The Wilo circulation pump in the Ariston double-circuit boiler ensures the supply of heated liquid to the heating radiators, cooling the primary heat exchanger, after dispensing hot water to protect the heat exchanger from the formation of scale on its internal walls.

Ariston boilers in the Genus Premium, Clas System, Genus, Clas models are equipped with a Wilo MTSL 15/5 HE - 2 circulation pump, its malfunction leads to an emergency stop of the heating device.

To repair the boiler circulation pump, you need to know its components. The working device includes the following components:

- housing with inlet and outlet pipes;

- rubber gasket;

- Electrical engine;

- turbine;

- plain bearings;

- fasteners;

- air vent;

- starting capacitor;

- control terminal.

Recommendations for using a heating circulation pump

Correct operation of the pump directly affects its service life. By following some simple recommendations, you can protect your equipment from unnecessary breakdowns.

Tips for using the pump:

- The water temperature in the pipeline should be constantly monitored: it is very important that it does not rise above +65 degrees. Exceeding this indicator will provoke the formation of hard salts, which, after settling on the internal walls, begin to create additional obstacles in the operation of the device.

- Prolonged downtime of pumping equipment can lead to blocking and oxidation of the shaft. To avoid this, it is recommended to perform a preventative start of the device once a month for a period of 10-15 minutes. Thanks to this simple procedure, the service life of the moving parts of the device significantly increases.

- The flow rate directly affects the efficiency of pumping equipment. Therefore, you need to try in every possible way to avoid violating it, otherwise you will have to resort to repairing the circulation pump.

- It is prohibited to start the equipment if there is no coolant in the system.

- The same applies to the operation of the device at zero supply.

- The serviceability of all components must be checked on a regular basis.

Checking for short circuit

One of the common failures in electric motors is a short circuit to the frame. To find this kind of breakdown with a multimeter, do the following:

- set the resistance measurement of the device to maximum;

- check the serviceability of the multimeter itself by connecting its probes to each other;

- Connect one of the probes to the engine body;

- Connect the remaining one in turn to each of the phases.

If the engine you tested is working properly, then the resistance will show hundreds and even thousands of megaohms.

It is even easier to investigate for a short circuit in the “Dialing” mode. You need to do the same steps, and if you hear a sound (as when the winding is being tested), this will indicate the presence of violations in the integrity of the winding insulation, as well as the presence of a short circuit to the housing.

It should be noted that a breakdown of this type not only has a negative impact on the engine itself, but is dangerous for the lives of people working with the machine (if the necessary protective equipment is not available).

Basic safety rules

Although the design of the circulation pump is quite simple, it will require certain qualifications to eliminate any breakdowns that occur. Therefore, it is easier to prevent a problem than to heroically eliminate it later. One sign that something is wrong with your equipment is if it becomes excessively hot during operation.

Compliance with the simplest operating rules will help prevent this:

- Under no circumstances should the wiring come into contact with moisture.

- Particular care should be taken to check the tightness of the connection between the pumping equipment and the pipeline. If there are leaks, the gaskets should be replaced.

- It is forbidden to turn on the device without first grounding it. The heating pump device includes special terminals.

- The internal pressure force should not exceed operating standards.

To figure out why the heating pump is not working, it is recommended to seek help from a professional technician. You can try to fix simple problems yourself.

Briefly about the main thing

The Gilex drainage pump is the first assistant when flooding a room or cleaning a country pond. Like any equipment, unfortunately, it is periodically prone to breakdowns. There are some malfunctions that you can fix on your own, but there are major breakdowns where you can’t go without a specialist. Try to take care of your device, do not overload it and use it carefully, this will extend its service life for many years.

Are you using a Gilex drain pump? Do you like this model? When breakdowns occurred, did you fix them yourself or turn to a specialist?

Source of the article: https://makipa.ru/stati/drenazhnye-nasosy/remont-nasosa-dzhileks-drenazhnik-kak-proizvesti-svoimi-rukami/

What kind of breakdowns occur and how to make repairs yourself

The operation of heating systems implies the possibility of servicing and eliminating many faults by the apartment owners. The circulation pump is no exception: the main thing is to understand its structure and operating principle. You will also need some tools. Before disassembling the circulation pump, you need to make sure that it is connected correctly to the electrical network. All parameters must comply with the instructions in the technical passport.

The most common malfunctions of the heating circulation pump are:

- The device makes noise . The reasons for this phenomenon may be the following: the motor shaft has become covered with rust after winter storage of the equipment, or a foreign object has gotten inside the impeller. To solve the first problem, you will need to disassemble the circulation pump - the pump must be turned off before doing this. After this, the rotor must be turned several times. In the second case, everything is much simpler - the device is disassembled to remove the foreign body. In the future, it is advisable to acquire a protective mesh filter.

- The pump shaft has stopped rotating . First of all, using a tester, you need to check the device for the presence of voltage in it. Another common reason is connection errors. Most models are equipped with fuses that blow out during power surges.

- The appearance of unusual noise . The causes of sounds uncharacteristic of the operation of the circulation pump are often air accumulated in the system. This kind of problem can be solved by cleaning the pipes from air pockets. In order to never return to a similar situation again, it is recommended to equip the upper section of the pipeline system with a special automatic unit. It will independently bleed air as it accumulates.

- The pump stopped starting . The most likely reason is that the power supply has stopped. To eliminate it, you need to check the correct switching of phases and fuses. If everything is fine with this, it is possible that the drive winding has burned out. As a rule, an ordinary user is not able to fix such a breakdown, since disassembling the heating pump is not easy.

- After working for a few minutes, the device turns off . This may occur due to incorrect phase connection of the wires inside the terminal block. Another reason is that the fuse contact has oxidized, which needs periodic cleaning of toxins.

- Strong vibration of equipment during operation . Most likely, the bearing has become loose (it will need to be replaced from time to time). It is better not to carry out such repairs of the heating pump yourself.

The most popular models of pumping units

Manufacturers offer a wide selection of equipment of different capacities, designed for pumping liquid media with various parameters. But we are only interested in flow-through models that operate in home heating and hot water supply networks.

How to distinguish circulation units from centrifugal and other types of pumps:

- in shape - the electric motor and impeller are installed in one housing, the pipes come out on the sides of the lower part (not in the middle);

- by the presence of a “wet” rotor, which significantly reduces the noise of impeller rotation;

- 2 standard sizes, installation length 130 and 180 mm;

- nominal diameter of the pipes is 15, 20, 25 and 32 mm, connection is coupling (threaded);

- nameplate pressure – 0.4, 0.6 and 0.8 Bar.

The specified parameters can be easily determined by the product labeling. Example: the numbers in the name Wilo Star-RS 15/4 indicate an internal diameter of the connecting pipes of 15 mm (DN 15) and a pressure of 4 m of water column (0.4 Bar). Example two: the Grundfos ALPHA2 25-60 device is connected to DN 25 pipes and develops a pressure of 0.6 Bar (6 meters).

Reference. Manufacturers usually release extended product lines. The German brand Wilo offers circulation blowers with a pressure of 2, 4, 6, 7 and 8 m of water. Art. But the “running” models still remain “fours” and “sixes”, less often – “eights”.

The design of a pump with a “wet” rotor

Of course, there are more powerful pumps, whose pressure reaches 1...10 Bar, but they are not used in private homes. Small units 130 mm long with ½ and ¾ inch pipes are usually installed inside boilers, large ones (18 cm, 1 and 1 ¼") are cut into the heating lines.

Reasons for device overheating

The most favorable situation is when the temperature of the coolant in the system coincides with the temperature of the pumping equipment. However, it happens that the pumping apparatus begins to heat up above normal: this is a serious signal that problems have arisen in the operation of the device.

The circulation pump overheats for the following reasons:

- Insufficient voltage in the supply network . Because of this, sooner or later the engine will overheat and break down. Therefore, when overheating is detected, the first thing you need to do is check the network parameters: often the problem lies there, and not inside the device.

- Poor bearing lubrication . This leads to their rapid erasure, which creates a real threat of rotor jamming. It is best to renew the lubricant in a workshop, because... Complete disassembly of the heating circulation pump will be required.

- A foreign object got inside the device, causing it to jam . This item could be a piece of limescale or rust.

- System contamination . If the circuit has not been cleaned for many years, its inner walls are usually covered with a thick layer of plaque, which leads to a decrease in the diameter of the tubes. The resistance of the pumped water increases, and the device can no longer cope with the load. To prevent such situations, the system must be periodically cleaned, with the obligatory dismantling of some components (including the pump).

- Installation errors . An indication that the pump is installed incorrectly is if it overheats from the very beginning of operation. Equipment of this type is a complex device, since only specialists can check the heating pump for correct connection.

Modern models of heating circulation pumps are practical and easy-to-use devices. They are characterized by a high degree of reliability, which allows, with proper installation, practically no subsequent maintenance. After detecting overheating or other malfunctions, you should carefully measure your strength before repairing the heating circulation pump yourself. Sometimes it happens that eliminating damage caused by unprofessional disassembly of a mechanism is more expensive than repairing the original defect.

A modern heating circulation pump is a reliable device that does not require maintenance.

In the event of a serious breakdown, repair of heating pumps is entrusted to professionals. Minor errors in work are repaired independently.

Frequent malfunctions

Before disassembling, be sure to look for sparking, which usually occurs in the contact-brush mechanism. If you notice an increased level of sparking, it is worth checking the contact of the brushes or the presence of an interturn short circuit in the commutator itself.

As a rule, the main reasons why commutator motors break down are severely worn brushes or a blackened commutator. Old brushes are usually replaced with new ones. They must be the same in size and shape. It is best to install original parts (from the same manufacturer as the engine). Changing them is quite simple: remove (move) the lock or unscrew the bolt. Some engine models may require changing not only brushes, but also brush holders. Don't forget to connect the copper lead to the contact.

If the brushes are normal, check the springs that press them by stretching them.

If the contact part of the commutator becomes dark, clean it using fine sandpaper. It is also called zero.

At times, a groove forms at the point where the brushes and commutator come into contact. It needs to be sharpened using a machine.

Single-phase brushed motor

Another common failure of a commutator single-phase motor is bearing wear. If the housing vibrates strongly during operation and the bearings break, they definitely need to be replaced. If you start the situation, the mentioned parts will touch the rotor and stator, which may lead to their inevitable replacement. This is already more difficult and more expensive.

Operating rules

To prevent breakdowns, follow the operating rules:

- It is prohibited to operate the house heating pump if there is no water in the system;

- do not use the unit at zero supply;

- During operation, feed limits are observed;

- to prevent oxidation during downtime, the unit must be turned on for fifteen minutes;

- the temperature of the working fluid does not exceed sixty-five degrees Celsius;

- no leaks at pipe connections;

- no heating of the unit;

- Do-it-yourself pump installation involves horizontal placement of the shaft.

How to call: conditions

Before checking the electric motor for malfunction, you must make sure that the cord and plug of the device are absolutely in good working order. Usually, the absence of a disruption in the supply of electric current to the device can be judged by a glowing indicator lamp.

After making sure that electric current is supplied to the electric motor, it is necessary to dismantle it from the device body, while the device itself must be completely de-energized while performing this operation.

Checking the armature and stator of the electric motor is done with a multimeter. The sequence of measurements depends on the model of the electrical unit, and before ringing the electric motor, you should make sure that the measuring device is in working order.

Breakdowns and troubleshooting methods

Depending on the problem, the cause of the breakdown and its elimination are determined:

- The circulation pump does not turn on and does not make noise. The reason is a burned out winding or a broken fuse. The fuse or winding is changed;

- When the unit is turned on, a hum is heard, but the shaft does not rotate. Why does the unit hum but not work? Most likely, during prolonged inactivity, oxidation of the shaft occurred. If the device is blocked, it is disconnected from the network. The screws connecting the engine and the housing are unscrewed. The motor is removed and the shaft is turned. For low-power units, the shaft is unlocked using a screwdriver;

- The pump turns off after it is turned on without starting to work. The reason is scale between the stator and rotor. After dismantling the engine, salt deposits are removed;

- During operation, the device begins to heat up. Why does the engine get hot? There are several reasons for heating. Incorrect installation, poorly lubricated bearing, low mains voltage, system clogging. To eliminate the voltage problem, an uninterruptible power supply (UPS) is installed for the heating pump. A UPS is used for continuous power supply and protection against power surges. In the absence of electricity in the network, the UPS will ensure the operation of the unit for fifteen minutes (used as a power source). The UPS will protect the pump motor in the event of a surge, sudden drop or fluctuation in the voltage in the network. By connecting a UPS, the heating system will be protected from power surges. Mains power will be safe;

- food problem. The compliance of the actual voltage in the network with that specified in the characteristics is checked;

- the impeller is blocked. To troubleshoot the problem, you need to know how to disassemble the device. To eliminate the breakdown, the wheel is dismantled and the foreign object is removed. To prevent reoccurrence of blocking, a filter is installed at the pump inlet;

- When turned on, the pump may hum. The reason is accumulated air. To fix the problem, you need to bleed the air from the system. Automatic air vents will constantly bleed air. An air vent is needed to bleed air during operation and startup of the system;

- The unit vibrates during operation. The reason is bearing wear. The bearing needs to be replaced. The second reason is a clogged filter. The filter needs to be washed and cleaned;

- after switching on, the electric motor protection is activated. The reason is the engine electrics. It is necessary to contact a specialist;

- The water pressure is lower than specified in the technical specifications. We made a mistake while installing the device. Found in three-phase types of equipment.

Do-it-yourself heating pump repair (video)

Prevention of breakdowns

To prevent breakdowns, you need to check the serviceability of the heating pump yourself. Before the heating season begins, the unit is checked for breakdowns.

- Check for lubrication. When the pipes dry out, lubricate them.

- Check that the device is connected to the network correctly. When planning the heating system, it is necessary to place the pump in front of the boiler. This measure will reduce the formation of air jams to zero.

- The equipment is checked using a tester for correct connection to the network.

- Cleaning the filter from dirt.

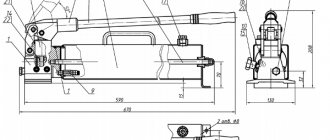

- Before starting the heating, the equipment is tested. To pressurize the heating system, water or air is supplied to the system. For crimping, a hydraulic or pneumatic pump is used.

Correct and incorrect installation of the circulation pump

The influence of the crimping process on the injection mechanism

The pressure testing process ensures high-quality maintenance of the entire heating system.

In order for the entire system to operate without leaks and turn on without problems, this procedure is carried out. The procedure is carried out after disconnecting the system from the network and removing the coolant. Before the procedure, the pipes must be pressed (cleaned) of scale. Scale, deposited on the internal parts of the pipes, reduces their permeability by fifty percent, increasing the load on the supercharger. It will become difficult for the pump to pump water through the system and it will quickly fail. Circulation will be disrupted throughout the entire system. Heating will not be effective.

If the heating system is not pressurized once every five years, the centrifugal pump will not cope with its task.

Continuity test of an asynchronous motor

This type of electric motor is quite often used in household devices operating from a 220 V network. After dismantling the unit from the device and visual inspection, during which no short circuit is detected, diagnostics are carried out in the following sequence:

- Measure the resistance between the motor terminals. This operation can be carried out with a multimeter, which must be switched to resistance measurement mode up to 100 Ohms. A working asynchronous motor should have a resistance of about 30 - 50 Ohms between one extreme and middle terminal of the connected winding, and 15 - 20 Ohms between the other extreme and middle contacts. These measurements indicate complete serviceability of the starting and main windings of the unit.

- Diagnose current leakage to ground. To test the unit for electric current leaks, you need to switch the multimeter operating mode to the resistance measurement position of up to 2,000 kOhm and alternately connect each terminal to the motor housing to determine the presence or absence of insulation damage. In all cases, the multimeter display should not show any readings. If an analog device is used to measure leakage, the needle should not deviate during diagnostic procedures.

If deviations from the norm were identified during the measurement process, the unit must be disassembled for more detailed studies. The most common failure of asynchronous electric motors is an interturn short circuit.

With such a malfunction, the device overheats and does not develop full power, and if operation of the device is not stopped, the electrical unit can be completely damaged.

To test turn-to-turn short circuits, the multimeter is switched to resistance measurement mode up to 100 Ohms.

It is necessary to ring each stator circuit and compare the results obtained. If the resistance value in one of them differs significantly, then in this way it is possible to confidently diagnose an interturn short circuit in the winding of an asynchronous electric motor.

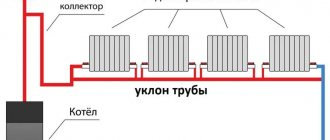

Single-pipe system - “Leningradka”

The diagram looks like this: at the bottom there is a filling pipe into which heating radiators are cut using tees.

This system is done very often. People reason like this: one filling pipe is always simpler and cheaper than two. But savings on pipes when installing a “Leningradka” only occur when it is possible to make a full circle, that is, to go around the entire room. If it is not possible to completely loop the bottling, then you have to return the blank pipe and all the savings come to naught. Very often, when installing the Leningradka, irreparable errors are made, which lead to the system not working at all or partially. As you know, the coolant always circulates along the path of least resistance, so most of it goes through the lower pipe in addition to the radiator. But the circulation in the battery is very weak and in order to increase it, a so-called reduction is installed. This is done in two ways - by narrowing the section of pipeline under the radiator or by installing shut-off valves on it.

Design

Almost all circulation pumps are centrifugal type. They have an impeller mounted on the motor shaft and placed in a special “shell” chamber. The entrance to the shell is located in the center, while the exit is the outer edge of the shell with a channel extending around the circumference in the direction of movement of the impeller. The engine spins the impeller, and water, under the influence of centripetal force, rushes from the center to the edges of the sink from inlet to outlet.

Pump structural elements:

- pump part, sink and impeller mounted on the shaft;

- electric motor;

- electronic control unit.

The most susceptible to wear is the moving part of the pump - the motor shaft and impeller, as well as the bearings on which they are mounted.

Control method

It is quite acceptable to constantly maintain the circulation of hot water in the pipes, but this is uneconomical and unjustified. Hot water is not used constantly. At night, while all the residents are sleeping, it is useless to keep the water in the pipes hot, the same applies to the time when everyone is at work or school.

If the pipes are laid out correctly, then thermal insulation is required, so that once hot water gets into the pipes, it does not cool down instantly. Therefore, there is no need to constantly pump water from the boiler into the pipes and back; periodic operation of the pump is sufficient, which reduces the load on it and the hot water system as a whole. There is no need to talk about saving electricity, since the consumption of the recirculation pump is low.

Two main control methods are used:

- according to temperature sensor readings;

- according to a timer (schedule).

Both options are in demand, although they differ significantly in their operating principles.

By temperature sensor

Grundfos UP 15-14 BT 80

In this case, the pump control unit relies on the readings of a temperature sensor immersed in water inside the circuit pipes. The pump resumes operation as soon as the water has cooled to a certain threshold temperature. This approach significantly reduces the load on the equipment and constantly keeps the water in the pipes heated. In addition, the safety of the hot water supply increases. Having set a sufficiently high response threshold, water is pumped more often through the boiler, where it is additionally heated and disinfected.

By timer

Grundfos UP 15-14 BU

The control unit alternately turns the pump on and off based on the time delays set in the settings. Knowing exactly the parameters of the hot water system, the length of the pipes and their internal volume, thermal insulation and average heat loss, you can select the optimal time during which the water will not have time to cool down. The pump is turned on by a timer signal and pumps all the water. In this case, the duration of operation is also calculated based on the volume of pipes and pump performance.

Another advantage of the timer is the ability to schedule the operation of the recirculation pump for a day or even a week. It is in this case that downtime when hot water is not used is taken into account.

Hydraulic resistance coefficient

Hydraulic losses are expressed either in pressure loss Δh in linear units of the medium column, or in pressure units ΔP:

where ρ is the density of the medium, g is the acceleration of gravity.

In industrial practice, the movement of liquid in flows is associated with the need to overcome the hydraulic resistance of the pipe along the length of the flow, as well as various local resistances:

Turns Diaphragms Gate Valves Cranes Various branches and the like

A certain part of the flow energy is expended to overcome local resistances, which is often called the loss of pressure due to local resistances. Typically, these losses are expressed as fractions of the velocity pressure corresponding to the average fluid velocity in the pipeline before or after local resistance.

Analytically, the head loss due to local hydraulic resistance is expressed as:

where ξ is the local resistance coefficient (usually determined experimentally).

Data on the value of the coefficients of various local resistances are given in the corresponding reference books, textbooks and various manuals on hydraulics in the form of individual values of the coefficient of hydraulic resistance, tables, empirical formulas, diagrams, etc.

The study of energy losses (pump pressure loss) caused by various local resistances has been carried out for more than a hundred years. As a result of experimental studies carried out in Russia and abroad at various times, a huge amount of data was obtained relating to a wide variety of local resistances for specific tasks. As for theoretical research, only some local resistance has so far yielded to it.

This article will discuss some characteristic local resistances that are often encountered in practice.

Local hydraulic resistance

As already written above, pressure losses in many cases are determined experimentally. In this case, any local resistance is similar to the resistance due to sudden expansion of the jet. There are sufficient grounds for this, if we take into account that the behavior of the flow at the moment it overcomes any local resistance is associated with the expansion or contraction of the cross section.

Hydraulic losses due to sudden narrowing of the pipe

Resistance during a sudden narrowing of the pipe is accompanied by the formation of a whirlpool region at the point of narrowing and a decrease in the jet to sizes smaller than the cross-section of the small pipe. Having passed the narrowing section, the jet expands to the size of the internal section of the pipeline. The value of the local resistance coefficient for a sudden narrowing of the pipe can be determined by the formula.

Harness

There are two types of heating systems - forced and natural circulation. Systems with forced circulation cannot work without a pump; systems with natural circulation work, but in this mode they have lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is installed into it. This gives high heating efficiency and reliability. It is clear that the installation of a circulation pump in these systems is different.

All heating systems with heated floors are forced - without a pump, the coolant will not pass through such large circuits

Forced circulation

Since a forced circulation heating system without a pump is inoperative, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They can jam the impeller and stop the motor. Therefore, a mesh dirt filter must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also advisable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps and remove the unit. Only that part of the water that was directly in this piece of the system is drained.

Natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not working. One ball shut-off valve is installed on the bypass, which is closed the entire time the pumping is running. In this mode, the system operates as forced.

Installation diagram of a circulation pump in a system with natural circulation

When the electricity goes out or the unit fails, the valve on the jumper is opened, the valve leading to the pump is closed, and the system operates as a gravity system.

Installation features

There is one important point, without which the installation of the circulation pump will require rework: it is necessary to rotate the rotor so that it is directed horizontally. The second point is the direction of flow. There is an arrow on the body indicating which direction the coolant should flow. This is how you turn the unit so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, just when selecting a model, make sure that it can work in both positions. And one more thing: with a vertical arrangement, the power (pressure created) drops by about 30%. This must be taken into account when choosing a model.