlaps the nipple of the first section. At the same time, the coolant outlet hole in the valve will be oriented upward.

They also make one-way connections of pipelines to the devices. This option is implemented when using a valve whose design includes a tubular probe. The device allows you to make a bottom connection to heating radiators in a two-pipe system and ensure the outflow of cooled water.

The listed fittings are compatible with aluminum and bimetallic devices intended for lateral connection of pipes. The exception is heaters that do not have nipples.

Heating device made of aluminum with side pipe connection Source teplo-land.ru

What radiators are used

The advantages of steel panel radiators include light weight and attractive external characteristics.

For bottom connections, there are some requirements that the radiators must meet, since in this case the coolant is distributed over a continuous area and the usual sectional designs will not be suitable here.

Panel

Made from aluminum alloys. Special U-shaped fins increase the heating area and heat transfer. The front side is made in the form of a solid panel. The main advantages of such a battery include: light weight, attractive external characteristics, energy savings, low price, wide range of models, durability.

For social institutions: hospitals, schools, kindergartens, special options are produced with a smoother surface, which facilitate regular maintenance.

Made from profiled steel

Tubular radiator made of steel profile pipe.

Simple in design, rectangular panels can be of different sizes. The battery consists of several plates connected by welding, inside of which there are vertical oblong channels designed for the circulation of hot liquid. To increase heat transfer, U-shaped steel fins are used.

Such a battery has a number of advantages: long service life, more than 25 years, compatibility with most types of boilers, there are no strict restrictions on the choice of coolant, aesthetics, ease of installation.

Since radiators made of profiled steel are prone to rapid contamination, it is recommended to install dirt filters in parallel during installation.

When purchasing a design, it is important to take seriously the quality of the coating, which should well protect the selected specimen from corrosion and maintain its original characteristics over many years of operation under intense thermal influences, where the maximum temperature reaches 130°C.

Suitable house heating circuits for bottom connections

If water moves in the upward direction, then it moves in the opposite direction of gravity. Therefore, the coolant is not supplied from below to room heaters in gravity heating systems.

If pipes are connected to the device from below and from 2 sides according to a standard scheme, then even in this case a specially designed valve is used. It is placed on the supply and allows less coolant to pass through compared to a conventional liner. Because of this, the local resistance coefficient of the battery increases. It becomes approximately 2 times larger than the nominal value. Because of this, a circulation pump unit has to be built into the system.

The number of difficulties increases if the piping of the heating radiator from below is done only on one side. This occurs due to a significant increase in the hydraulic resistance of the heating device. It increases because the tap used is split into two channels. Moreover, each of them has a small nominal bore.

Pipe supply from below and on one side of the heating radiator Source build-experts.ru

For this connection option, it is still difficult to select high-quality fittings, the design of which includes a thermostatic head. Most of these products are made in China. It does not differ in accuracy of adjustment.

Another problem is adjusting the amount of water. Many available injection units are designed with a bypass rather than a rod that changes the flow rate. Because of this, the way of balancing completely changes. In addition, injection units that are equipped with a thermostatic head and a separate throttling device are often impossible to install due to their large size.

The best option when supplying pipes from below is a two-pipe polypropylene piping of the heating radiator. Ideally, the system will have a passing water movement. One of the best options is also radial isolation.

On a note! If you decide to connect the heating radiator to a single-pipe system from below, then this is not the best solution. When choosing this option, balancing becomes significantly more complicated.

What you need for efficient battery operation

An efficient heating system can save money on fuel costs. Therefore, when designing it, you should make informed decisions. After all, sometimes the advice of a neighbor in the country or a friend who recommends a system like his is not at all suitable.

It happens that there is no time to deal with these issues yourself. In this case, it is better to turn to professionals who have been working in this field for at least 5 years and have grateful reviews.

Correct connection is guaranteed to ensure comfortable living in the house for all family members. After all, when choosing a scheme, you need to take into account a number of features of your home

Having decided to independently connect heating radiators, you need to take into account that their efficiency is directly affected by the following indicators:

- size and thermal power of heating devices;

- their location in the room;

- connection method.

The choice of heating devices amazes the imagination of the inexperienced consumer. Among the offers are wall-mounted radiators made of various materials, floor and baseboard convectors. They all have different shapes, sizes, heat transfer levels, and connection types. These characteristics must be taken into account when installing heating devices into the system.

Among the models of heating devices on the market, it is better to choose based on the material and thermal power specified by the manufacturer

For each room, the number of radiators and their size will be different. It all depends on the area of the room, the level of insulation of the external walls of the building, the connection diagram, the thermal power indicated by the manufacturer in the product passport.

The location of the batteries is under the window, between windows located at a fairly long distance from each other, along a blank wall or in the corner of the room, in the hallway, pantry, bathroom, in the entrances of apartment buildings.

Depending on the location and method of installation of the heating device, there will be different heat losses. The worst option is a radiator completely covered with a screen

It is recommended to install a heat-reflecting screen between the wall and the heating device. You can make it yourself using one of the heat-reflecting materials - penofol, isospan or another foil analogue. Also, you should adhere to the following basic rules for installing a battery under a window:

- all radiators in one room are located on the same level;

- convector fins in a vertical position;

- the center of the heating equipment coincides with the center of the window or is 2 cm to the right (to the left);

- the length of the battery is at least 75% of the length of the window itself;

- the distance to the window sill is at least 5 cm, to the floor - no less than 6 cm. The optimal distance is 10-12 cm.

The level of heat transfer from devices and heat loss depends on the correct connection of radiators to the heating system in the house.

By following the basic standards for the placement of radiators, you can maximally prevent the penetration of cold into the room through the window

It happens that the owner of a home is guided by the advice of a friend, but the result is not at all as expected. Everything is done like his, but the batteries don’t want to heat up. This means that the selected connection diagram was not suitable specifically for this house, the area of the premises, the thermal power of the heating devices were not taken into account, or annoying mistakes were made during installation.

Piping to the room heater

Currently, the best piping options are polypropylene and cross-linked polyethylene pipes. They are reliable and have an attractive appearance. Experts do not recommend using steel pipelines for wiring the heating system.

Pipes connected to the battery from below are often laid under the floor covering or even along the ceiling of the floor below. For this installation method, steel pipelines are not the best option. The optimal solution, proven in practice, is tying heating radiators with polypropylene. A good solution is also to use copper and PEX piping for heating distribution.

Polypropylene pipe for heating system Source vyborexperta.ru

The use of insulation on pipes also has its own characteristics:

- the absence of thermal insulation protection will provide additional heating of the room;

- the presence of thermal insulation will reduce heat loss - this is an important nuance if the pipelines are laid in the suspended ceiling of the floor below;

- the thermal insulation layer replaces the damping material when heating is installed in the screed - the insulation compensates for the thermal expansion of the polymer, which allows the plastic to expand in any direction without negative consequences.

Thermally insulated heating pipes laid in a screed Source odstroy.ru

Before installing pipelines, be sure to determine the exact location of the heating devices. Their horizontal displacement is unacceptable, unlike height. The reason for this is the lack of a swivel fitting above the floor covering.

Usually only small straight sections of piping are above the surface. They are connected to the heater taps. The exception is batteries that are tied from below using knots that provide lower side connection to the pipes. This option assumes that the pipeline outlets are located at a distance of approximately 120 mm from the fittings.

Radiator installation area

As a rule, batteries are installed under windows, this allows you to cut off the flow of cold air coming from the window and prevent frosting of the glass. To achieve the desired effect, the radiator must occupy at least 70% of the width of the window opening, so when choosing the power of the device, you should measure the window opening and look at the battery parameters. The second important nuance is the height of the radiator and its installation area.

The following rules must be followed:

- distance from the lower collector to the floor is 80-120 mm;

- distance to the window sill 100-120 mm;

- distance to wall panel 30-50 mm.

If you place the battery according to the rules, your feet will be warm, the windows will not ice up, and the window sill will not prevent the flow of warm air from rising upward and will not reduce the intensity of heat movement.

Reinforcement elements and consumables

Installation of batteries, to which the pipelines are connected from below, is not difficult. However, the process is carried out using special fittings. Its type is selected for the installed radiators.

Bottom connection of the heating battery with polypropylene or other pipelines involves the use of a set of adapters. They are selected according to the material of the connected pipes. Typically solder sleeves and press fittings are used. If polypropylene pipes are connected, it is recommended to use “American” threads.

Completed lower piping of the heating device using a set of fittings and adapters Source remontnik.ru

On a note! Adjustment fittings are rarely installed under heating equipment. It is usually located on the manifold.

If a lateral pipe supply is made from below, a control and thermostatic valve is installed on the heater. Installation of fittings is carried out using threads.

On a note! When installing any room heating device, 2 shut-off valves are installed. They allow you to turn off and remove heating equipment without stopping the operation of the heating circuit of the house.

When installing the battery, radiator plugs and air vents are also used, which are often Mayevsky taps. To seal threaded connections, tow is usually used together with a special paste.

Manual air vent - Mayevsky tap Source eurobion.info

Classification of heating systems

The main criterion for dividing heating systems is the number of circuits. Based on this criterion, all heating systems are divided into two groups:

The first option is the simplest and cheapest. This is essentially a ring from boiler to boiler, with heating radiators installed in between. If it comes to a one-story building, then this is a justified option in which you can use the natural circulation of the coolant. But in order for the temperature to be uniform in all rooms of the house, it is necessary to take some measures. For example, build up sections on the outermost radiators in the chain.

The best option for such a pipe circuit is to connect the battery using the Leningrad method. In fact, it turns out that an ordinary pipe runs through all the rooms near the floor, and radiator radiators crash into it. In this case, the so-called bottom cut is used. That is, the radiator is connected to the pipe through two lower pipes - the coolant enters one and exits from the other.

Attention! Heat loss with this type of battery connection is 12–13%. This is the highest level of heat loss

So before making such a decision, weigh the pros and cons. Initial savings can turn into large expenses during operation.

In general, this is a good connection scheme that justifies itself in small buildings. And in order to evenly distribute the coolant over all radiators, you can install a circulation pump in it. The investment is inexpensive, and the device works perfectly and requires little power consumption. But it ensures uniform heat distribution throughout all rooms.

By the way, a single-pipe piping scheme is very often used in city apartments. True, the bottom battery connection cannot be used here. The same should be said about the two-pipe system.

Main installation features

When assembling and installing fittings on a heating device, it is laid lying on the floor. Instead of a radiator liner, a special valve is used, which allows you to connect the supply and return to the bottom of the battery. An O-ring seal is used to seal the connections.

On a note! It is recommended to mark the location of the through hole on the valve, which is located on the shank. This will allow you to align it in a vertical direction during installation.

The design of the injection unit often lacks a nut, which is used instead of a radiator liner. Despite this, its installation is similar to that of a valve. If a one-sided bottom connection is created, plug the outlet located on the reverse side with a plug. After this, install all the fittings on the battery using tow and paste. Then the assembled radiator is usually hung on wall brackets. Finally, it is connected to the heating system pipelines.

Installed and connected radiator to polypropylene pipelines Source santeh42.ru

How to connect a heating radiator to a polypropylene pipe

Connecting a radiator to polypropylene pipes is a process consisting of several stages:

- Drawing up a drawing, marking.

- Fastening batteries to walls using brackets.

- Installation of pipes, connection of individual parts.

- Pipeline testing.

There are several ways to connect the battery to the pipes:

- Bottom connection. The tubes are connected on both sides of the radiator at the bottom. Suitable for horizontal installation of a single-circuit pipeline.

- Lateral connection. On one side of the battery there are two holes for the liquid supply and waste outlet.

- Diagonal connection. A classic option for connecting radiators to pipes. The coolant supply and outlet openings are located on both sides in the lower and upper parts.

Briefly about the main thing

The bottom connection of heating devices with a thermostat allows you to hide the pipes under the floor covering or in the wall. However, when piping, air vents must be installed on all batteries, and a circulation pump unit must be installed in the system itself.

In devices, even with a bottom connection, water moves in a diagonal direction. This is ensured by the special internal design of the heating equipment. The lower one-sided or two-sided connection to radiators in the usual design is made using fittings.

Piping from below is often carried out if there is a two-pipe system in the house. It is not recommended to make a bottom connection if the facility has a single-pipe heating circuit, as balancing becomes more difficult.

Ratings 0

Two-pipe heating system

This is a wiring with a pair of pipelines, through one of which coolant flows, and through the second the return flows out. The line fits to each radiator, ensuring a stable coolant temperature. This is called a parallel connection and allows you to regulate the media flow rate by installing a thermostat on the battery.

The disadvantages include significant costs - you will need twice as many pipes, shut-off valves, and other elements. But this minus is offset by the ease of balancing and the opportunity to save. For example, in a private house you can reduce the coolant temperature for a period while no one is at home, which will reduce fuel costs.

(no votes yet)

Possible connection diagrams

The most efficient connection of batteries is quite easy to carry out - both in terms of the number of nodes and in terms of installation technology.

Heating radiator designTwo-pipe heating system

Option #1. Tichelman scheme

The most popular connection scheme, its main advantage is the maximum efficiency of all heating radiators at any point in the system. In addition, the Tichelman circuit allows you to regulate a separate radiator without any effect on the rest of the system. So, if it is very hot in one of the rooms, then the battery there can be completely/partially disconnected from the supply of hot coolant. And the thermal energy that is released as a result will be evenly distributed over the remaining radiators.

Tichelman's schemeAlbert Tichelman's solution

Another advantage of the scheme is that the water in both pipes has a common direction of movement. In terms of hydraulics, this is very good, since the load on all components of the system (in particular, the pump and heating boiler) drops noticeably.

Hot water begins to move from the boiler, moving alternately through all radiators. The return movement also starts from the first battery. It turns out that battery No. 1 will be the last on the return path, but the first on the hot coolant supply. Water will flow to battery No. 2 at a slightly lower temperature, but this unit is already closer than the first to the boiler on the “return” circuit.

Water flow process

The situation is similar with each subsequent radiator: the further it is from the source of hot coolant, the shorter the distance to the cold water outlet point. As a result, the conditions for all batteries are approximately equal (in terms of heat exchange with the system); they all heat up equally, regardless of their location.

Pipes with a diameter of 25 mm are used for wiring, while the batteries are connected to the network using pipes of 20 mm.

The radiator in the middle will not work

The Tichelman scheme has only one drawback - radiators cannot be placed exactly in the middle of the system (they simply will not heat in this place). This is explained by the hydraulic effect that occurs in the middle - here the outflow of cold and the supply of hot fluid form equal pressure. In reality, this almost never happens; the problem is solved by slightly moving the battery to the right or left. Although there is a simpler option - to create a small turn on one of the circuits in order to increase its length and thereby move the heating battery from the middle.

Dead-end and associated house heating schemes

Option #2. Connection via two double collectors

This scheme differs from the previous one in that the battery, which is the first to the heating boiler on the supply side, is also the first on the “return” path. This first battery operates as efficiently as possible, while the remaining nodes lose efficiency as they move further into the system.

Connection via two double collectors

The use of two collectors makes it possible to minimize this effect, since two circuits are created. Thanks to this, the number of radiators in one circuit is reduced, and thermal energy is distributed more or less evenly.

Two circuits

In this circuit, each subsequent radiator heats up worse, as we already mentioned above, but this effect can be partially eliminated using balancing valves. If you tighten this valve a little at the supply to the first radiator, then a better flow of coolant will be ensured to the remaining nodes, which are more distant. We also note that it is necessary to adjust the valves in any case, since in reality the length of the circuits created by the manifolds always differs somewhat. Consequently, the batteries will not produce the same amount of heat and therefore need to be balanced to balance their operating efficiency.

Which scheme should I choose?

From everything we said above, we can conclude: the simplest, most flexible and effective is the Tichelman scheme. The use of two double collectors can be an alternative - the efficiency of liquid distribution in such a scheme is quite high, but there are some difficulties during installation; in addition, additional adjustment will be required in the future.

Tichelman loop diagram

Single-pipe scheme (apartment version)

This connection scheme is very common in apartment buildings (from 9 floors and above).

One pipe (riser) descends from the technical floor, passes through all floors and enters the basement, where it enters the return pipe. In such a connection system, there will be heat in the upper apartments, since, having passed through all the floors and given off the heat to the bottom, the water in the pipe will cool down.

And if there is no technical floor (5-story buildings and below), then such a system is “ringed”. One pipe (riser) rises from the basement, passes through all floors, goes through the apartment on the top floor to the next room and descends, also through all floors, to the basement. In this case, it is not known who is lucky. On the ground floor, in one room, it may be warm where the pipe rises, but in the next room it is cold, where the same pipe descends, giving off heat to all apartments.

Types of fittings for the assembly

Types of fittings that are used to connect pipes and radiators in a heating system.

You can connect communications using the bottom method using three types of fittings:

- Direct. They are used to connect radiator modules to pipes emerging from the floor in a vertical position. The direct fitting scheme involves the presence of fittings with an “American” (flare nut) or compression adapter coupling.

- Angular. The pipes come out of the wall at a minimum height from the floor surface. The corner fitting is connected by an American connector located at the ends of the pipes.

- Taps for closing the system and adjusting the temperature. The fitting is built into the battery housing and provides quick connection to the two-pipe wiring. Using ball or valve valves with recessed tips, you can adjust the return, flow, and turn off radiators.

Parts of the steel pipeline are fixed with a metal-plastic union nut with a Eurocone type connector.

Radiator connection methods

The heat transfer efficiency of the radiator directly depends on the choice of heating piping connection scheme. If the coolant does not circulate throughout its entire internal area, but quickly exits into the return line, then the battery releases heat to a minimum.

The most effective connection method is diagonal. With it, the water inside the radiator has time to cover all sections on the way from the entrance to the exit, giving off thermal energy to each

There are three ways to connect pipes with coolant to the radiator:

- lateral one-sided - pipes are located on the side on one side;

- horizontal - lower or upper - the pipes are at the same level horizontally relative to each other on top or bottom of the battery - one fits on the right, and the second on the left;

- diagonal cross - pipes are connected diagonally.

In radiator data sheets, heat transfer is usually indicated for the diagonal connection method. With a side connection, heat loss will reach 10% of this maximum. And with the horizontal option they can reach all of 20–25%.

However, much here depends on the number of sections and the internal structure of the battery. Plus, the material used to make the radiator, as well as its location in the room, plays an important role.

Pipeline layouts for coolant supply are:

- with top supply;

- with bottom inlet.

If the system is with natural circulation, then a scheme with top wiring will be more efficient and preferable. But if you have a circulation pump, both options are acceptable.

The process of connecting the radiator itself does not depend much on the method of supplying the heating pipes. The supply and return are connected to the battery in accordance with the selected circuit. And the remaining two holes are closed with a Mayevsky tap and a plug.

Option #1 – with top wiring

In this scheme, the coolant line approaches the radiator from above. The outlet pipe can be connected on the same side, in the side version, or on the other (diagonal analogue). In this case, the movement of water in the supply and return circuits can be either forward or counter (dead-end).

If there are fewer than ten sections in the radiator, then the lateral method of connecting the pipes is almost as good as the diagonal one - but if there are more of them, the coolant will reach the edge of the battery farthest from the entrance only with strong pressure in the system

When choosing an upper connection, it is recommended to organize the movement of the coolant according to a parallel scheme. In this case, the return and supply circuits are approximately the same length, which greatly simplifies the balancing of the entire system.

In practice, a dead-end scheme is more often used, since it requires slightly smaller pipes.

If the house is small - up to 200 sq. m and want to save as much as possible on the heating system, you should prefer a scheme with counter-movement of heated water. Here the adjustment is not so complicated and quite feasible. But for a large cottage - two to four floors, it is better to choose something else.

Option #2 – with bottom supply

In this case, the coolant is supplied from below. If such wiring is built in a one-story house, then this allows you to get rid of risers. Both pipes are laid from the boiler along the floor and do not disturb the interior with their appearance. The fewer pipelines there are in a room, the more beautiful everything looks.

The main advantage of the lower supply is the absence of risers, which slightly reduces the amount of the estimate for installing a heating system in the house

The return line can be connected in the following scheme:

- side;

- horizontally from below;

- diagonally.

If a regular radiator is used, without a special partition for more efficient circulation of coolant inside, then it is best to choose a diagonal connection method.

However, the hydraulic resistance in this case is greater than with the horizontal version. Here you need to carefully consider what is more profitable when making thermal engineering calculations.

Often the horizontal method is the most efficient in terms of heat loss. But this is only possible if there is a plug at the inlet between the first and second sections of the battery, which directs the coolant upward throughout the radiator. This way the resistance is minimal and the heat transfer is maximum.

It is recommended to choose the bottom supply only for circulation heating systems. With the natural movement of the coolant, air will constantly accumulate in the radiators, especially with horizontal and lateral pipeline connections.

It will have to be constantly lowered using Mayevsky cranes. And these are additional body movements, so it is better to initially rid yourself of such worries.

We connect heating radiators correctly

Regardless of the type of radiators chosen and the connection diagram suitable for them, it is important to calculate and install everything correctly. Each specific case will have its own optimal system.

For expensive houses with a large area, it is advisable to contact specialists who can offer the optimal design. This is not an issue to skimp on.

Each specific case will have its own optimal system. For expensive houses with a large area, it is advisable to contact specialists who can offer the optimal design. This is not an issue on which you need to skimp.

In order to properly install and connect heating devices in complex design schemes, it is better to use the services of professionals

For small residential houses, you can independently choose a suitable scheme and install heating devices. It is imperative to take into account the features of your home, the rules for installing batteries and the feasibility of using one or another scheme.

When installing radiators, do not forget that the type of material for the battery itself and the pipes must be the same. Plastic pipes connected to cast iron heating devices will cause many problems, ruining the heating system.

When installing heating radiators yourself, you should not forget to install ball valves for bleeding air and a regulator at the inlet

Radiator location standards

Radiator location standards are observed

Regardless of the chosen method of connecting the radiator, it must be located at some distance from:

- walls – 5 cm;

- floor – 10 cm (deviation in any direction is allowed no more than 2 cm);

- window sill - 10 cm (a minimum distance of 5 cm is allowed).

When purchasing a mount, it is important to take into account the thickness of the installed thermal insulation with a reflective layer (if any). In this case, you will need slightly longer locking hooks.

Features of the diagonal connection scheme

If you also wondered why a diagonal connection is the most effective, then you should consider this option in more detail.

If we take into account the process where hot air or water is involved, then the action will occur according to one physical law, which involves the rise of warm masses upward, while the cold ones sink downwards

To ensure uniform heat distribution throughout the volume of the radiator, the coolant should be distributed throughout the battery. As mentioned above, lateral connection in city apartments acts as the main circuit. After all, forced circulation under high pressure is used there. The diameter of the incoming and outgoing pipes is only 20 mm. Through them, water enters the battery under high pressure, which allows the device to be filled evenly and quickly.

If we are talking about private housing construction, where the circulation is natural, the filling of radiators occurs under the influence of the above-mentioned physical law. That is why hot streams penetrate through the upper pipe, pushing cold water through the lower outlet on the opposite side. The two pipes are located diagonally when viewing the device. This is where the name of the connection comes from. The coolant fills the battery gradually, releasing heat to the entire volume. It is necessary to take into account not only the law of heat transfer, but also the physical law. That is why this scheme is the most effective.