If you insulate a cold attic used for storing unnecessary items, it will turn into a cozy residential attic. First of all, of course, you need to insulate the roof itself. The roofing of an attic roof is more complex than the roofing of a cold attic, but the result is worth it - the room can be used all year round. Here it is most important to fully comply with the technology, because each layer carries certain functions, without which the roof can suffer large heat losses without fulfilling its functions, or quickly collapse, as a result of which it will have to be completely redone.

The need to insulate the attic space

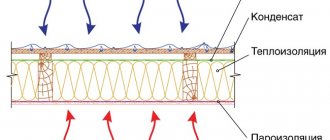

Experts call the pie of attic insulation a heat-insulating structure consisting of successively laid layers of materials, starting with the roof covering and ending with the internal lining of the room.

The filling consists of insulating materials laid in a certain order. Poor implementation of roof insulation technologies can lead to the appearance of the main enemy of a wooden house - dampness. Moisture can come from both outside and from living quarters. The formation of condensation in the under-roof space will lead to wetness of the thermal insulation material, the appearance of mold and rot, destruction of rafter structures and damage to the roofing material. The result will be complex, expensive repairs. The correct attic pie will not only protect the living space from heat loss, but will also protect the wooden and metal elements of the roof. Since the attic is located in close proximity to the roof, the process of heating and cooling the air in it occurs much more intensely than in other rooms. Thermal insulation materials are designed not only to protect the internal space from the penetration of cold from the outside, but also from overheating in hot weather.

When building a new house with an attic, all stages of insulation occur during the process of creating the roof. But often the owners of already built houses with an attic strive to independently rebuild the upper part of the building and create additional living space under the roof. The technology for roof insulation is not too complicated, and if you have some construction skills and the necessary information, it is quite possible to create a high-quality attic roof pie with your own hands.

What to look for when choosing insulation for an attic?

When purchasing this or that thermal insulation material, be sure to pay attention to:

- versatility of use;

- thermal insulation properties;

- ability to repel moisture;

- presence of soundproofing properties;

- price;

- ease of installation;

- insulation service life;

- resistance to temperature changes;

- environmental friendliness.

Obviously, the main selection criterion is the ability to retain heat . After all, this is especially important for an attic room. In addition, versatility of application is important: it will be great if the material can be used to insulate both the roof, floor and walls. And if you don’t want to hear the noise coming from outside, then choose insulation with soundproofing properties . All these parameters are important. Ideally, the chosen thermal insulator should correspond to most of them.

Video - Types of insulation

Necessary insulation materials for insulating the attic roof

The correct selection of insulating materials to create the right attic cake is of great importance.

Many owners of country houses prefer mineral wool as a material that has all the characteristics necessary for insulation and is low cost. No less popular is the use of polystyrene foam. It has good thermal insulation properties, water resistance and light weight. The dense structure allows it to be cut into pieces of the required size, which greatly facilitates the process of installing the insulation. Modern industry offers a wide variety of thermal insulation materials made using the latest technologies and with excellent characteristics. But usually their cost is higher than traditionally used materials.

You need to be no less careful when choosing hydro- and vapor barrier materials. The efficiency of the thermal insulation material depends on their quality.

Requirements for insulation

The industry produces a wide range of materials used for insulating buildings. Regardless of the production technology, they all must meet several universal requirements.

- Low moisture permeability. A very important parameter - the durability of the attic space depends on it. In addition, increasing humidity significantly increases thermal conductivity.

- Low thermal conductivity. All modern insulation materials meet this requirement. A slight difference in thousandths can be ignored and it can be assumed that there is no difference in heat saving between them. The fact is that such minimal differences are completely leveled out during construction work: it is almost impossible to maintain a perfectly uniform thickness of insulation.

Thermal conductivity is the main indicator of thermal insulation materials

- Light weight. This requirement is the easiest to satisfy - absolutely all insulation materials have a minimum density, otherwise they are not insulation materials. And low density automatically reduces weight.

- Fire safety. As with all building materials, one requirement is put forward for insulation: the less the likelihood of ignition, the better.

Fire safety indicators of materials

These are general requirements, and popular insulation materials meet optimal performance to varying degrees.

Sequence and rules for arranging an attic pie

The main attention should be paid to the technological side of creating an attic insulation cake. To do this, you need to have knowledge about the processes occurring in the under-roof space under the influence of external conditions.

Work must be carried out in strict sequence and in compliance with all installation rules:

- First of all, all cases of destruction of rafter structures should be identified. Areas affected by rot are thoroughly cleaned until healthy wood appears. It may be necessary to replace some elements with new ones if the destruction process has gone too far. To protect against mold and bugs, rafters are treated with special products.

- The next stage is laying the waterproofing layer. The material is attached to the rafter system using a stapler. All seams must be sealed with self-adhesive tape. A prerequisite for creating an attic pie is the arrangement of proper ventilation of the under-roof space. It is necessary to create the possibility of natural air circulation, protecting the inner surface of roofing materials from moisture. To do this, there must be a ventilation gap between the roof and the waterproofing material, the width of which is determined by the type of roofing material. When using soft roll roofing and flat materials, it must be at least 5 cm. For profile materials, 2.5 cm is sufficient. Free air exchange allows you to maintain a constant temperature of the roofing, which protects it from icing and the formation of icicles in winter and from overheating of air in the attic in summer. . To allow air to enter and exit, ventilation openings must be provided at the bottom of the roof and at the ridge of the roof.

- Next comes the installation of the thermal insulation layer. A layer of insulation is laid between the rafters. The layers of mineral wool must fit tightly to the beams to prevent the occurrence of “cold bridges”. When using polystyrene foam, the cracks are sealed with polyurethane foam. It is also necessary to leave free space between the waterproofing material and the insulation to prevent the occurrence of condensation, leading to wetting and damage to the thermal insulation layer. To do this, a system of wooden counter slats is installed to provide the required gap width (2-3 cm).

- Installing a vapor barrier layer will protect the insulation from fumes occurring in residential premises. The barrier film is nailed to the rafters on top of the insulating material.

- The entire assembled structure is covered with a sheathing made from wooden slats or metal guides. Facing materials will be attached to it. The choice of materials for interior decoration depends on the design decisions of the interior arrangement.

Dew point problem

Ideally, the roof in the attic should be insulated from the outside at the stage of forming the roofing pie. However, often this is done the other way around from the inside, when the house is already covered with a roof. And here certain problems arise.

The correct and ideal roofing pie is several layers of different materials laid on top of the rafters tightly on top of each other without gaps. Such a sandwich ensures that the dew point will be located on its outer side. As a result, all condensate formed outside will quickly evaporate into the atmosphere.

When insulating an attic roof from the inside, it is extremely important to leave a gap between the insulation and the existing roof for ventilation and evaporation of condensate formed due to temperature changes

By doing insulation from the inside, after installing the roof, it is impossible to form the exemplary roofing pie described above. It will not be possible to press the insulation onto the roof so that there are no voids left between them.

But steam always moves towards cold air. And then, each of the formed cavities will begin to accumulate condensation and moisture. And this is a direct path to damage to the thermal insulation material and wooden elements of the rafter system.

When insulating an attic internally, the dew point has to be shifted into the space between the laid roof and the insulation, leaving an additional 5–10 cm gap there for ventilation. Only such a technology and such a cake will avoid moisture in the insulating material.

To achieve proper air exchange in the under-roof space, it is recommended to install deflectors on the ridge and provide special holes in the eaves

To reduce the amount of water vapor in the insulation, its installation should be done using a vapor barrier film. A vapor barrier is installed from the inside of the attic on top of the thermal insulation material.

The steam must first encounter this film and mostly remain in the room. The less of it gets into the insulation layer, the better.

Video - Attic insulation, roofing pie

- The main preparatory stages of insulation of wooden houses::

Almost every home needs insulation. How to properly prepare for insulation in wood.

“>The main preparatory stages of insulating wooden houses - 03/11/2015 06:56 Do-it-yourself utility blocks for a summer cottage::

Even at the planning stage of dacha construction, experts advise thinking about the construction.

“>Do-it-yourself utility blocks for a summer cottage - 10/23/2015 05:56 Methods of clearing a plot of land for construction::

The site selected for development must be level and free of trees, stumps and dead wood.

- Pit for the foundation of a house - preparation for construction work::

Any serious business must begin with laying the foundations. Construction is no exception.

“>Pit for the foundation of a house - preparation for construction work - 03/05/2015 05:37 Insulation of the roof of a house - a necessary stage of construction and repair::

To ensure that your home has a comfortable microclimate all year round, you need to take care of everything.

“>Insulation of the roof of a house is a necessary stage of construction and repair - 02/19/2015 05:19 Do-it-yourself installation of electrical wiring in a house::

Electrical appliances won’t work on their own, chandeliers won’t shine either, that’s what they need.

Mansard roof installation: design features

Mansard roofs have always been very popular. Its adherents are attracted by the originality of the shape of the room and the volume of space that such a roof creates, the opportunity to create another residential floor, only partially using the walls and the entire roof rafter system, etc. The non-standard attic room is especially loved by those for whom this is another way to create your world unique and bright.

By definition, an attic is a floor at the attic level that has a facade formed entirely or partially by either a sloping or sloping roof. In this case, the planes of the facade and roof must intersect at a height not exceeding 1.5 m from the floor plane. Attics can have different geometric shapes - the silhouette of a triangle or a broken line, be symmetrical or not, located on one side of the longitudinal axis of the attic floor or along its entire width.

Installation of windows in the attic

When installing roofs of this type, two main types of windows are used - standard, installed in openings along the facades, and special attic windows, embedded directly into the roof.

There are no problems with installing regular windows; the main thing is to order a translucent structure of the required size.

The situation with roof windows is somewhat different. They must be installed in strict accordance with the manufacturer's instructions, otherwise it will not be possible to achieve tightness, and the roof will leak precisely in the area of the window openings.

Additionally, it is recommended to insulate the slopes with penoplex or other similar material. This will help reduce heat loss through the window opening.

How to properly prepare for the device ↑

The dimensions of the attic roof must correspond to the volume completely necessary for arranging the attic room. In this case, the optimal width of the structure should not be less than 4.8 m, and the height – 2.5 m. To select the slope of the rafter system, the shape of the roof is also of great importance.

- In the case of a broken line, the slope of the lower part of the attic is steep (60–70°), and the upper part is flat (15–30°).

- If the roof is gable, then the optimal roof slope, at which it is possible to fully use the attic space, is more than 45°. As you know, roofs with such a slope are more susceptible to wind loads, so in areas with strong winds their supporting structure is strengthened.

For multi-gable roofs or if heavy roofing materials are to be used, it is recommended to use metal structures. The fact is that if you use wooden structures, then to strengthen the supporting frame they must be quite massive, and this will noticeably limit the volume of the attic.

When calculating an attic roof, it must be taken into account that with a large slope of the rafter structure, the length of the rafters and the roof covering area will also increase, and the usable area of the resulting room will be smaller.

The greater the angle of inclination of the attic roof of a house, the more carefully it is necessary to choose the material from which the roof will be made.

The roof over the attic is a complex engineering structure, which, in addition to the supporting frame, also includes a “roofing pie”, so the installation of attic roofs requires solving a certain set of problems. Even before calculating the attic roof, the architectural details and the possibility of ensuring proper thermal protection and tightness of the room must be fully worked out, a project for the attic floor must be prepared, and the main components of the attic roof

and optimal design of load-bearing structures.

The use of stone or concrete for load-bearing structures of the attic is strictly prohibited.

Preparing the under-roof space for insulation

You should know that, according to GOST standards, the height of ceilings in the attic cannot be less than 2.5 meters. But this does not apply to the entire area of the attic, but only to half of it, that is, in the remaining 50 percent, the height of the room may be slightly less.

What factors influence heat loss in the attic floor:

- type of main building material of the house;

- the presence of common communications with other rooms of the house;

- features of roof geometry, number and shape of slopes;

- type of load-bearing roof materials;

- placement of the attic relative to the main building (with access beyond its boundaries or not).

All these factors must be taken into account before you begin to insulate the roof from the inside with your own hands. Building regulations dictate that insulation of a house must be carried out from the outside so that the freezing point moves to its outer part. But this rule does not apply to attic floors. Here, the specifics of construction require internal insulation, since roofing material must be placed outside.

The only surface that can be insulated from the outside is the roof gable

In terms of preparation for insulation work, you need to carefully study the options for thermal insulation coating and select a high-quality waterproofing film.

Features of the attic roof ↑

The attic room is simultaneously exposed to influences from two directions - above and below.

- From living spaces located below, rising upward, warm air can fall onto the inward-facing roof surface in the form of condensation. Therefore, the design of the attic roof requires careful steam, hydro and thermal insulation.

- The contact area of the attic with the external environment is quite large, so the attic floor must be carefully insulated with excellent thermal insulation. In most cases, mineral wool slabs are used for these purposes, although the best way to insulate an attic roof is a question that has not yet been fully resolved. They are placed between floor beams and rafters.

Mansard roof pie: correct design diagram ↑

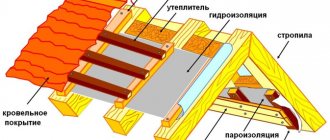

The standard design of an attic roof involves combining roofing material and insulation into a single structure.

In order for them to function normally, a multilayer structure is created in which the order of layers is strictly observed: vapor barrier, insulation, waterproofing and roofing, and ventilated gaps are left. Each of the elements of this design has certain physical and technical properties and plays a certain role in creating comfortable conditions in the attic.

Waterproofing prevents the insulation from getting wet on the outside.

It is laid on the counter-lattice with an overlap of no less than 10 cm, allowing for slight sagging taking into account its thermal expansion.

The joints are carefully sealed. Waterproofing an attic roof

, if the roof covering is a metal roof, is not necessary - its functions are taken over by an anti-condensation film, which prevents condensation from forming on the inside of the metal surface. Its bottom layer is made of viscose, so the anti-condensation film dries quickly and is able to retain a sufficient amount of water.

The next step is to lay insulation between the rafters - tightly, without gaps. Today, insulation based on basalt mineral wool, fiberglass, and extruded polystyrene foam is used for attic roofs.

- Semi-rigid and rigid mineral wool insulation

has high vapor permeability and fire resistance, does not deform at high temperatures, does not shrink over time, does not absorb moisture and is environmentally friendly. - Fiberglass insulation

also has good performance characteristics. They provide high-quality insulation, have high elasticity and guaranteed fire safety. Due to their low density, the load on the supporting structure of the attic roof is reduced. - Expanded polystyrene

has remarkable thermal insulation properties, which are explained by the uniformity of its structure - it consists of closed small cells. This design has practically zero water absorption, low thermal conductivity, and high resistance to water vapor pressure. Insulation of an attic roof with foam plastic, due to the high compressive strength of the material, is optimal in places where the insulation is subject to heavy loads.

On the room side, the insulation is covered with a vapor barrier film.

A vapor barrier is needed to ensure that water vapor arising from human activity does not penetrate from the interior into the insulation.

The vapor barrier film, regardless of the chosen roofing material, is mounted on the inside of the structure as closely as possible to the insulation. To ensure the reliability of the vapor barrier, the seams of the film are sealed with special connecting tape.

The structure of the structure must provide ventilation gaps with a minimum thickness of 50 mm. One of them should be between the insulation and waterproofing. To do this, counter-lattice bars (45 x 50 mm) are nailed to the edge of the rafters. The other is between the waterproofing and the roofing material; it is provided by sheathing bars.

Using a superdiffusion membrane as a waterproofing material eliminates the need for ventilation devices. This material is also waterproof and windproof.

Review of roofing materials

Profiled sheet

A roof covered with corrugated sheets, a modular material produced by profiling rolled sheets followed by chrome plating and applying a decorative layer, has high strength and wear resistance. Corrugated sheeting is light in weight and easy to install, but has low noise absorption and high thermal conductivity - such a roof requires additional insulation.

Minimum roof slope: 12 degrees. Weight: 5 kg/sq.m. Price: 150-250 rub. m sq.

Ruberoid

Ruberoid is a roll-type roofing sheet, which is made by impregnating specific cardboard with petroleum bitumen and sprinkled with protective granulate. The “advantages” of roofing felt include light weight, low price, ease of installation, and relative durability. The disadvantages are high flammability, poor resistance to critically high temperatures.

Minimum roof slope: any. Weight: 4 kg/sq.m. Price: 20-30 rub. m sq.

Slate

Sheet slate is a material made from a cement mixture and reinforced with asbestos fibers. Slate is a non-flammable coating; it is quite durable and easy to install, but is fragile and does not resist moisture well.

Minimum roof slope: 10 degrees. Weight: 10-15 kg/sq.m. Price: 120-250 rub. m sq.

Ondulin

Environmentally friendly and beautiful, moisture-resistant and resistant to aggressive environments, silent and durable - this is a roof made of ondulin - a polymer sheet material made from cellulose fibers impregnated with bitumen. Among other advantages, ondulin is light in weight and easy to install. Among the disadvantages of this roofing sheeting, it is worth mentioning its flammability and tendency to fade from ultraviolet radiation.

Minimum roof slope: 5 degrees. Weight: 6.5 kg/sq.m. Price: from 254 rub. m sq.

Metal tiles

Metal tiles are a profiled metal sheet (galvanized steel, aluminum, copper) with a polymer coating (polyester, polyurethane, plastisol, acrylate), which performs protective and decorative functions. Metal tile flooring almost reliably imitates ceramic tiles and is produced in a wide range of colors and textures. Due to the light weight of the modules, metal tiles place minimal load on the rafter system, walls and foundation of the house, and therefore can significantly reduce the cost of construction and simplify the installation of the roof. This material is durable and environmentally friendly, but prone to corrosion, has high thermal conductivity and noise, requiring additional sound and heat insulation.

Minimum roof slope: 14 degrees. Weight: 5 kg/sq.m. Price: 210-290 rub. m sq.

Soft roof

Flexible tiles are produced in the form of cut modules, formed from fiberglass, impregnated with modified bitumen and covered with stone dressing (basalt, slate). A soft roof has multiple advantages - it provides reliable waterproofing, protection from mechanical damage, high and low temperatures, and exposure to ultraviolet radiation. It has strength in combination with low weight and elasticity, which allows you to equip roofs of complex configurations with minimal labor costs. Flexible tiles are durable, silent during rain, visually attractive and vary in color, texture, and shape. The main “minus” of soft roofing is its high cost: its price is lower than ceramic tiles, but higher than other roofing coverings.

Minimum roof slope: 12 degrees. Weight: 8-12 kg/sq.m. Price: 220-260 rub. m sq.

We build an insulated attic roof without errors

A residential attic can be no less comfortable than a full floor, but only if you choose the right roofing design. We talk about the advantages and disadvantages of different options, as well as typical mistakes made by roofers.

Unusual for a city dweller, sloping walls, stars and clouds outside the windows, the light rustle of rain on the roof - these features of country romance, as well as the opportunity to reduce the construction budget, make the idea of a residential attic very attractive for those who are planning to build a dacha or cottage. But to prevent heating and air conditioning costs from making a hole in the family budget, it is necessary to properly insulate the roof.

How to choose and install insulation

First of all, you need to decide what kind of insulation to use, where to place it and in what order to carry out construction.

Insulation between rafters

The easiest to install and popular option for roof insulation involves the use of slabs and mats made of mineral wool with a density of 30–50 kg/m3 - “LightButts SCANDIC” (ROCKWOOL), Technolight Extra (TechnoNIKOL), Terra (URSA), etc. These materials are easily compressed and restore their shape, so that they can be installed tightly, without gaps, between the rafters. In central Russia, experts recommend installing insulation in two layers 100 mm thick, that is, the width of the rafter legs should be 200 mm. Lumber of the required cross-section is expensive and is mainly supplied to order, but it is not so difficult to build up standard boards with a cross-section of 50 × 150 mm with 50 × 50 mm bars.

Stone wool for attic insulation

One of the most common insulation materials in pitched roofs is stone wool, as the optimal material in terms of performance and cost. It has such properties as:

- low thermal conductivity;

- biostability;

- fire resistance;

- non-flammability;

- sound absorption;

- minimal hygroscopicity;

- durability;

- practicality (and ease of installation, and preservation of the original parameters for the entire service life).

When vapor passes through the fibers, the stone wool is not moistened, its thermal conductivity and volume remain unchanged, that is, during operation the insulation remains dry and effective and does not lose its properties.

ra093FORUMHOUSE Member

Please give advice on how best to insulate the attic of a 10x10 m timber house, Middle Urals. The pie is now standard: flexible tiles, ventilation gap 50 mm, membrane, rafters 200x50 mm. The attic is quite low, I don’t want to lower the ceiling too much.

I see options:

- 200 mm stone wool. Then straight finishing. The rafters look like cold bridges. But how much heat do they take away, considering that 200 mm, and my house itself is made of 190 mm timber, essentially like a cold bridge.

- 50 mm gap between the wool and the membrane, 150 mm of wool, there is already a 30 mm pier plate on the rafters. It turns out more expensive, but it seems to me it should be warmer than 200 mm of wool. The downside is that the ceiling will be lowered a little more.

What other options are there that are not too expensive? Of course, I would like to blow out everything with 150-200 polyurethane foam or lay it all out with slabs, but the price turns out to be very high. Can he handle the entire feast with 100 mm slabs? Judging by the advertised thermal conductivity, it will be like 200 mm of wool.

Anatoly Zemlyanko Technical specialist of ROCKWOOL company

Definitely the first option. 200 mm stone wool, which is the most effective vapor-permeable and breathable material. All other materials will act as a vapor barrier, so it is not advisable to mix these insulation materials. Logs are not cold bridges, since the thermal conductivity coefficient of wood is quite low, which indicates its effectiveness.

Vapor barrier

In the absence of a vapor barrier layer, warm, moist air freely penetrates into the roof structure, where it condenses, as a result of which the fiber insulation becomes damp and ceases to protect against the cold, and the rafters and sheathing begin to rot. In turn, hot air from the under-roof space easily enters the rooms.

Modern vapor barrier films are made of two layers of polyethylene or polypropylene and reinforced with synthetic fiber; they are durable, elastic and do not tear during installation. And foil films, in addition, reflect radiant heat back into the attic, which helps reduce heating costs.

The film strips are placed perpendicular to the rafters and nailed through clamping bars or staples. They start from the ridge and provide an overlap of about 10 cm. The joints, as well as the places pierced with staples, are glued with special tape.

The minimum cross-section of the clamping bars or sheathing bars is 40 × 40 mm; with a smaller thickness, it will not be possible to provide a gap under the finish, and when installing electrical installation products, the vapor barrier will almost certainly be torn or cut through.

The insulation must be protected not only from below, but also from above. The fact is that condensation forms on the inner surface of a metal roof, and some water almost always seeps through the joints between the roofing elements and the holes from the fasteners. In addition, fibrous materials are destroyed over time by the air flow that forms in the under-roof ventilation gap. These negative impacts will be prevented by wind and moisture protection mounted on top of the insulation.

The best materials for its construction are vapor-permeable two- and three-layer diffusion films that do not interfere with the evaporation of moisture from the insulation.

Strips of wind- and moisture-proof material are rolled out across the rafters, starting from the bottom, and pressed against the counter-battens with bars. In this case, as in the case of vapor barrier, it is necessary to ensure an overlap of the strips of at least 10 cm; it also does not hurt to glue the joints with double-sided tape.

Features of each layer

Next we will look at the attic cake layer by layer, indicating the design features, as well as the nuances of selecting and laying materials. We will consider all layers of the attic roof structure, moving from the room to the outside.

The very first layer, which is located on the side of the room, is the interior decoration. For these purposes, you can use sheets of plasterboard, plastic panels, wooden lining and other finishes. Among all the materials for finishing the attic, plasterboard and wood have an advantage, since they can naturally regulate the humidity in the room, which contributes to a favorable microclimate.

Vapor barrier

The vapor barrier layer is attached to the rafter system from below. It is needed to protect the internal structures of the roof and insulation from the formation of condensation due to temperature differences indoors and outdoors.

Attention! The absence or poor quality of vapor barrier leads to the accumulation of condensate moisture in the insulation. Due to dampness, the insulation cannot perform its thermal insulation functions, and the room will be cold.

Vapor barrier roll materials are rolled out across the direction of the rafters and attached to them using a construction stapler. In this case, it is necessary to overlap the strips by 150 mm. The joints between strips of material are additionally sealed with special tapes or regular tape.

The following materials are used as vapor barrier:

- The most accessible and inexpensive vapor barrier is glassine. Over the years, its properties for protection against condensate moisture decrease, so it is better not to use it.

- Special vapor barrier membrane. This is a polyethylene film that may have additional reinforcing and reflective layers. She copes with her tasks perfectly and does not sag.

- Foil vapor barrier. This is the most expensive material, but in addition to protecting against moisture, it allows you to effectively retain heat in the room due to the reflective layer. The foil film must be attached with a gap of 10-20 mm from the insulation. To obtain this gap, slats of appropriate thickness are placed on the rafters before fixing the film.

It is worth knowing: the vapor barrier should not fit tightly to the insulation laid between the rafters, so the material is attached to the rafters with a slight sag (about 2 mm).

Rafter system

For the manufacture of pitched roof rafters in a private house, elements made of coniferous wood of at least grade 1 with a moisture content of no more than 15% are used. The optimal rafter section is 150x50 mm. In the middle climate zone of our country, to effectively insulate an attic roof, it is necessary to use thermal insulation material 200 mm thick. As you can see, a rafter height of 15 cm will not be enough, so a beam with a cross section of 50x50 mm can be attached to them from below.

The installation step of the rafter system depends on the roof structure, the width of the thermal insulation material used and the type of roofing. It is also worth remembering that the larger the pitch of the rafter system, the larger the cross-section of one element should be. For rafters with a cross section of 5x15 cm, the optimal pitch is 800-900 mm.

Important! All wooden elements of the roof supporting frame must be protected from rotting and burning. To do this, they are pre-treated with antiseptics and fire retardants.

Insulation

The most important thing in the design of an attic roof is the insulation layer, because the comfort of living in the attic, as well as the level of sound insulation of the premises, depends on it. For thermal insulation of pitched structures, the following is usually used:

- Mineral slabs. They are made on the basis of basalt fiber, are quite dense, non-flammable and retain heat well.

- Fiberglass is a non-flammable, environmentally friendly material. Its disadvantage is the instability of the structure and the possibility of sagging.

- Polystyrene foam is an inexpensive, effective material that does not absorb moisture at all, but releases toxic compounds when burned.

- Expanded polystyrene is a very light, non-flammable and non-toxic material that does not accumulate moisture. However, it has increased vapor permeability, so in summer there may be high humidity on the attic floor. Due to its high rigidity, expanded polystyrene is difficult to install on difficult areas of the roof.

Advice: to insulate the attic, it is better to use soft mineral wool slabs based on basalt. They are easy to install in difficult areas and fit tightly to the rafters without forming cold bridges.

For each construction region, the thickness of the thermal insulation material is calculated individually. The minimum insulation layer is 150 mm. For regions with harsh winters, it is necessary to use thermal insulation material with a thickness of at least 20 cm. In this case, the insulation is laid only on dry rafter wood. Otherwise, moisture will penetrate into the thermal insulation material and reduce its effectiveness.

Waterproofing

The main purpose of waterproofing is to protect the insulation from moisture penetrating from the roof, as well as the ability to transmit water vapor that will evaporate from the insulating material. This is why vapor barrier film is not suitable for these purposes, because it does not allow water vapor to pass through. Special materials are used to waterproof roofs:

- Diffusion membranes. These are films with microscopic funnel-shaped holes. The material is laid so that the wide part of the funnel is turned towards the insulation, and the narrow part towards the roofing. In this case, it is necessary to create two ventilation gaps and lay the material away from the insulation at a short distance so that the funnels do not become clogged with water vapor. These membranes can only be used with those roofing coverings that are not susceptible to moisture collecting on the back side.

- Superdiffusion membranes. The effectiveness of this material does not require the installation of an air gap on the insulation side. Such films are suitable for houses where the roof is laid on an already inhabited building. The membranes protect well from the wind.

Important! Both types of membranes cannot be used with European slate and metal tile coverings, since their back side must be reliably protected from condensation. But these membranes are ideal for coverings made of soft and traditional tiles.

- Condensate films are used for roofing made of euro slate and metal tiles, since they do not allow water vapor to pass through. In this case, excess moisture from the heat-insulating material accumulates on the fleecy side and is removed outside through the ventilation gap. In such structures, it is necessary to create a second ventilation gap between the waterproofing carpet and the coating so that condensation does not accumulate on the back side of the roof.

Counter batten and sheathing

If it is necessary to arrange ventilation of the under-roof space, then counter battens are placed on top of the waterproofing carpet. To do this, use a beam with a section height of 30-40 mm, which is nailed in the direction of the rafters.

Next comes a layer of sheathing. It can be continuous or sparse. The first option is installed under soft roofing coverings, for example, flexible tiles, and is made of OSB or moisture-resistant plywood. A deformation gap of 2-3 mm should be left between the elements of the continuous sheathing. In the second case, 25 mm thick boards are used, which are nailed across the rafters in increments of 30-40 cm. After this, the roofing covering is laid.

Roof ventilation

Alas, to this day, annoying stereotypes are widespread among our builders, according to which the roof should be as simple as possible, without unnecessary holes and voids, and ventilation gaps and aerators only increase the likelihood of leaks. This is true for a regular attic, but an attic roof may begin to leak precisely due to the lack of ventilation in the roofing pie.

Thermal insulation material cannot be enclosed in a completely hermetic shell: one way or another it is exposed to external influences, as a result of which it can change properties and be destroyed. Fiber insulation suffers from moisture, and many foam plastics suffer from high temperatures (when heated above 75 ° C, the process of their thermal destruction begins). To prevent these phenomena, a ventilated roofing system was created. Air circulating freely under the roof promotes the evaporation of moisture from the insulation and reduces its temperature.

Tilt angle

A very important parameter in roof construction is determining the angle of inclination of the roof. This value is determined not only by the design of the building, the features of the facade, but also by the selected roofing material and local climatic conditions.

If precipitation in the area where the house is located is of great importance, then the angle of the roof ranges from 45 to 60 degrees .

This value of the slope will ensure better snow removal from the surface , and, accordingly, a reduction in the level of load. In addition to precipitation, this angle parameter protects the roof from icing.

If the house is located in an area where strong winds are a common occurrence, then the value of the slope angle should be minimal . Otherwise, the structure may be destroyed due to weather conditions. Under such conditions, variations of this parameter range from 9 to 20 degrees .

However, the most common and optimal roof angle is 20-35 degrees . This value is suitable for arranging a roof with almost any type of material.

CAREFULLY!

The angle of inclination largely determines the durability and reliability of the structure.

Tilt angle

Construction of a residential attic space

When building a private house, some owners even try to use the attic area as living space.

Mansard roof design.

In some cases, “summer”, that is, unheated, rooms are planned on the attic floors. But it is still preferable to have rooms that are fully insulated and you can live comfortably not only in the warm, but also in the cold season.

Insulation material in attic spaces is usually installed on the floor: this helps to retain the heat that comes out from the floor below it. The empty attic serves as a layer that prevents cold from entering the room from the roof.

When insulating an attic room, everything happens a little differently. All thermal insulation material from the floor is transferred into the roof structure. Therefore, the roofing pie in buildings with attics will be a mandatory design element.

Tips from builders

For successful installation of an attic roof, you must follow the advice of professionals:

- To avoid errors in calculations, it is necessary to leave the work to an experienced professional.

- All wooden elements must be treated with an anti-rot agent.

- To maintain heat in the house, it is necessary to use insulation that has moisture-resistant properties.

- Support beams should be carefully secured to the walls, this will prevent the roof from moving

- For a denser insulation flooring, it is necessary to install it in a checkerboard pattern.

- You should not use polystyrene foam instead of insulation; it can emit fumes that are harmful to the body.

- To avoid the accumulation of vapors, ventilation must be installed correctly.

When choosing the required roofing decking, you should remember that the entire structure has quite a lot of weight.

Therefore, it is necessary to pay attention to high-quality and lightweight materials, such as metal tiles or corrugated sheets, which can reduce the load on the foundation of the building.

Installation of a roof insulation system

In a roof insulation system, each layer is designed to perform a specific task. The performance properties of the roofing pie will only be at their best when the order of placement of materials is observed. It is better to entrust its creation to specialists, but this does not mean that the owner should not figure everything out on his own. In this case, he will be able to monitor how the work is being carried out and determine which materials will be more profitable to purchase.

If the installation of the roofing pie is not carried out according to the standard, there will always be large heat losses during operation.

In these cases, a large amount of condensation forms, which in winter leads to the constant formation of icicles and ice. To prevent insulation from being wasted, before performing calculations, it is necessary to familiarize yourself not only with the sequence in which the layers of material are laid, but also with the characteristics of the materials. This will allow you to calculate which of them should be selected for the layer.

Roof thermal insulation

Obviously, to ensure a favorable microclimate in the attic, the roof slopes must be insulated. At the same time, a cold attic also needs thermal insulation measures. In this case, the insulation is laid on the ceiling of the upper floor.

Roofing pie. Ceramic tiles

The thickness of the heat insulator is determined by a special calculation, which takes into account local climatic conditions, the operating conditions of the building and other parameters. Heat in the interior of the house must be maintained in such a way that the roof remains cold, i.e. its temperature in winter should not fall below - 5 °C. Fulfilling this condition not only saves heating costs, but also contributes to the long service life of the roofing structure. With large heat losses through the roof slopes, massive ice deposits form on the roof, which negatively affects the condition of both the coating itself and other components of the roofing “pie.”

Roofing pie. Soft tiles

To insulate pitched roofs, two types of thermal insulation materials are used: slabs made of fiberglass (ISOVER, URSA) or basalt wool (ROCKWOOL, PAROC, ISOROC, TECHNONICOL, etc.). Note that the effectiveness of thermal insulation largely depends on the quality of installation. When installing insulation, you must strictly follow the manufacturer's instructions. When laying the heat insulator, no “cold bridges” or convection voids should form. The slabs should tightly fill the space between the rafters. In addition, the installation of various types of thermal insulation materials has its own characteristics. For example, fiberglass products need to be installed “by surprise”, while preventing the insulation from creasing along the edges of the slabs and compressing along the thickness.

Installation of metal roofing pie | Installation of sheathing for metal tiles |

Roofing pie diagram: 1. Rafter; 2. Counter rail, spacer bar; 3. Waterproofing film; 4. Vertical lathing; 5. The initial sheathing is horizontal; 6. Horizontal lathing; 7. Additional sheathing bars; 8. Frontal plate; 9. Gutter hook; 10. Cornice strip; 11. Sheet of metal tiles; 12. Ventilated ridge; 13. Seal; 14. Dormer window; 15. Insulation; 16. Vapor barrier film; 17. Ceiling flooring; 18. Self-tapping screw; 19. Junction strip; 20. Valley planks; 21. Bracket for tubular snow retainer; 22. Plug; 23. Connecting tape; 24. Finishing bar; 25. J-chamfer; 26. J-profile.

Non-insulated roofing pie

Types of insulation for roofing pie.

This type of roofing pie structure is created if the building has an insulated ceiling under the attic, and it is planned to be in the attic room only in the summer. Here, the main task of the insulating structure will be to insulate the attic space from condensation entering from the outside, so that moisture can escape outside. To prevent air microcirculation from being disrupted, a gasket should be made of waterproofing perforated film.

When arranging an uninsulated roofing pie, the sequence will be as follows:

- arrangement of the rafter system;

- laying a waterproofing layer;

- fixing the counter-lattice;

- fastening the sheathing;

- laying roofing material.

The insulated design includes a larger number of layers. It is used for arranging residential attics and its task is not only to waterproof, but also to ensure heat preservation. Under the roof, the thermal regime is much different from that on the ground floor of the building.

In the summer, the roof itself can warm up to fairly high temperatures, and in the winter, the phenomenon of the roof freezing is not uncommon. It is impossible to achieve a comfortable atmosphere in such housing. A roofing pie is designed to perform the following tasks: retaining heat inside in winter, providing insulation for air that may come into contact with a frozen roof, and in hot weather the pie does not let hot air in.

Roof waterproofing

Three types of materials are used as roofing waterproofing: diffusion membranes (Yutafol D P O Standard, Slafol Kon, Izospan A, Silver RR, Tektoten-L, etc.), anti-condensation films (Yutakon, "Stafol Kon") and superdiffusion windproof membranes ("Yutavek", Monorperm 500, Tyvek, "Diforol PRO", EUROTOP N, etc.). The first are films with micro-holes in the form of funnels, with the wide side facing the inside of the roof. Thanks to “smart” microperforation, diffusion membranes allow internal vapors to pass through, being an insurmountable barrier to moisture coming from outside. Please note that a ventilation gap must be maintained between the insulation and the waterproofing.

An example of a roofing “pie” based on flexible tiles and other materials.

Anti-condensation films are made of polypropylene fabric, film (providing strength, water and vapor resistance) and non-woven material that absorbs water vapor. The material is the optimal waterproofing for metal roofing.

Superdiffusion waterproofing membranes are made from high-strength non-woven material based on polypropylene. Such waterproofing is not only capable of allowing internal vapors to pass through and retaining external moisture, but also performs the function of wind protection. The material is laid directly on the insulation, which makes it possible to eliminate the counter-lattice from the rafter system.

We emphasize that the effective operation of waterproofing materials is impossible without proper organization of under-roof ventilation. In addition to air gaps, it is necessary to provide vents in the eaves boxes and roof aerators or fans at the roof ridge.

These articles may also be of interest to you:

- My house. Roofs and roofs 2

- Finishing the eaves of the roof. Methods and materials

- “Lawn” on the roof or landscaping the roof of the house

- Installation of facade blocks

The structure of an insulated roofing pie

Roof pie made of corrugated sheets.

Rafters. All layers of the pie together should be approximately 35 cm. This must be taken into account when constructing the rafter system. Decide on the material that you will install as a heat insulator - this will help you find out whether the height of the rafters will be sufficient.

The main load of the roof's weight is carried by the rafters. Therefore, it is better to create them from coniferous trees, choosing elements that have no flaws. The moisture level of wood should not exceed 22%. All wooden elements must be impregnated with an antiseptic. The pitch of the rafters and their thickness are chosen depending on what material is selected for covering the roof.

Vapor barrier. The actual installation of the roofing pie begins with this layer. The last of the inner layers will be the trim.

Moisture must be present inside the home. Most of it is contained in warm air, which, obeying the laws of physics, rushes upward - into the attic. Ventilation is not able to ventilate to such an extent that all excess moisture is eliminated; it falls on the roof structure and settles in the form of condensation. The vapor barrier layer protects the insulation installed next from moisture penetration. When saturated with moisture, thermal insulation loses its performance characteristics.

Among the materials used to create a vapor barrier layer, the following are most often used:

- vapor barrier film. It is made multilayer, with the addition of a polymer reinforcing frame, which does not allow it to sag;

- glassine is a vapor barrier with an affordable price, which has a significant disadvantage: over time, its ability to retain moisture disappears;

- foil materials.

The latter are a film, one side of which is covered with foil. There is also a material similar to chocolate wrappers, one side of it is made of foil, the other is paper. Both options not only perform a waterproofing function, but are also a good barrier to infrared radiation. It causes heat to leak out of the room, and the foil layer helps to significantly reduce heat loss even without insulating materials.

The vapor barrier is attached to the rafters as follows:

- Rolled material is rolled out along the rafter legs in the direction along the ridge. Laying should be done from below, with an overlap of 15 cm on the previous layer.

- The film is attached to the surface using a construction stapler.

- The joints of the material and the edge adjacent to the wall are sealed using connecting tape or tape.

When laying the film, do not stretch it; it should sag slightly between the rafters.

Which roof is better for a country house, cottage or cottage?

One of the most important parts of the house is the roof - its quality determines the warmth and comfort, noise level and frequency of repairs of the building.

Naturally, when planning a development, the question arises, what type of roof to choose, or which roof is better - cheaper, more expensive, broken or gable, or maybe hipped?

It is not enough for a roof to be simply durable and attractive. It must also have a number of important properties: provide good protection from rain and snow, protect from heat and cold, and be fireproof. Let's look at the main types of roofs and their characteristic features, because the choice of roofing material depends on the type of roof.

Which roof is best for a country house?

Main types of roofs

- Flat roofs

. They are usually erected above outbuildings and utility buildings, garages, bathhouses, sheds, as well as houses with a terrace on the roof. - Pitched roofs

. This type of roof is more widespread, and there are several classifications of pitched roofs, one of which we will give below. Among other things, pitched roofs can be divided into warm and cold, with an attic and without an attic.