Floor insulation is necessary to reduce heat loss both after laying a heated floor system and during installation of the finishing coating. Now there are many types of this useful material on the market, but foil floor insulation is recognized as the leader among them. How to choose the right foil insulation? What are the nuances during installation? We will answer these questions in our article.

Foil insulation for floors

Foil insulation

Foil insulation for floors

The variety of products in construction stores is very large and it is extremely difficult not to get confused among the entire assortment and choose a truly high-quality, effective material, the use of which will not force you to soon redo all the repairs, but, on the contrary, will give you the joy of the fact that it was carried out using high-quality materials .

What is reflective insulation

Foil insulation is a relatively new material on the market. Previously, the category of insulation for floors, walls, and roofs was represented by one single type - mineral wool, which had a lot of disadvantages. This material gets wet, and when in contact with water it loses most of its properties. At the same time, working with it was difficult due to unpleasant tactile sensations, and sometimes dangerous.

Mineral wool

Foil insulation is a two-layer material, most often supplied in rolls, but is sometimes also found in the form of slabs. Layers are represented:

- directly with insulating material, such as polystyrene foam, polystyrene foam, penofol, etc.;

- foil on a layer of insulation, which has certain heat-reflecting qualities.

On a note! Foil insulation has special properties precisely due to the presence of a foil layer. It has the ability to reflect thermal energy and direct it inside the room, preventing it from escaping outside, strictly limiting the area of heat distribution.

Foil floor insulation consists of two layers

Also, material covered with foil does not get wet, which means it also has certain water-repellent properties, although it cannot be used as a waterproofing coating.

Depending on the type of material from which this type of insulation is made, it can be thick or thin, retain heat worse or better, have pores of different sizes, which contain air in one quantity or another.

Polyethylene foam

Features of choosing a substrate

You need to choose the substrate carefully, since not only the operation of the heated floor, but also the atmosphere in your home depends on it. Therefore, when purchasing insulation, professionals advise paying attention to the following points and making a choice based on the parameters listed below.

Foil substrates

A substrate with a foil surface is widely used. A huge plus is that its basis can be: extruded polystyrene foam tiles, polystyrene foam, polystyrene foam or cork. The use of metallized film leads to a significant improvement in the characteristics of the base.

A film of aluminum or lavsan acts as a reflective outer covering. It increases the efficiency of the water system up to 98%, and affects the uniform distribution of heat. The degree of heat reflection depends on the size of the foil layer. An important property of this material is that it is not subject to deformation and can withstand heavy loads.

It is worth noting a special property of lavsan - it has the ability to maintain reflective qualities and moisture retention functions, even with prolonged contact with a concrete screed.

Sources:

https://lumber-mill.ru/pol/podlozhka-pod-teplyj-pol-nuzhna-li.html https://trubanet.ru/teplyjj-pol/podlozhka-pod-tjoplyjj-pol.html

Properties of foil thermal insulator

Good insulation with a layer of foil has not only heat-insulating properties. It is distinguished by high levels of sound insulation, is not afraid of temperature changes, protects the room from moisture penetration, and has vapor barrier properties.

Expert opinion

Afanasyev E.V.

Chief editor of the pol-exp.com project Engineer.

A heat insulator with a foil layer is in most cases an environmentally friendly material; it does not harm human health or the environment. It can be safely used in children's rooms, as it is non-toxic.

Penofol

Foil insulation, especially from the category of materials made from penofol or expanded polystyrene, is resistant to mechanical stress - even heavy furniture can be placed on the floor under which such material is laid. The insulation will not lose its properties even in this case.

It is especially important to use foil insulation when installing heated floors. It will minimize heat loss, making the room warmer, and the cost of paying utility bills will be significantly reduced. The working insulating layer itself prevents cold air from outside from penetrating into the apartment, and the foil will ensure that heat is retained inside it.

Installation of penofol inside the house

At the same time, installation of foil insulation is very simple and it does not matter whether it is supplied in rolls or slabs. The material is easy to process - in order to cut a piece of a suitable size, you do not need to purchase any complex equipment. It is enough to have any cutting tool with you.

Attention! If no insulation was used during the installation of the floor covering or heated floor system, this is considered a gross mistake and a violation of the material laying technology.

What does a pie look like for a heated floor?

OSB or chipboard boards

They have been used for a relatively long time and allow the installation of heating pipes of increased diameter. They have high levels of mechanical strength and are of the average level in terms of heat-saving characteristics. A prerequisite is that the slabs must be moisture resistant. The P5 chipboard substrate can withstand cement screed.

Warm water floor in a prefabricated dry floor screed

OSB board

Advantages and disadvantages

The main advantage of any insulation with a foil layer is its technical performance, which is significantly increased compared to similar materials, but without a foil layer. However, due to additional production costs and complicated technology, such a heat insulator is more expensive. In general, foil insulation has a lot of positive qualities.

Insulation with foil is significantly superior to conventional heat insulators

Advantages of the material:

- sound insulation;

- safety from an ecological point of view in most species;

- resistance to temperature changes;

- moisture resistance;

- easy installation;

- high thermal insulation properties;

- durability.

Pros and cons of foil insulation

The disadvantages of the material include softness, which prevents the use of foil insulation when laying some soft types of floor coverings, as well as high cost compared to ordinary thermal insulation materials.

Technical characteristics of isolon

Main technical characteristics:

- The thermal conductivity coefficient is 0.031-0.037 W/(m*C).

- Vapor permeability coefficient - 0.001 mg/(m*hour*Pa).

- Moisture absorption coefficient - 0.2-0.7%.

- The density of isolon PPE ranges from 25 to 200 kg/m³.

- Compressive strength - 0.031-033 MPa.

- The operating temperature range of the material is from 60 to +75 °C.

- Heat reflection rates - from 95 to 97%.

- Sound absorption rate - up to 68%.

Table 3 . Comparison of the characteristics of various materials used for insulation

| Options | Izolon PPE | Penofol | Poliizol |

| Thermal conductivity coefficient, W/(m*C) | 0,031-0,037 | 0,039-0,051 | 0,044-0,051 |

| Vapor permeability coefficient, mg/(m*hour*Pa) | 0,001 | 0,001 | 0,0023 |

| Density, kg/m³ | 25-200 | 25-50 | 25-50 |

| Moisture absorption,% | 0,2-0,7 | 0,35-0,7 | 0,25-0,43 |

| Sound absorption | excellent | excellent | high |

The table shows that isolon PPE has one of the lowest thermal conductivity and vapor permeability, and has excellent sound absorption .

How and where to use insulation with foil

Foil insulation can be used on almost all surfaces of the room, depending on its purpose. They are used for laying walls, roofs, ceilings and floors.

Izover

On a note! Foil insulation for floors is indispensable in rooms located on the first floors.

Where can foil insulation be used:

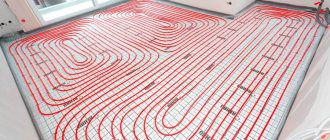

- when installing a heated floor system;

- to protect floors from penetration of cold from the basement;

- to ensure thermal insulation of walls;

- when installing a roof in a private house;

- when insulating balconies, loggias, verandas;

- when laying water supply and drainage pipes;

- in baths and saunas in order to preserve thermal energy indoors.

Using foil insulation in a bathhouse

In general, the type and method of using foil insulation depends on the room in which the repair work is being carried out, as well as on the purpose of this room, the properties and microclimate of the building, etc.

Types of foil insulation

| Photo | Name | Rating | Price | |

| #1 | Expanded polystyrene | ⭐ 96 / 100 | More details | |

| #2 | Polyethylene foam | ⭐ 98 / 100 | More details | |

| #3 | Mineral wool | ⭐ 81 / 100 | More details | |

| #4 | Basalt insulation | ⭐ 87 / 100 | More details |

In general terms, it is clear what properties a heat insulator with foil has, however, depending on the type of material, they may differ slightly.

Expanded polystyrene

It is a rather voluminous and thick sheet of material with a layer of foil on one of the surfaces. It is produced using complex technology, during which individual polystyrene granules are fused into a single whole. As a rule, it is installed where there is high humidity and significant mechanical impacts on the floor covering are possible. Most often - when installing a water heating system.

pros

- durable material that is not subject to rotting;

- not afraid of fungus and mold;

- does not lose its qualities during sudden temperature changes ranging from -180 to +180 degrees.

Minuses

- This material is used only for installing a thermal insulation layer on the floor.

Foiled polystyrene foam

Polyethylene foam

Rolled material with a thin aluminum coating on one or both sides. The thickness of the heat insulator varies from 2 to 10 mm. It is usually used to insulate floors and walls, sewers or ventilation shafts. Interestingly, foamed polyethylene is also used in the shoe industry - insoles are made from it.

pros

- easy to install;

- has low weight;

- often equipped with an adhesive layer on one side, which simplifies its attachment to surfaces.

Minuses

not detected.

Foamed polyethylene foil

Specifications:

- specific gravity of a coating with a thickness of 5 mm – 60 kg/m;

- thermal conductivity – 0.038 W/(mK).

Foiled polyethylene foam includes penofol, ecofol, isolon and other materials.

Most often, penofol (ethylene foam) is used for installing floors. This material, depending on its qualities and characteristics, can be divided into 4 types:

- A – covered with foil on only one side, a classic and familiar material. Rarely used in rooms with high air humidity, but can be installed in such rooms when laying a layer of waterproofing;

- B – has a foil coating on both sides, a very dense type of heat insulator. No additional installation of a moisture-protecting layer is required;

- C – material that has a foil layer on one side and a self-adhesive layer on the other;

- ALP is a heat insulator with one layer of foil, but laminated with polyethylene. Used when installing an electric floor heating system;

- R – one side is embossed, the other is smooth;

- Super NET - among all types, has the maximum thermal insulation performance, can be used for many years and not lose its properties.

Penofol can be of several types

On a note! A good insulation material is polypropylene film, which has metal inclusions, due to which heat is evenly distributed over the entire surface of the floor and is retained for a long time.

The material is self-adhesive. Peel off the film

Polyethylene foam foil

Mineral wool

A type of insulation familiar to many. Mineral wool with foil is sold in the form of rolls or slabs and is usually used for thermal insulation of roofs, floors in bathhouses and on loggias or balconies. The foil layer is applied only to one side of the material. The thickness of mineral wool can vary from 5 to 10 cm. The base is a basalt slab or fiberglass. When installing even in non-residential premises or outside the house, it is recommended to cover it with film.

pros

- low cost.

Minuses

The material is far from safe for health, and it is not worth using such insulation in an apartment. It can cause the development of respiratory tract diseases, as it releases a dangerous substance – phenol – into the air.

Mineral wool foil

Basalt insulation

This type of insulation belongs to the category of materials based on mineral wool. It is used in the construction of stoves and fireplaces due to its non-flammability. Used for thermal insulation of walls and roofs, floors between floors.

pros

- not afraid of exposure to external environmental factors;

- not flammable;

- ease of installation.

Minuses

- increased thermal conductivity when wet.

Foil basalt insulation

Polypropylene boards

One of the optimal options for thermal insulation of water heating, it is not afraid of elevated temperatures and humidity, and is the cheapest material in terms of cost. It is not afraid of aggressive chemical compounds and does not emit harmful substances during heating. It has low flammability and does not support open combustion. The reproduction of various microorganisms, including mold, is inhibited on the surface. It is approved for use by sanitary control organizations without restrictions. The slabs may have ready-made grooves for laying pipelines.

Polypropylene boards

Sheet polypropylene

Nuances of fastening and installation

When laying foil insulation, you may need the following tools and materials:

- nails with large heads;

- stapler;

- hammer;

- construction tape.

When installing insulation with foil, it is important to avoid the mistake of laying the material with the shiny side down. In this case, the material will not perform its heat-reflecting functions. The foil side must “look” into the room in order to be able to return thermal energy to the room.

An example of laying lag on foil insulation

Advice! You can leave a small air gap between the insulation and the floor covering. Then the floors will be even warmer.

It is also important to remember that the insulation does not overlap. The sheets should be placed end to end and secured with tape or nails, depending on the type of base. Insulation with an adhesive layer may not be additionally fixed, but it is still recommended to secure it with fastening materials. All joints after laying the material are taped.

Thermal insulation for heated floors

Work on laying insulation can be dry or wet. In the second case, the material will be filled with concrete screed. In the first one, it is advisable to install an additional waterproofing layer.

Preparing the base

Unlike penoplex, polystyrene foam and even mineral wool, Izolon is quite sensitive to mechanical load, so the material can only be laid on a flat horizontal surface. Especially if the flooring is supposed to be laminate or, even worse, linoleum. In this case, the height difference in a one-meter area should not exceed 2-3 mm, and in principle there should be no bumps and depressions.

The concrete floor must be cleaned of loose “cakes”, dust and dirt must be removed. We carefully knock down the cones with a hammer and chisel, and clean off the remains with a grinder. Any depressions must be filled and smoothed to floor level. Next, it is advisable to wash the concrete and cover the floor with a primer. Not with paint, not with varnish, but with a primer for concrete.

Important! Additional treatment does not affect the insulation of concrete with isolon, but the concrete surface, even if covered with thermal insulation, will mercilessly collect dust. This is especially true for thin screeds.

When people walk on the floor, the Izospan cloth will work like an air pump, and all the dust will slowly move from the surface to the walls, and then get inside the room through the baseboards.

Completely worn-out floors need to be overhauled before insulation; a new screed may have to be made. It is impossible to lay Izolon on a surface full of cavities and cracks; under load, the glued panel will separate into separate sheets or strips.

If you plan to insulate the floor with isolon in a wooden house, then first you will need to remove the old floor covering, clean or sand off the paint, and treat the wood with a bioprotective solution. The floorboards are wedged together with wooden inserts, but the cracks cannot be completely sealed, otherwise the floor will rot under the insulation. After sanding, they can be selectively blown out with foam.

Plywood floors are prepared in the same way as concrete floors, you just need to additionally check that all the sheets lie on the base without “popping” or “bubbles”. Holes are drilled in problem areas, foam is blown in and immediately loaded with pressure weighing at least 10 kg.

Roll material laying technology

Step 1. The material produced in a roll must be laid on a surface cleared of debris. The base is swept, washed if necessary and dried.

Preparing the base

Step 2. The insulation is cut into pieces of the required length and size.

Cutting foil insulation

Step 3. The material is leveled over the surface of the room.

The insulation is leveled over the surface

Another photo of the process

Step 4. In small rooms, the insulation is attached along the walls and across with wooden blocks. Its individual sheets are glued together with tape.

The insulation is attached using bars

The process of installing bars

Step 5. If the floor covering allows it (it is quite dense), then lathing is done on top of the laid insulation. This makes it possible to create an air gap.

Creating a sheathing

Next, the floor is covered with a finishing coating or filled with concrete screed; work is also carried out on the installation of heated floors, if necessary.

Warm floors are a serious cost item during renovation, so it is important to accurately calculate how much and what materials will be needed. To ease your labor costs, we have prepared special instructions telling you how to calculate a heated floor - water or electric. Online calculators included. And in the article “ What do you need for a heated floor? » you will find a complete list of everything that may be needed during installation.

Video - Laying roll backing

Insulation with a layer of foil is a good option for high-quality thermal insulation material. It will serve for many years if you choose it correctly in accordance with operating conditions, as well as with proper installation. It’s easy to avoid mistakes; the main thing is to carefully familiarize yourself with all the nuances of using the material.

* * * * * * *

For purely practical reasons, and also as an example of the effectiveness of using foil insulation, especially when combined with other thermal insulation material, below is a calculator for calculating the insulation of a balcony. Since it makes no sense to consider the floor on a balcony or loggia separately, the calculator allows you to make calculations for the entire room, for each of the surfaces that require thermal insulation.

Brief explanations on how to use the program will be given below.

Step-by-step algorithm for laying a substrate under a laminate board on a heated floor

Let's consider the procedure for laying a foam polyethylene backing under a laminate board on a heated floor.

First of all, you need to clear out your workspace. To do this, you can use a regular broom or vacuum cleaner.

Cleaning up the workspace

Then we lay the rolled backing on the cleaned surface.

Place the roll backing on the cleaned surface

The spread substrate can be secured with double-sided tape, after which you can proceed directly to laying the laminate boards.

We fix the substrate and proceed to laying the laminate